A kind of highly branched polyvinyl alcohol-acrylamide graft copolymer and its preparation method and application

A technology of graft copolymer and polyvinyl alcohol, which is applied in the field of polymer synthesis and dry strength agent, can solve the problems of few bonding points between reinforcing agent and fiber, it is not suitable for adding in pulp, and the degree of branching is not high, so as to achieve Good water solubility, delayed polymerization reaction rate, and easy controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

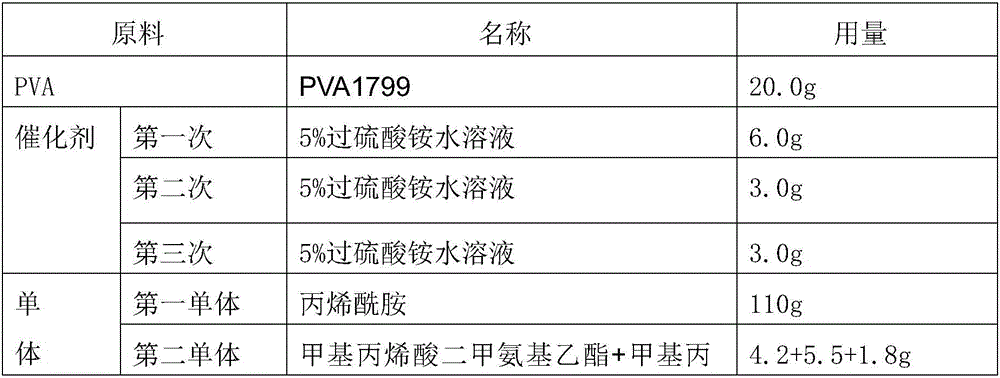

[0035] This example provides a preparation method of a highly branched polyvinyl alcohol-acrylamide graft copolymer. The main raw materials and dosages used are shown in the following table:

[0036]

[0037]

[0038] The specific implementation of the method is as follows:

[0039] Add 200g of deionized water to a 1-liter four-necked flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet tube, slowly add 20.0g of PVA1799 while stirring, raise the temperature to 95°C and keep it warm for 30 minutes, until the PVA is completely dissolved Afterwards, pass nitrogen gas for 30 minutes, lower the temperature to 70°C, add 6.0 g of 5% ammonium persulfate aqueous solution, react for 20 minutes, and then dropwise add the monomer mixture, which consists of 110 g of acrylamide, dimethylaminomethacrylate Ethyl ester 4.2g, methacryloyloxyethyl trimethyl ammonium chloride (78% active ingredient) 5.5g, methacryloyloxyethyl dimethyl benzyl ammonium chloride (act...

Embodiment 2

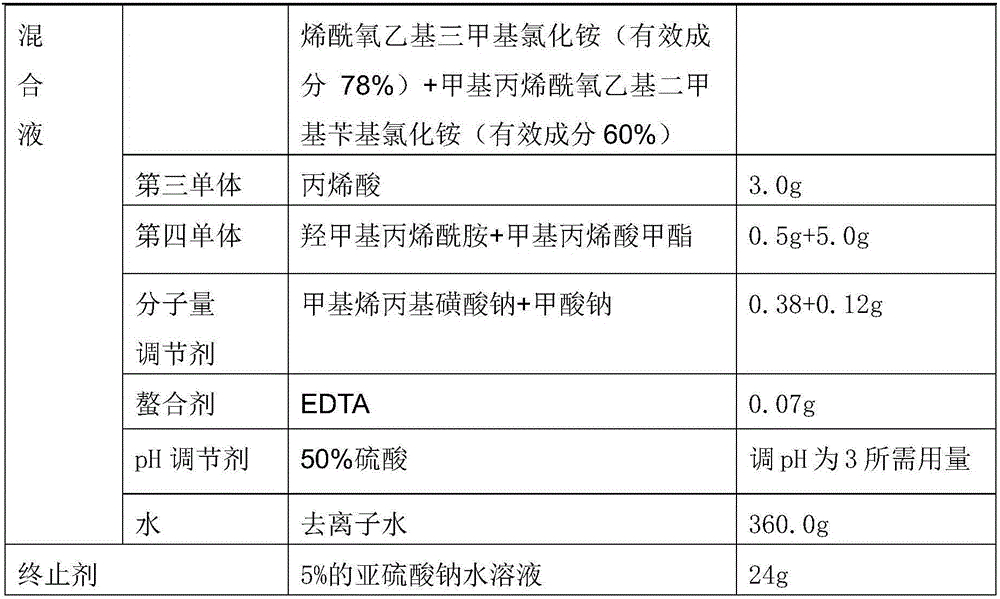

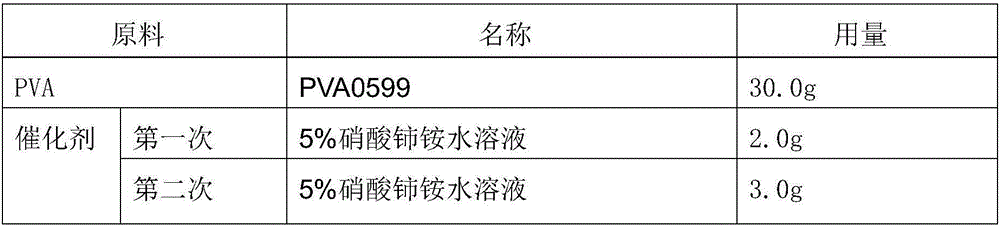

[0041] This example provides a preparation method of a highly branched polyvinyl alcohol-acrylamide graft copolymer. The main raw materials and dosages used are shown in the following table:

[0042]

[0043]

[0044] The specific implementation of the method is as follows:

[0045] Add 200g of deionized water to a 1-liter four-neck flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet tube, slowly add 30.0g of PVA 0599 under stirring, raise the temperature to 95°C and keep it warm for 30 minutes, until the PVA is completely After dissolving, pass nitrogen for 30 minutes, lower the temperature to 75°C, add 2.0 g of 5% cerium ammonium nitrate aqueous solution, react for 30 minutes, and then add dropwise the monomer mixture, which consists of 98 g of acrylamide, dimethyl methacrylate Aminoethyl ester 3.2g, N,N-dimethylaminopropylacrylamide 2.1g, methacryloyloxyethyltrimethylammonium chloride (78% active ingredient) 5.5g, itaconic acid 2g, fumaric ...

Embodiment 3

[0047] This example provides a preparation method of a highly branched polyvinyl alcohol-acrylamide graft copolymer. The main raw materials and dosages used are shown in the following table:

[0048]

[0049] The specific implementation of the method is as follows:

[0050] Add 150g of deionized water to a 1-liter four-necked flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet tube, slowly add 15.0g of PVA1788 under stirring, raise the temperature to 90°C and keep it warm for 30 minutes, until the PVA is completely dissolved Afterwards, pass nitrogen gas for 30 minutes, lower the temperature to 68°C, add 4 g of 5% ammonium persulfate aqueous solution, react for 15 minutes, and then dropwise add the monomer mixture, which consists of 113 g of acrylamide, N,N-dimethylamino Propylacrylamide 5.1g, Acryloyloxyethyltrimethylammonium chloride (78% active ingredient) 5.0g, Methacryloyloxyethyldimethylbenzylammonium chloride (Active ingredient 60%) 2.8g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com