High-current ethylene-vinyl acetate copolymer grafted maleic anhydride product, preparation method and application thereof

A technology of grafting maleic anhydride and vinyl acetate, which is applied in the directions of grafting polymer adhesives, adhesive types, adhesives, etc., can solve the problems of unreliable controllability and stability of raw material mixing uniformity, etc. To achieve the effect of less gel, increased polarity and better interface effect

Active Publication Date: 2010-09-08

合诚技术股份有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

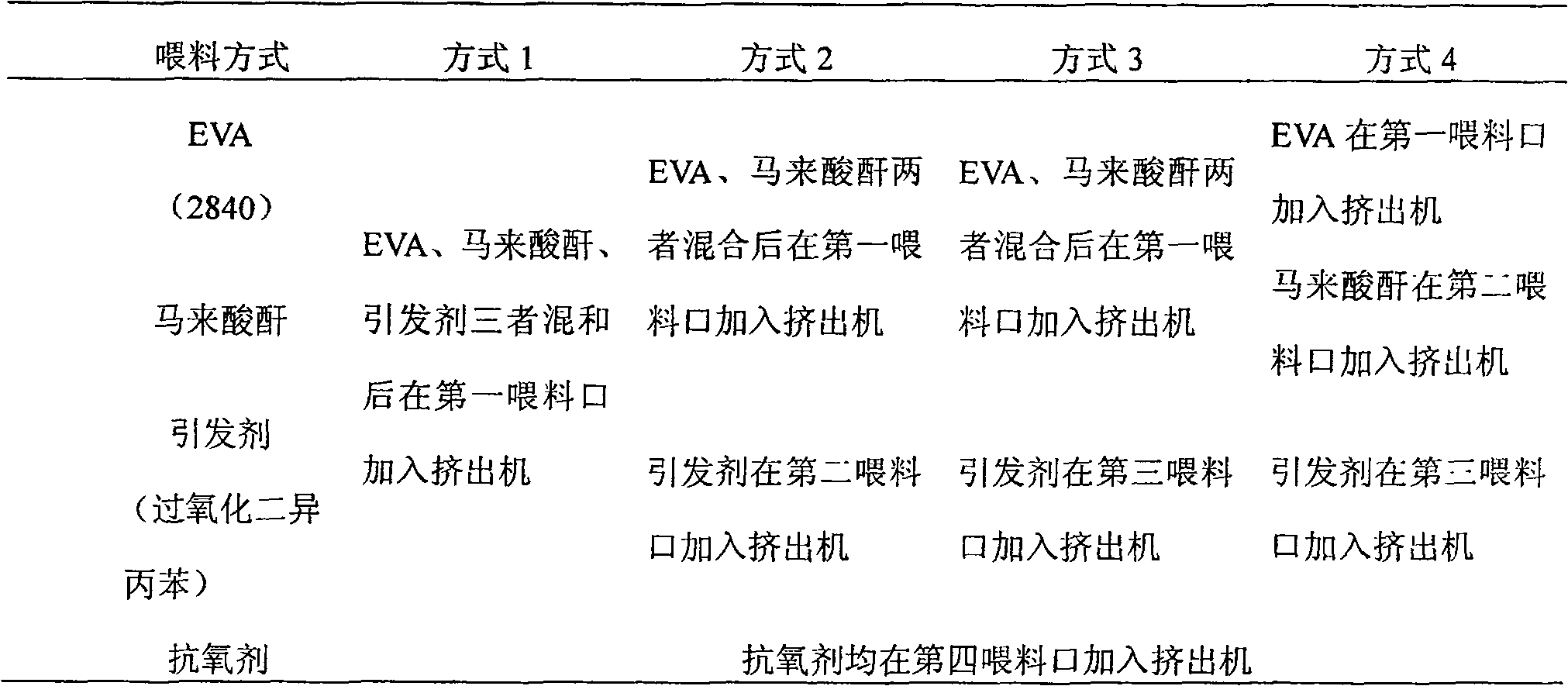

The existing general and simple grafting technology is to mix the raw materials directly into the extruder for reaction, extrusion and granulation. The uniformity of raw material mixing, the controllability of the reaction process and the stability of the long-term production of the product are not reliable.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Login to View More

Abstract

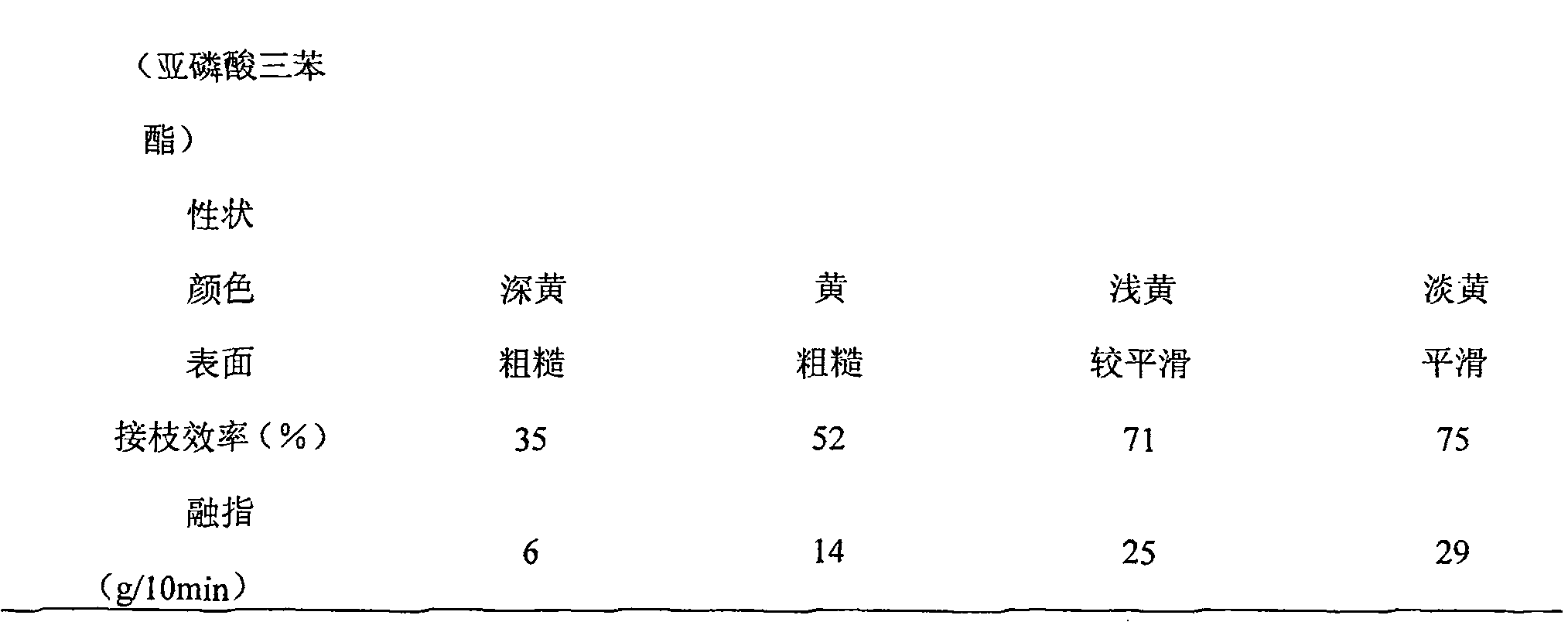

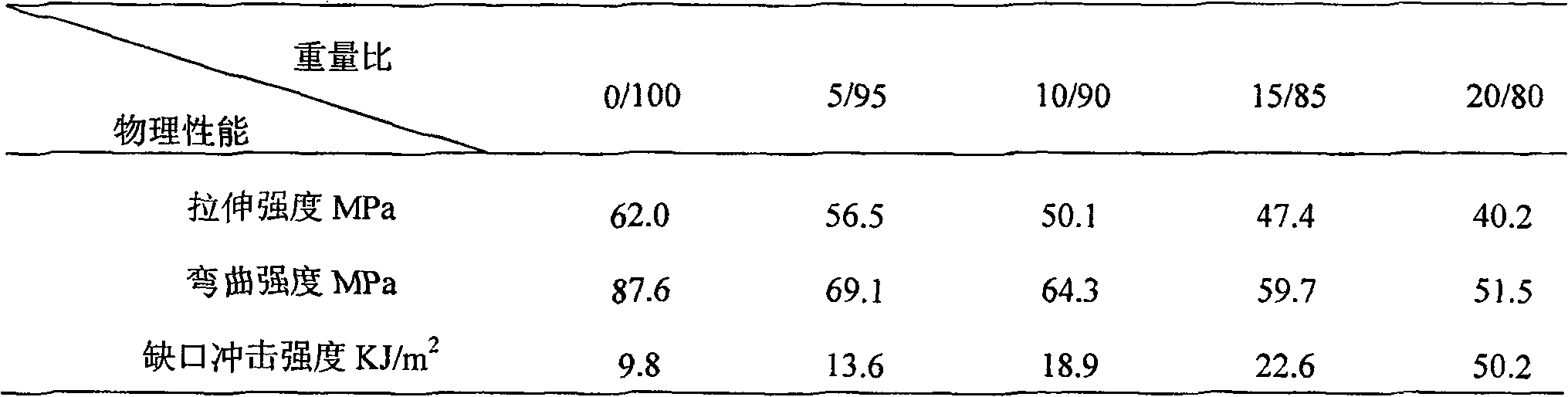

The invention discloses a searching ethylene-vinylacetate copolymer grafted maleic anhydride product which is made of the raw materials with following weight percentage: ethylene-vinylacetate copolymer is 100 percent by weight, maleic anhydride is 0.5 to 5 percent by weight, an initiator is 0.03 to 0.4 percent by weight, and an antioxidant is 0.1 to 0.5 percent by weight. The preparation method is that the raw materials with the weight percentage are added into an extruder, reaction is carried out at the temperature between 150 DEG C and 190 DEG C, and then granulation is extruded to obtain the needed product. The searching ethylene-vinylacetate copolymer grafted maleic anhydride product of the invention can be applied for preparing hot-melt adhesive. The entire preparation process of theproduct has the advantages of high controllability and little gelatinization in the reaction product; the grafting efficiency of maleic anhydride can reach as high as 75 percent. The prepared searching ethylene-vinylacetate copolymer grafted maleic anhydride product can be easily dispersed on the interfaces of multiple blends containing polar polymers, so as to improve the cohesive force among interfaces, thus promoting the overall property of the blends.

Description

technical field The invention belongs to the technical field of polymer materials, in particular to a high-fluidity ethylene-vinyl acetate copolymer (EVA) grafted maleic anhydride product and its preparation method and application. Background technique Ethylene-vinyl acetate copolymer (EVA) is the fourth largest ethylene series copolymer after high-density polyethylene (HDPE), low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE). With the increase of ester (VA) content, the elasticity, softness, transparency, adhesion, compatibility and solubility of EVA are also improved accordingly. According to the different VA content, it can be divided into three categories: VA resin with a mass percentage of 5% to 40%, called EVA resin, is mainly used to modify polyethylene and other materials, and manufacture wire and cable materials; If the mass percentage is 40% to 70%, it is generally called EVA elastomer, which is mainly used as rubber elastomer, polyvinyl ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F255/02C08F2/44C08K5/524B29B9/12B29C47/92C09J151/06C08L77/06C08L51/06C08K5/20B29C48/92

CPCB29C48/92B29C2948/92704B29C2948/92895

Inventor 游华燕匡俊杰李刚蒋文真

Owner 合诚技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com