A hyperbranched polymer viscosity reducer for high-strength concrete and preparation method thereof

A technology of hyperbranched polymer and viscosity reducer, applied in the field of concrete admixtures, can solve the problem of not using hyperbranched viscosity reducer, and achieve the effects of reducing the risk of cracking, improving repulsion, and large space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for hyperbranched polymer viscosity reducer for high-strength concrete, comprising the following steps:

[0031] Step 1: Ring-opening reaction between primary amino group and epichlorohydrin: dissolve the benzene ring compound with two or more primary amino functional groups in an aprotic polar solvent, add a catalyst, and heat up to 60-100 ℃; then dropwise add epichlorohydrin solution, fully react, remove the solvent and dry to obtain compound A; wherein the molar ratio of benzene ring compound and epichlorohydrin is 1:3-10.

[0032] The benzene ring compounds are 1,3,5-triaminobenzene, p-phenylenediamine, p-diaminobiphenyl, 4,4'-diaminodiphenylmethane, 1,4-xylylenediamine, 2,4,6 -Triethylbenzene-1,3,5-trimethylamine, 4,4',4"-(1,3,5-triazine-2,4,6-triyl) triphenylamine. Not Protic polar solvents are benzene, toluene, xylene, cyclohexane, chloroform, dimethyl sulfoxide, N,N-dimethylformamide, 1,3-dimethyl-3.4,5,6-tetra Hydrogen-2-pyrimidinone, eth...

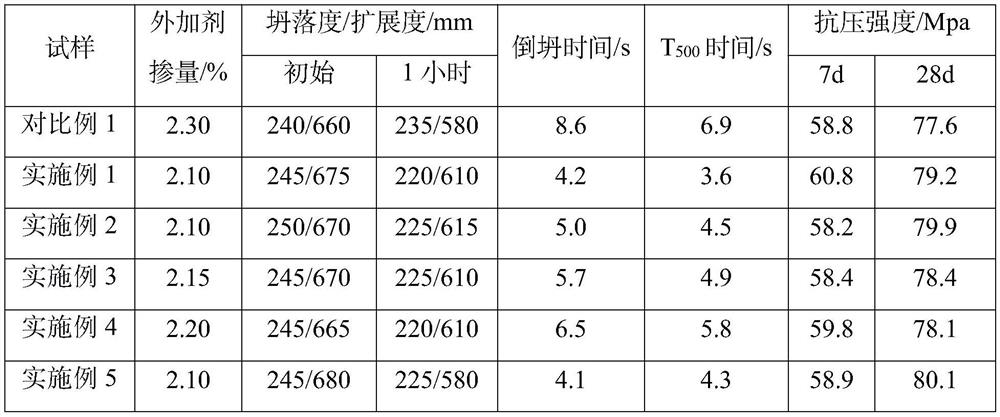

Embodiment 1

[0042] Prepare a hyperbranched polymer viscosity reducer for high-strength concrete according to the following steps:

[0043] Step 1: Weigh 0.5 mol of 1,3,5-triaminobenzene and dissolve it in an aprotic polar solvent; then add a mixed catalyst consisting of triethylbenzylammonium chloride and tetraethylammonium bromide. After heating to 80° C., 3.0 mol of epichlorohydrin was added dropwise within 0.5 hours and then kept for 2.0 hours. After removing the solvent from the obtained solution by a rotary evaporator, compound A was obtained after vacuum drying at room temperature for 24.0 hours.

[0044] The amount of the aprotic polar solvent used is not particularly limited, and is generally subject to the ability to dissolve the solid raw material. It can be 50-1000 parts by weight of the total mass of solid raw materials, preferably 100 parts by weight in this embodiment. Aprotic polar solvents are dimethylsulfoxide, N,N-dimethylformamide, 1,3-dimethyl-3,4,5,6-tetrahydro-2-py...

Embodiment 2

[0049] Prepare a hyperbranched polymer viscosity reducer for high-strength concrete according to the following steps:

[0050] Step 1: Weigh 0.5 mol of p-phenylenediamine and dissolve it in an aprotic polar solvent; then add a mixed catalyst consisting of triethylbenzylammonium chloride and tetraethylammonium bromide. After heating to 80° C., 2.0 mol of epichlorohydrin was added dropwise within 0.5 hours and then kept for 2.0 hours. After removing the solvent from the obtained solution by a rotary evaporator, compound A was obtained after vacuum drying at room temperature for 24.0 hours.

[0051] The amount of the aprotic polar solvent used is not particularly limited, and is generally subject to the ability to dissolve the solid raw material. It can be 50-1000 parts by weight of the total mass of solid raw materials, preferably 100 parts by weight in this embodiment. The aprotic polar solvent is a mixed solvent composed of dimethyl sulfoxide, chloroform, and 1,3-dimethyl-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com