Patents

Literature

49results about How to "Bad apperance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

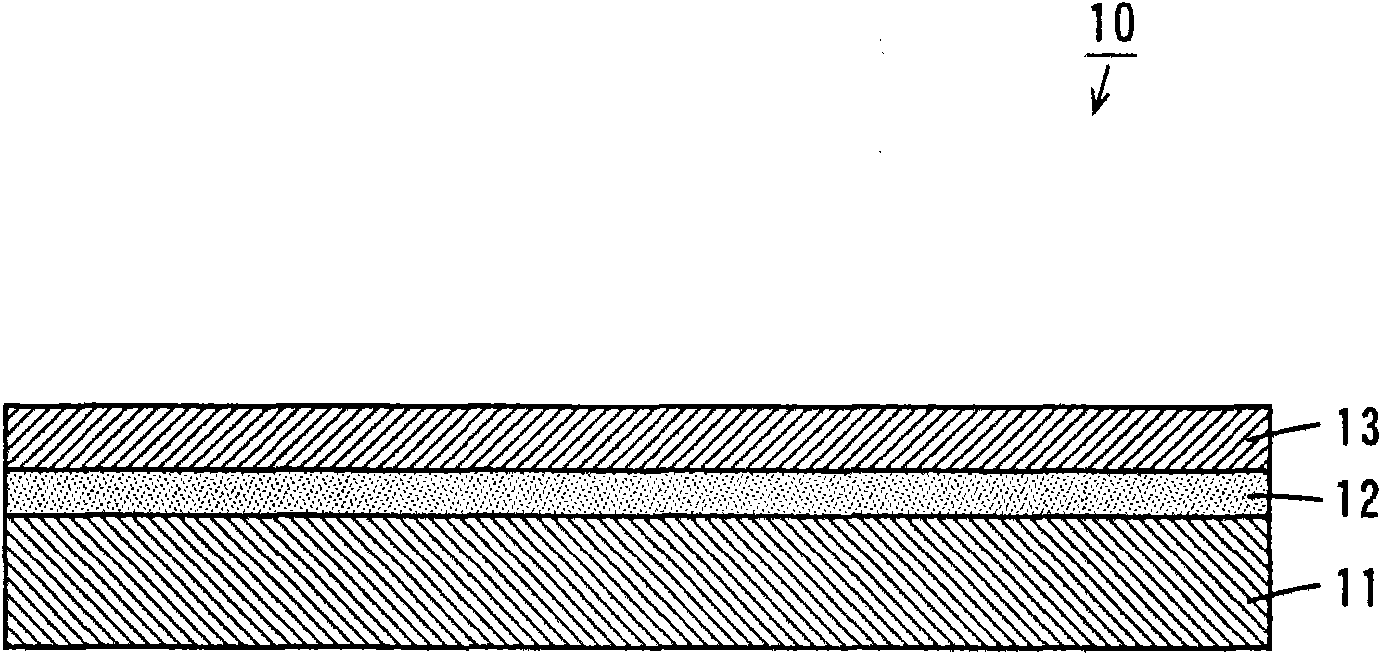

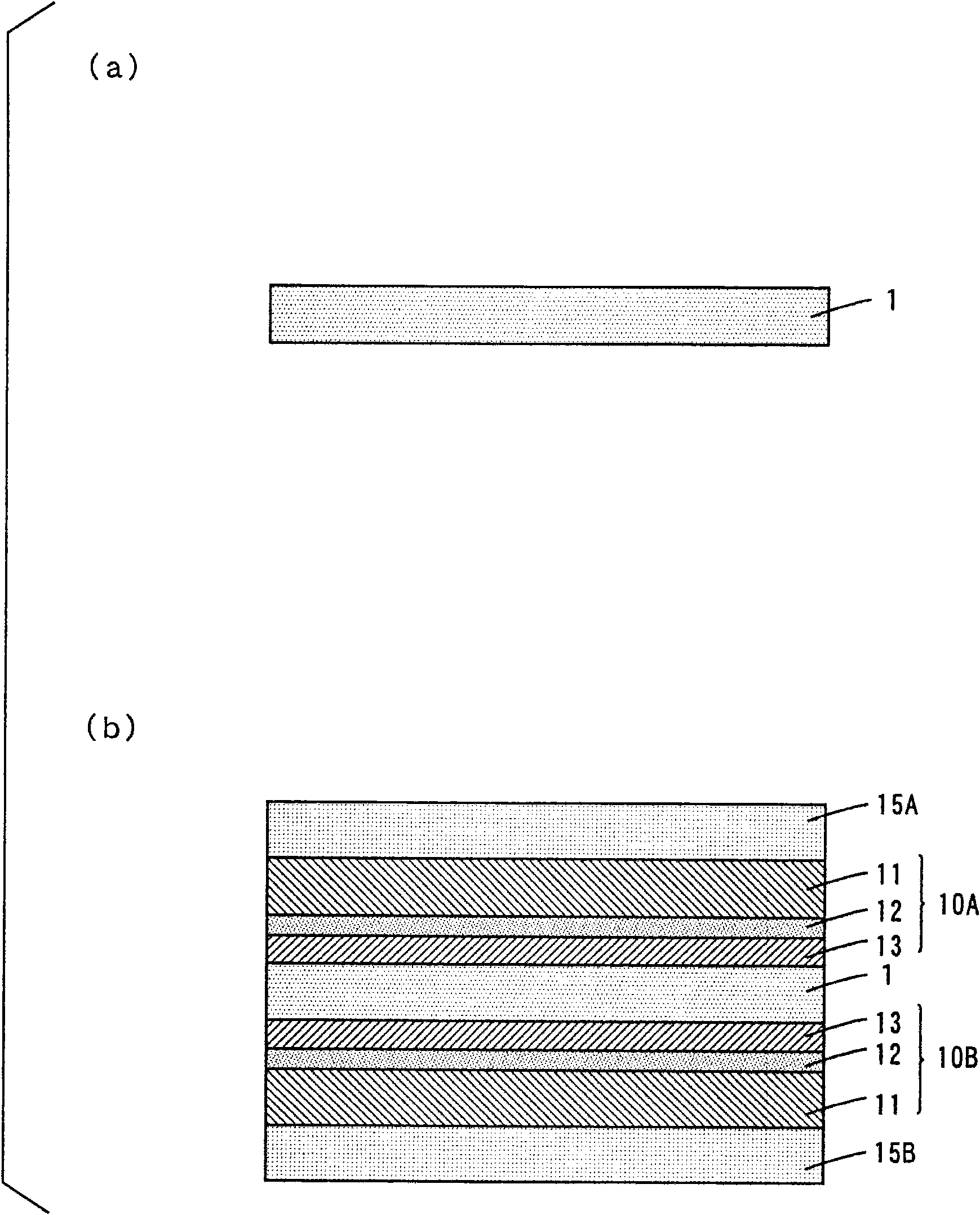

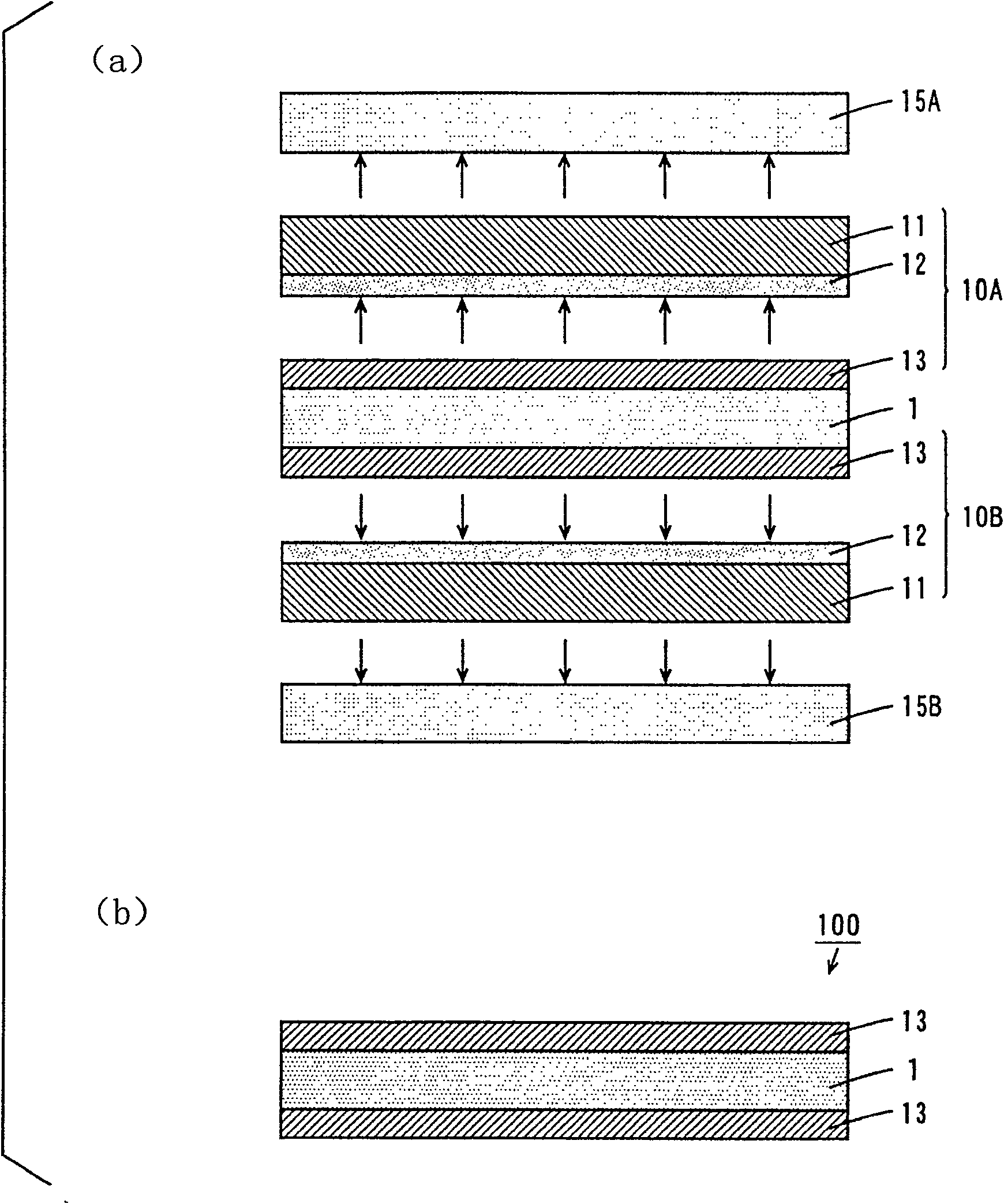

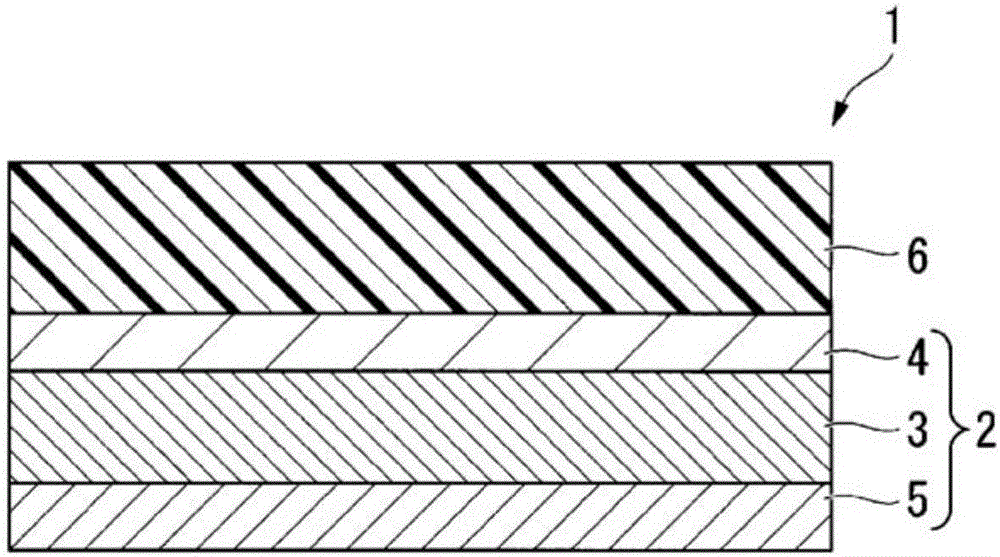

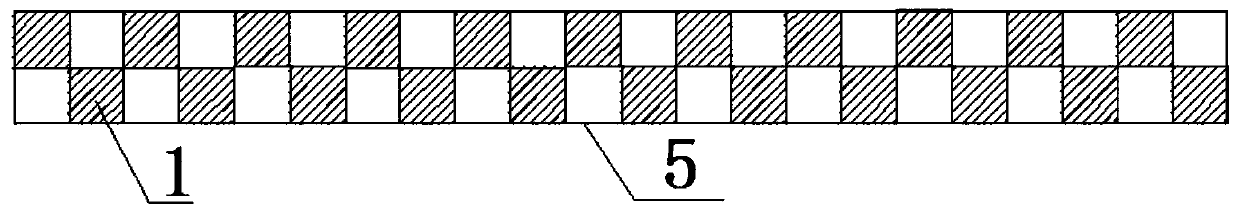

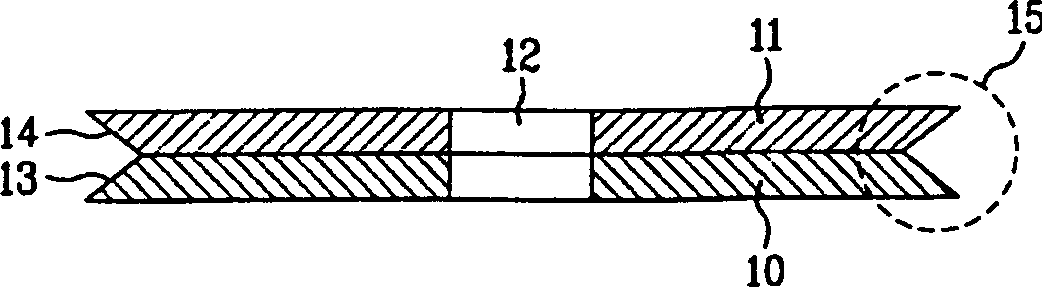

Solar battery piece packaging glue structure and preparation method thereof

ActiveCN103865420AAdhesion effectLow costFilm/foil adhesivesSynthetic resin layered productsCross-linkEngineering

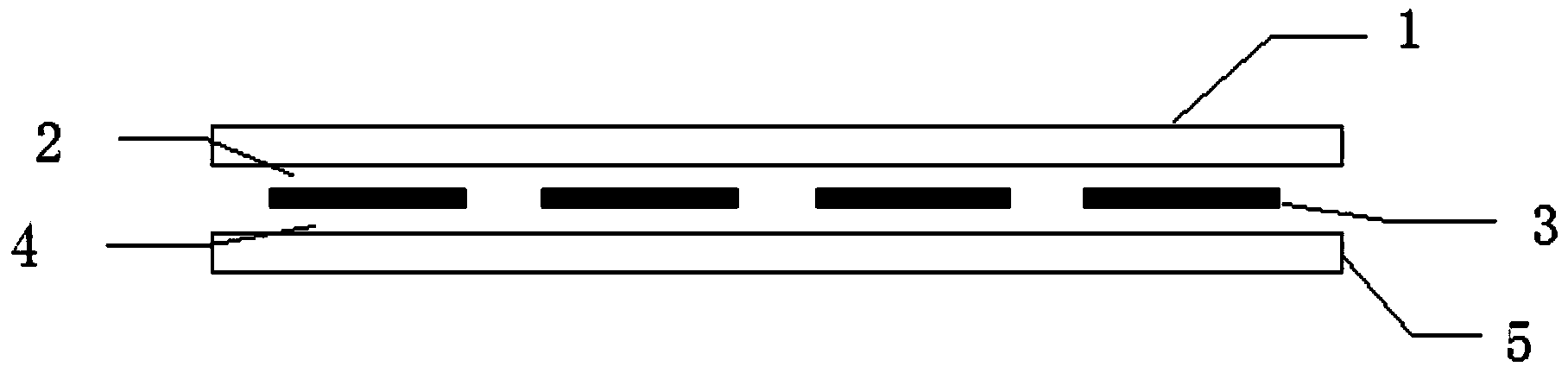

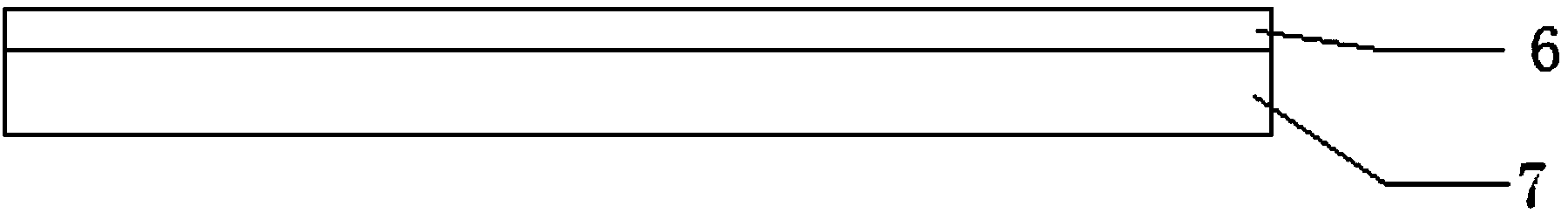

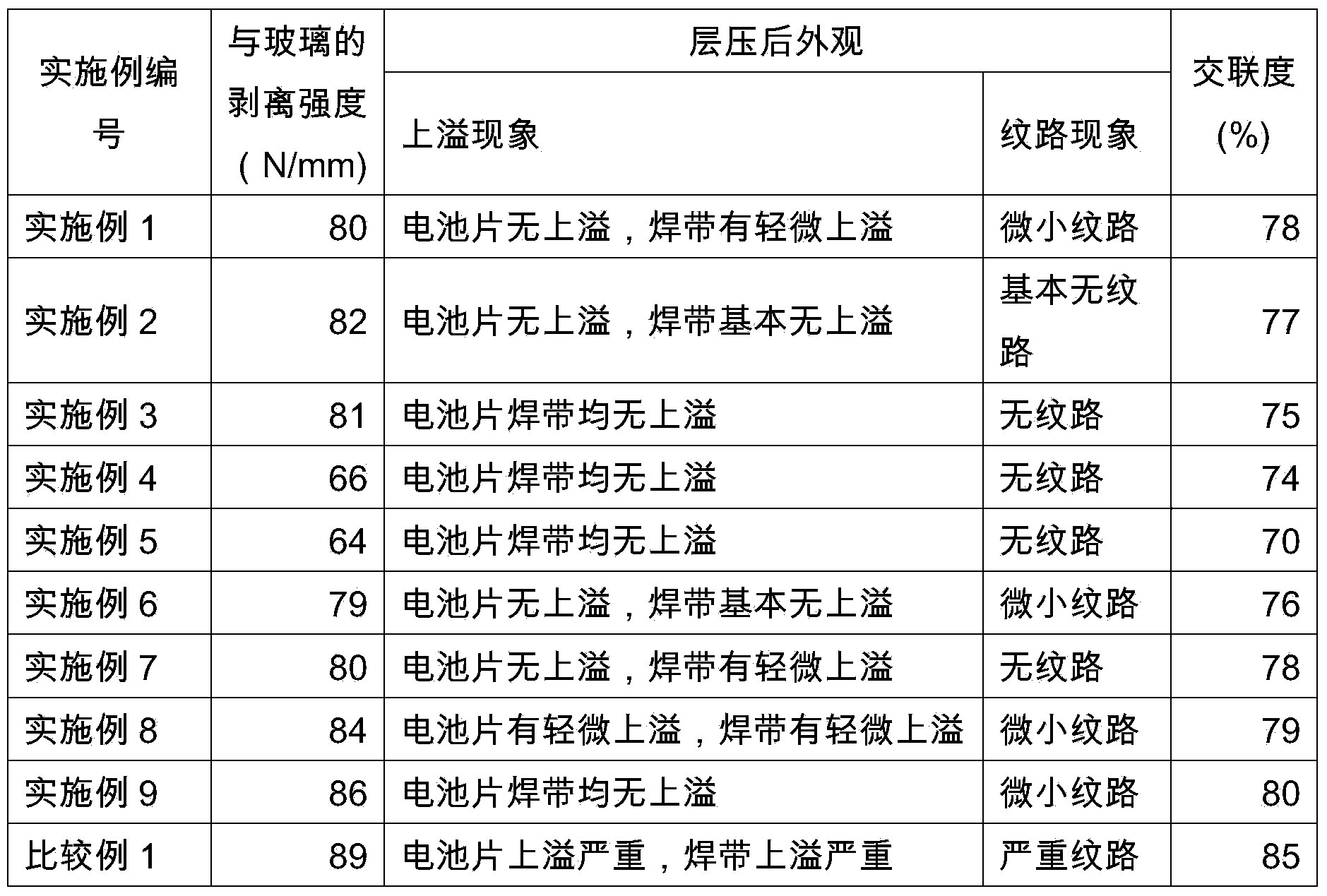

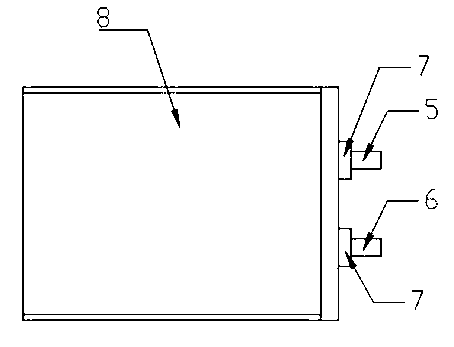

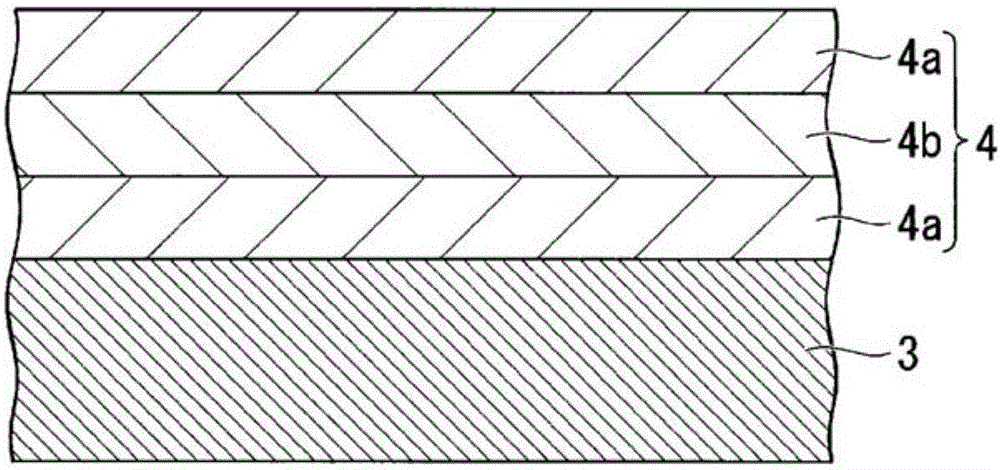

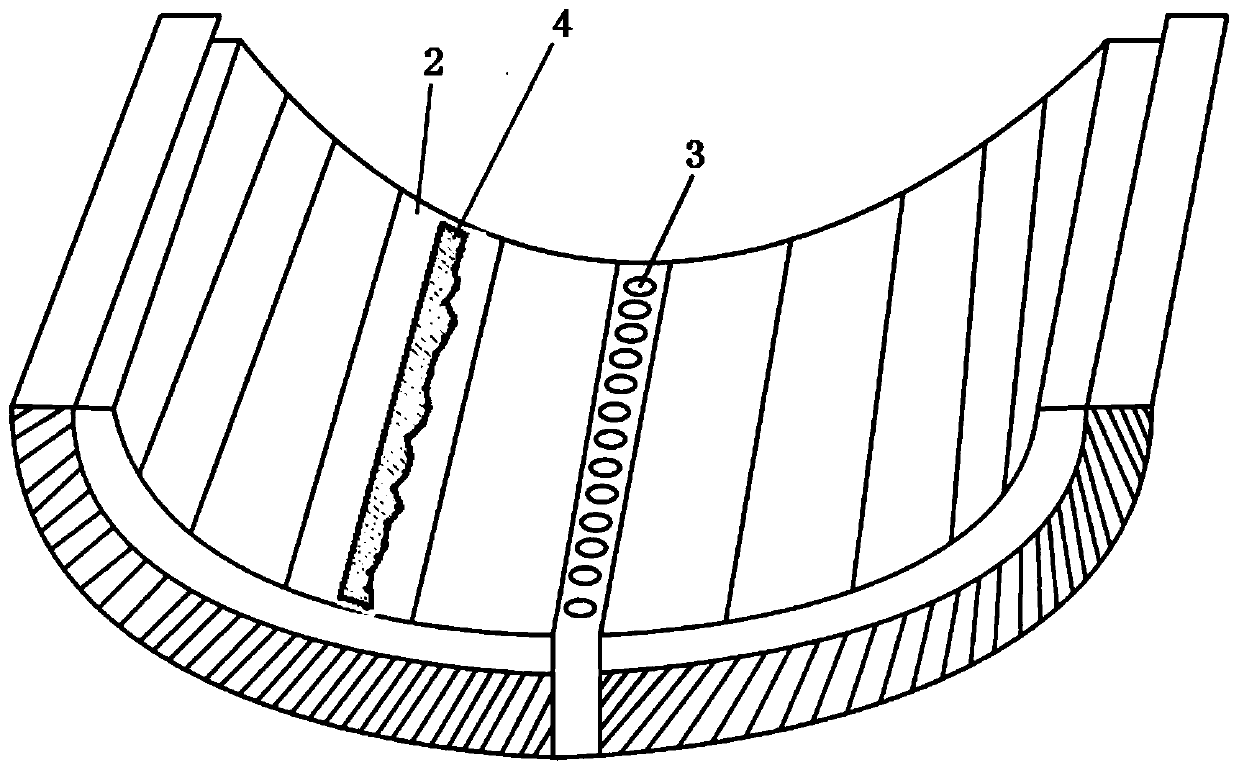

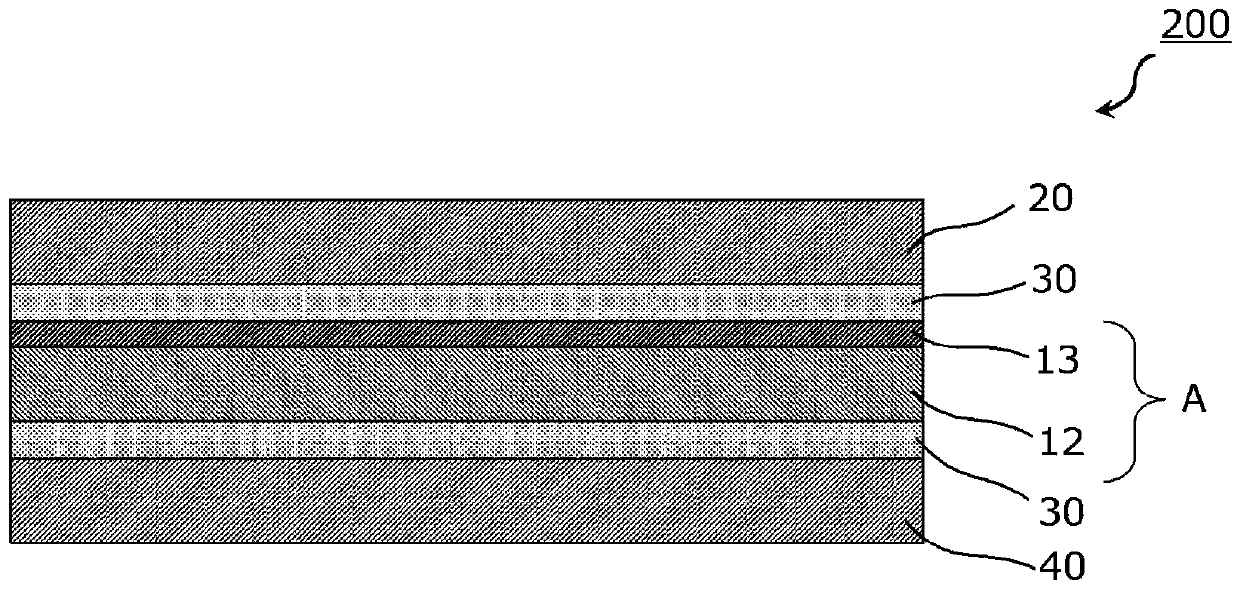

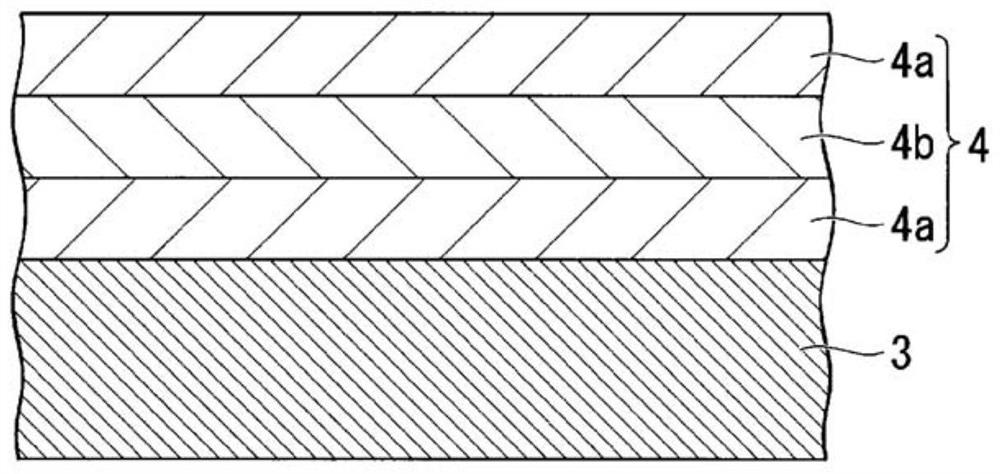

The invention relates to a solar battery piece packaging glue structure and a preparation method thereof. The structure comprises a packaging glue layer and at least one partitioning membrane layer, or comprises a packaging glue layer, at least one layer of partitioning membrane and at least one adhesive layer distributed on one side, which is close to a battery piece, of the partitioning membrane, wherein the partitioning membrane is compounded with the packaging glue layer, or the partitioning membrane is compounded with the packaging glue layer and the adhesive layer; the flowability of the partitioning membrane is smaller than that of the packaging glue layer. According to the solar battery piece packaging glue structure, as one layer of the partitioning membrane with very low flowability is compounded with the packaging glue and the flowability of the partitioning membrane self is lower than that of the packaging glue, the packaging glue is harder to overflow, and moreover a good partitioning function is achieved for overflowing of the packaging glue with high flowability. When the structure is laminated, the packaging glue of a cross-linking system with high flowability at a lower layer can be fused with the partitioning membrane with low flowability at an upper layer at high temperature, so that sufficient binding force can be still maintained.

Owner:仇桂芬

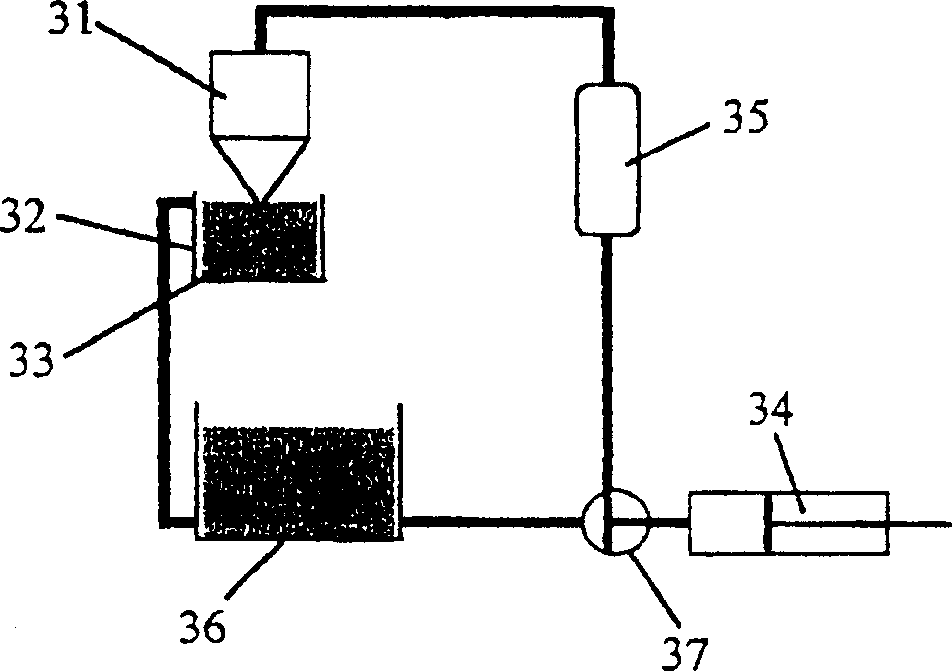

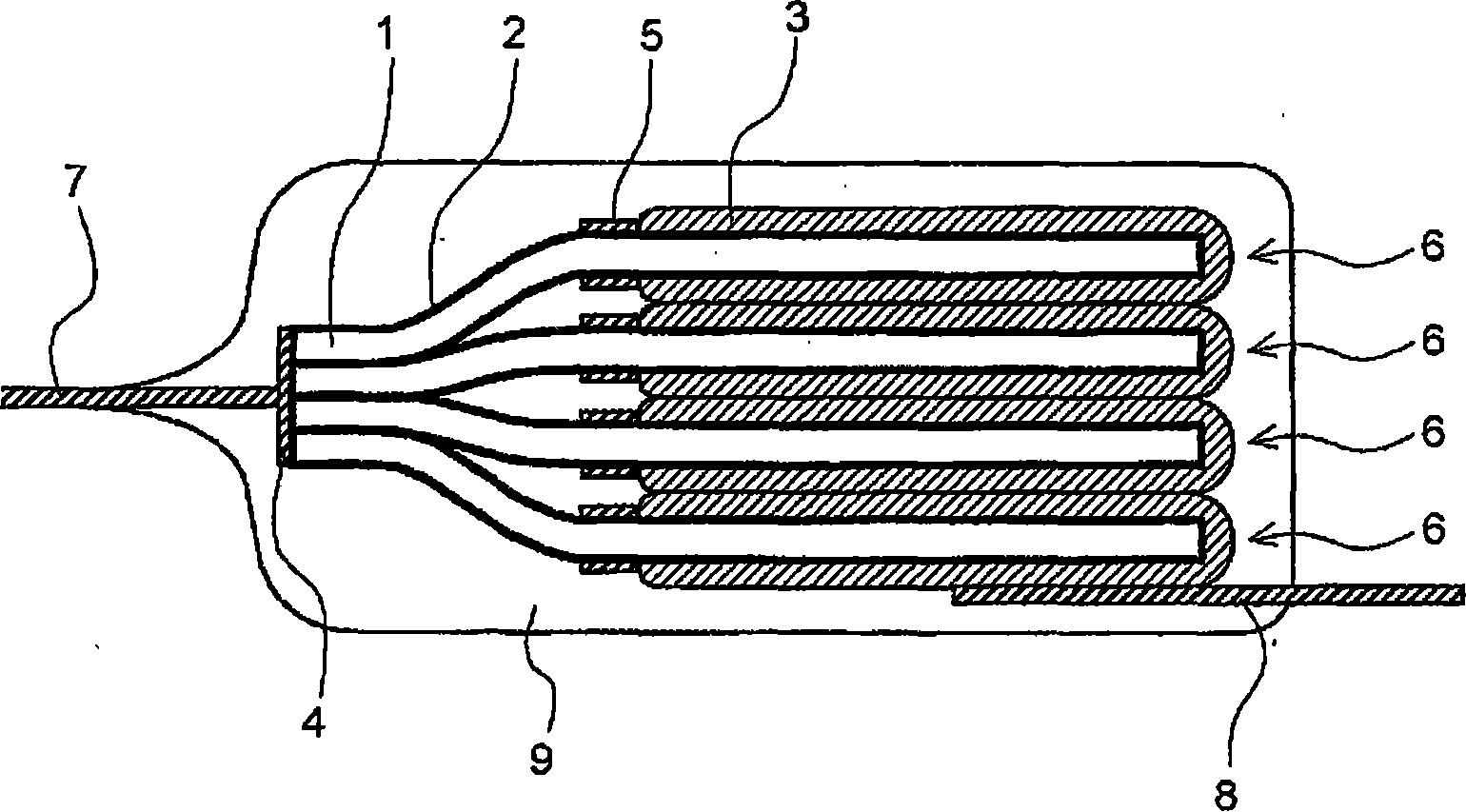

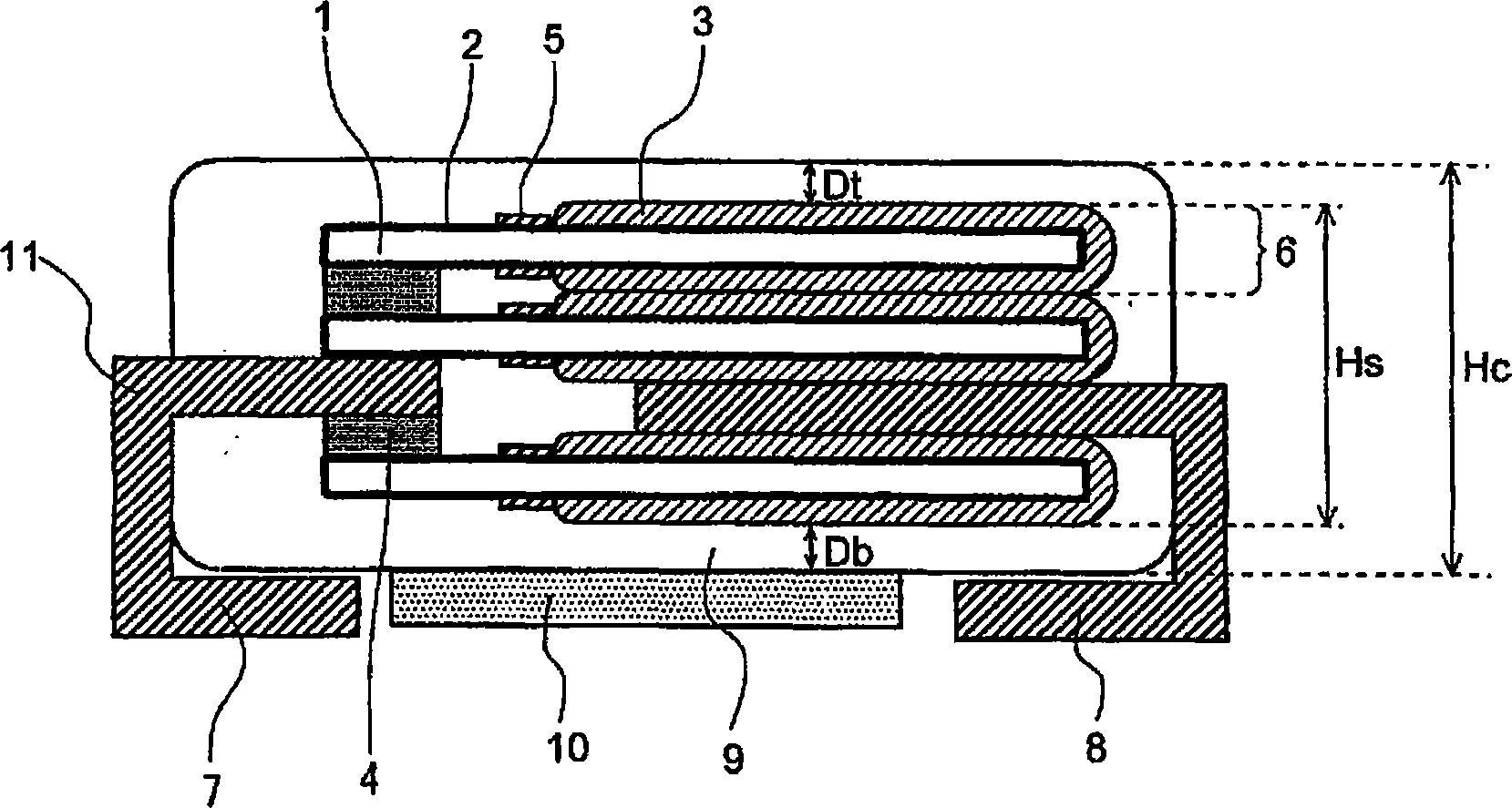

Manufacturing method of lithium ion battery containing gel electrolyte

ActiveCN103000956AEasy to prepareImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

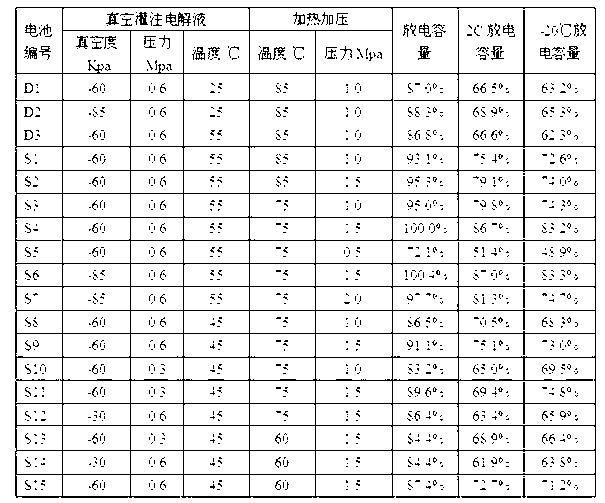

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a manufacturing method of a lithium ion battery containing gel electrolyte. The manufacturing method comprises the steps of preparation of a micro-pore isolating diaphragm plate, preparation of a cell, pouring of the electrolyte, after-treatment and the like. Compared with the prior art, the manufacturing method provided by the invention adopts a two-step method to polymerize gel; a good cathode pole sheet / electrolyte interface and a good anode pole sheet / electrolyte interface are formed on the cell by a pre-gelling step; in a formation process, a cathode activity material and an anode activity material can be sufficiently activated; the lithium ion battery is pressurized in a heating process after the formation is completed, so that air bubbles generated in the formation process of the battery and existing between the cathode pole sheet / electrolyte interface and the anode pole sheet / electrolyte interface can be removed; and an interface gap can be smaller, thereby being beneficial to the generation of the cathode pole sheet / electrolyte interface and the anode pole sheet / electrolyte interface. Therefore, the battery has better electrochemical performance.

Owner:DONGGUAN AMPEREX TECH

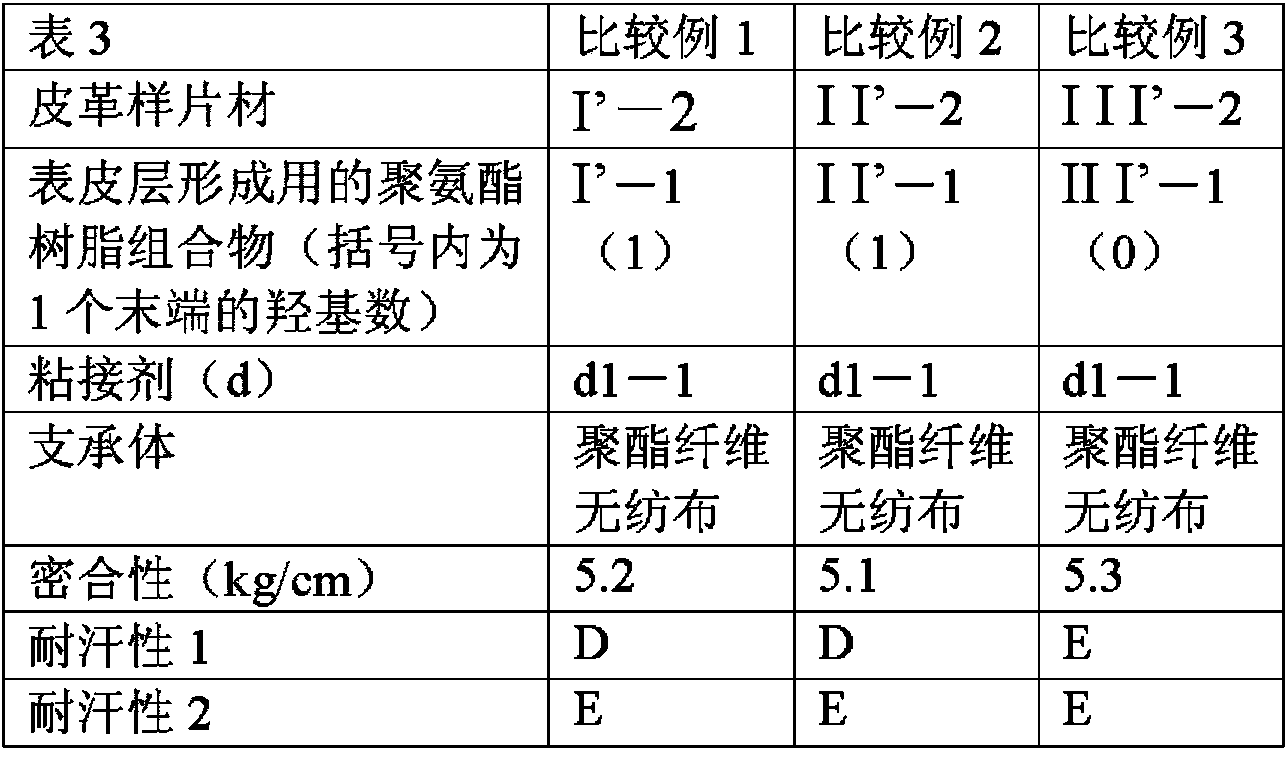

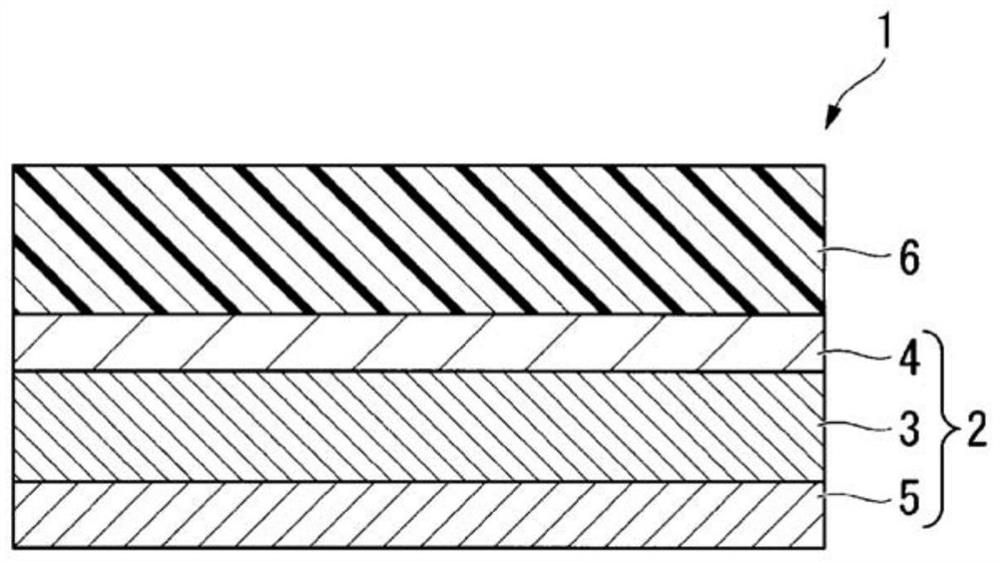

Leather-like sheet and method for producing same

ActiveCN103764899ABad apperanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPerspirationAqueous medium

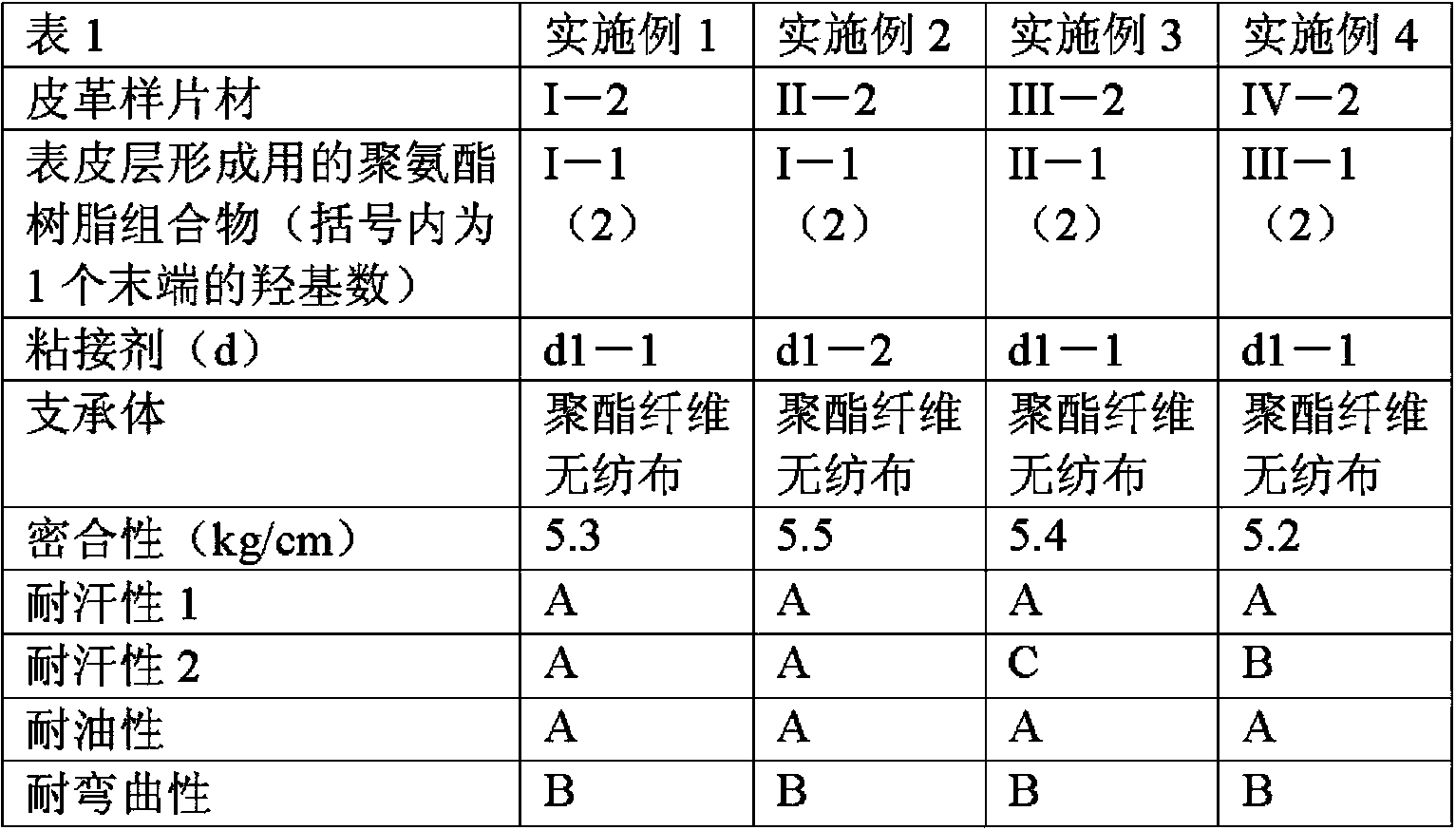

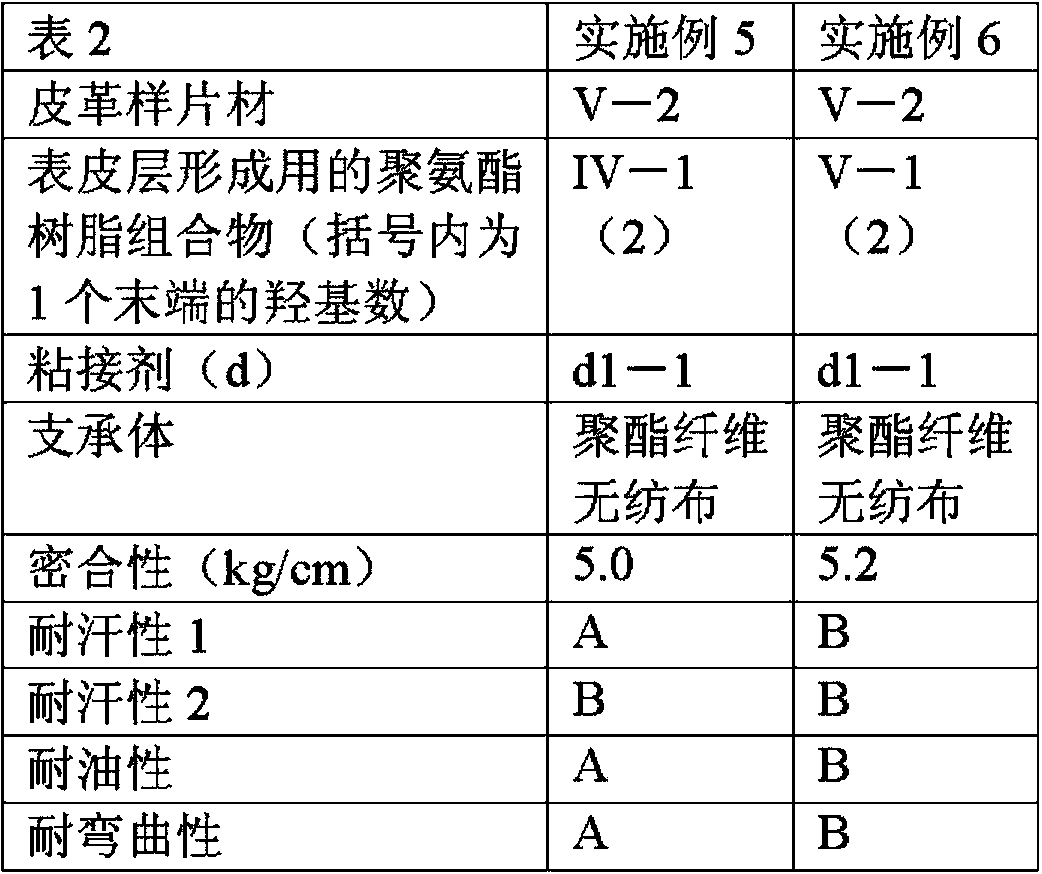

The present invention addresses the problem of providing a urethane resin composition for forming a surface skin layer of a leather-like sheet, said urethane resin composition enabling the formation of the surface skin layer which has an excellent durability, such as perspiration resistance and oil resistance, at such a level that the leather-like sheet shows neither deterioration in appearance nor peeling from a substrate over time even in the case where, for example, sweat, oil or the like sticks thereto. The leather-like sheet according to the present invention is characterized by comprising: a surface skin layer (C) formed by using a urethane resin composition comprising a urethane resin (A) that has two or more hydroxyl groups at least at one end thereof, and an aqueous medium (B); an adhesive layer (D); and a substrate layer (E).

Owner:DIC CORP

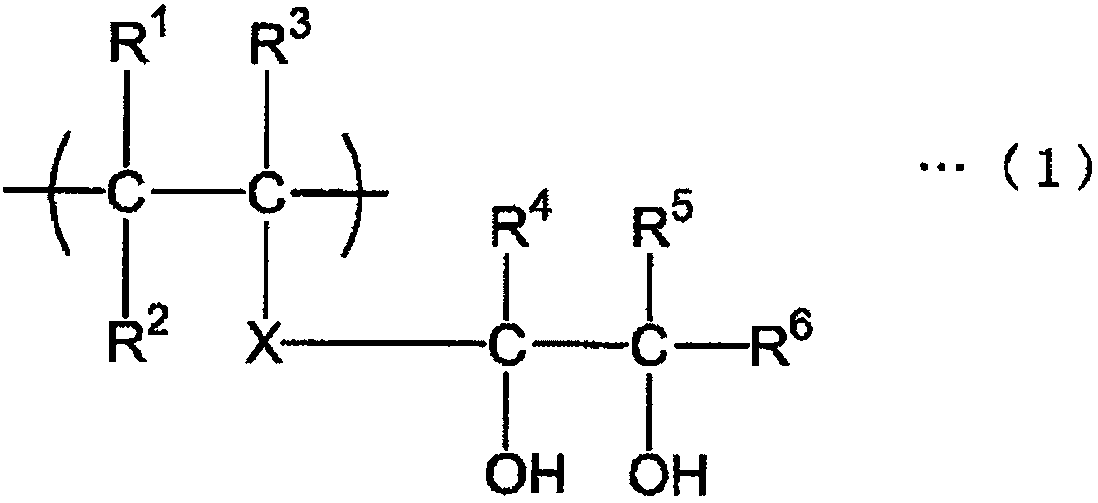

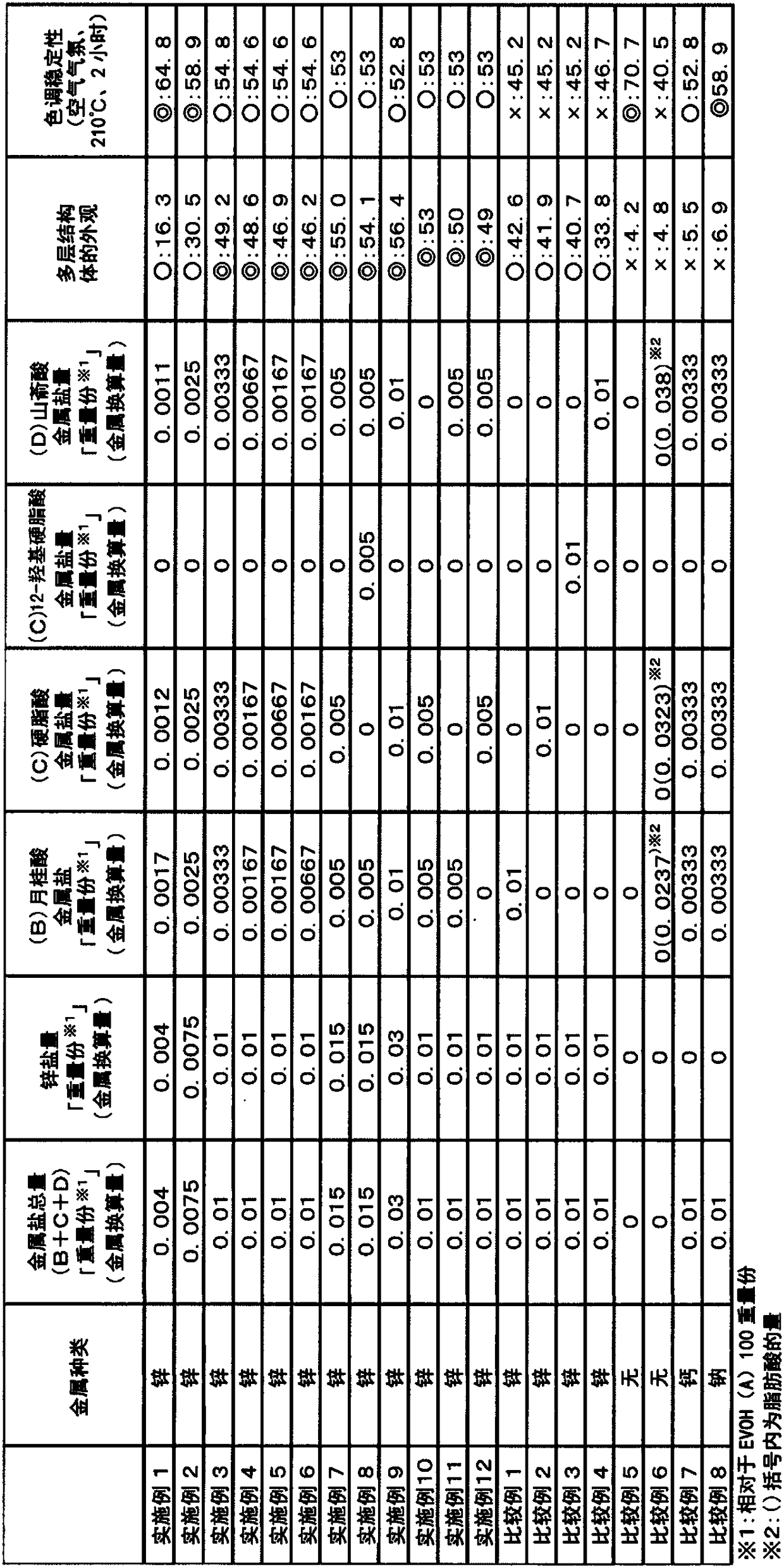

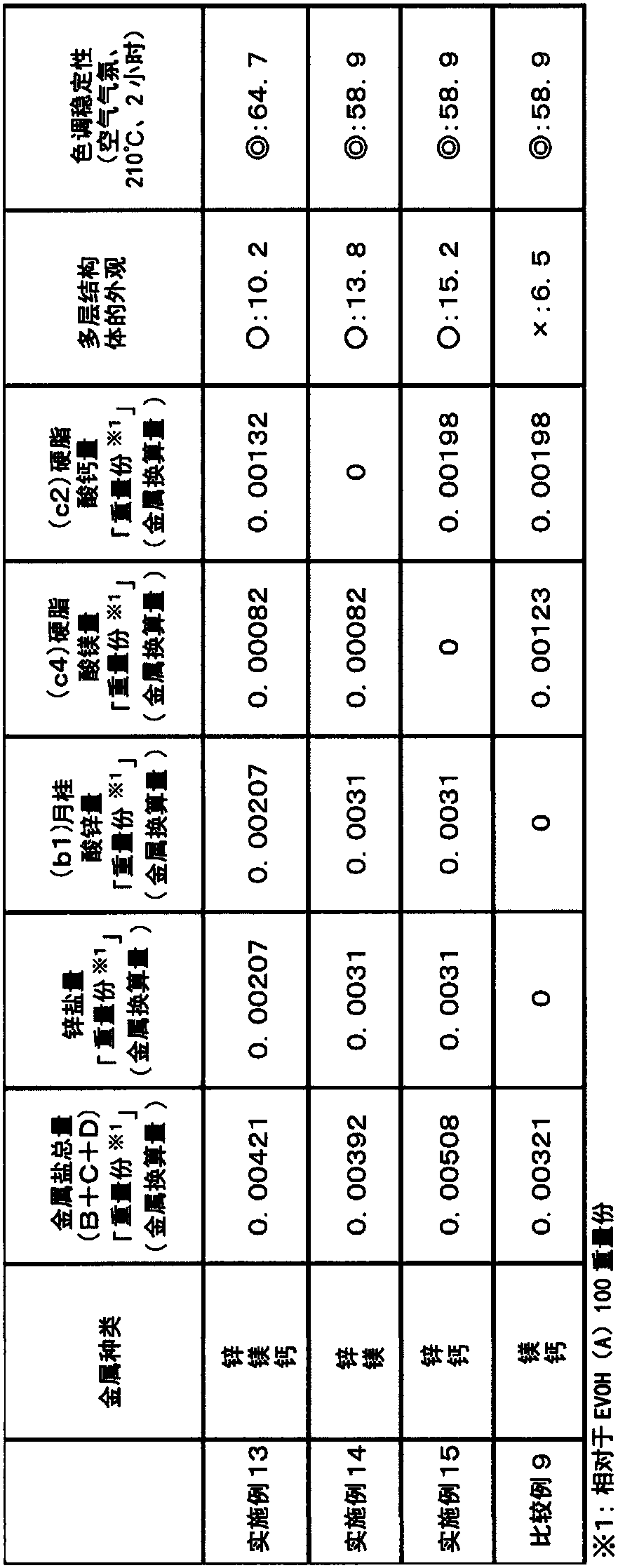

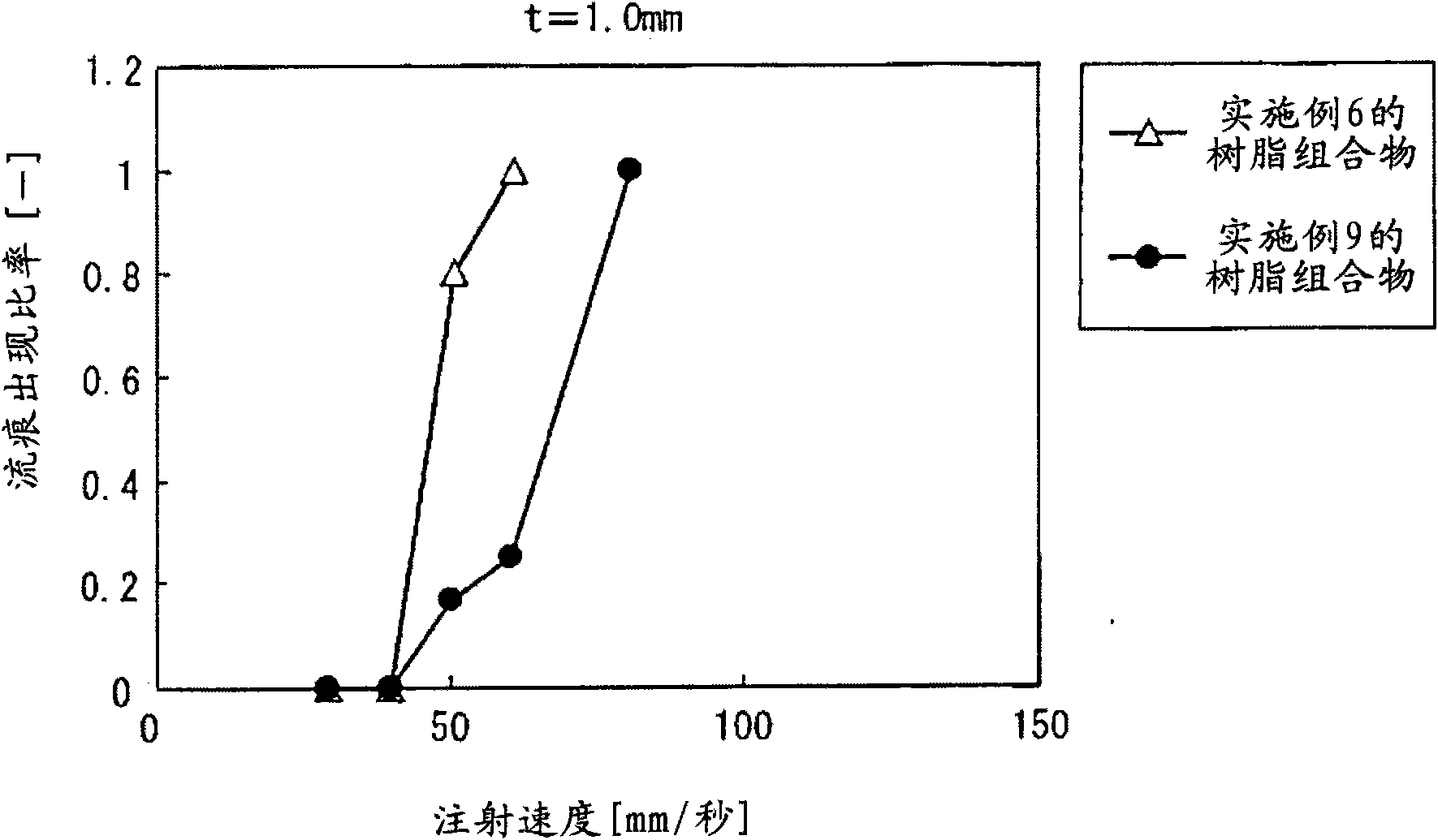

Resin composition and multilayer structure using same

PendingCN108473743ABad apperanceImprove tone deteriorationSynthetic resin layered productsPolymer scienceVinyl ester

Provided is a resin composition containing a saponified ethylene-vinyl ester copolymer (A) and fatty acid metal salts, the resin composition being intended to make it possible to form a multilayer structure having suppressed occurrence of defects of appearance and improved deterioration of color tone during melt molding, wherein the resin composition is characterized in that the fatty acid metal salts are at least two fatty acid metal salts selected from C3-12 fatty acid metal salts (B), C13-20 fatty acid metal salts (C), and C21-29 fatty acid metal salts, and at least one among the fatty acidmetal salts selected from (B), (C), and (D) is a zinc salt.

Owner:MITSUBISHI CHEM CORP

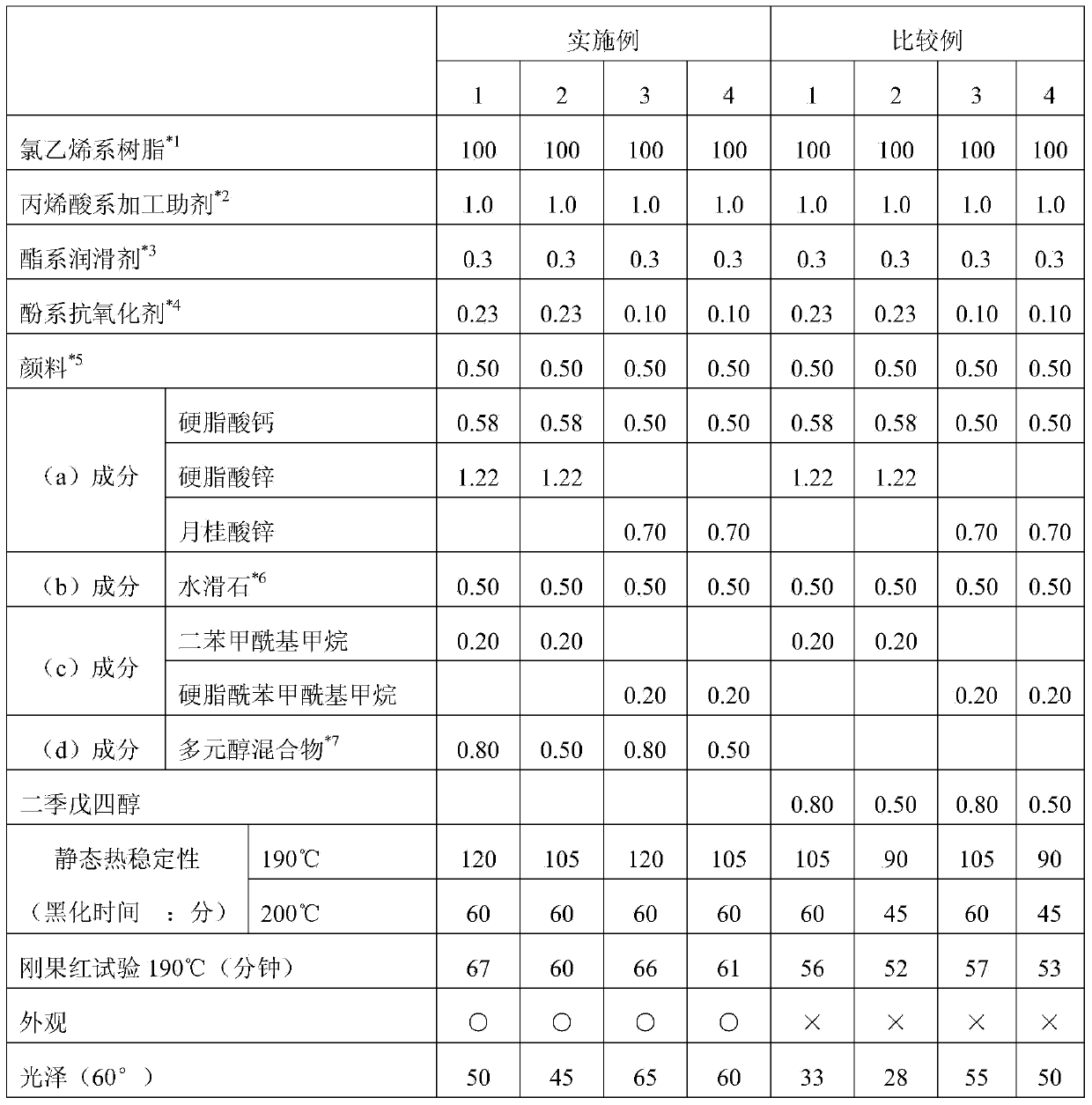

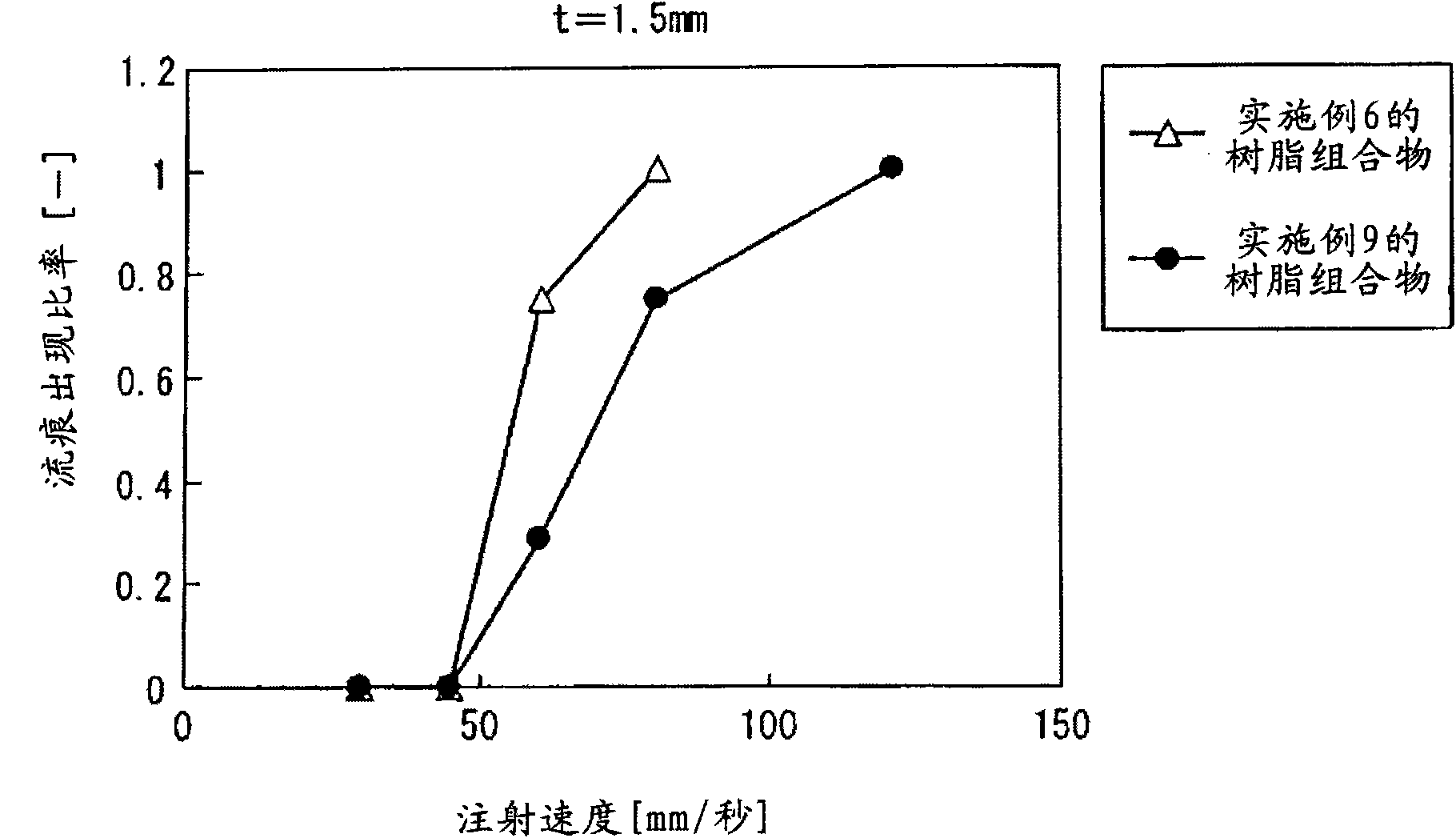

Vinyl chloride resin composition for injection molding

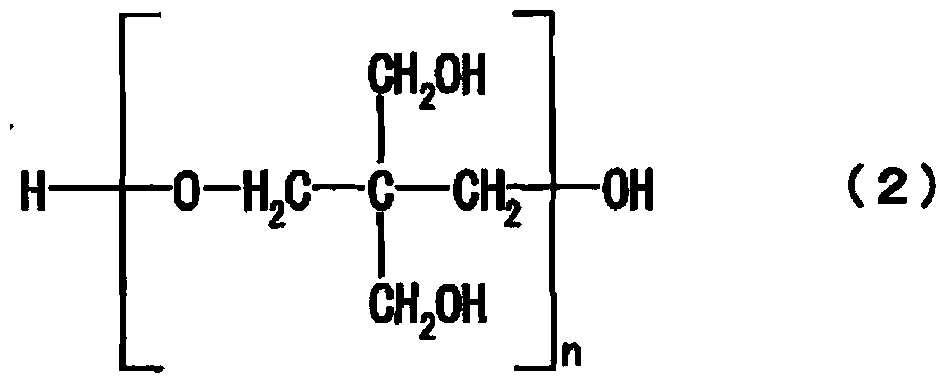

The present invention provides a vinyl chloride resin composition for injection molding, which comprises 100 parts by mass of a vinyl chloride resin, 0.01-10 parts by mass of (a) an organic acid calcium salt and / or an organic acid zinc salt, 0.01-10 parts by mass of (b) a hydrotalcite compound, 0.01-10 parts by mass of (c) a ss-diketone compound, and 0.01-10 parts by mass of (d) a polyol mixture, and which is characterized in that the component (d), i.e., the polyol mixture, is a polyol mixture comprising pentaerythritol and a condensation product thereof and the content of pentaerythritol and the condensation product thereof having a value n of 1 to 3 is 5-40 mass% relative to the total amount of the polyol mixture, wherein n represents the degree of condensation of pentaerythritol.

Owner:ADEKA CORP

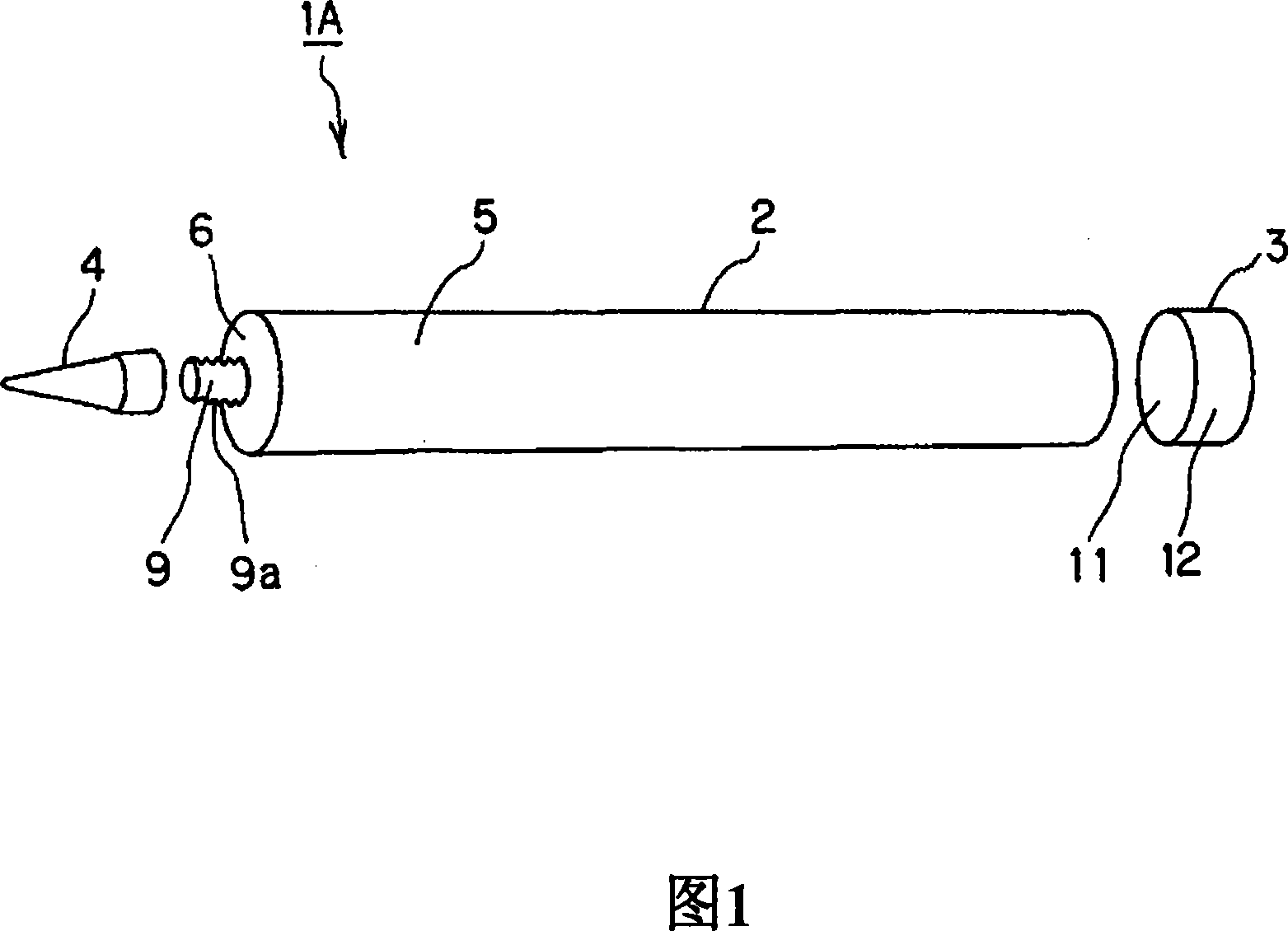

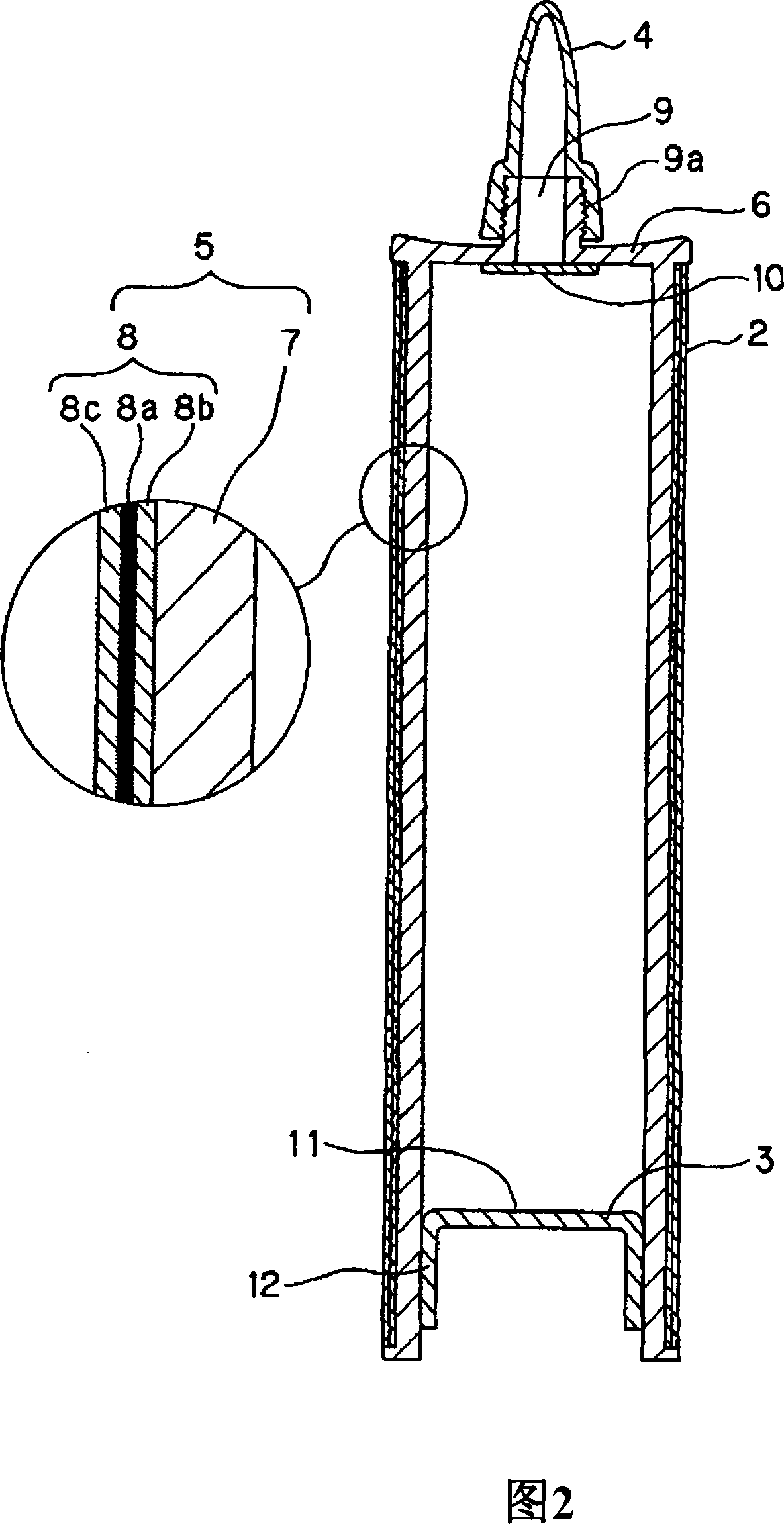

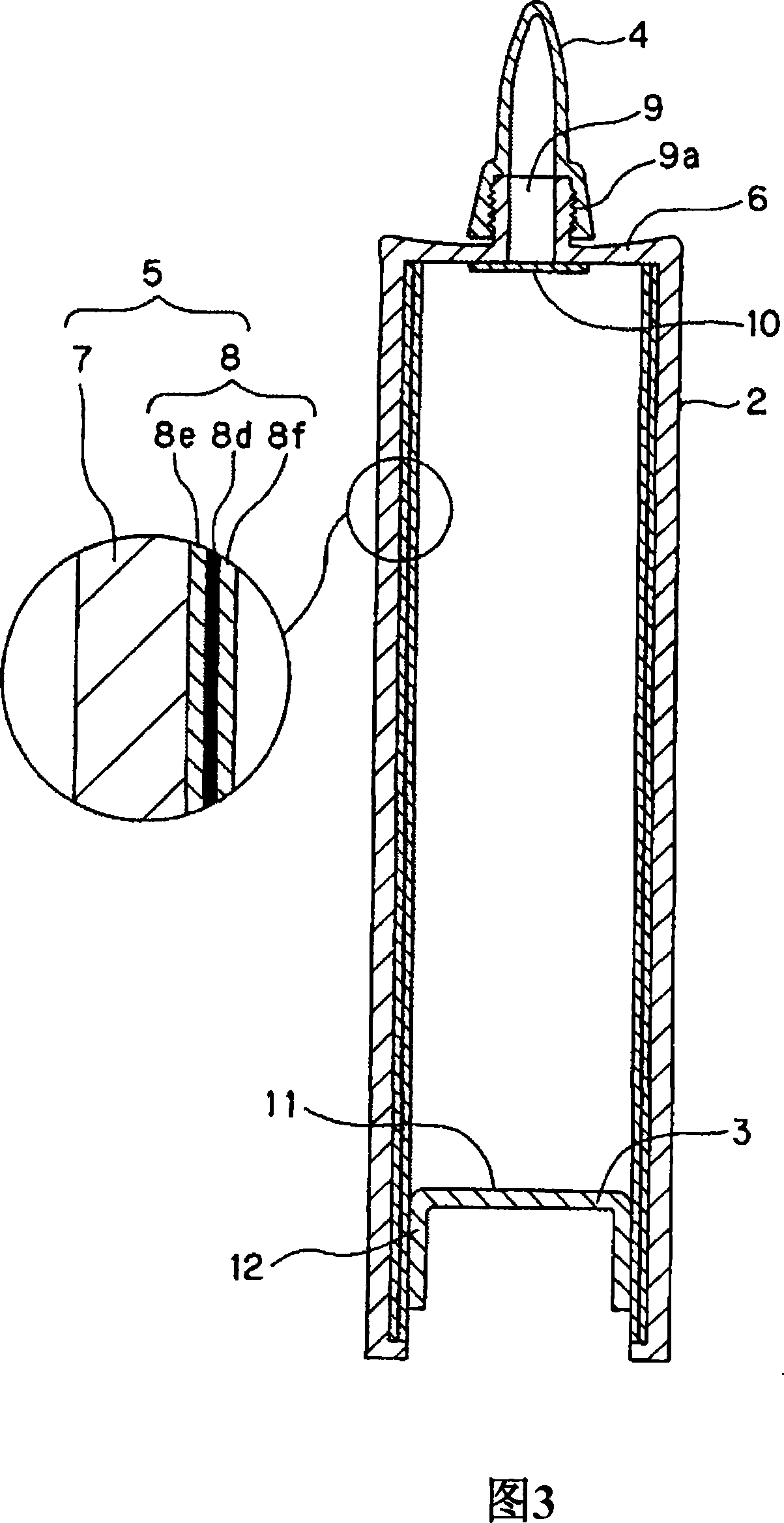

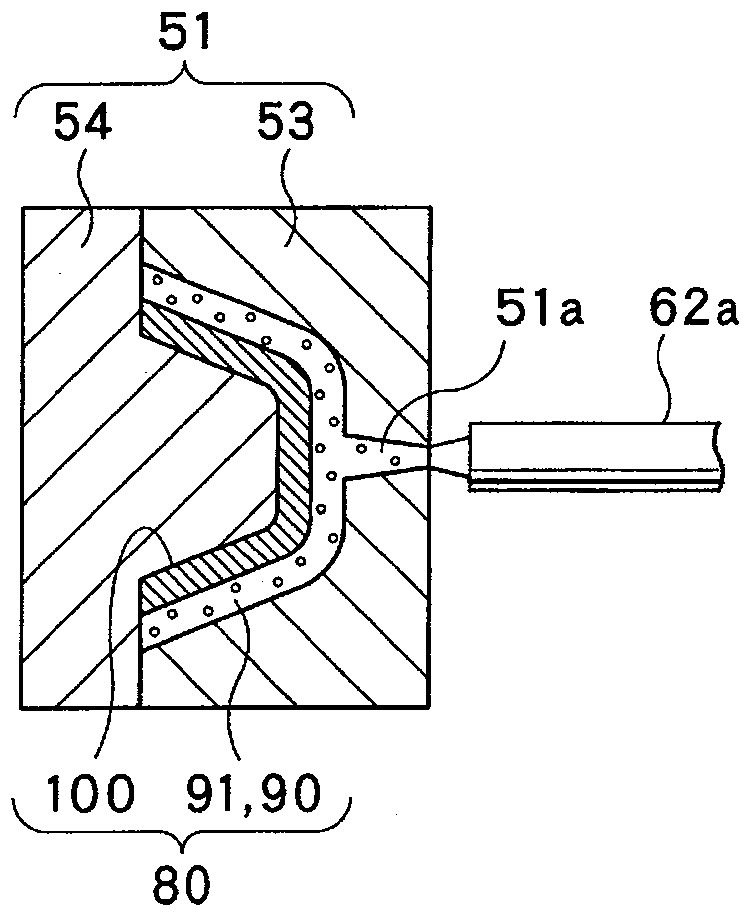

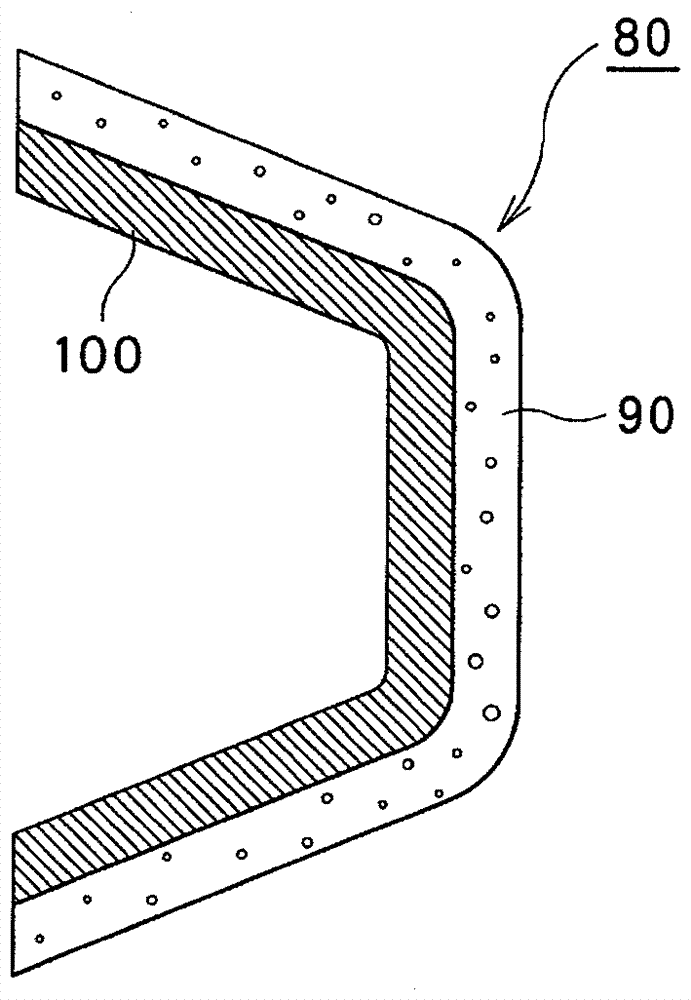

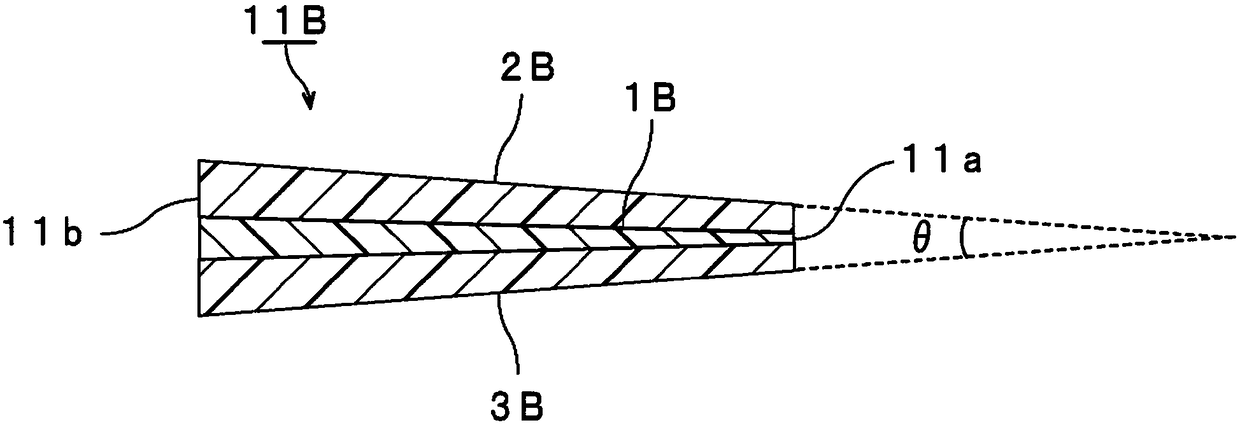

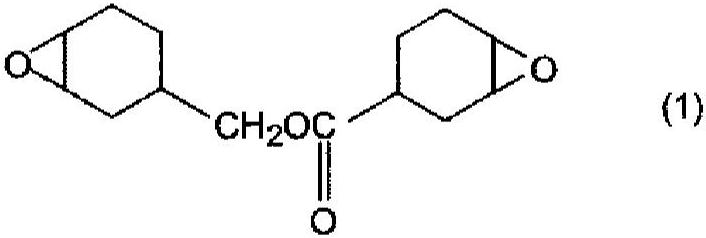

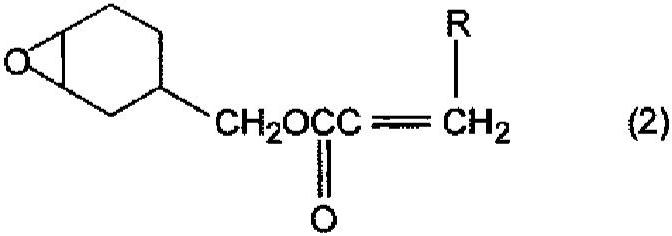

Cartridge for viscous fluid object

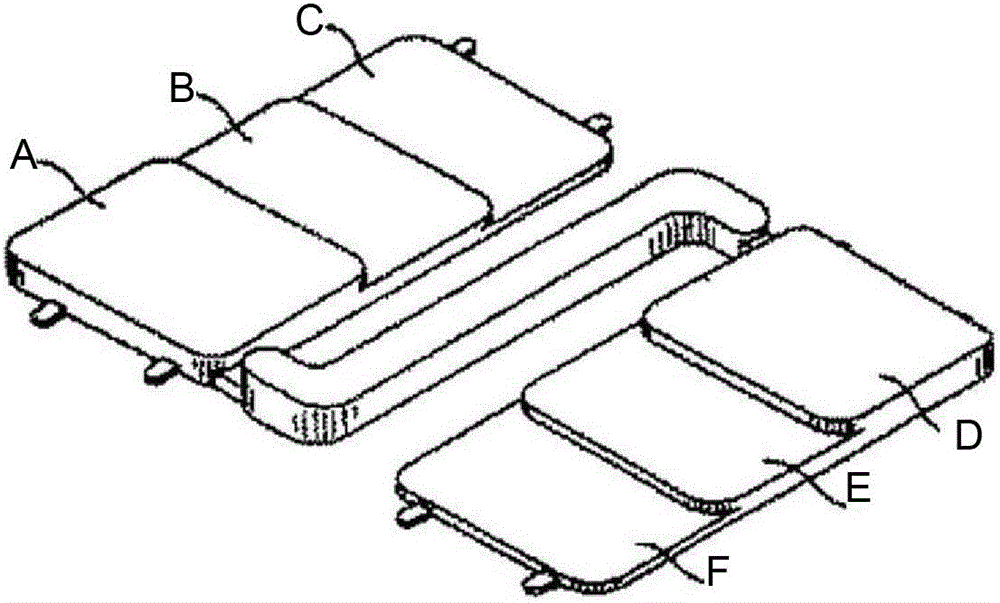

ActiveCN101124127AImprove productivityExcellent gas barrierLiquid surface applicatorsDispensing apparatusProduction rateThin layer

A cartridge for storing and dispensing viscous fluid materials providing excellent productivity and gas barrier properties and free from external appearance defects at the site of film wrapping. The inventive cartridge for viscous fluid materials has a plunger 3 inserted into the bottom portion of a cartridge body 2 fabricated using insert injection molding by integrally molding a cylindrical barrel portion 5 of a multilayer structure produced by laminating a gas barrier layer 8 including a metal thin layer 8a on the exterior periphery or interior periphery of a plastic layer 7, and a lid 6 covering the top of said cylindrical barrel portion.

Owner:DOW CORNING TORAY CO LTD

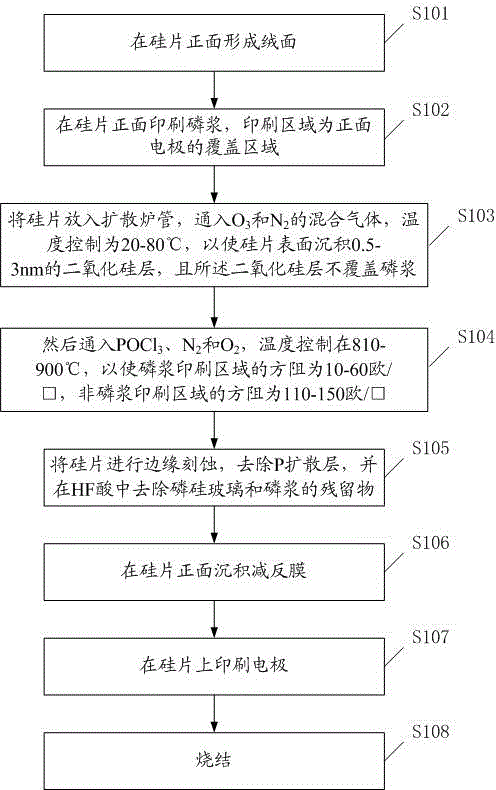

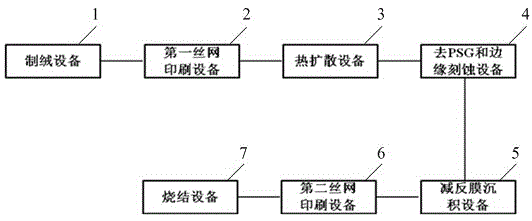

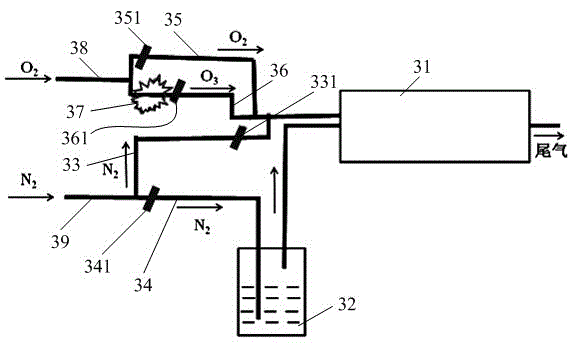

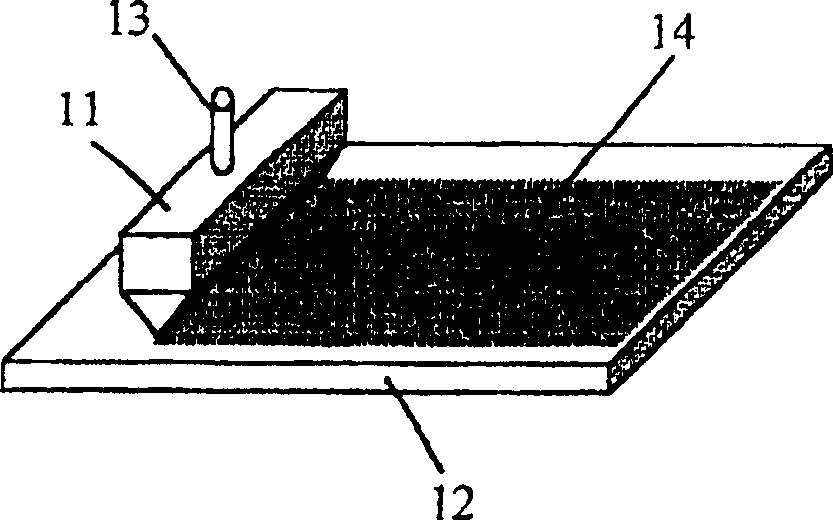

Preparation method and preparation system of selective emitter electrode solar cell

ActiveCN104409562ASimple processLow costFinal product manufacturePhotovoltaic energy generationSlurrySolar cell

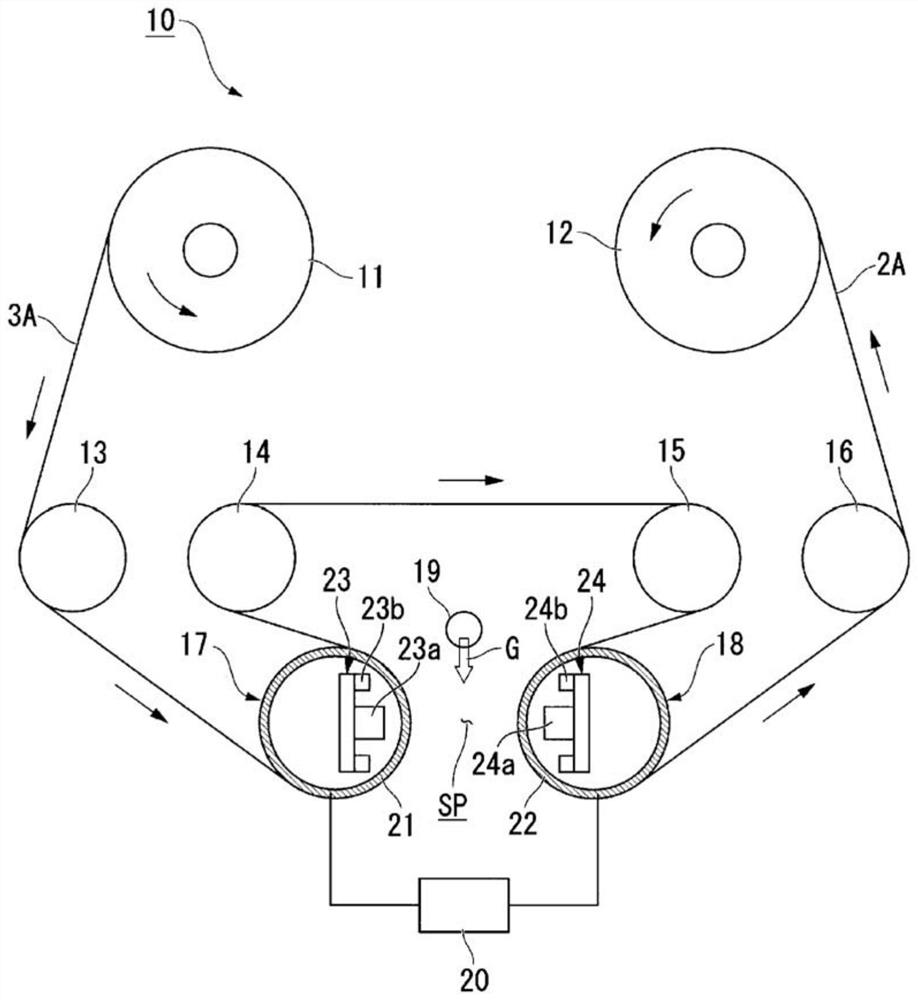

Disclosed in the invention is a preparation method of a selective emitter electrode solar cell. The preparation method comprises: A, forming a pile surface at the front side of a silicon wafer; B, printing a phosphorus slurry at the front side of the silicon wafer; C, placing the silicon wafer into a diffusion furnace pipe, introducing mixed gas with O3 and N2 at the controlled temperature of 20 to 80 DEG C; D, introducing POCL3, N2 and O2 at the controlled temperature of 810 to 900 DEG C; E, carrying out edge etching on the silicon wafer, removing a P diffusion layer, and removing a piece of phosphorosilicate glass and the residue of the phosphorus slurry from HF acid; F, depositing an anti-reflection film at the front side of the silicon wafer; G, printing an electrode at the silicon wafer; and H, carrying out sintering. Correspondingly, the invention also provides a preparation system of a selective emitter electrode solar cell. With the method and the system, the influence on the silicon wafer by a phosphorus slurry volatile matter can be prevented; the appearance quality of the silicon wafer can be improved; and the cell conversion efficiency can be guaranteed.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

Equipment and method for manufacturing pattern on product surface

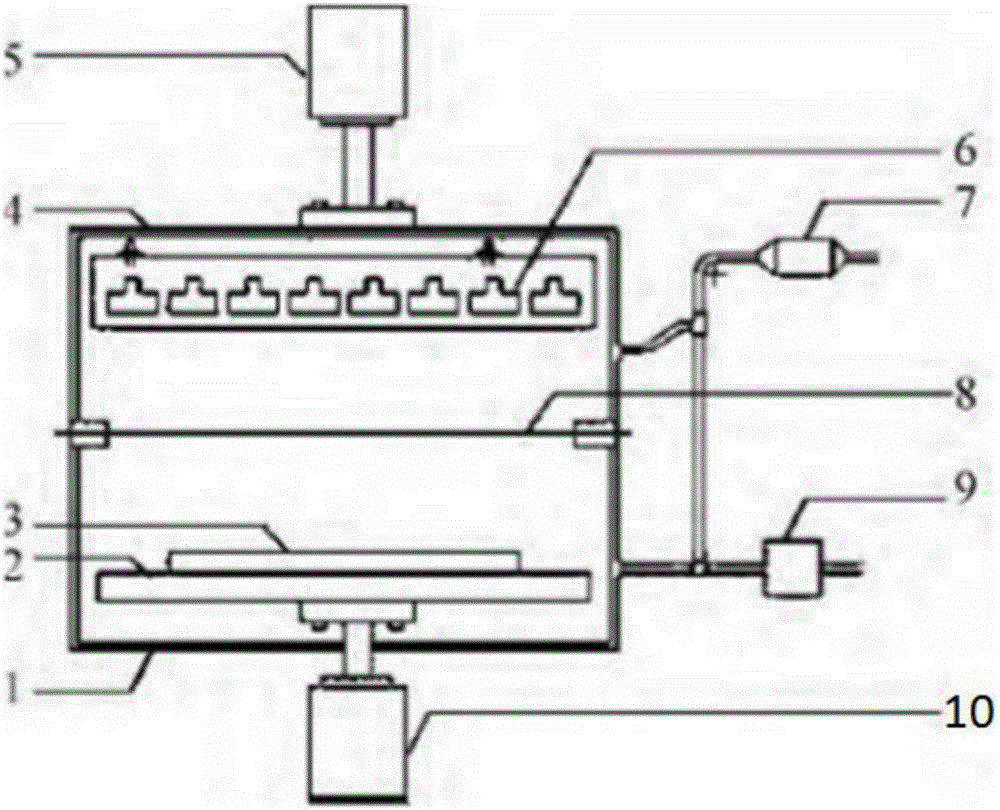

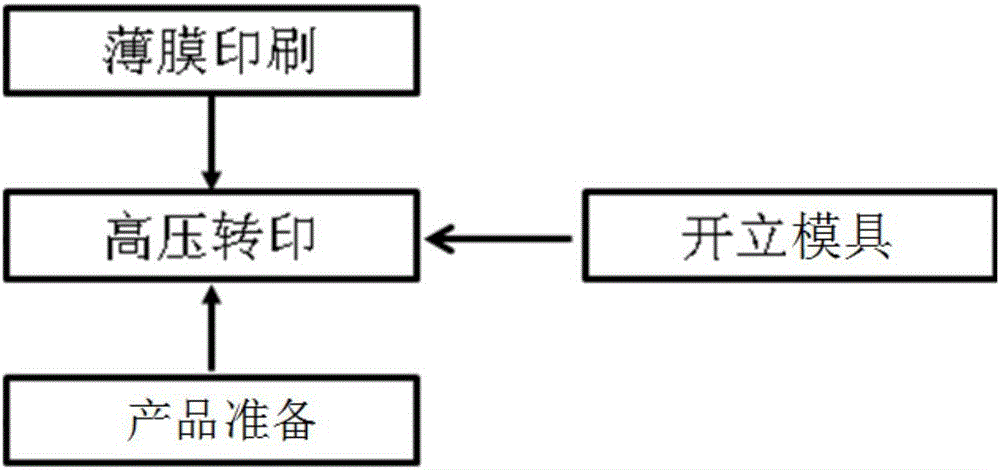

InactiveCN106218210AImprove fitImprove stabilityTransfer printingDuplicating/marking methodsEngineeringClosed cavity

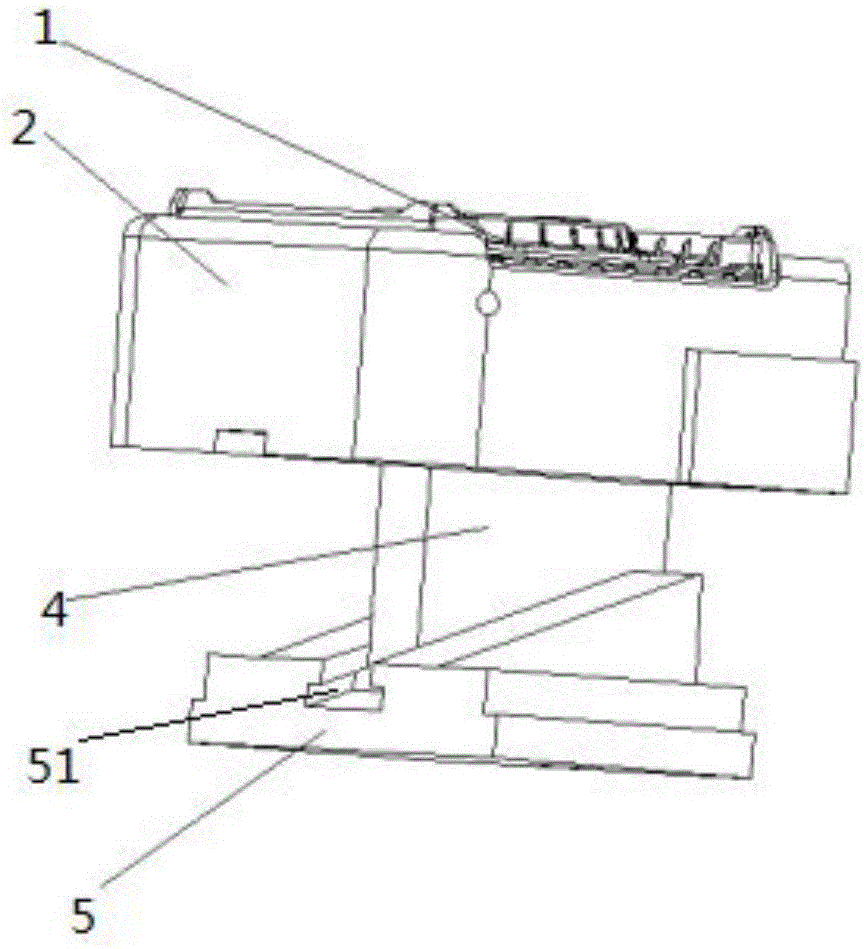

The invention discloses equipment and a method for manufacturing a pattern on a product surface. The equipment comprises an upper cavity, a lower cavity, a cavity mold closing driving device, a bearing platform, a bearing platform driving device, a vacuumizing device and a heating device; openings of the upper cavity and the lower cavity are oppositely arranged; a film printed with the pattern is fixed on the opening of the upper cavity or the lower cavity; the cavity mold closing driving device is used for driving the mold closing of the upper cavity and the lower cavity to form a closed cavity; the film separates the closed cavity into a first closed cavity and a second closed cavity; the heating device is arranged in the upper cavity and / or the lower cavity for heating the film; the vacuumizing device is respectively communicated with the first closed cavity and the second closed cavity; the bearing platform is arranged in the lower cavity for bearing a product to be manufactured with the pattern; and the bearing platform is connected with the bearing platform driving device. The equipment can clearly transfer the pattern onto the product, can simplify the process, and improves the yield.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Fluidity improver for aromatic polycarbonate resin, process for producing the fluidity improver for aromatic polycarbonate resin, aromatic polycarbonate resin composition, and molded product

Disclosed is a fluidity improver for a PC resin that can improve melt fluidity during molding without sacrificing excellent properties (such as heat resistance and mechanical properties) of the PC resin and, at the same time, is less likely to cause a poor appearance of the resultant molded product. The fluidity improver for an aromatic polycarbonate resin comprises a polymer (X) obtained by polymerizing 0.5 to 99.5 parts by mass of a monomer mixture (b) containing 0.5 to 99.5% by mass of styrene (b1) and 0.5 to 99.5% by mass of a phenyl (meth)acrylate compound (b2), wherein the total amount of the components (a) and (b) is 100 parts by mass, in the presence of a polymer (A) obtained by polymerizing 0.5 to 99.5 parts by mass of a monomer mixture (a) containing 0.5 to 50% by mass of a-methylstyrene (a1), 0.5 to 99% by mass of styrene (a2), and 0.5 to 99% by mass of a phenyl (meth)acrylate compound (a3).

Owner:MITSUBISHI CHEM CORP +1

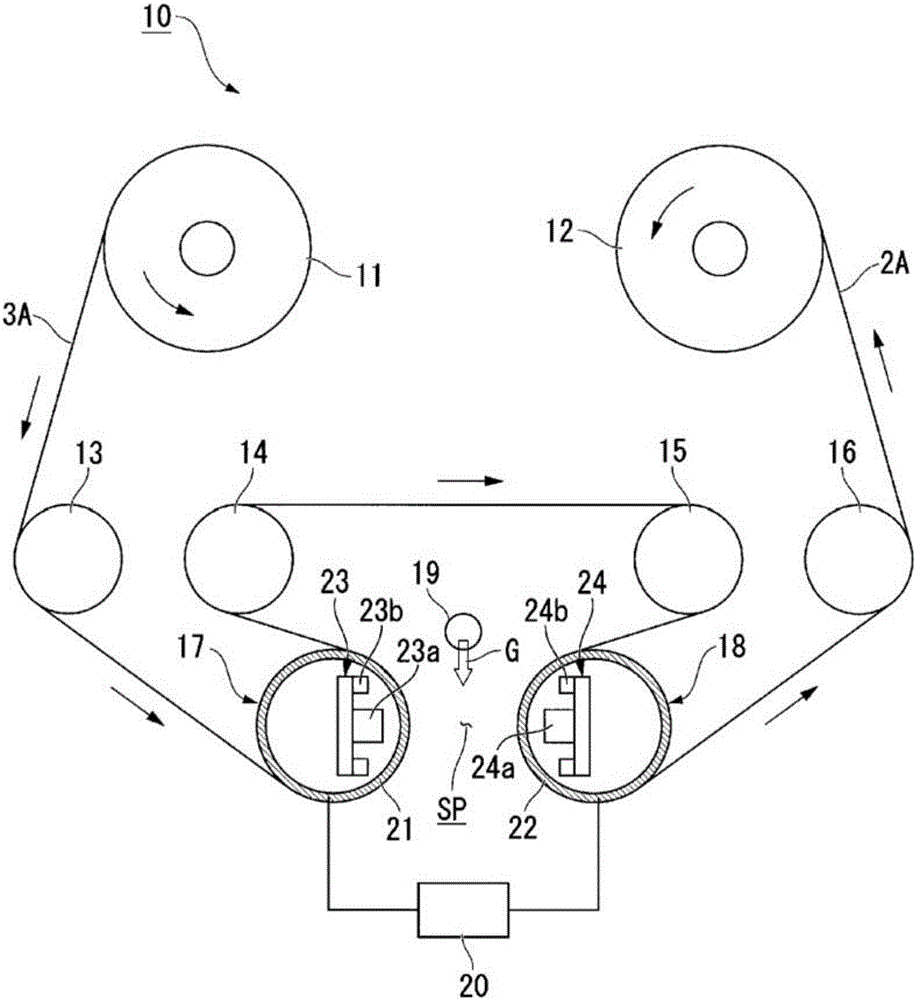

Method of manufacturing printed circuit board base sheet

InactiveCN101625979ABad apperanceSemiconductor/solid-state device manufacturingCircuit precursor manufactureTectorial membraneHeating time

A combined metal layer and a protective film are arranged on one surface side of an insulating layer, and a combined metal layer and a protective film are arranged on the other surface side of the insulating layer. These layers are overlapped one another to be passed between a pair of laminating rollers. In this case, a temperature with which the combined metal layers are heated by the laminating rollers is adjusted to not less than 300 DEG C. and not more than 360 DEG C. A time period during which the combined metal layers are heated by the laminating rollers is adjusted to not less than 0.1 second and not more than 0.8 second.

Owner:NITTO DENKO CORP

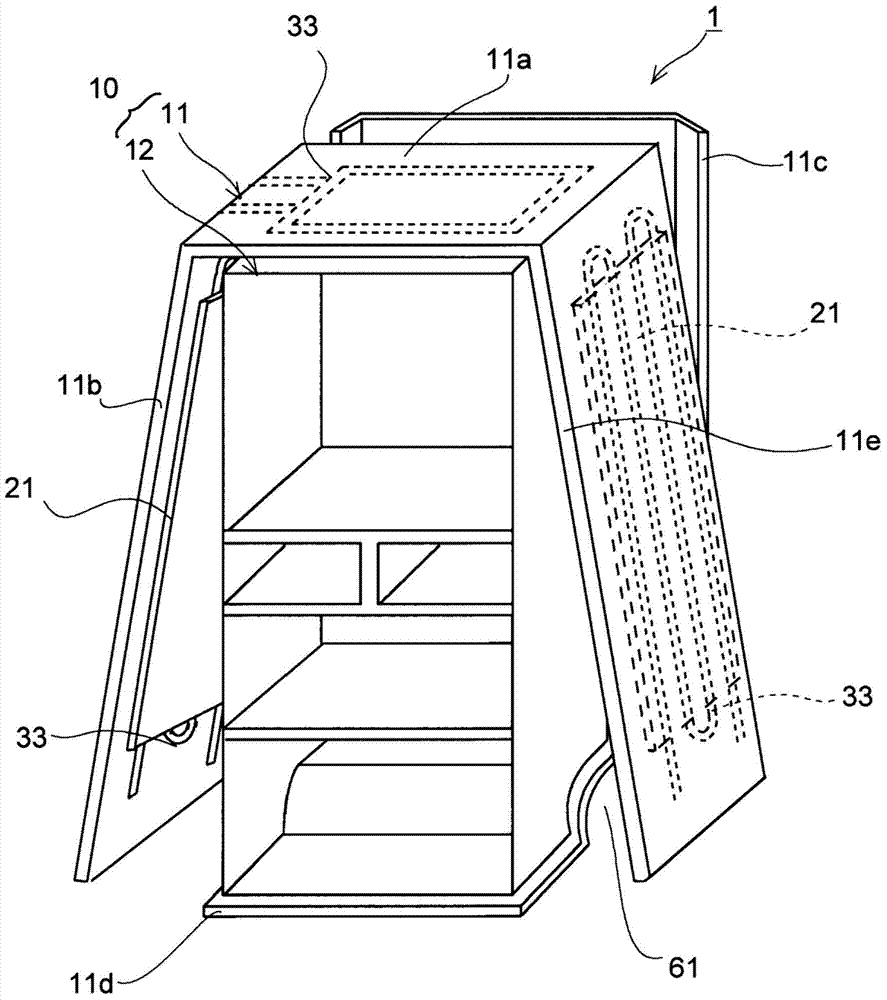

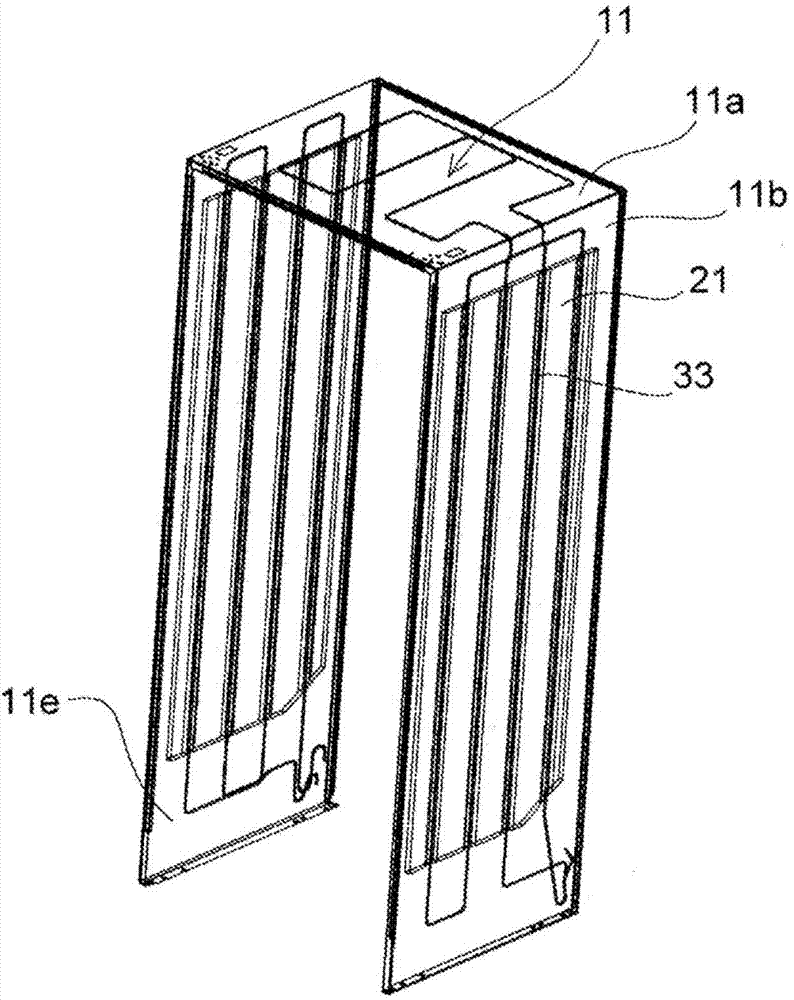

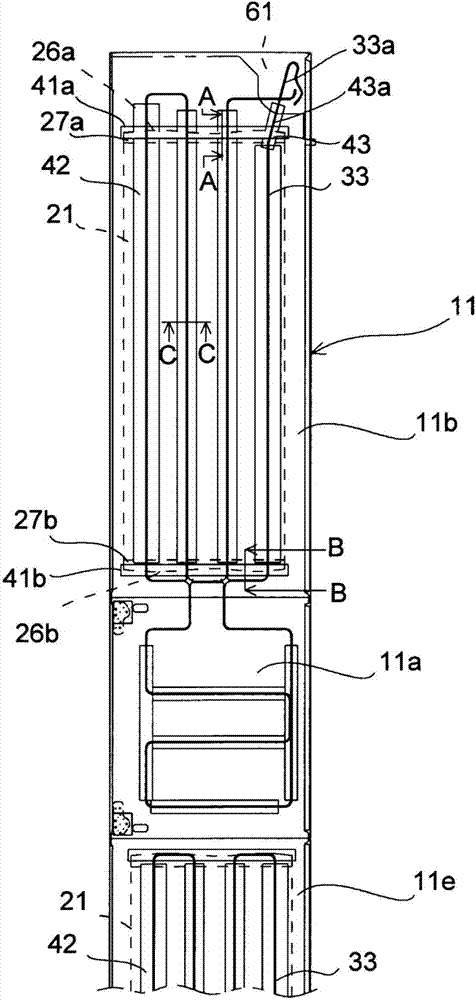

Refrigerator

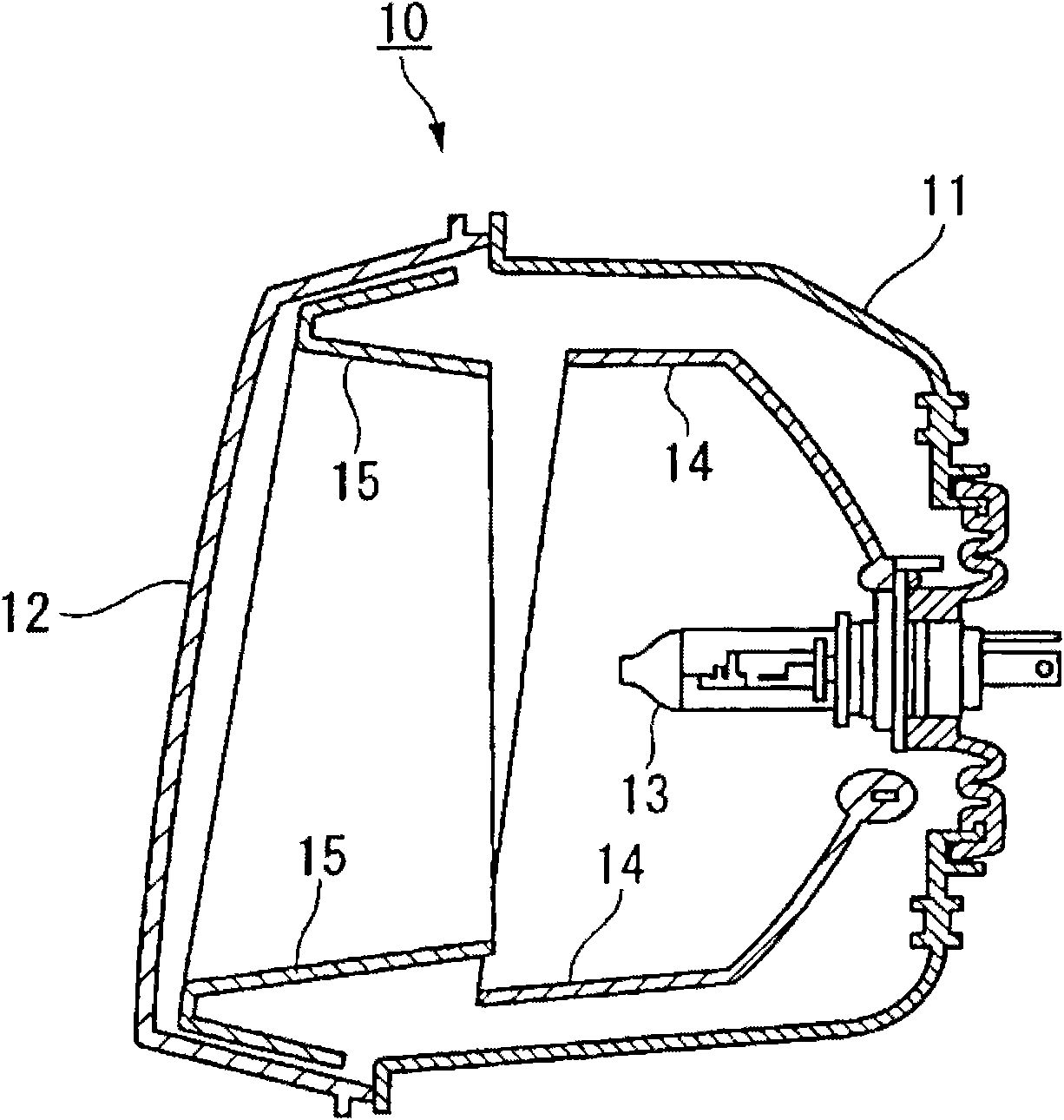

ActiveCN103597304AAvoid deformationGood lookingLighting and heating apparatusInsulation for cooling apparatusEngineeringPressure difference

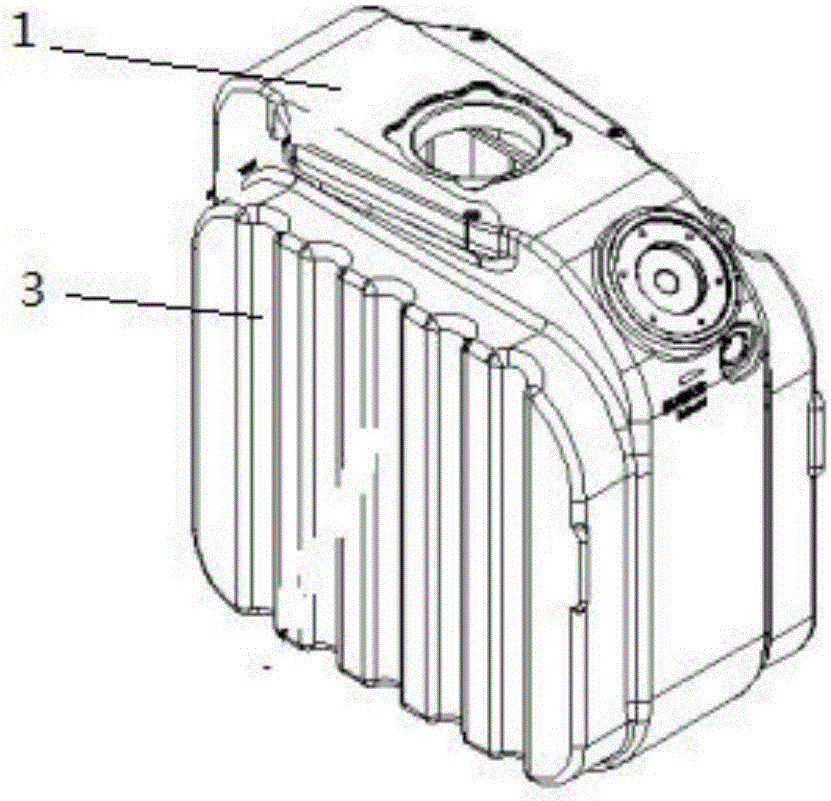

Provided is a refrigerator that can prevent deformation of an outer case due to an air pressure difference between the interior and exterior of an insulating box body and that can prevent the occurrence of appearance defects. The refrigerator comprises: an insulating box body (10) in which a space between an inner case (12) and a metal outer case (11) has been filled with a foam insulating material; heat dissipation pipes (33) extending in one direction, snaking so as to be disposed in a plurality of parallel rows, having both ends disposed to be in contact with an inner surface of the outer case (11), and having an extending part (33a) at one end thereof that extends out to the exterior of the insulating box body (10); and a vacuum insulation member (21) that is mounted onto the inner surface of the outer case (11) and has a core (25) covered with a covering material (26), the interior of the core being depressurized, and a plurality of groove parts (22) to which the heat dissipation pipes (33) are fitted being disposed therein in parallel. A communication path (43a) that enables communication between the groove parts (22) and the exterior of the insulating box body (10) is provided to the periphery of the extending part (33a), and there is communication between neighboring groove parts (22) in the direction of parallel disposition.

Owner:SHARP KK

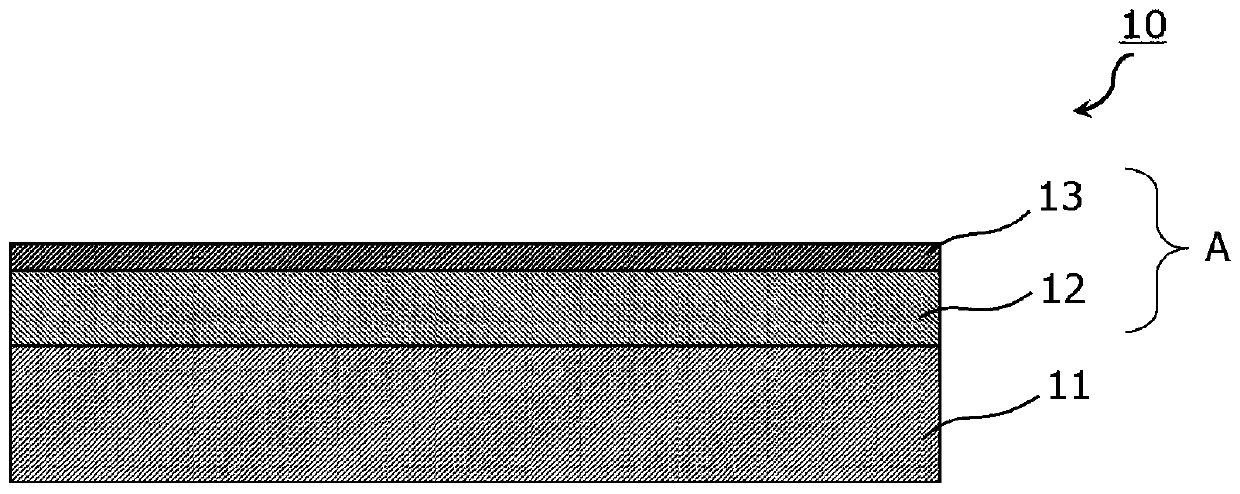

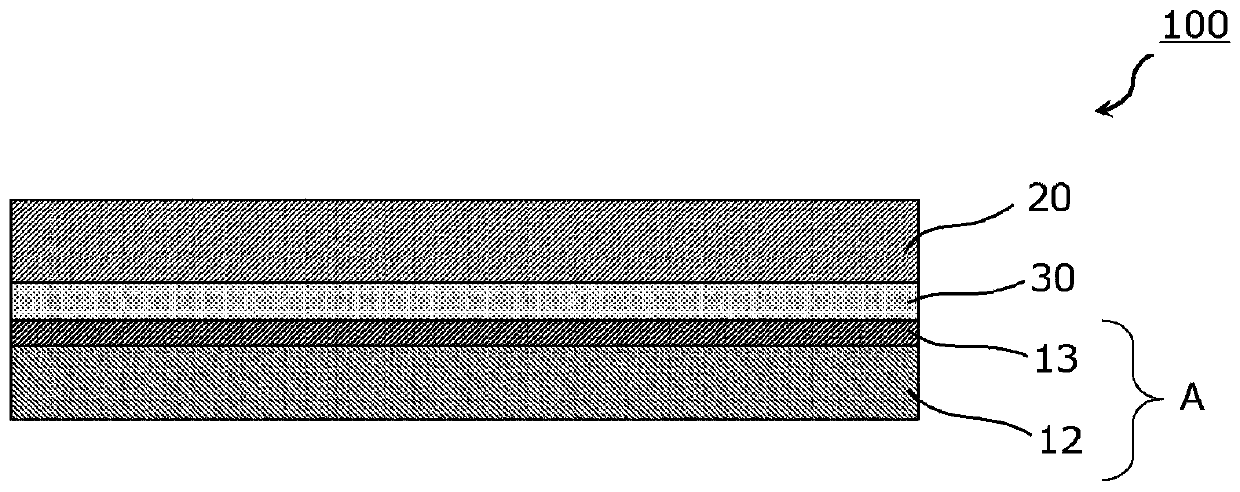

Manufacturing method for laminated body

ActiveCN106794689AAvoid breakingBad apperanceElectroluminescent light sourcesSynthetic resin layered productsSiliconRaw material

A manufacturing method for a laminated body comprising a laminated film and an adhesive layer, the manufacturing method comprising a step of forming the adhesive layer on one surface of the laminated film, the laminated film being a laminated film comprising at least a base material and a thin film layer containing at least silicon, wherein the step of forming the adhesive layer includes forming the adhesive layer on a surface of a laminated film raw material on which the thin film layer is laminated, in a state where the laminated film raw material, which is the laminated film in a continuous ribbon form, is conveyed in a longitudinal direction while a tensile strength of 0.5 N / mm2 to 50 N / mm2 per unit of cross-sectional area is applied in the longitudinal direction with respect to the laminated film raw material.

Owner:SUMITOMO CHEM CO LTD

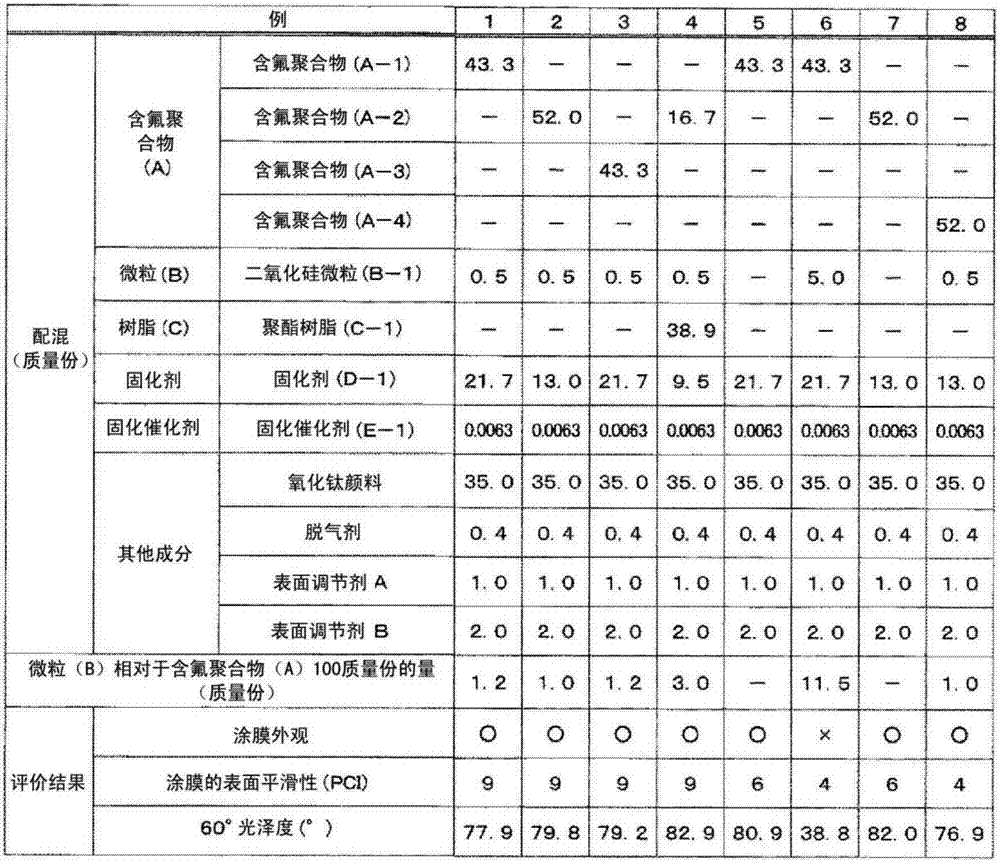

Powder coating composition, powder coating, and coated article

InactiveCN107109096ABad apperanceImprove surface smoothnessLiquid surface applicatorsPowdery paintsMicroparticleZinc

The present invention provides: a powder coating composition with which a coating film that does not have appearance defects such as bumps and cissing and has excellent surface smoothness can be formed; a powder coating that uses said powder coating composition; and a coated article that has a coating film formed by the powder coating. Provided is a powder coating composition including a fluorine-containing polymer, which has a fluoro-olefin-derived unit and of which the melt viscosity at 190 DEG C measured using a rotary rheometer at a heating rate of 10 DEG C / minute is in the range of 0.1-25 Pa*s, and fine particles, which comprise at least one selected from silica, alumina, titania, and zinc oxide, have a specific surface area of 10-500 m<2> / g, and have an average primary particle size in the range of 0.1-100 nm, and containing 0.01-10 parts by mass of fine particles relative to 100 parts by mass of the fluorine-containing polymer.

Owner:ASAHI GLASS CO LTD

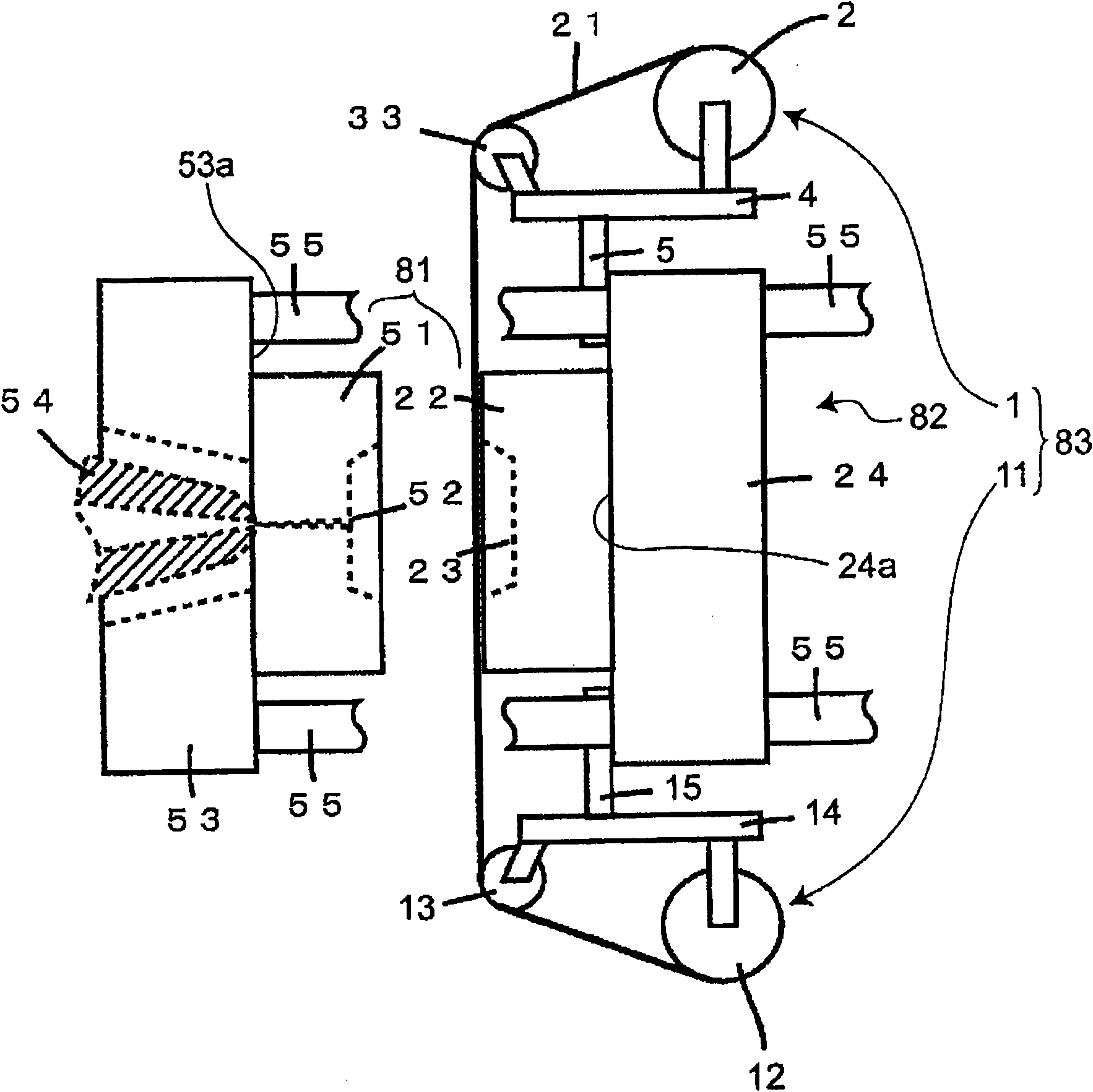

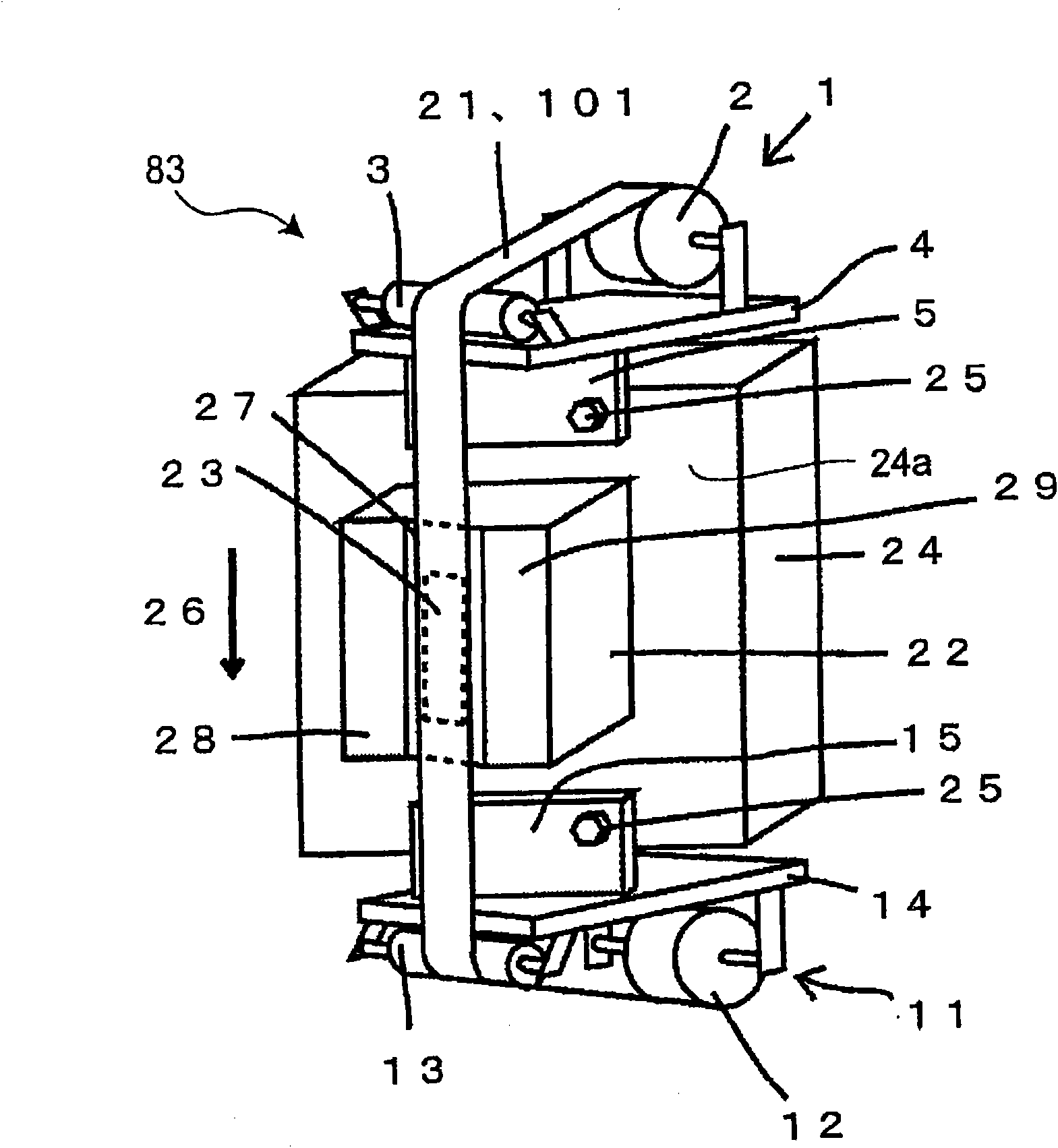

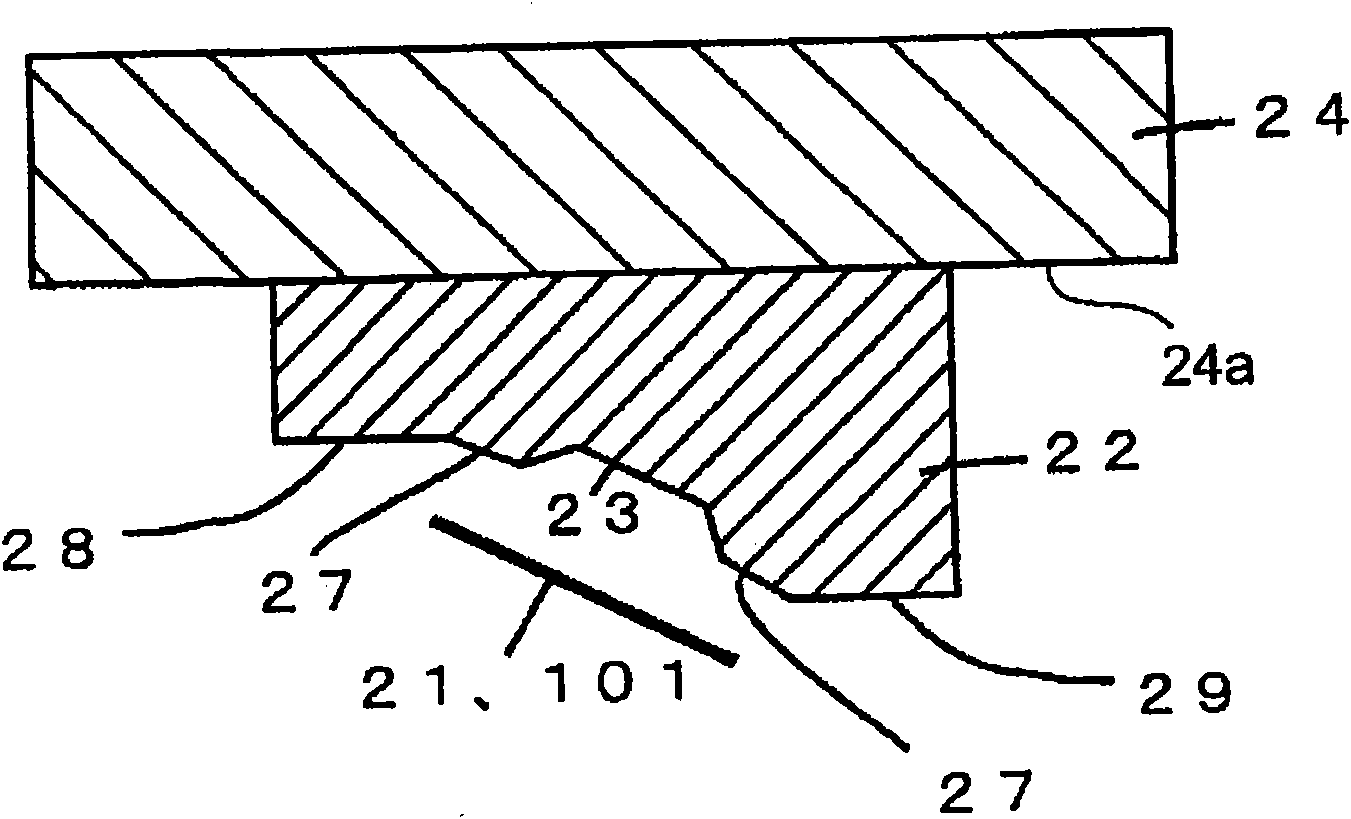

In-mold decorating apparatus and method for manufacturing in-mold decorated molded product

ActiveCN101657312ANot prone to offsetSuppression distance deviationCoatingsEngineeringSheet material

Provided is a simultaneous molding-decorating apparatus, in which the axis of rotation of a decorative sheet let-off roll (2) of a decorative sheet feeding device (83) and the axis of rotation of a guide roller (3) are made parallel to a parking face (27) to have a decorative sheet (21) arranged thereon, so that the appearance defect of a resin molding due to the break and wrinkle of the decorative sheet (21) and the crack of a pattern layer may not be caused in the state where the parking face (27) is inclined with respect to a platen face (24a).

Owner:NISSHA PRINTING COMPANY

Method for adjusting surface density of high-tensile-resistance copper foil

ActiveCN110042441ABad apperanceHigh tensile strengthCellsElectroforming processesDensity curveGeneration process

The invention discloses a method for adjusting the surface density of a high-tensile-resistance copper foil. The method comprises the following steps that the surface density value of the transverse position of the copper foil is acquired, a surface density curve is drawn, smooth processing is carried out, an insulating shielding rubber tape which is overlapped with the obtained smooth curve is correspondingly cut according to the smooth surface density curve, the insulation shielding rubber tape is attached to an anode plate in the axial direction, and in the next copper foil generation process, the insulation shielding rubber tape can influence the current density, and the opposite density adjustment is correspondingly realized. According to the method for adjusting the surface density of the high-tensile-resistance copper foil, the shielding effect of the insulating shielding rubber tape and the surface density of the corresponding position are utilized, so that the fine adjustmentof the current size is realized, the difference between the liquid inlet flow and the speed of a liquid inlet hole is ensured, the lateral surface density of the foil surface is more uniform in the copper foil production process, the poor appearance of the copper foil caused by the flow difference of the liquid inlet hole is reduced, and the purpose of improving the tensile strength of the copperfoil is achieved.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

Fit forming device for integrated accessory connected with adblue tank

InactiveCN106696237ABad apperanceReduce risk of leakageBiochemical engineeringUltimate tensile strength

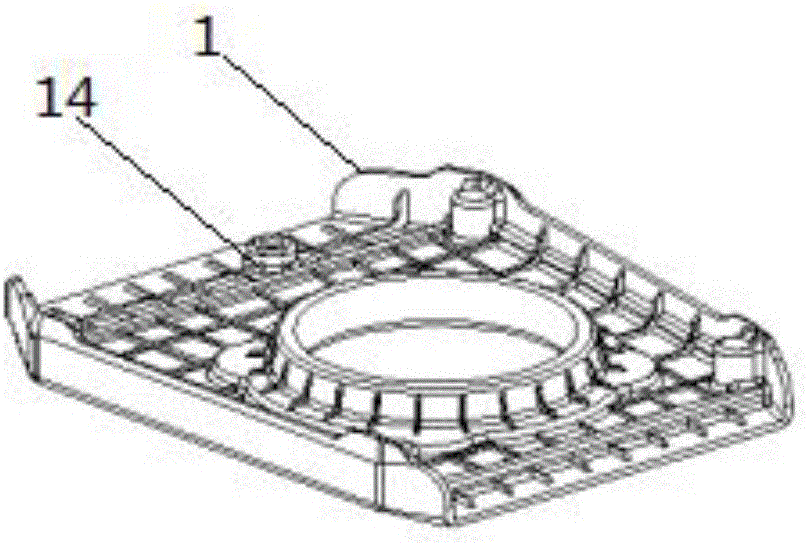

The invention discloses a fit forming device for an integrated accessory connected with an adblue tank. The fit forming device comprises an adblue tank body and the integrated accessory of a pump connecting joint, pump mounting joints and a pump exhaust joint, wherein the integrated accessory is mounted on the adblue tank body. According to the fit forming device, the intra-mold fit process is adopted, the component integrating the pump mounting joints, the pump connecting joint and the pump exhaust joint is organically combined with the tank body, leakage of urea is avoided, safe and firm fixing of an urea metering injection pump is guaranteed, the structure of the adblue tank is optimized, the manufacturing process is simplified, the production efficiency is improved, the potential quality hazard is reduced, the quality consistency of finished products is improved, the production cost of the products is lowered, the integral strength and rigidity of the products are improved, and the stability of the adblue tank and a postprocessing system in the long-term operating process of vehicles is guaranteed.

Owner:天雄科技十堰有限公司

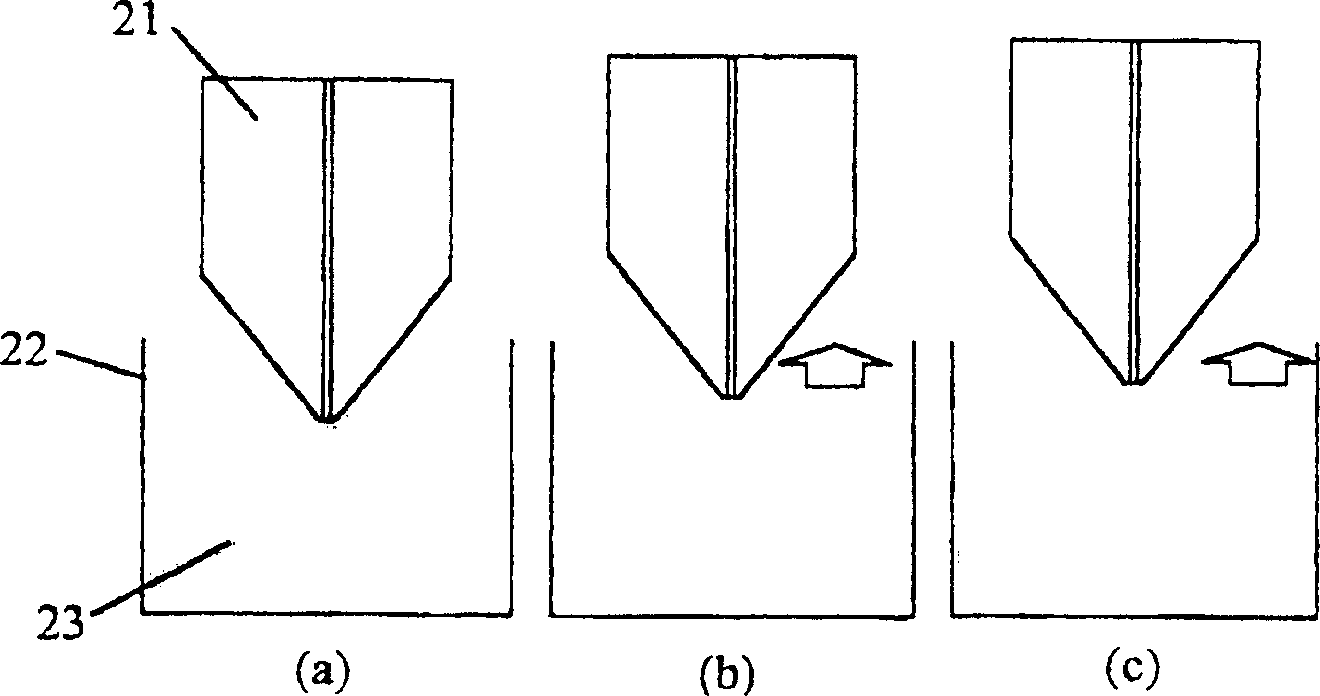

Mold type coater coating method and photolithagraphic protector adhesive film assembly made therefrom

ActiveCN1736615ASlow condensationAvoid uneven concentrationLiquid surface applicatorsSpray nozzlesForeign matterComputerized maintenance management system

The invention aims to establish a maintenance management method of the die in a die coater and produce a large-size protection glue film subassembly with an extremely-low content of foreign matters with low costs. In order to achieve the purpose, the invention provides a coating method for die coaters, which comprises allowing the front end of the die to be immersed and contacted with a coating solution stored in a container; holding the die as lifted above the coating solution until the drops of the coating solution slowly hanging from the front end of the die disappear by dint of the surface tension of the coating solution; and ejecting the coating solution onto a substrate for coating. When the coating operation is not performed, it is preferable that the die is usually immersed or contacted with the coating solution, the coating solution is ejected continuously or intermittently from the front end of the die after passing a filter, and the die immersed in the coating solution is subjected to ultrasonic cleaning.

Owner:SHIN ETSU CHEM IND CO LTD

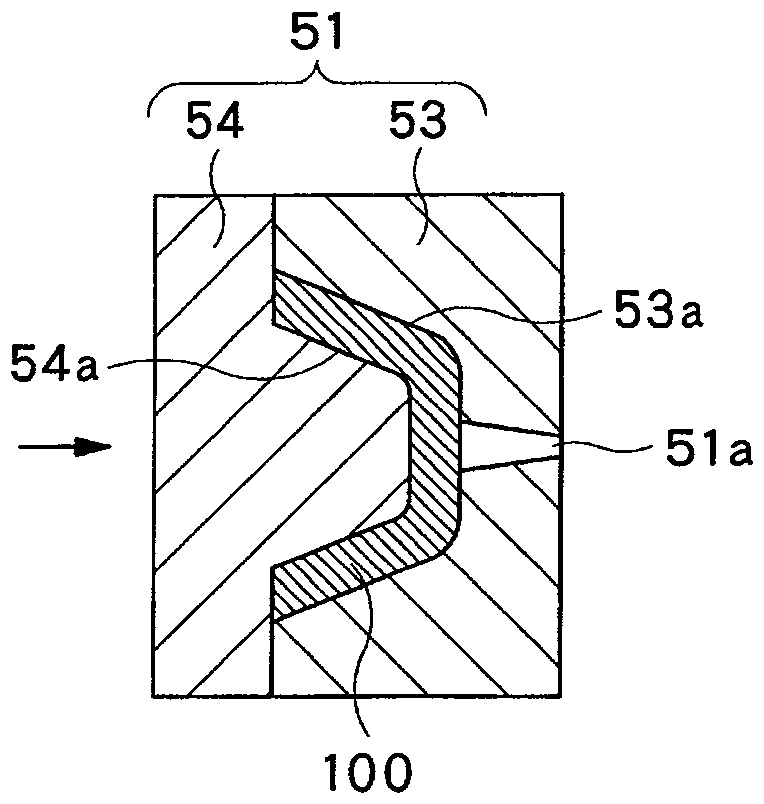

Method for manufacturing molded article, molded article, and device for manufacturing molded article

Owner:TOSHIBA MASCH CO LTD

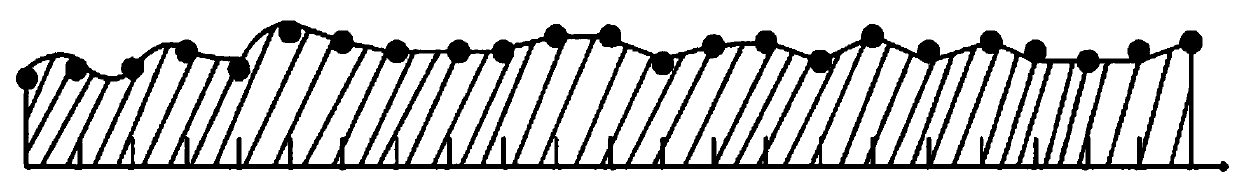

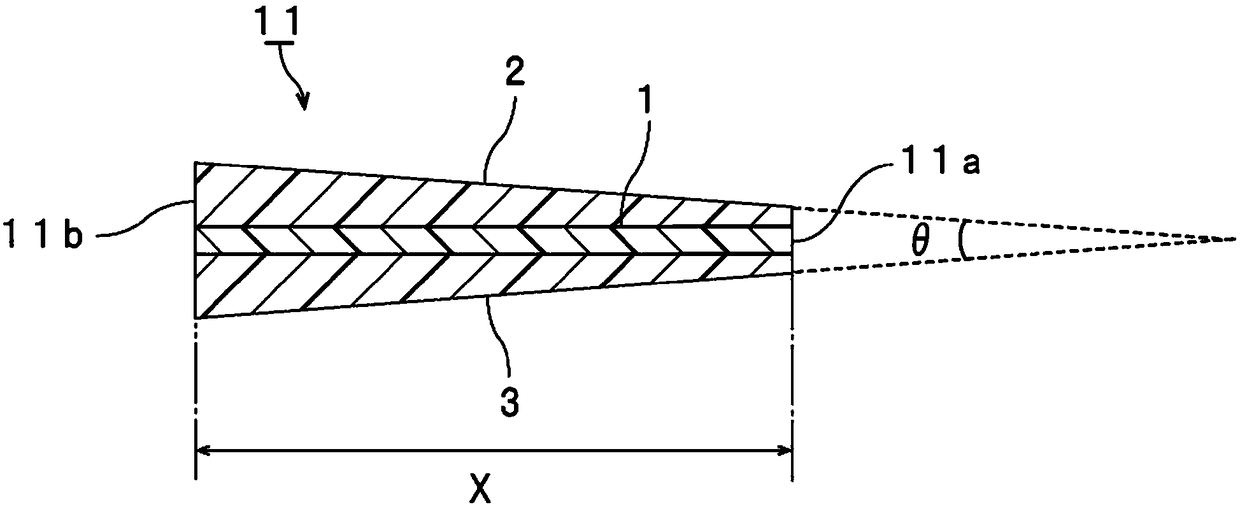

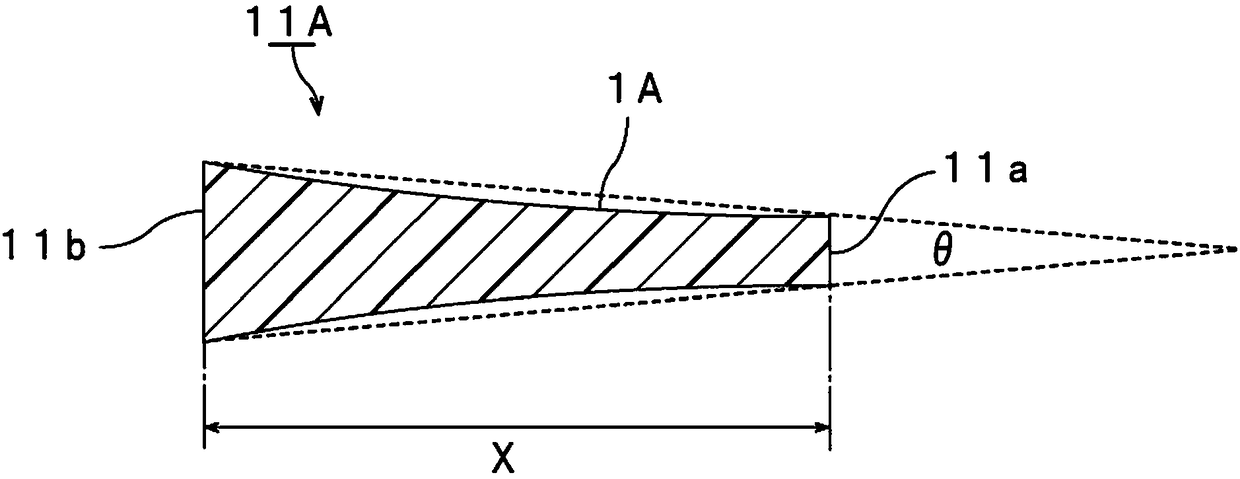

Interlayer for laminated glass and laminated glass

ActiveCN108137404ABad apperanceLess prone to wrinklesWindowsLayered product treatmentEngineeringMechanical engineering

Provided is an interlayer for laminated glass, whereby a laminated glass unlikely to have creases in the interlayer and having suppressed external defects can be obtained. This interlayer for laminated glass has: an MD direction and a TD direction; and one end and another end on the opposite side to the one end and having a greater thickness than the one end. The one end and the other end are positioned on both sides of the interlayer, in the TD direction. When the distance between the one end and the other end is X, the absolute value for the difference between a maximum heat shrinkage and aminimum heat shrinkage is no more than 5%, between: a first heat shrinkage at 150 DEG C at a first position at 0.05 X from the one end towards the other end, in the MD direction; a second heat shrinkage at 150 DEG C at a second position at 0.5 X from the one end towards the other end, in the MD direction; and a third heat shrinkage at 150 DEG C at a third position at 0.95 X from the one end towards the other end, in the MD direction.

Owner:SEKISUI CHEM CO LTD

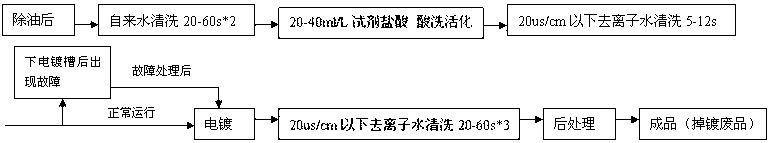

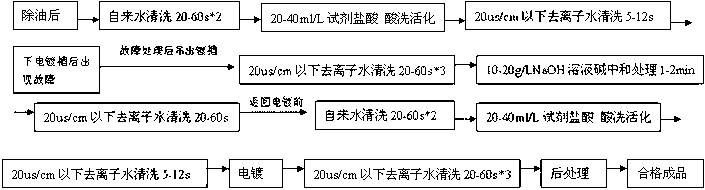

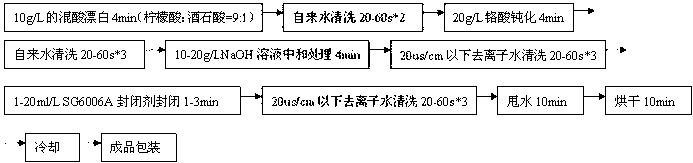

Battery case nickel-plating fault treatment process

The invention belongs to the technical field of battery case nickel plating, and discloses a battery case nickel-plating fault treatment process. The treatment process comprises the following steps: washing a battery cell by using tap water for twice, scouring and activating; washing with de-ionized water after removing oil on the battery cell orderly, wherein a lower trough has burst fault before being electroplated; and after treating the fault, continuing the normal electroplating, orderly washing by using the de-ionized water for three times after outputting the battery case, and performing the subsequent treatment. The treatment process is characterized in that the lower trough has burst fault before being electroplated, after the fault is treated, the battery case is firstly output to be washed by the de-ionized water for three times, each time is 20-60 seconds, then the alkali is added for neutralizing, and then the de-ionized water is used for washing for 20-60 seconds; then the tap water washing is returned for twice, scouring and activating, and washing with the de-ionized water before electroplating are performed, wherein a low-foaming wetting agent is added in a scouring solution when the scouring and activating are performed, then the lower trough is electroplated according to the normal process, then the battery case is normally output, and the subsequent treatment and normal operation are performed. The finished product treated by the process provided by the invention is good in appearance and good in combination after being checked, various feature characteristics such as salt mist and blue point and the like are accordant with the normal index.

Owner:新乡市正元电子材料有限公司

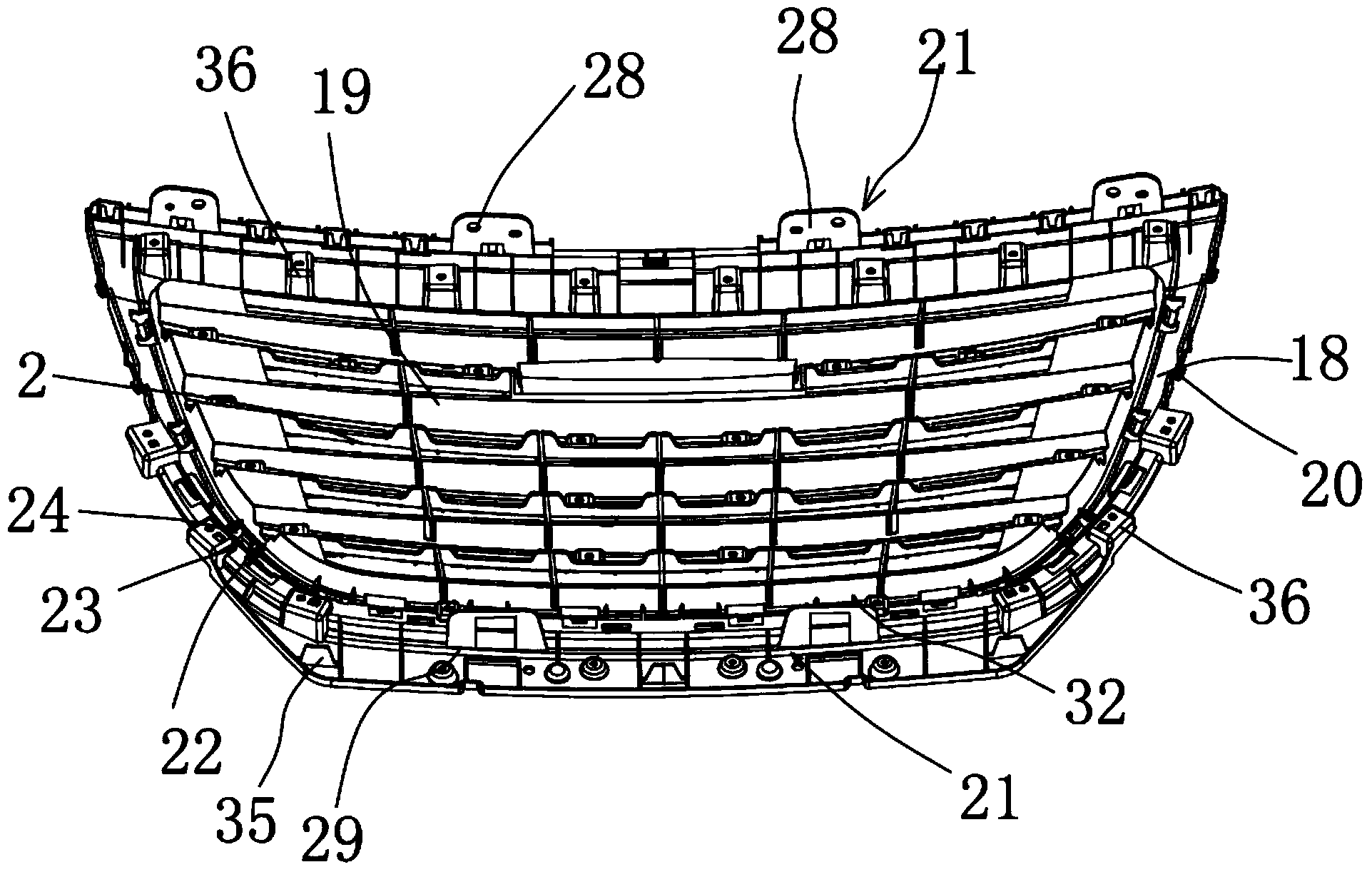

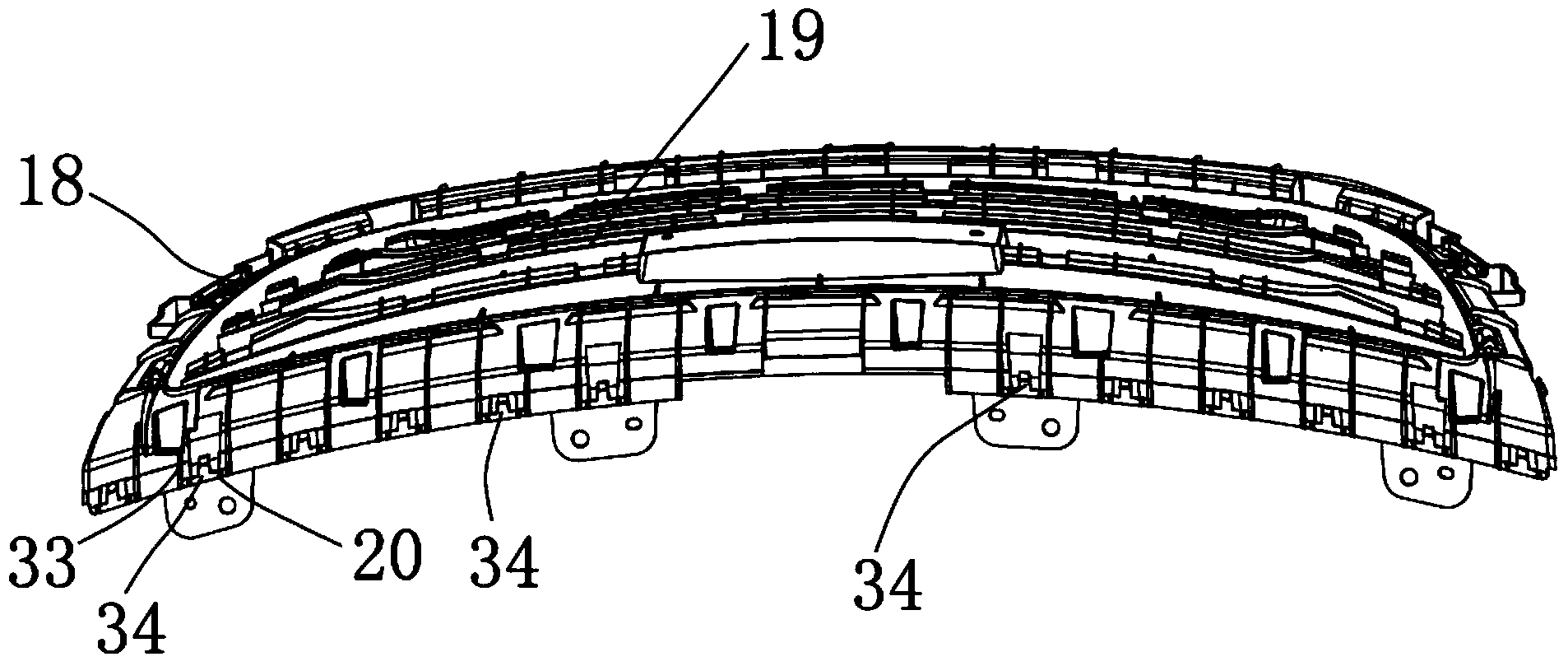

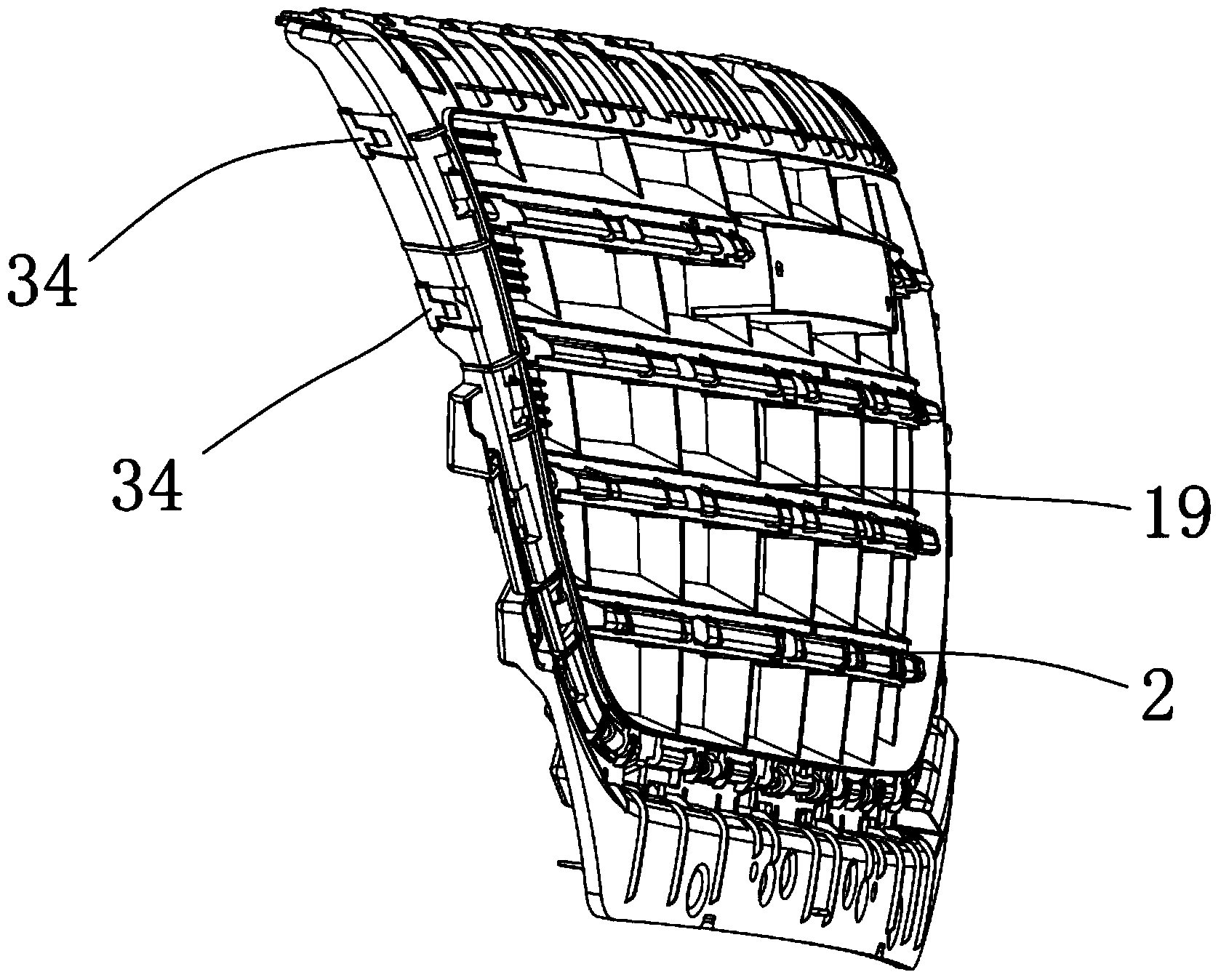

Automotive radiator grille body structure

ActiveCN103909890AGuaranteed appearanceGuaranteed appearance and commercial performanceRadiatorsEngineeringRejection rate

The invention belongs to the technical field of decorating members and provides an automotive radiator grille body structure which comprises an outer frame bright strip fixing area, a transverse bright strip fixing area, a peripheral lateral side fixing portion, an upper fixing portion and a lower fixing portion. The transverse bright strip fixing area comprises multiple transverse bodies, an outer frame clamping claw portion is arranged on the outer frame bright strip fixing area and comprises a U-shaped clamping claw and a fixing port, the U-shaped clamping claw is fixed in the fixing port, a protruding face is arranged on the U-shaped clamping claw, and a slant face is arranged on the protruding face. The automotive radiator grille body structure has the advantages that under the premise that performance is guaranteed, appearance performance of an automotive radiator grille decorating strip is guaranteed, rejection rate of injection molding and electroplating processes is greatly reduced, die processing technique is improved, die service life is prolonged, and wind dryness after the automotive radiator grille body structure is mounted on an automobile is prevented.

Owner:WUHAN HESHENG AUTO PARTS

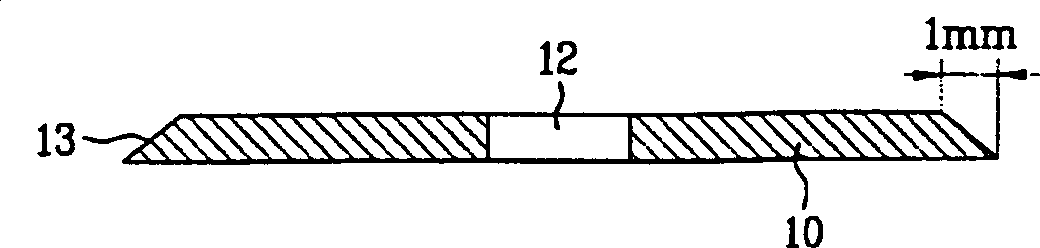

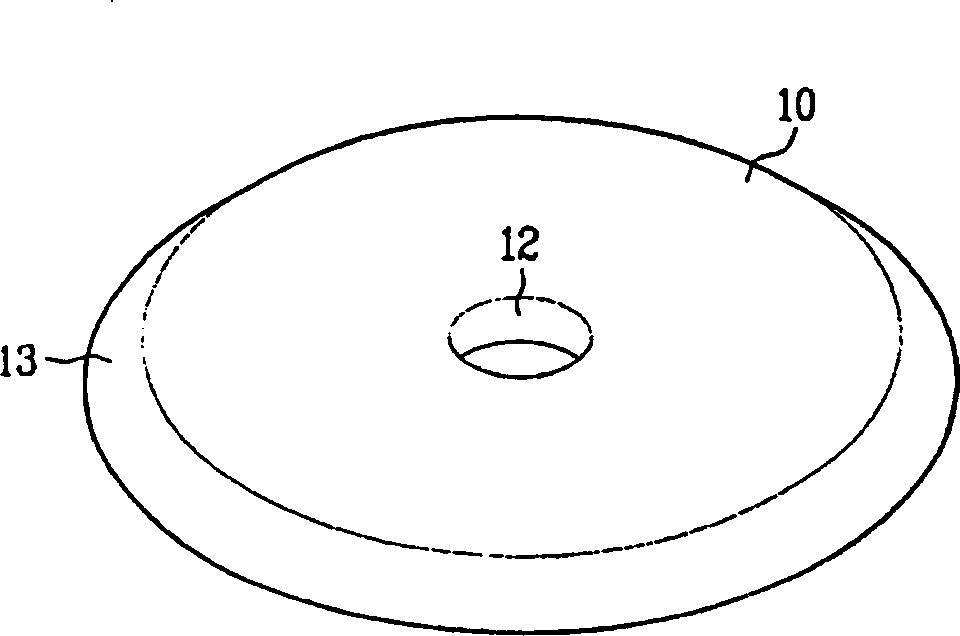

Optical disc

InactiveCN1790513ABad apperanceRecord information storageOptical recording/reproducingSmall holeComputer engineering

The invention discloses a disk, which comprises the following parts: disk blank base plate, storage base plate and flute part, wherein the disk blank base plate is formed on the disk with a small hole in the center part; the storage base plate bonds the blank base plate, whose center part forms a small hole; the flute part is formed on the periphery of joint storage base plate and blank base plate, which is easy to hold disk. The invention can prevent joint liquid from flowing to influence the appearance when the blank base plate bonds the storage base plate.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

Conductive transfer film

ActiveCN111032336AImprove conductivityGood light transmissionConductive layers on insulating-supportsLayered productsPolymer scienceThin membrane

Provided is a conductive transfer film capable of preventing generation of poor appearance such as hologram-like appearance. The conductive transfer film according to the present invention comprises:a temporary support; a resin layer provided so as to be peelable from the temporary support; and a conductive layer disposed directly on the resin layer, wherein the conductive layer is constituted bya metal oxide, and the hardness of the resin layer at a depth of 50 nm as measured by a nanoindentation method is 0.3 GPa or higher. In one embodiment, the thickness of the resin layer is 1-20 mcirons.

Owner:NITTO DENKO CORP

Shell polishing and shaping method, shell and electronic product

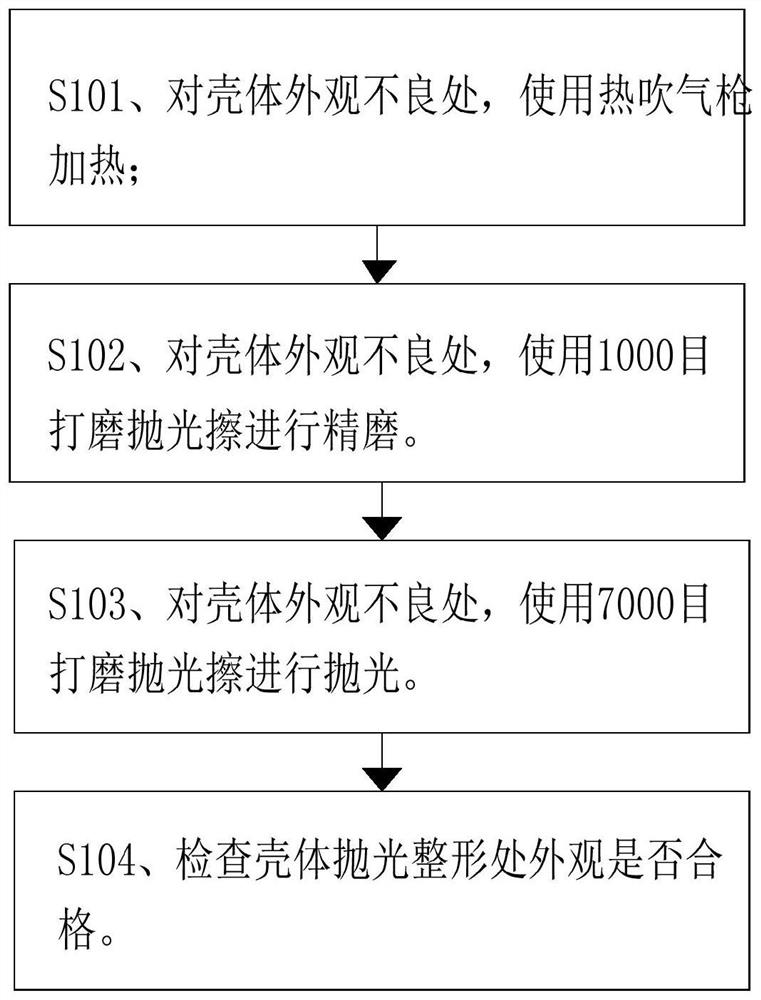

InactiveCN112261184AIncrease profitImprove appearance yieldTelephone set constructionsPolishingProcess engineering

The invention provides a shell polishing and shaping method, a shell and an electronic product, and the method comprises the following steps: heating a poor-appearance part of the shell through a hotair blow gun; performing fine grinding on the poor appearance of the shell; polishing the poor appearance part of the shell; and checking whether the appearance of the shell polishing and shaping partis qualified. According to the shell polishing and shaping method, the appearance yield of the electronic product shell can be effectively improved, the utilization rate of the shell can be greatly increased, and the production cost is saved.

Owner:SHANGHAI LONGCHEER TECH CO LTD

Polyethylene terephthalate and its production method

ActiveCN103289064BLow intrinsic viscosityBad apperancePolymer sciencePolyethylene terephthalate glycol

Owner:MITSUI CHEM INC

Polycarbonate resin composition and molded article thereof

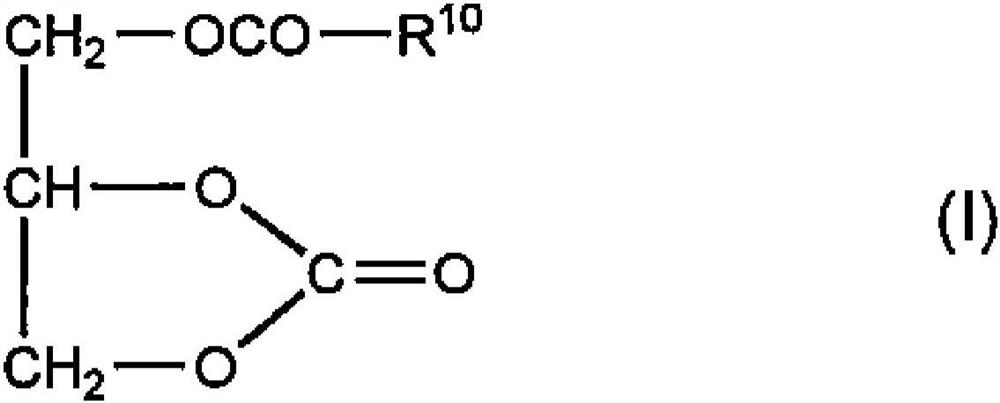

A polycarbonate resin composition (1) comprising (B) 0.01 to 0.25 parts by mass of a silicone compound and (C) an aliphatic compound having 12 to 22 carbon atoms with respect to 100 parts by mass of the (A) polycarbonate resin. 0.015 to 0.25 parts by mass of ester of carboxylic acid and glycerin, the sodium content in the above-mentioned component (B) is 15 mass ppm or less, or the polycarbonate resin composition (2), wherein, with respect to 100 parts by mass of (A), contains (B) 0.01 to 0.25 parts by mass and (C) 0.015 to 0.25 parts by mass, the modification rate of component (C) is 30% or less; and the molded polycarbonate resin composition (1) or (2) obtained Taste.

Owner:IDEMITSU KOSAN CO LTD

Capacitor chip and method for manufacturing same

ActiveCN101317241BBad apperanceIncrease electrostatic capacitanceSolid electrolytic capacitorsCapacitor electrodesElectricityCapacitance

Provided are a capacitor chip and a solid electrolytic capacitor wherein one or more capacitor elements are laminated on a metal lead frame which is provided for taking out electricity to the outside of the capacitor chip, the capacitor elements are sealed with a resin, and the laminated body is arranged within a fixed range. The allowable range of the total thickness of the laminated capacitor elements is widened and the capacitance is increased without causing appearance failure of the laminated solid electrolytic capacitor.

Owner:MURATA MFG CO LTD

Machining method of die core surface of graphite die for glass hot bending

InactiveCN108857047AAccuracy is not affectedShorten polishing timeLaser beam welding apparatusLaser lightOptoelectronics

The invention provides a machining method of a die core surface of a graphite die for glass hot bending. The die core surface comprises a hook face structure, the machining method includes the step ofadopting a laser device to irradiate the die core surface of the graphite die so as to achieve the polishing effect on the dire core surface, the irradiation scope of the laser device is larger thanor equal to the projection scope of the die core surface on the horizontal face, the moving speed of irradiation burning of laser light on the die core surface is 200-20000 mm / s, all paths generated when the laser light moves on the die core surface each comprise a plurality of parallel straight lines, the number of times of irradiation burning of the laser light on the die core surface is two ormore, and the parallel straight lines of every two adjacent laser paths are crossed. By means of the machining method, the poor appearance generated after CNC of the graphite die can be removed, thedie accuracy is not influenced, the die polishing time is saved, the conditions such as edge collapse and face collapse on the die core surface are avoided, and the service life of the die is prolonged.

Owner:LENS TECH CHANGSHA

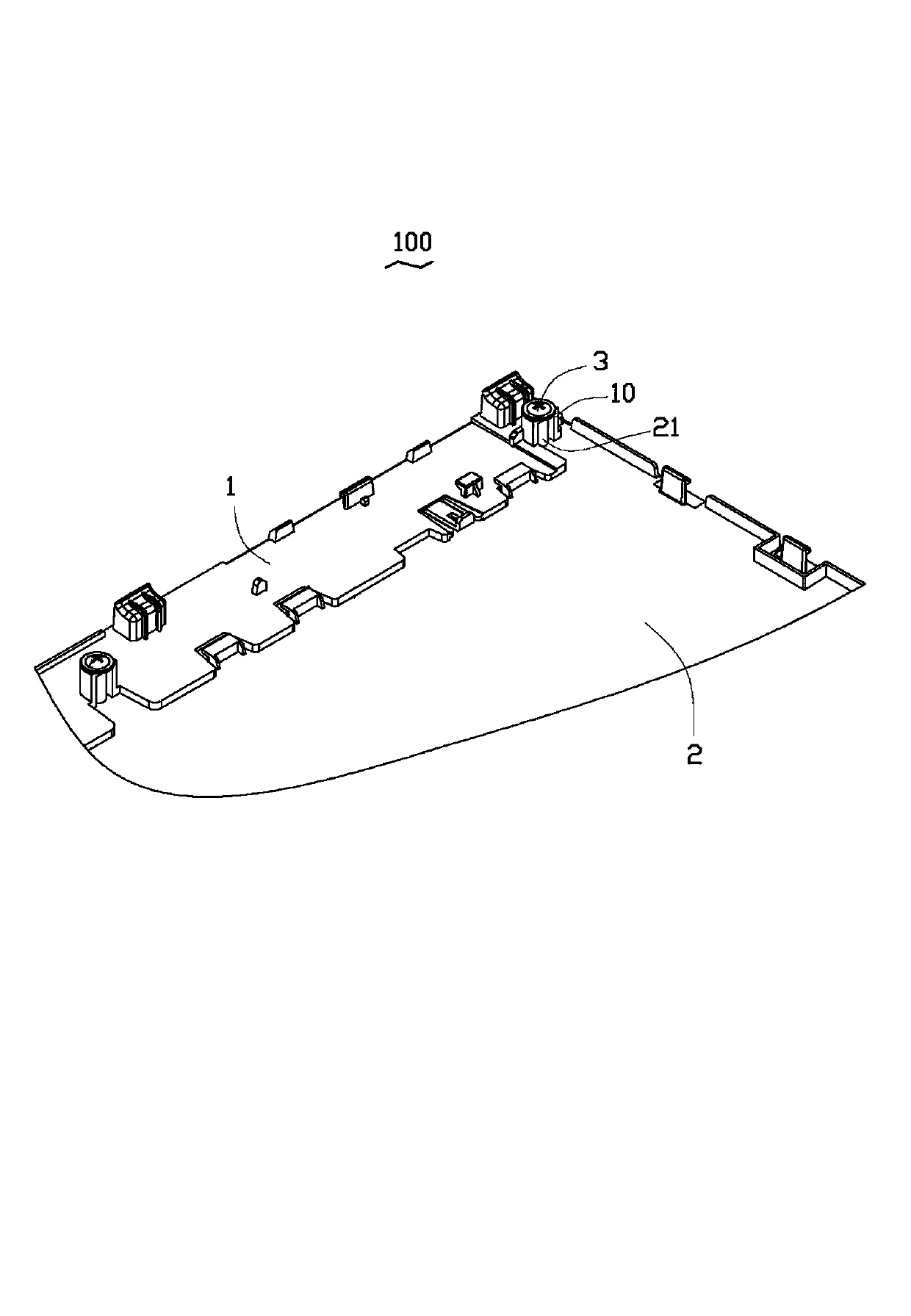

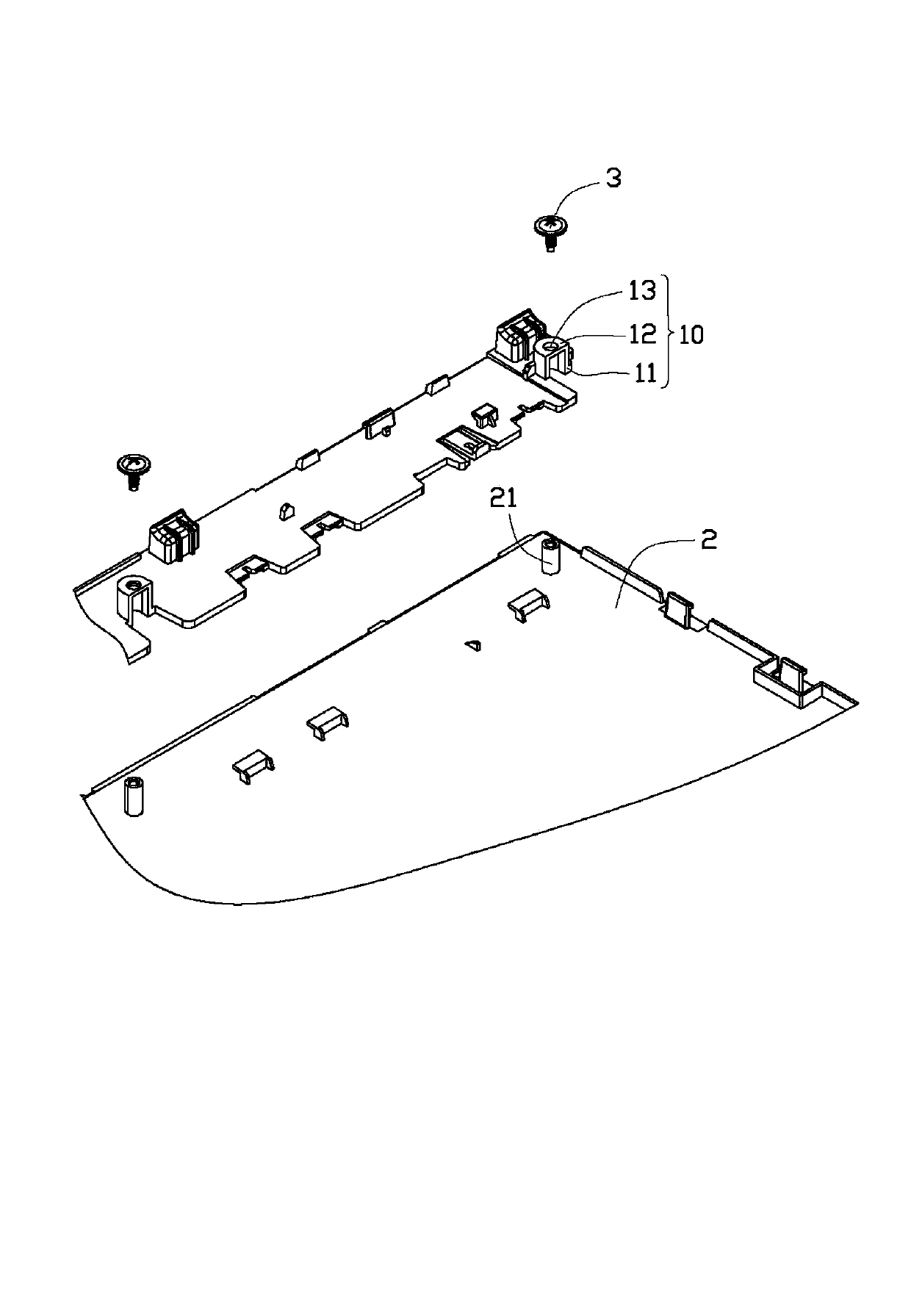

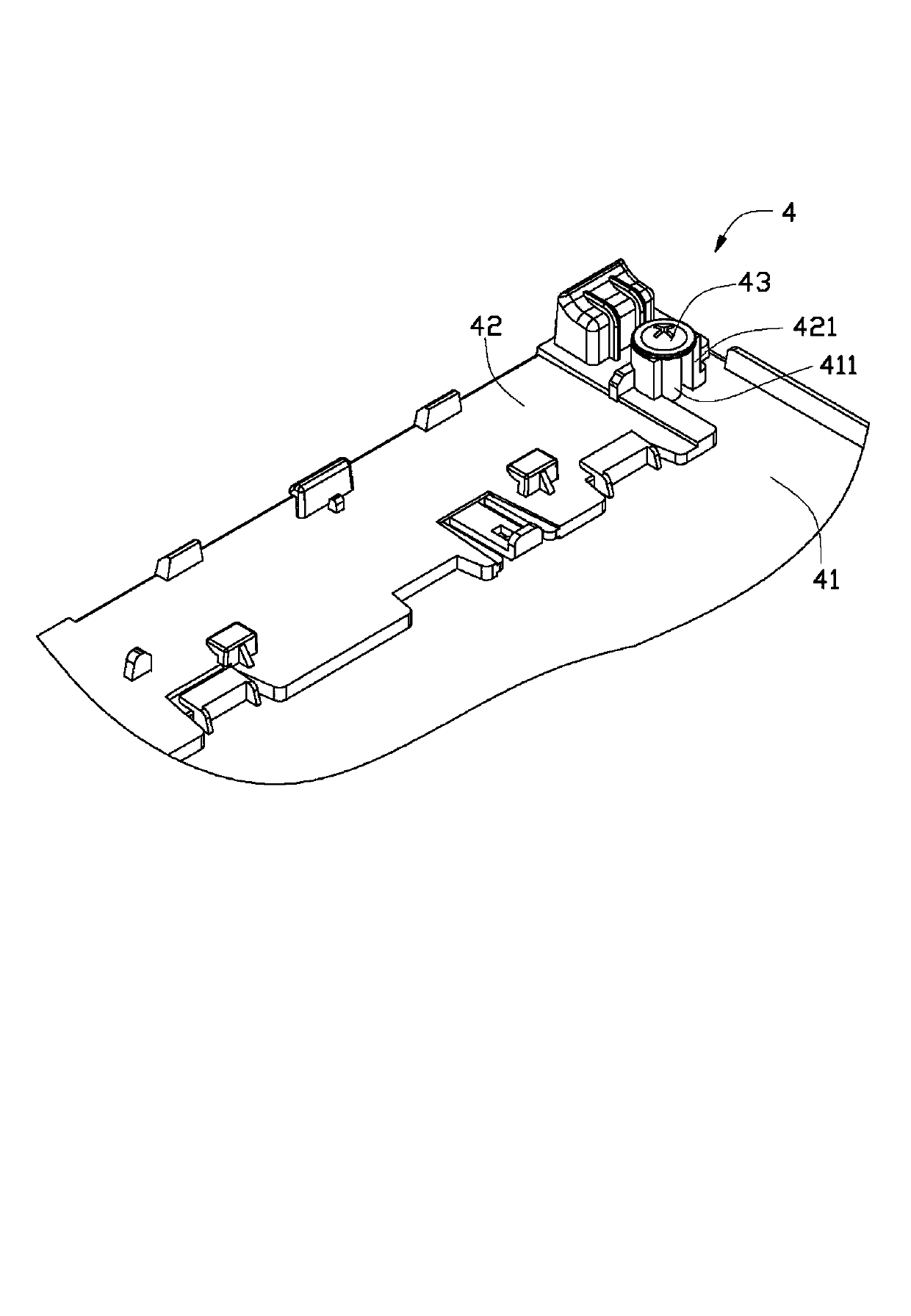

Fixing structure

A fastening structure assembly includes a housing, a to-be-fixed element, and at least one fastening element. The housing defines at least one fastening post. The to-be-fixed element includes at least one supporter each of which is bent to surround one of the at least one fastening post. Each of the at least one fastening element includes a stopper and a fastening pole extending from the stopper. Each of the fastening pole engages with one of the fastening posts to make the corresponding stopper resist an edge of the supporter surrounding the fastening post to fasten the to-be-fixed element to the housing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Manufacturing method of laminated body

ActiveCN106794689BAvoid breakingBad apperanceElectroluminescent light sourcesSynthetic resin layered productsThin membraneComposite material

The present invention provides a method for producing a laminated body, which is a method for producing a laminated body having a laminated film and an adhesive layer, the production method including the step of forming the adhesive layer on one surface of the laminated film, wherein the laminated film is at least laminated A laminated film comprising a base material and a thin film layer, wherein the thin film layer contains at least silicon, and the step of forming the adhesive layer comprises the steps of conveying the laminated film web of the laminated film in a tape-like continuous longitudinal direction while aligning the above-mentioned laminated film in the longitudinal direction. Laminated film rolls are applied per unit cross-sectional area in the length direction to be greater than or equal to 0.5N / mm 2 and less than 50N / mm 2 In a state of tension, the adhesive layer is formed on the surface of the laminated film web on which the film layer is laminated.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com