Light-shielding coating slurry and preparation method thereof

A technology of light-shielding coating and slurry, which is applied in the direction of textiles and papermaking, etc. It can solve the problems that the compatibility between emulsion and filler cannot reach the level of light-shielding coating slurry, and the hiding rate is low, so as to improve storage stability and good optical performance , Improve the effect of covering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

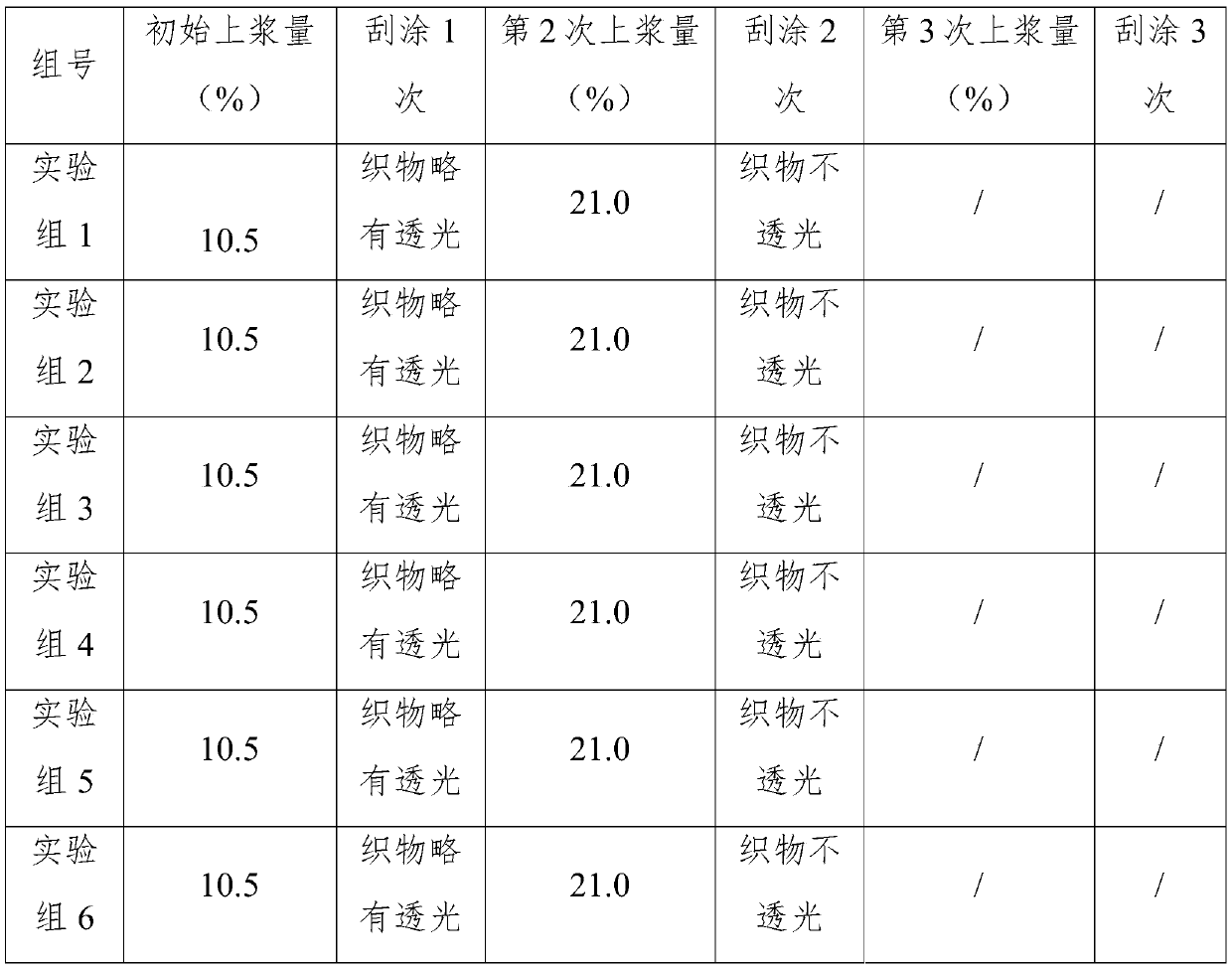

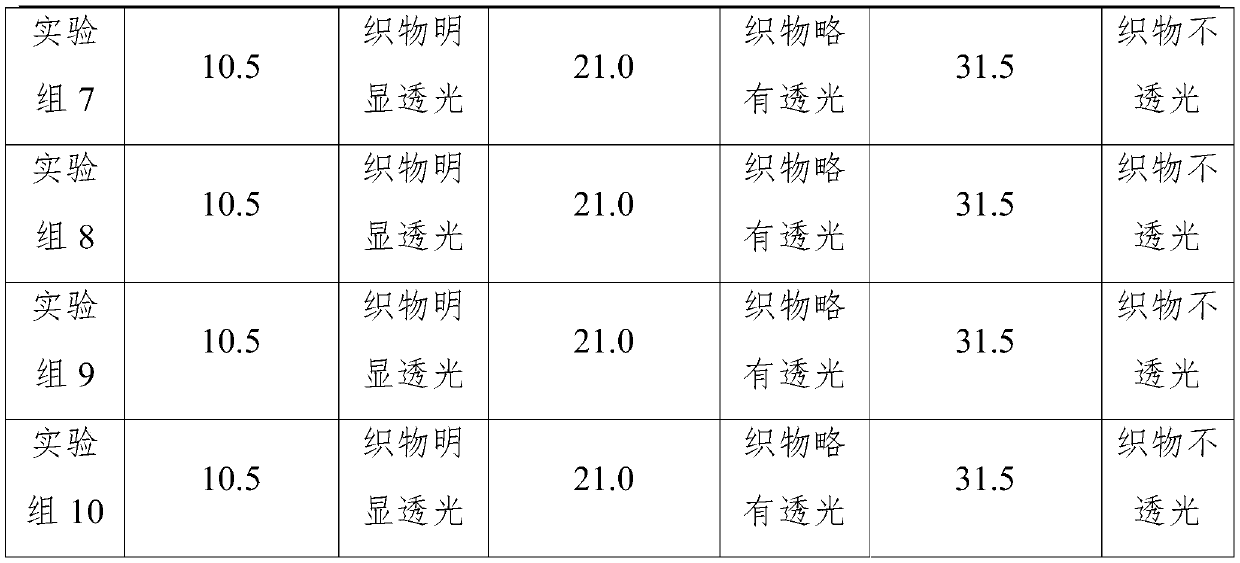

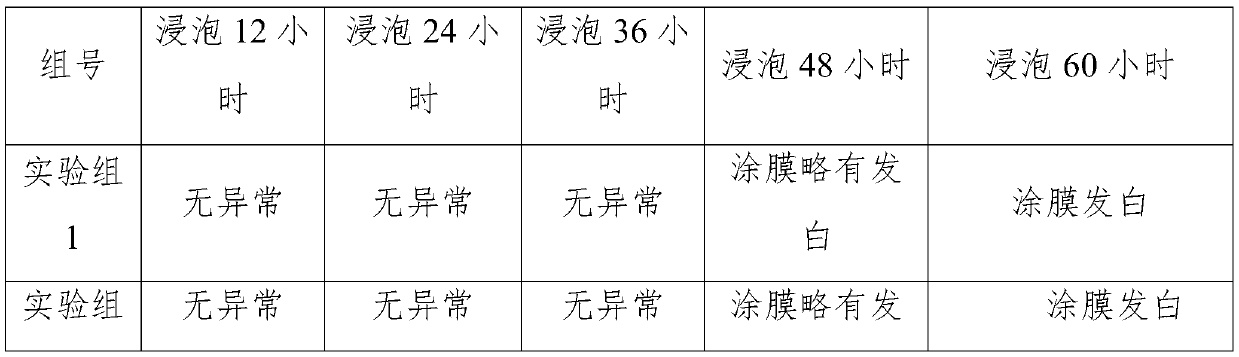

Examples

preparation example Construction

[0027] A method for preparing a light-shielding coating slurry, comprising the following steps:

[0028] (1) adopt pre-emulsification semi-continuous method emulsion polymerization to prepare acrylic acid emulsion;

[0029](2) Slowly add part of the thickener to the acrylic emulsion in step (1) while stirring. After the viscosity of the system is constant, add the dispersant, defoamer and filler. After the dissolution is complete, continue to add the remaining thickener agent, and stirred until the viscosity of the system was constant, that is, the light-shielding coating slurry was prepared.

[0030] Further, the following method is adopted in the step (1):

[0031] 1) Add part of the anionic emulsifier and nonionic emulsifier into the polymerization kettle, and add part of the water, stir evenly, and prepare a primer solution;

[0032] 2) Add the remaining anionic emulsifier and nonionic emulsifier into the emulsification tank, and add the remaining water, stir until the a...

Embodiment 1

[0041] A light-shielding coating slurry, comprising the following components in parts by weight: 2 parts of ammonium lauryl polyoxyethylene ether sulfate, 3 parts of isomeric alcohol polyoxyethylene ether, 5 parts of itaconic acid, 5 parts of acrylamide 5 parts, 5 parts of methylol acrylamide, 50 parts of butyl acrylate, 90 parts of ethyl acrylate, 15 parts of isooctyl acrylate, 50 parts of methyl methacrylate, 0.05 parts of diallyl phthalate, methylol 6 parts of base silicone oil, 0.2 parts of potassium persulfate, 0.2 parts of sodium bisulfite, 150 parts of nano-calcium carbonate, 1 part of D607 dispersant, 1 part of T301 defoamer, 15 parts of DM-5233G thickener, 500 parts of deionized water share.

[0042] A method for preparing a light-shielding coating slurry, comprising the following steps:

[0043] 1) Add 13% by weight of lauryl polyoxyethylene ammonium sulfate and isomeric alcohol polyoxyethylene ether into the polymerization kettle, and add 25% of water, stir evenly,...

Embodiment 2

[0051] A light-shielding coating slurry, comprising the following components by weight: 3 parts of lauryl polyoxyethylene ether ammonium sulfate, 4 parts of isomeric alcohol polyoxyethylene ether, 10 parts of itaconic acid, 10 parts of acrylamide 10 parts of methylol acrylamide, 80 parts of butyl acrylate, 100 parts of ethyl acrylate, 20 parts of isooctyl acrylate, 60 parts of methyl methacrylate, 0.15 parts of diallyl phthalate, methylol 10 parts of base silicone oil, 0.25 parts of potassium persulfate, 0.25 parts of sodium bisulfite, 200 parts of nano-calcium carbonate, 3 parts of D607 dispersant, 3 parts of T301 defoamer, 20 parts of DM-5233G thickener, 650 parts of deionized water share.

[0052] A preparation method of a light-shielding coating slurry is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com