Application method of solvent type polymethacrylate pressure-sensitive adhesive

A technology of polymethacrylic acid and pressure-sensitive adhesives, which is applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., and can solve insufficient heat and weather resistance, incomplete curing, and decreased cohesion To achieve the effects of reducing the impact of post-curing, avoiding surface haze, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

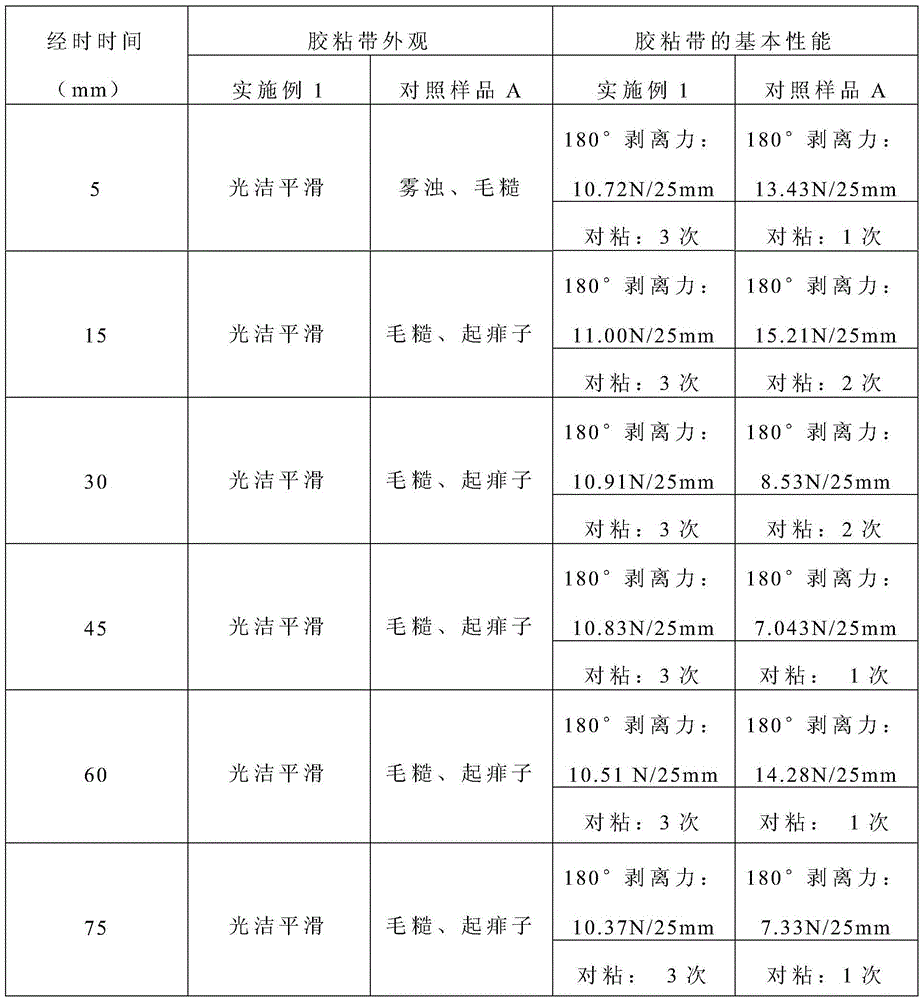

Embodiment 1

[0026] A solvent-based polymethacrylate pressure-sensitive adhesive coating solution for humid environments, including poly(meth)acrylate pressure-sensitive adhesives with hydroxyl groups as functional groups, Bayer curing agent N3300, organotin catalyst, water remover ALT-201, acetic acid and solvent ethyl acetate.

[0027] The preparation method of the solvent-based polymethacrylate pressure-sensitive adhesive coating liquid used in a humid environment is:

[0028] First, pour 5kg of ethyl acetate into a clean stainless steel container, then pour 50kg of solvent-based polymethacrylate pressure-sensitive adhesive, then pour 5kg of ethyl acetate, and stir for 10 minutes to obtain Adhesive diluent; add 2000g of ethyl methyl acetate to 500g of water remover ALT-201 and stir for 10 minutes until uniform to obtain water remover dilution; add 1000g of dibutyltin dilaurate to 20g of Ethyl acetate solution, stirred for 5 minutes until uniform, prepared catalyst dilution; in the sta...

Embodiment 2

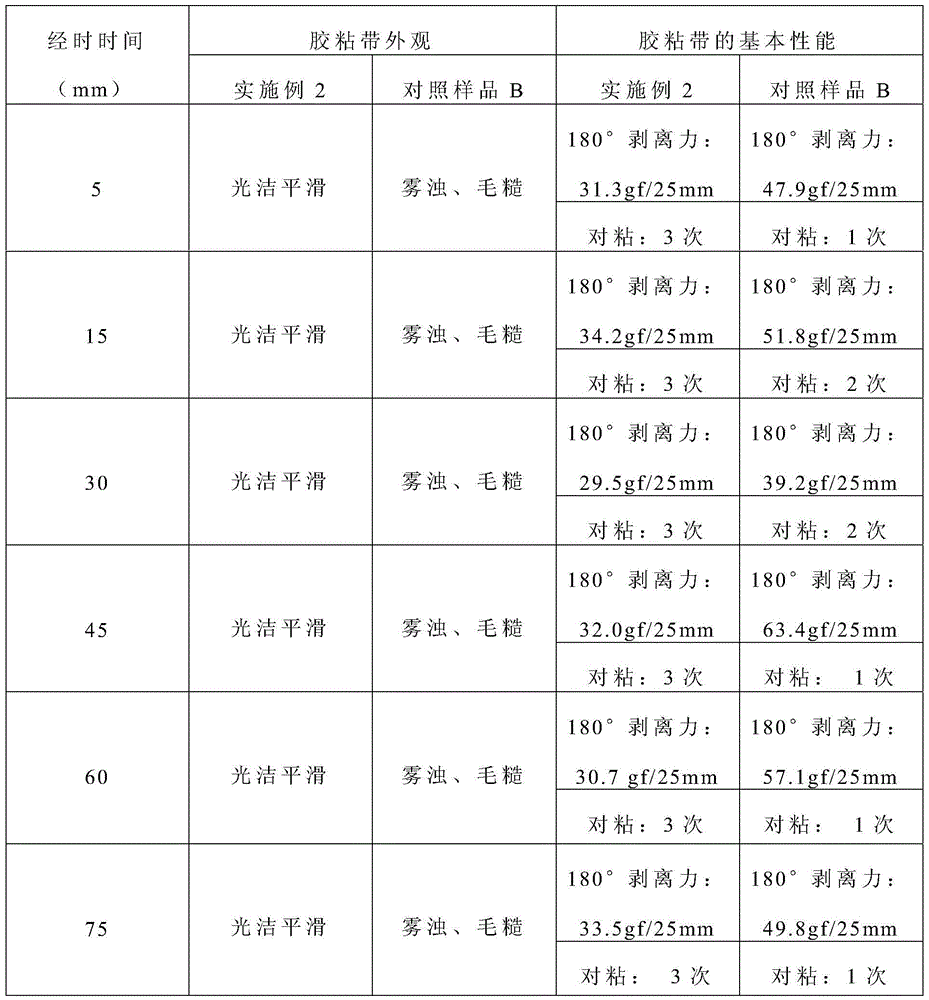

[0036] A solvent-based polymethacrylate pressure-sensitive adhesive coating solution for humid environments, including poly(meth)acrylate pressure-sensitive adhesives with hydroxyl groups as functional groups, Bayer curing agent N75, organotin catalyst, water remover ALT-202, acetic acid and solvent ethyl acetate.

[0037] The preparation method of the solvent-based polymethacrylate pressure-sensitive adhesive coating liquid used in a humid environment is:

[0038] First, pour 5kg of ethyl acetate into a clean stainless steel container, then pour 50kg of solvent-based polymethacrylate pressure-sensitive adhesive, then pour 15kg of ethyl acetate, and stir for 10 minutes to obtain Adhesive diluent; add 2000g of ethyl methyl acetate to 600g of water remover ALT-202 and stir for 10 minutes until uniform to obtain water remover dilution; add 1000g of dibutyltin dilaurate to 20g of Ethyl acetate solution, stirred for 5 minutes until uniform, prepared catalyst dilution; in the stat...

Embodiment 3

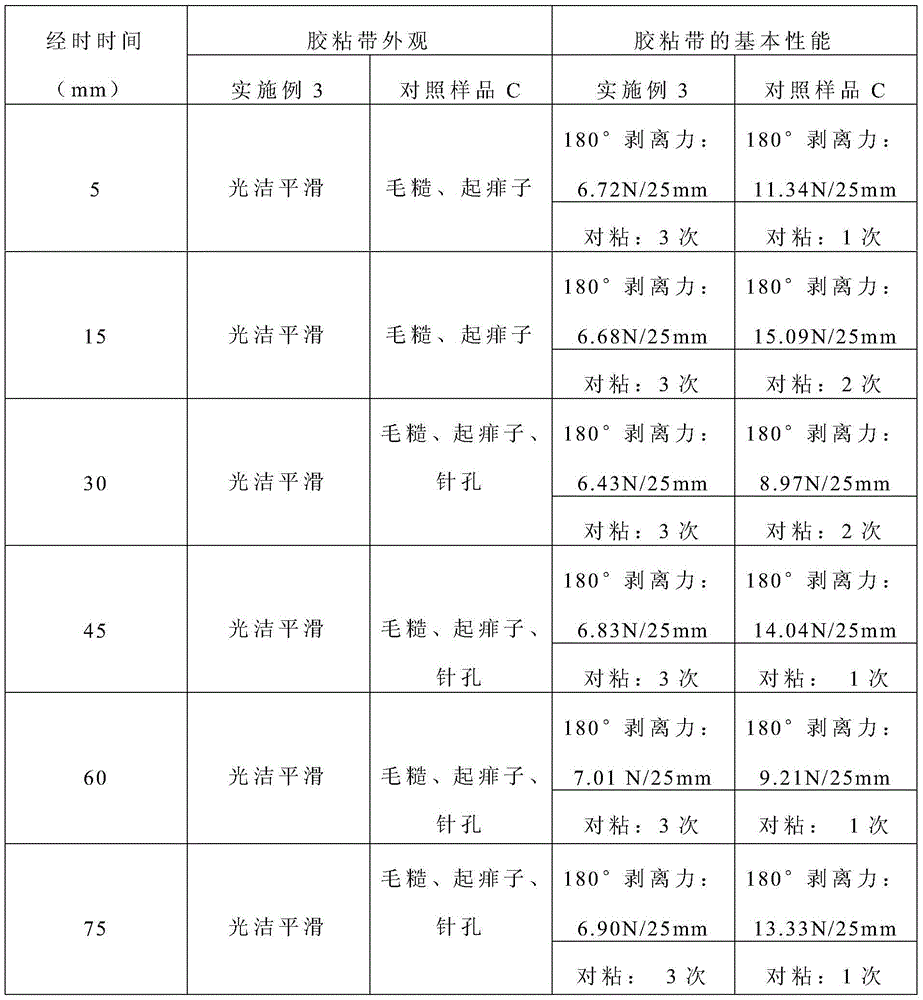

[0046] A solvent-based polymethacrylate pressure-sensitive adhesive coating solution for humid environments, including poly(meth)acrylate pressure-sensitive adhesives with hydroxyl groups as functional groups, Bayer curing agent N3390, organotin catalyst, water remover A, acetic acid and solvent ethyl acetate.

[0047] The preparation method of the solvent-based polymethacrylate pressure-sensitive adhesive coating liquid used in a humid environment is:

[0048] First, pour 5kg of ethyl acetate into a clean stainless steel container, then pour 50kg of solvent-based polymethacrylate pressure-sensitive adhesive, then pour 5kg of ethyl acetate, and stir for 10 minutes to obtain Adhesive diluent; add 2000g of ethyl formate to 500g of water remover A and stir for 10 minutes until uniform to obtain water remover dilution; add 1000g of ethyl acetate to 20g of dibutyltin dilaurate solution, stirred for 5 minutes until uniform, and the catalyst dilution was prepared; under stirring, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com