Polyamide resin composition

A technology of polyamide resin and composition, which is applied in the field of polyamide and resin composition containing other polyamides as needed, and can solve the problems of increased gel and low commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

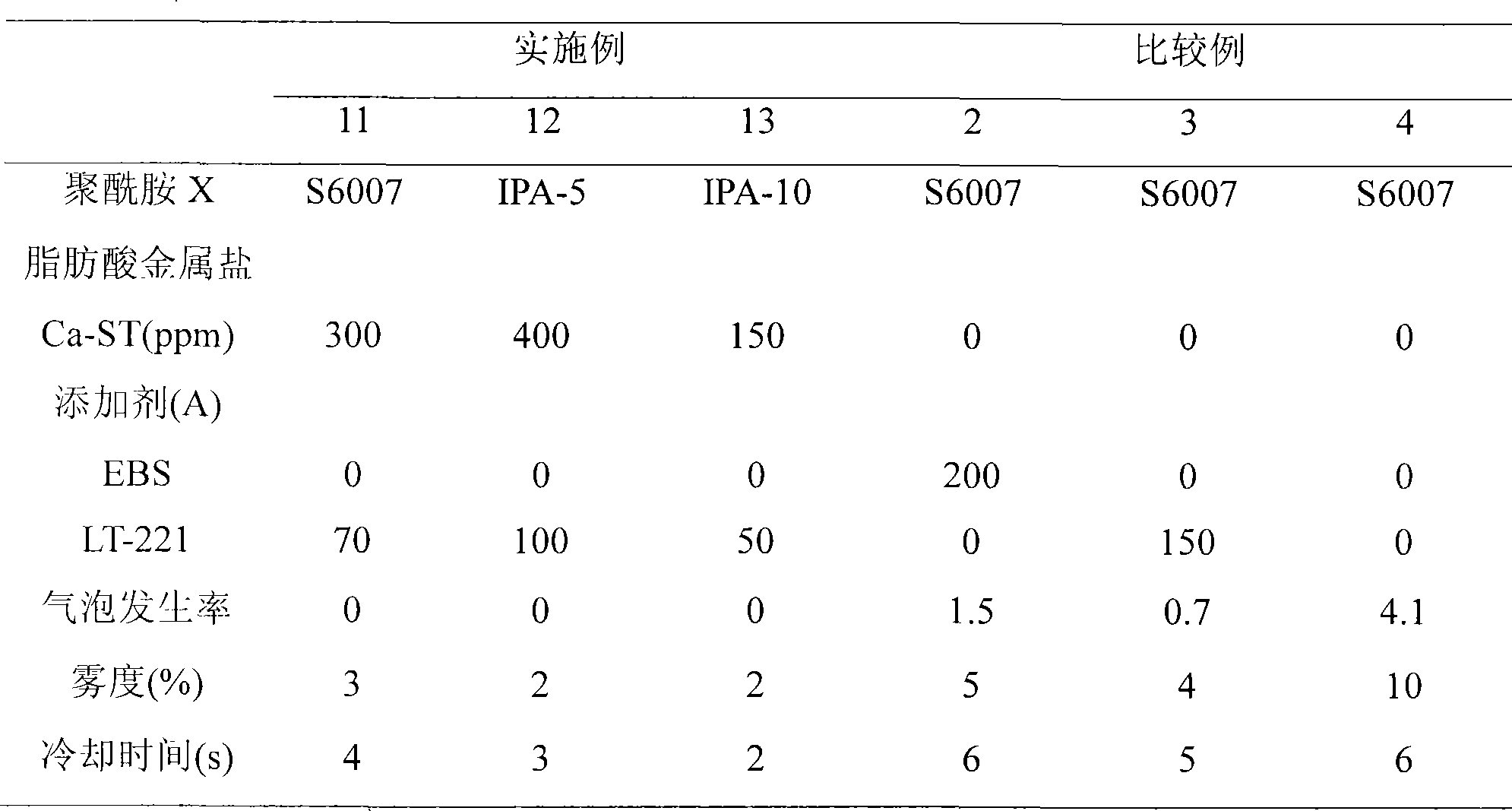

[0088] The method for producing the multilayer structure is not particularly limited, and known techniques can be used. For example, after being formed into a film by a co-extrusion method, it is processed into various containers. As the coextrusion method, known methods such as a T-die method and an expansion method can be used. In addition, it is also possible to blow mold a multilayer bottle after preparing a multilayer preform by injection molding. When the polyamide resin composition of the present invention is used as a barrier layer, it is preferable because the effect of preventing air bubbles from entering and the effect of preventing whitening are good, and the productivity and transparency are good when preparing a multilayer preform by injection molding.

[0089] In the preparation of a multilayer structure using the polyamide resin composition of the present invention as a barrier layer, for nylon or polyolefin, slow compression, sudden compression type, single f...

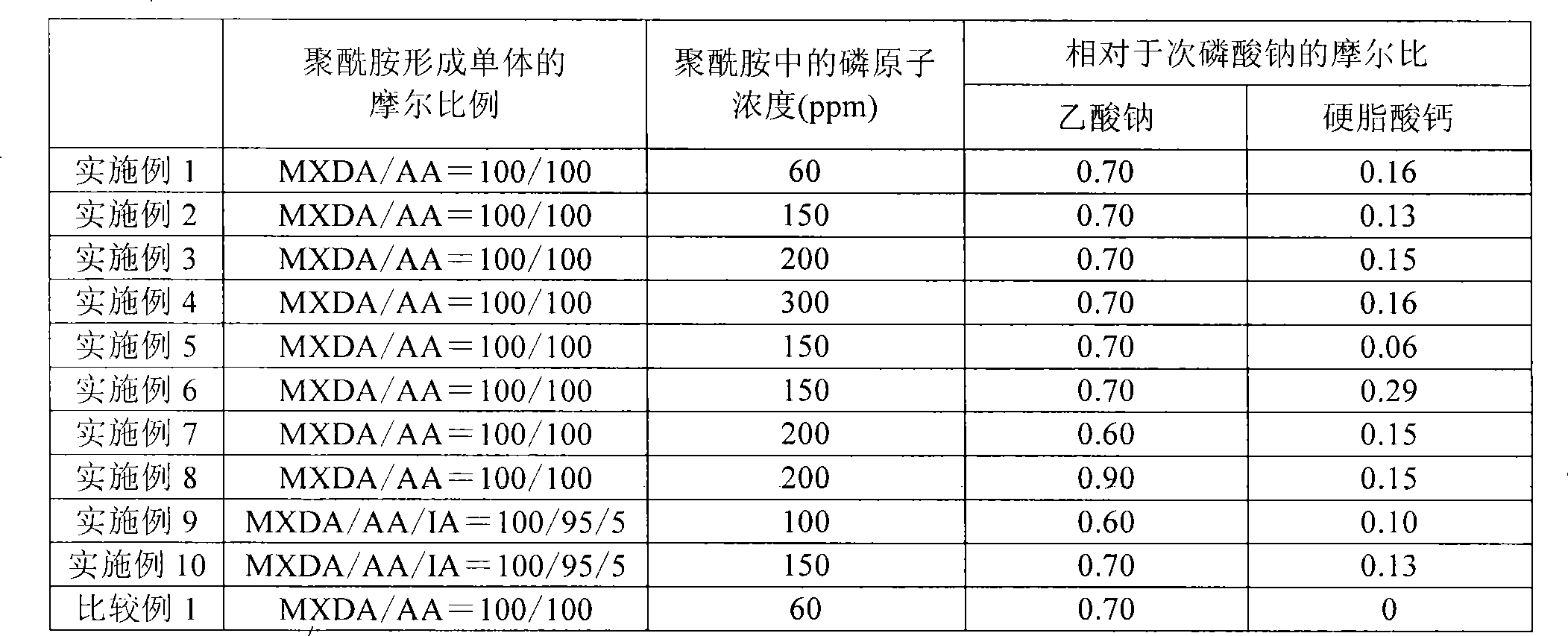

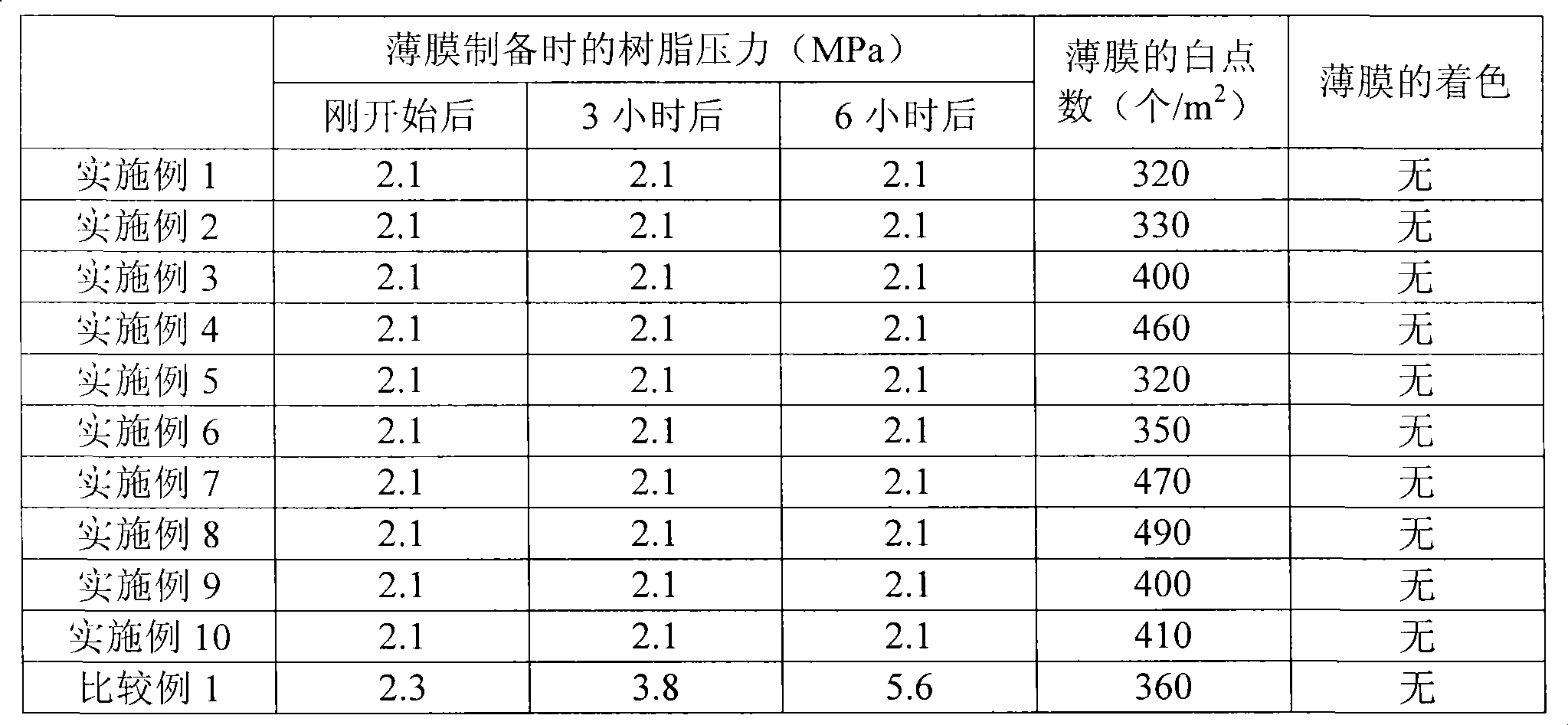

Embodiment 1

[0134] (melt polymerization of polyamide)

[0135] Add accurately weighed 15000 g (102.6 mol) to a reaction vessel with an inner volume of 50 liters having a stirrer, a partial condenser, a total condenser, a thermometer, a dropping funnel, and a nitrogen inlet tube, and a strand die Adipic acid, 5.174g (0.0488mol) of sodium hypophosphite, and 2.803g (0.0342mol) of sodium acetate were fully replaced with nitrogen, then stirred inside the system under a small amount of nitrogen flow, and heated to 170°C at the same time. Then, 13,974 g (102.6 mol) of m-xylylenediamine was added dropwise under stirring, and the generated condensation water was discharged out of the system while the temperature inside the system was continuously raised. After completion of m-xylylenediamine dropwise addition, the internal temperature was made 260° C., and the reaction was continued for 40 minutes. Then, the inside of the system was pressurized with nitrogen, the polymer was taken out from the st...

Embodiment 2

[0143] Except using 12.953g (0.1220mol) sodium hypophosphite, 7.008g (0.0854mol) sodium acetate, same as embodiment 1, carry out melt polymerization and solid state polymerization, obtain relative viscosity and be 2.6, b * Polyamide 2 with a value of -2.0. In addition, the time during which the particle temperature was maintained at 200° C. was 20 minutes.

[0144] Then, with respect to the polyamide 2 of 20kg, add 7.6g (0.0126mol) calcium stearate, stir and mix in the tumbler for 10 minutes, obtain polyamide resin composition 2, same as embodiment 1, carry out counting of white spot, resin Observation of changes in pressure and observation of coloring conditions. The results are shown in Table 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Full length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com