A special material for medical grade breathable film and its preparation method

A technology of breathable film and special material, which is applied in the field of medical-grade breathable film special material and its preparation, and can solve the problems of film products such as poor surface brightness, smoothness and gloss, poor softness and air permeability, and high production and processing temperature , to achieve the effects of prolonging the continuous processing time, eliminating the phenomenon of die accumulation and low processing temperature

Active Publication Date: 2016-08-24

广西工程技术研究院有限公司

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The matrix materials of domestic special materials for breathable membranes are mostly heavy calcium carbonate and light calcium as the main matrix materials, and then add an appropriate amount of unsaturated acid monomers, macromolecular coupling agents, initiators, antioxidants and other additives. The production of special materials for breathable membranes prepared by the method needs to add many additives, the production process line is long, the preparation process is complicated, and the cost of raw materials is high

The prepared special materials have surface defects in the process of casting and forming films, such as common melt fracture phenomena, and the surface brightness, smoothness and gloss of film products are not good; in the process of film production, there is a phenomenon of die deposits ;Gel dripping film phenomenon exists in the extrusion process; the production and processing temperature is high, energy consumption is large, and there are many waste products, etc. The softness and air permeability of the special material produced are not good after being prepared into a breathable film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

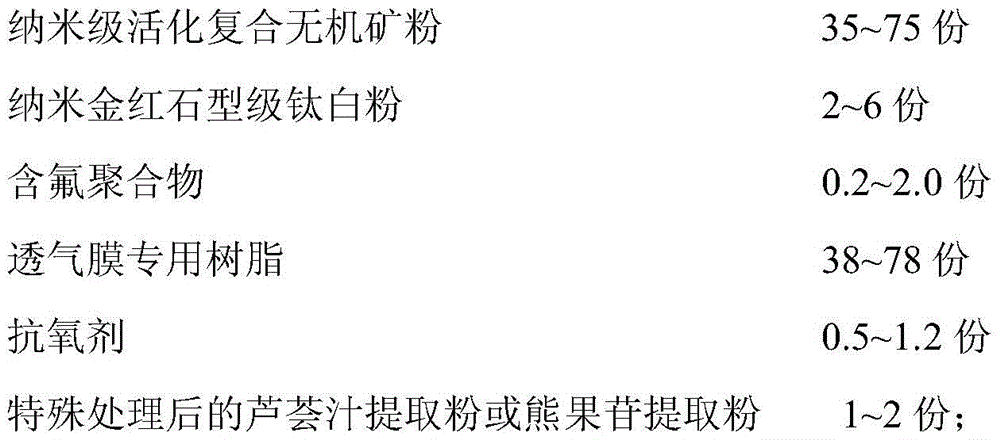

[0035]

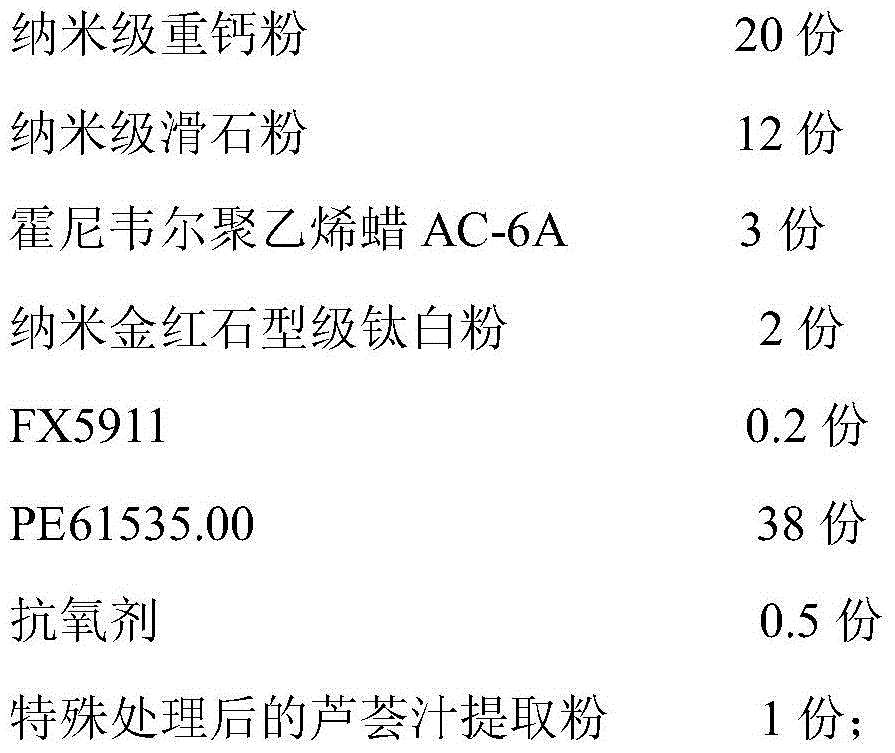

Embodiment 2

[0037]

[0038]

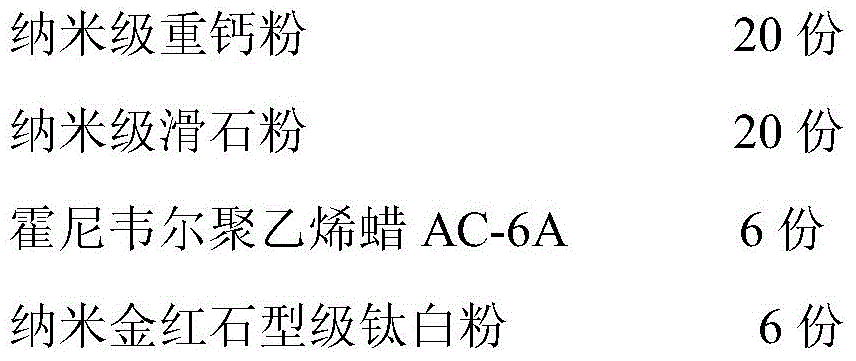

Embodiment 3

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a medical grade gas-permeable membrane special material. The medical grade gas-permeable membrane special material is prepared from the following components in parts by weight: 35-75 parts of nanoscale activated composite inorganic mineral powder, 2-6 parts of nano rutile type titanium dioxide, 0.2-2.0 parts of fluorine-containing polymer, 38-78 parts of gas-permeable membrane special resin, 0.5-1.2 parts of antioxidant and 1-2 parts of specially treated aloe juice extract powder or arbutin extract powder, wherein the nanoscale activated composite inorganic mineral powder comprises nanoscale ground calcium carbonate powder, nanoscale talcum powder and a surface active agent. A preparation method of the medical grade gas-permeable membrane special material comprises the following steps: firstly carrying out high-speed mixing on the nanoscale activated composite inorganic mineral powder for removing water; secondly, preparing a gas permeable membrane special material mixture; and thirdly, preparing a gas permeable membrane special material finished product. The medical grade gas-permeable membrane special material has the advantages that raw materials are simple, source of the raw materials is rich, a technology is simplified and cost is low.

Description

technical field [0001] The invention belongs to the technical field of gas-permeable membranes, and in particular relates to a special material for medical-grade gas-permeable membranes and a preparation method thereof. Background technique [0002] The breathable film is filled with calcium carbonate and other inorganic materials, and is made into a film by calendering, casting, and blow molding, and then stretched in one direction or two directions to form a breathable film. [0003] The matrix materials of domestic special materials for breathable membranes are mostly heavy calcium carbonate and light calcium as the main matrix materials, and then add an appropriate amount of unsaturated acid monomers, macromolecular coupling agents, initiators, antioxidants and other additives. The production of the special material for the breathable membrane prepared by the method needs to add many additives, the production process line is long, the preparation process is complicated, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L23/06C08L23/08C08L27/12C08K13/02C08K3/22C08K3/26C08K3/34

CPCC08K2003/2241

Inventor 谢冬梅兰黄鲜李勇

Owner 广西工程技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com