High-toughness polyvinyl butyral film and preparation method thereof

A polyvinyl butyral adhesive film and polyvinyl butyral technology are applied in the field of preparation of high-toughness polyvinyl butyral adhesive films and high-toughness polyvinyl butyral adhesive films, and can solve PVB problems. The lack of elasticity of the diaphragm, the improvement of weather resistance, and the poor softness of the film achieve the effects of good viscosity, good softness, and accelerated reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

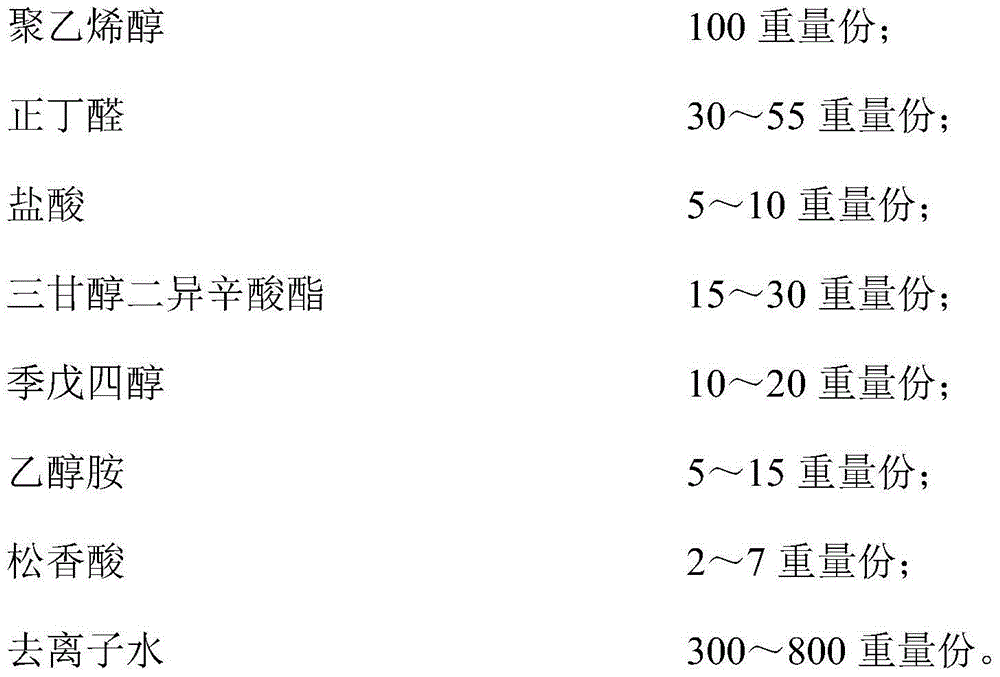

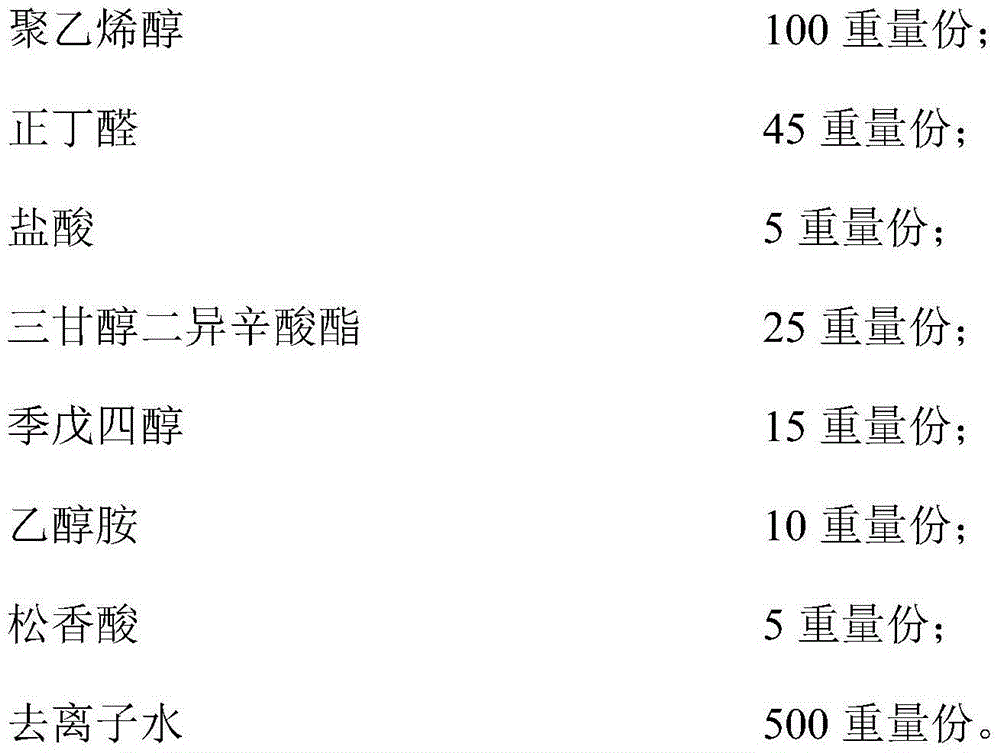

[0025] Embodiment 1 of a kind of high-toughness polyvinyl butyral adhesive film of the present invention comprises following components, and each component weight is respectively:

[0026]

[0027]

[0028] Wherein, the mass fraction of the hydrochloric acid is 25%.

[0029] The preparation method of this kind of high-toughness polyvinyl butyral adhesive film comprises the following steps successively:

[0030] Step 1. Dissolve polyvinyl alcohol and 1 / 2 n-butyraldehyde in deionized water, and heat to 85°C, slowly add 1 / 2 hydrochloric acid dropwise while stirring, the hydrochloric acid is added dropwise within 1.5h, continue stirring for 5h , cooling down to 30-40°C in a 20-25°C water bath to obtain a mixed solution;

[0031] Step 2: Add pentaerythritol and the remaining n-butyraldehyde to the mixed solution, add ethanolamine and abietic acid, heat to 65°C, and slowly add the remaining hydrochloric acid dropwise while stirring. The hydrochloric acid is added dropwise wit...

Embodiment 3

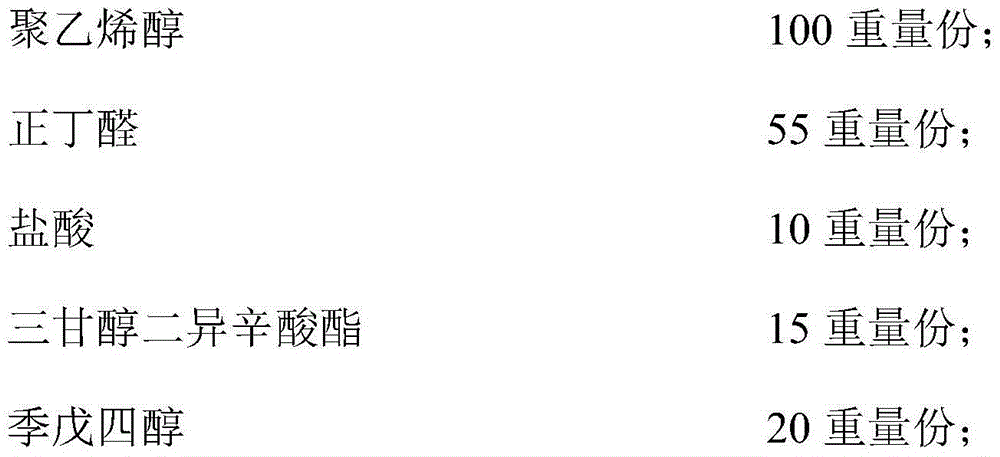

[0041] Embodiment 3 of a kind of high-toughness polyvinyl butyral adhesive film of the present invention comprises following components, and each component weight is respectively:

[0042]

[0043]

[0044] Wherein, the mass fraction of the hydrochloric acid is 20%.

[0045] The preparation method of this kind of high-toughness polyvinyl butyral adhesive film comprises the following steps successively:

[0046]Step 1. Dissolve polyvinyl alcohol and 1 / 2 n-butyraldehyde in deionized water, and heat to 90°C. Slowly add 1 / 2 hydrochloric acid dropwise while stirring. The hydrochloric acid is added dropwise within 1 hour. After continuing to stir for 4 hours, Cool down to 30-40°C in a 20-25°C water bath to obtain a mixed solution;

[0047] Step 2: Add pentaerythritol and the remaining n-butyraldehyde, ethanolamine and abietic acid to the mixed solution, heat to 75°C, and slowly add the remaining hydrochloric acid dropwise while stirring. The hydrochloric acid is added dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com