Preparation method of viscosity-controllable polyamide acid solution

A technology of polyamic acid and solution, which is applied in the direction of spinning solution preparation, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of unstable viscosity control, high molecular weight, high viscosity, etc., and achieve improvement. spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

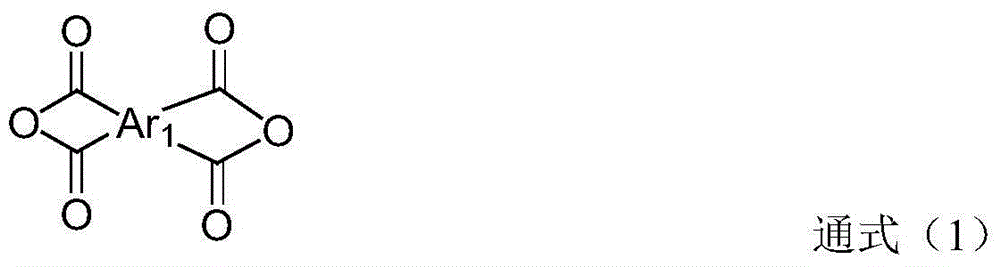

Method used

Image

Examples

Embodiment 1

[0029] Proportion p-phenylenediamine and 3,3′,4,4′-biphenyltetraacid dianhydride in a total molar ratio of 1:0.99, and 10.0807g (0.1mol) of p-phenylenediamine and 203.3gN, Add N-dimethylacetamide and 22.3g of 1-methyl-2-pyrrolidone into a four-necked flask (water content 410ppm), stir at room temperature and under the protection of N2, after completely dissolving, cool in an ice-water bath to 0°C, Add 29.1080 g (0.099 mol) of 3,3′,4,4′-biphenyltetraacid dianhydride powder at 250 rpm, and continue stirring for 0.5 hour to obtain the desired polyamic acid solution with a solid content of 14.8%. The solution was tested by filtration without gel generation, the apparent viscosity of the solution was 108 Pa·s at 25°C, and the intrinsic viscosity was 1.43dL / g at 25°C.

Embodiment 2

[0031] Proportion p-phenylenediamine and 3,3′,4,4′-biphenyltetraacid dianhydride in a total molar ratio of 1:1.01, mix 10.0807g (0.1mol) of p-phenylenediamine and 275.4gN, Add N-dimethylacetamide and 82.6g 1-methyl-2-pyrrolidone into a four-neck flask (water content 410ppm), stir at room temperature and 2 Under protection, after completely dissolving, cool in an ice-water bath to 10°C, add 29.6940g (0.101mol) of 3,3′,4,4′-biphenyltetraacid dianhydride powder at a stirring speed of 250 rpm, and continue stirring After 1.5 hours, the desired polyamic acid solution with a solid content of 10% was obtained. The solution was tested by filtration without gel formation, the apparent viscosity of the solution was 90 Pa·S at 25°C, and the intrinsic viscosity was 1.19 dL / g at 25°C.

Embodiment 3

[0033] Proportion p-phenylenediamine and 3,3′,4,4′-biphenyltetraacid dianhydride in a total molar ratio of 1:1, mix 10.0807g (0.1mol) of p-phenylenediamine and 112.8gN, Add N-dimethylacetamide and 5.6g 1-methyl-2-pyrrolidone into a four-neck flask (water content 410ppm), stir at room temperature and 2 Under protection, after complete dissolution, adjust the temperature to 35°C, add 29.400g (0.1mol) 3,3′,4,4′-biphenyltetraacid dianhydride powder at a stirring speed of 250 rpm, and continue stirring for 5 hours, the desired polyamic acid solution with a solid content of 25% was obtained. No gel was produced in the solution after filtration test, the apparent viscosity of the solution was 233 Pa·S at 25°C, and the intrinsic viscosity was 1.98dL / g at 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com