Functional master-batch for organosilane crosslinked polyethylene pipe, and preparation method and application of functional master-batch

A polyethylene pipe and silane crosslinking technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of limiting the application and promotion of PEX pipes, increasing site investment and energy consumption, and short continuous production cycles, etc., to achieve suitable It can be used in industrial production, improve the appearance and processing performance, and shorten the crosslinking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

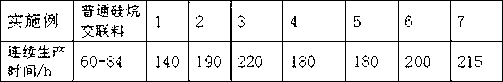

Examples

Embodiment 2

[0030] Example 2: 100 parts of high-density polyethylene (PE80), 35 parts of 1000 mesh aluminosilicate minerals with a porous structure, N, N-hexene bisstearamide and high molecular weight ( 400,000) 10 parts of polydimethylsiloxane mixture, 5 parts of antioxidant 330, light stabilizer 2-(3',5'-ditert-butyl-2'-hydroxyphenyl) 5-chlorobenzo 5 parts of triazole, 6 parts of cross-linking accelerator p-tert-butylbenzoic acid.

[0031] Its preparation method and application are the same as in Example 1, wherein the twin-screw melt extrusion granulation temperature is 200° C., and the twin-screw speed is 300 rpm.

Embodiment 3

[0032] Example 3: 100 parts of high-density polyethylene (PE80), 30 parts of aluminosilicate minerals with a porous structure of 3000 mesh, N, N-hexene bisstearamide and high molecular weight ( 800,000) 8 parts of polydimethylsiloxane mixture, 4 parts of antioxidant 1010, 4 parts of light stabilizer bis(2,2,6,6-tetramethylpiperidinyl) sebacate, Joint accelerator 5 parts of p-tert-butylbenzoic acid.

[0033] Its preparation method and application are the same as in Example 1, wherein the twin-screw melt extrusion granulation temperature is 190° C., and the twin-screw speed is 280 rpm.

Embodiment 4

[0034] Example 4: Same as Example 1, wherein the particle size of the aluminosilicate mineral with a porous structure is 2000 mesh, and the dosage is 30 parts. The performance test results of the extruded pipe are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com