Polyethylene terephthalate and its production method

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of polyethylene terephthalate and its manufacturing, can solve the problem of increasing the cleaning frequency and replacement frequency of molds and nozzles , lower commodity value, lower productivity, etc., to achieve the effect of not easy to have bad appearance, good hue, good (b value)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

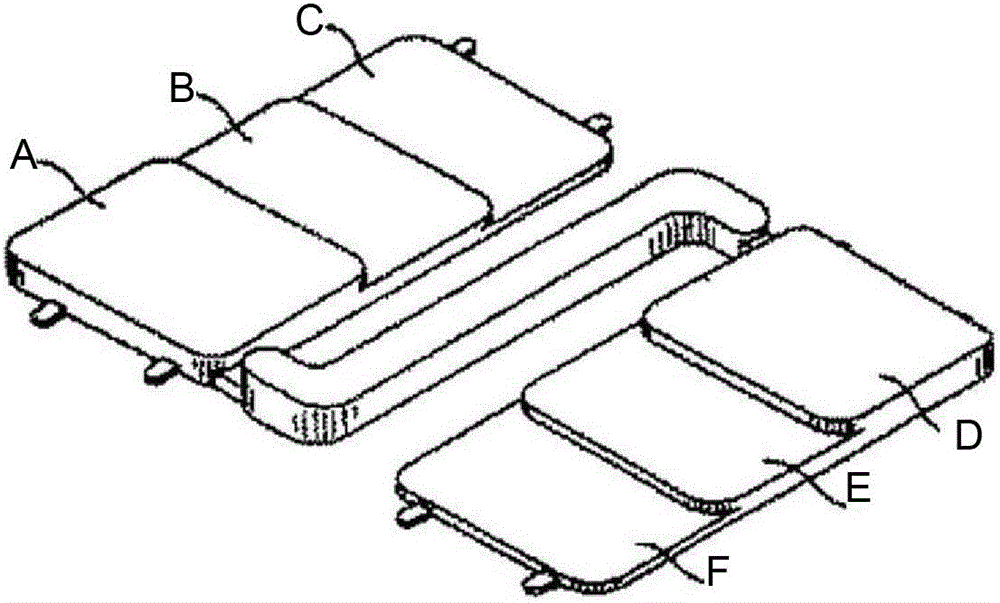

Image

Examples

Embodiment 1

[0131] Add 13,000 parts of high-purity terephthalic acid, 5,000 parts of monoethylene glycol, and 6.88 parts of a 20% aqueous solution of tetraethylammonium hydroxide into the autoclave. With a pressure of 0.17MPaG, it takes 4 hours to raise the temperature from 100°C to 260°C for further reaction It took 1.5 hours. The water generated by this reaction was distilled out of the system from time to time. Next, 2.1 parts of germanium dioxide and 2.2 parts of trimethyl phosphate (hereinafter referred to as TMP) were added as a polycondensation catalyst. The temperature was raised to 280° C. over 1 hour, the pressure in the system was reduced to 0.27 kPa abs, the reaction was continued for 43 minutes, and ethylene glycol was distilled out of the system. After the reaction is terminated, the reactant is cut into a chip shape. The intrinsic viscosity (IV) of polyethylene terephthalate obtained by the above liquid phase polycondensation L ) is 0.54dl / g. In addition, the terminal C...

Embodiment 2

[0138] Except having changed the solid-phase polymerization conditions as follows, it carried out similarly to Example 1, and produced polyethylene terephthalate. Solid-phase polymerization conditions were such that solid-state polycondensation was performed at 220° C. for 7 hours in a batch-type solid-phase polycondensation apparatus in a nitrogen stream containing 0.38% by weight of monoethylene glycol. The intrinsic viscosity (IV) of polyethylene terephthalate after solid-state polycondensation S ) is 0.62dl / g, and the IV increase range ΔIV (IV from liquid phase polycondensation to solid phase polycondensation S -IV L ) is 0.08dl / g. In addition, the cyclic trimer (CT) content was 0.34% by weight.

[0139] This polyethylene terephthalate was hot-water-treated by the same method as Example 1.

[0140] The polyethylene terephthalate obtained in this way has an intrinsic viscosity of 0.62 dl / g, a CT content of 0.34% by weight, a Ge content of 66 ppm, Si and Al of 1 ppm or l...

Embodiment 3

[0147] Using a continuous polycondensation device in which the first, second, third, and fourth reactors are tank-type and the fifth reactor is a twin-screw rotary horizontal reactor, continuous polymerization is performed as follows to produce polyethylene terephthalate. In advance, in the reactor in which 33500 parts by weight of the reaction solution (at the time of steady operation) was retained, 6458 parts by weight / hour of The slurry prepared by mixing high-purity terephthalic acid and 2615 parts by weight / hour of ethylene glycol was subjected to esterification reaction. In this esterification reaction, the mixed solution of water and ethylene glycol was distilled off.

[0148]The esterification reaction product (lower condensate) was controlled so that the average residence time would be 3.5 hours, and was continuously introduced with stirring into the second reactor maintained at 260° C. and normal pressure. In this reactor 2, the ethylene glycol solution of germaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com