Leather-like sheet and method for producing same

A leather-like sheet and skin layer technology, applied in chemical instruments and methods, textiles and papermaking, adhesive types, etc., can solve problems such as peeling, poor appearance of leather-like sheets, skin layer swelling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

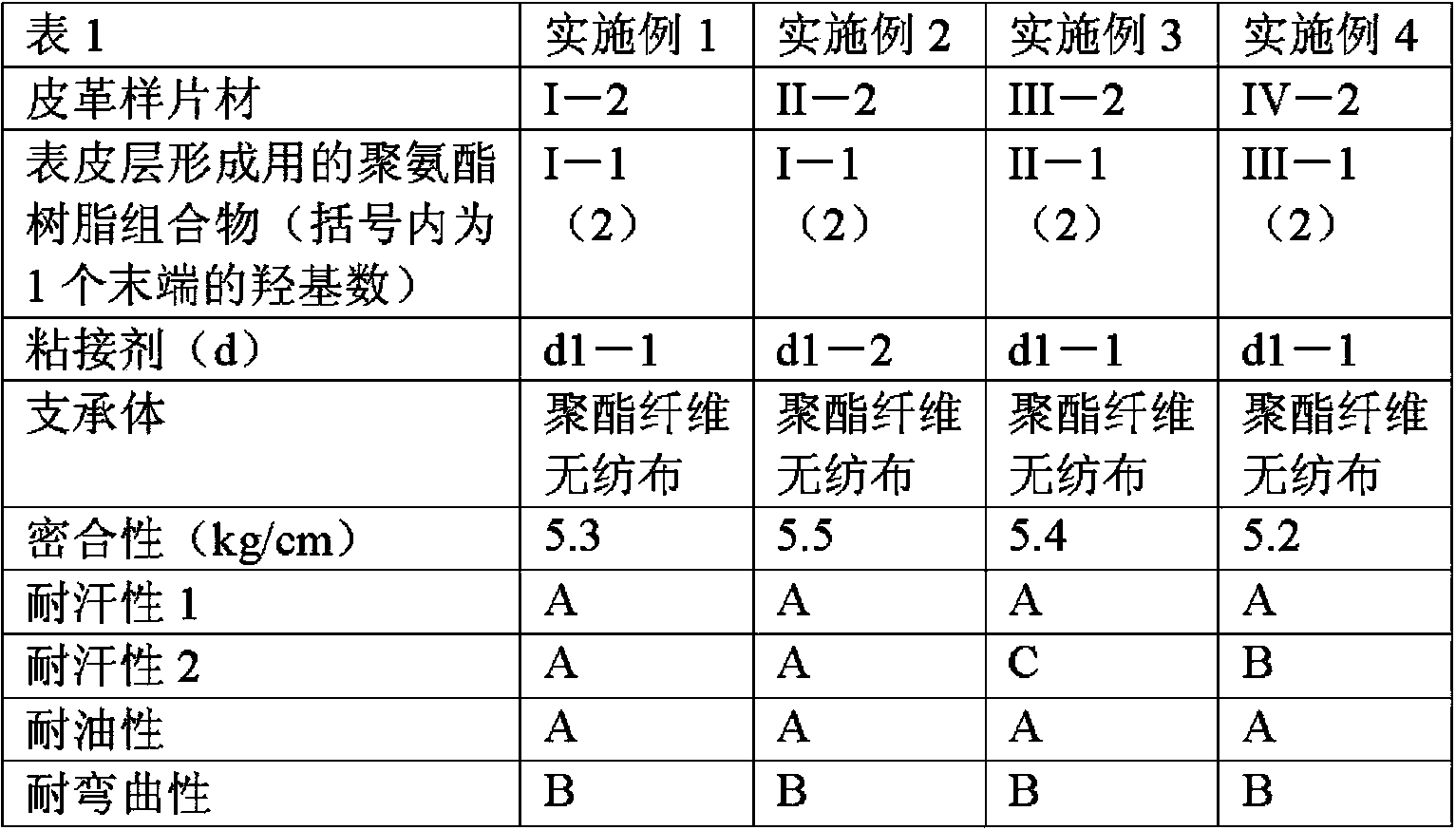

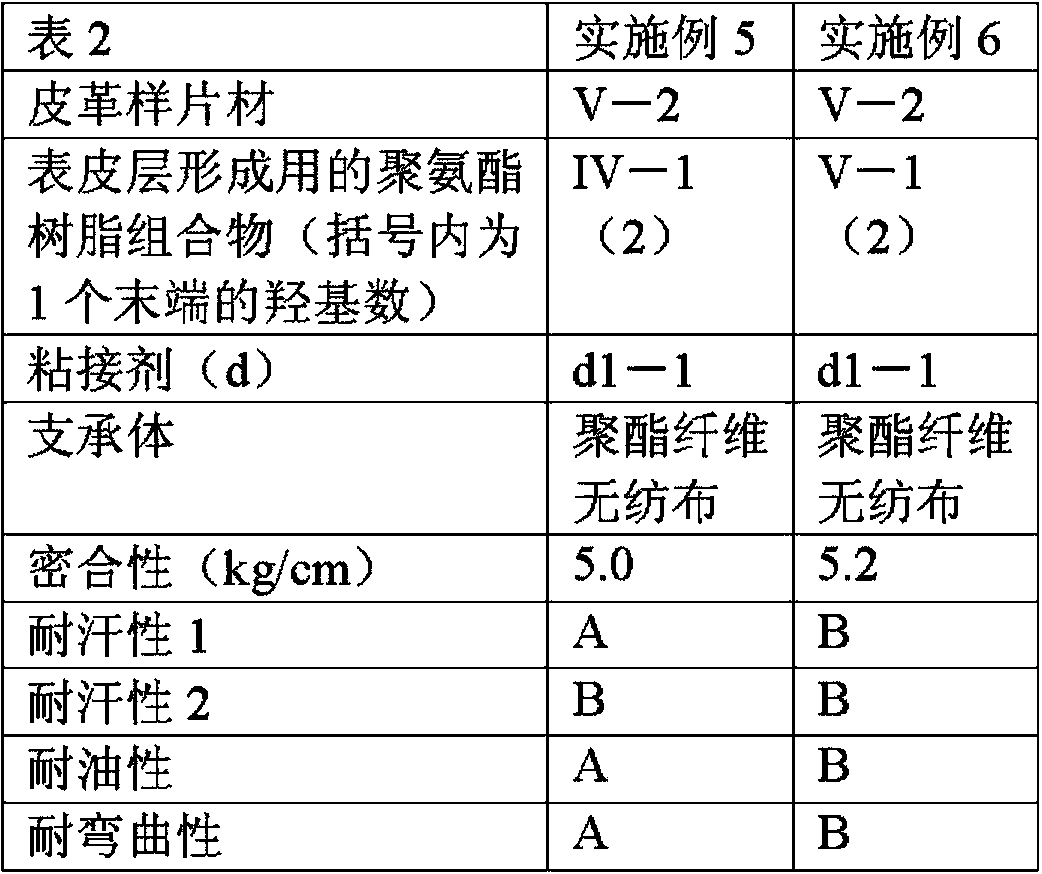

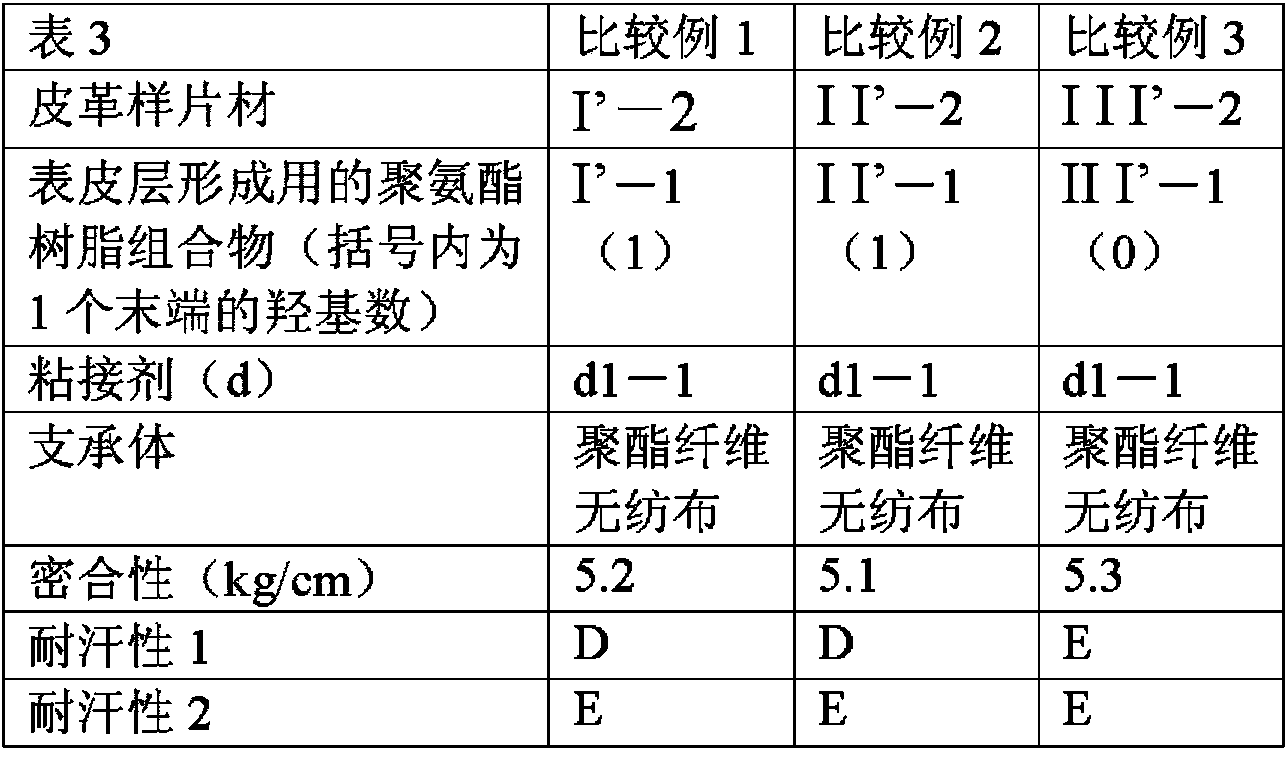

Examples

preparation example 1

[0101] [Preparation Example 1] Preparation of Adhesive (d1-1)

[0102] In the presence of 1221 g of methyl ethyl ketone and 0.1 g of stannous octoate, 1000 g of polycarbonate diol (NIPPOLAN N980R; Japan Polyurethane Industry Co., Ltd.: number average molecular weight 2000), 34 g of dimethylol propionic acid and dicyclohexylmethane 187 g of isocyanate (HMDI) was reacted at 70 degreeC until the isocyanate group disappeared, and the methyl ethyl ketone solution of the polyurethane resin which has a hydroxyl group at the terminal was obtained.

[0103] After mixing 2462 g of the methyl ethyl ketone solution of the polyurethane resin and 25 g of triethylamine, it was mixed with 2442 g of pure water and phase inversion emulsified to obtain an emulsion.

[0104] Next, methyl ethyl ketone was distilled off from the emulsion to obtain a polyurethane resin composition [d1-1-1] having a nonvolatile content of 45% by mass.

[0105] Add 100g of the polyurethane resin composition [d1-1-1] ...

preparation example 2

[0106] [Preparation Example 2] Preparation of Adhesive (d12)

[0107] In the presence of a nitrogen atmosphere and 0.1 g of stannous octoate, 100 g of polycarbonate diol (NIPPOLAN N980R; Nippon Polyurethane Industry Co., Ltd.: number average molecular weight 2000) heated to 80°C and dicyclohexylmethane diisocyanate (HMDI ) 14 g was stirred at 2000 rpm for 2 minutes using a mechanical mixer, and then defoamed using a vacuum defoamer to obtain a solvent-free adhesive (d1-2).

Embodiment 1

[0108] [Example 1] Production of leather-like sheet

[0109] In the presence of 710 g of methyl ethyl ketone and 0.1 g of stannous octoate, 1000 g of polycarbonate diol (NIPPOLAN N981; Nippon Polyurethane Industry Co., Ltd.: number average molecular weight 1000), 67 g of dimethylol propionic acid and dicyclohexylmethane 590 g of isocyanate (HMDI) was reacted at 70 degreeC until NCO% became 2.7 mass %, and the methyl ethyl ketone solution of the terminal isocyanate group containing urethane prepolymer (A'-1) was obtained by this. In addition, said NCO% is the ratio of the mass of the isocyanate group which the polyisocyanate has with respect to the gross mass of the raw material used for manufacture of the said polyurethane among them.

[0110] After mixing 2367 g of the methyl ethyl ketone solution of the above-mentioned terminal isocyanate group-containing urethane prepolymer (A'-1) and 50 g of triethylamine, it was mixed with 2367 g of pure water and phase inversion emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com