A preparing method of dicyclopentadiene hydrogenated petroleum resin

A technology of hydrogenated petroleum resin and dicyclopentadiene, which is applied in the field of preparation of dicyclopentadiene hydrogenated petroleum resin, and can solve the problems such as the decrease of petroleum resin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

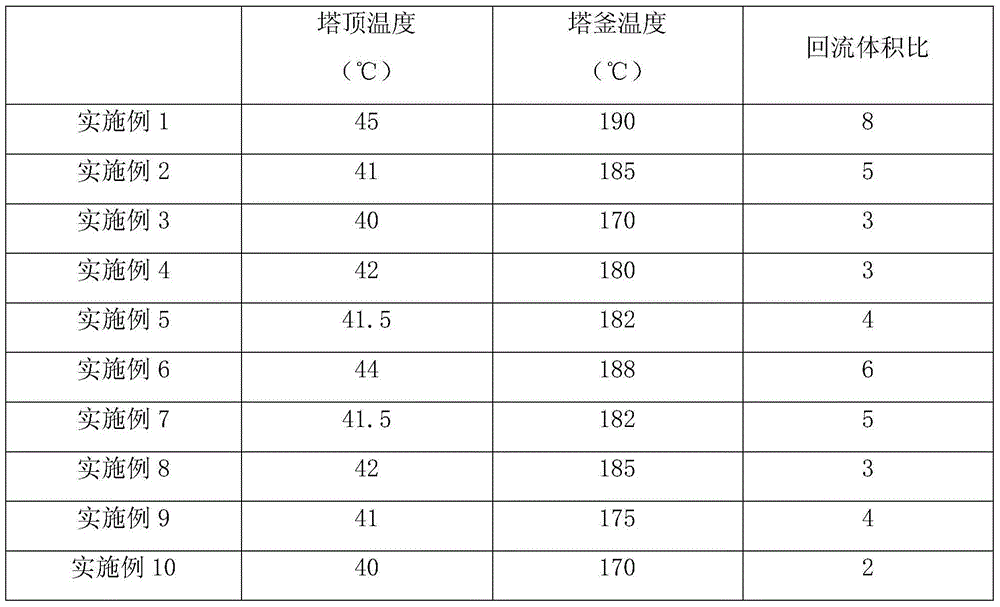

[0020] Embodiment [1-10]

[0021] 1) Under normal pressure, the crude dicyclopentadiene is decomposed into cyclopentadiene by reactive distillation, the temperature of the tower bottom is 170-190°C, the temperature of the tower top is 40-45°C, and the reflux ratio is 2-8;

[0022] 2) The high-purity cyclopentadiene obtained in step 1) is mixed with a solvent, and after mixing, part of the mixture (1 / 2) enters the reaction kettle for polymerization, and the remaining cyclopentadiene solvent mixture is 1.0 after the reaction begins. Add the same amount evenly after h and 2.0h; the mass ratio of cyclopentadiene to solvent is 1:0.5~1.5, the reaction pressure is 1.0~2.0MPa, the reaction time is 3~5h, and the reaction temperature is 230~260℃;

[0023] 3) The reaction solution obtained from step 2) enters the tubular reactor, and at the same time the catalyst and hydrogen are pre-mixed and then enters the tubular reactor, and reacts at a temperature of 150-250°C and a pressure of 3.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com