Dispersing agent, positive electrode slurry and lithium ion battery

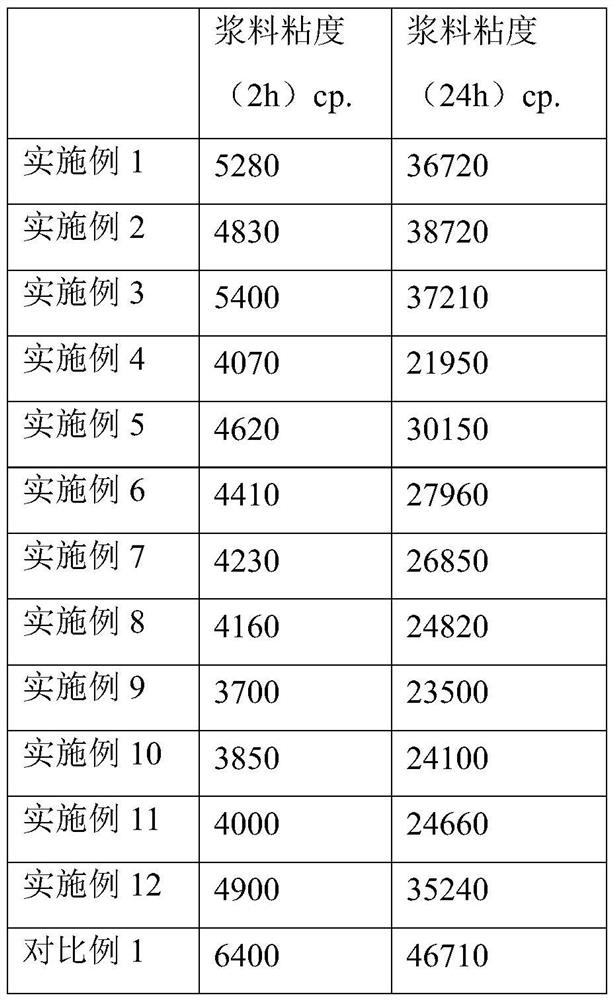

A technology of positive electrode slurry and dispersant, applied in the field of dispersant, positive electrode slurry and lithium ion battery, can solve the problems affecting production efficiency, material agglomeration, slurry gel, etc., to reduce the phenomenon of material gelation and agglomeration, The effect of reducing slurry viscosity and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation of embodiment 1, polyacrylonitrile and polystyrene dispersant

[0059] Set the molecular weight to 10 5 ~10 6 g / mol of polyacrylonitrile and a molecular weight of 10 5 ~10 6 The g / mol polystyrene is mixed according to the mass ratio of 1:1, and added to the NMP solution, so that the polymer mass fraction is 20-40%, and the polyacrylonitrile and polystyrene dispersant are made.

Embodiment 2

[0060] Embodiment 2, the preparation of polyacrylonitrile, polystyrene and polyacrylic acid dispersant

[0061] Set the molecular weight to 10 5 ~10 6 g / mol polyacrylonitrile, molecular weight 10 5 ~10 6 g / mol polystyrene and a molecular weight of 10 3 ~10 4 The g / mol polyacrylic acid is mixed according to the mass ratio of 1:1:1, and added to the NMP solution, so that the polymer mass fraction is 20-40%, and the polyacrylonitrile, polystyrene and polyacrylic acid dispersants are made.

Embodiment 3

[0062] Embodiment 3, the preparation of polyacrylonitrile-styrene dispersant

[0063] Step 1: Preparation of Acrylonitrile and Styrene Copolymer

[0064] Take 60g of acrylonitrile and 104g of styrene purified by vacuum distillation, mix the two in a nitrogen atmosphere, put them into a single-port polymerization bottle containing toluene solvent, polymerize at a constant temperature of 80°C for 8 hours, add an ethanol solution containing hydrochloric acid to terminate the reaction, and obtain The polymer was washed with absolute ethanol and dried under vacuum. Molecular weight and molecular weight distribution test using Tosoh Co., Ltd. gel permeation chromatography, the mobile phase is tetrahydrofuran, and the measured molecular weight of the polymer is 10 6 g / mol.

[0065] Step 2:

[0066] Add the acrylonitrile and styrene copolymer obtained in step 1 into the NMP solution so that the mass fraction of the polymer is 20-40%, and stir in an anhydrous environment for 30-120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com