Fixing structure

A technology for fixing structures and fixing parts, which is applied in the direction of circuit layout, circuits, connections, etc. on the supporting structure, and can solve problems such as poor appearance of the shell 2 and dents in the shell 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

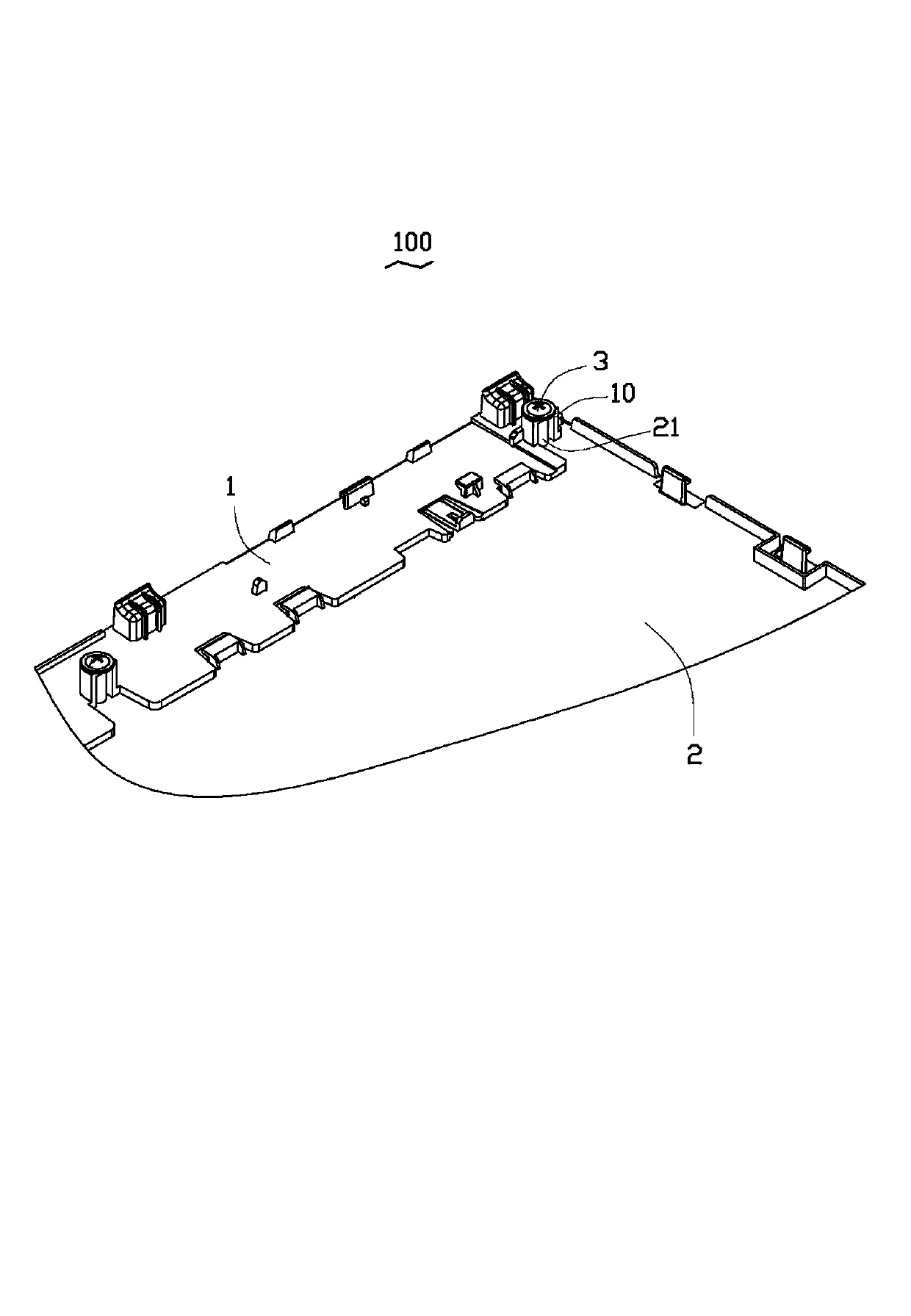

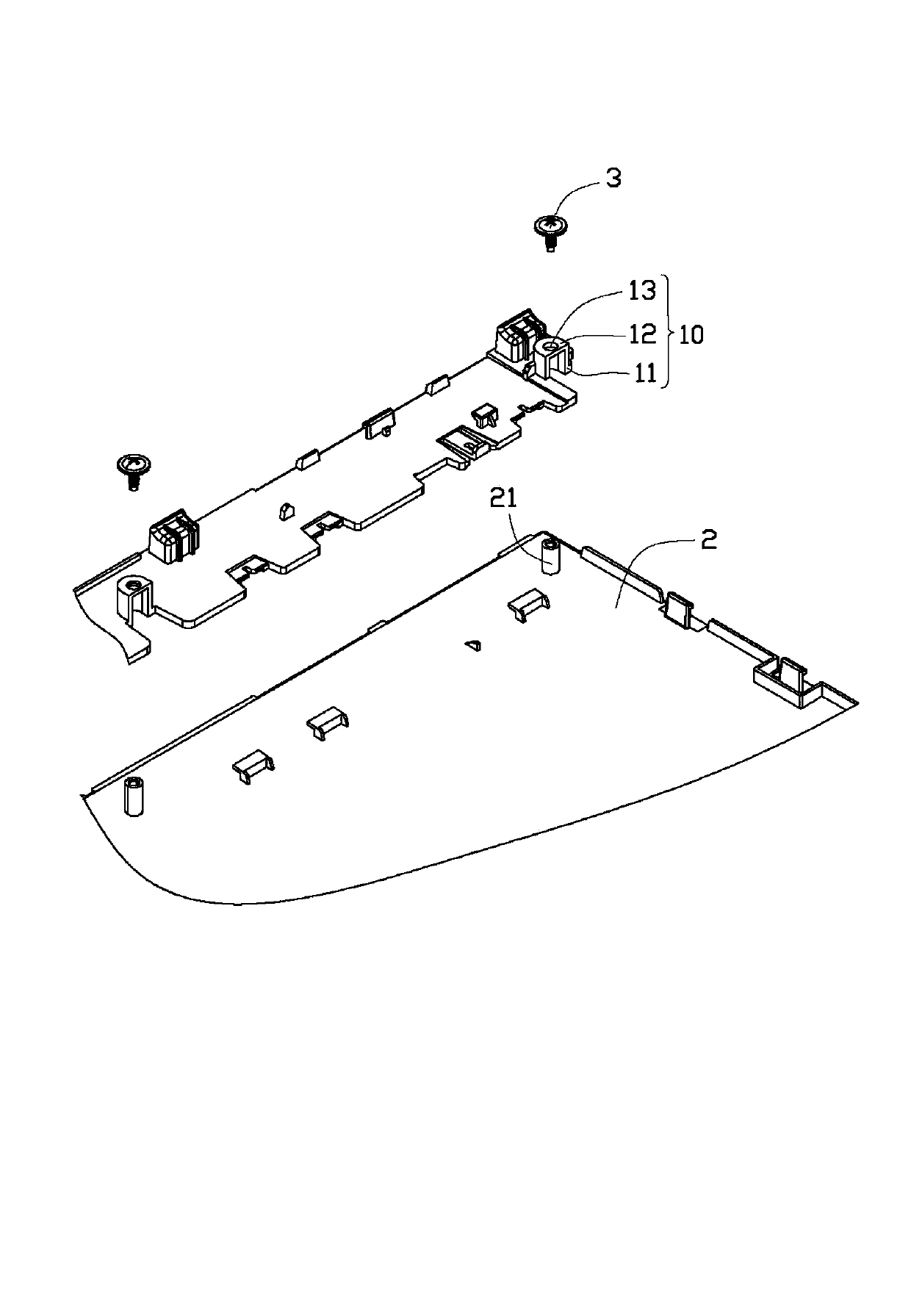

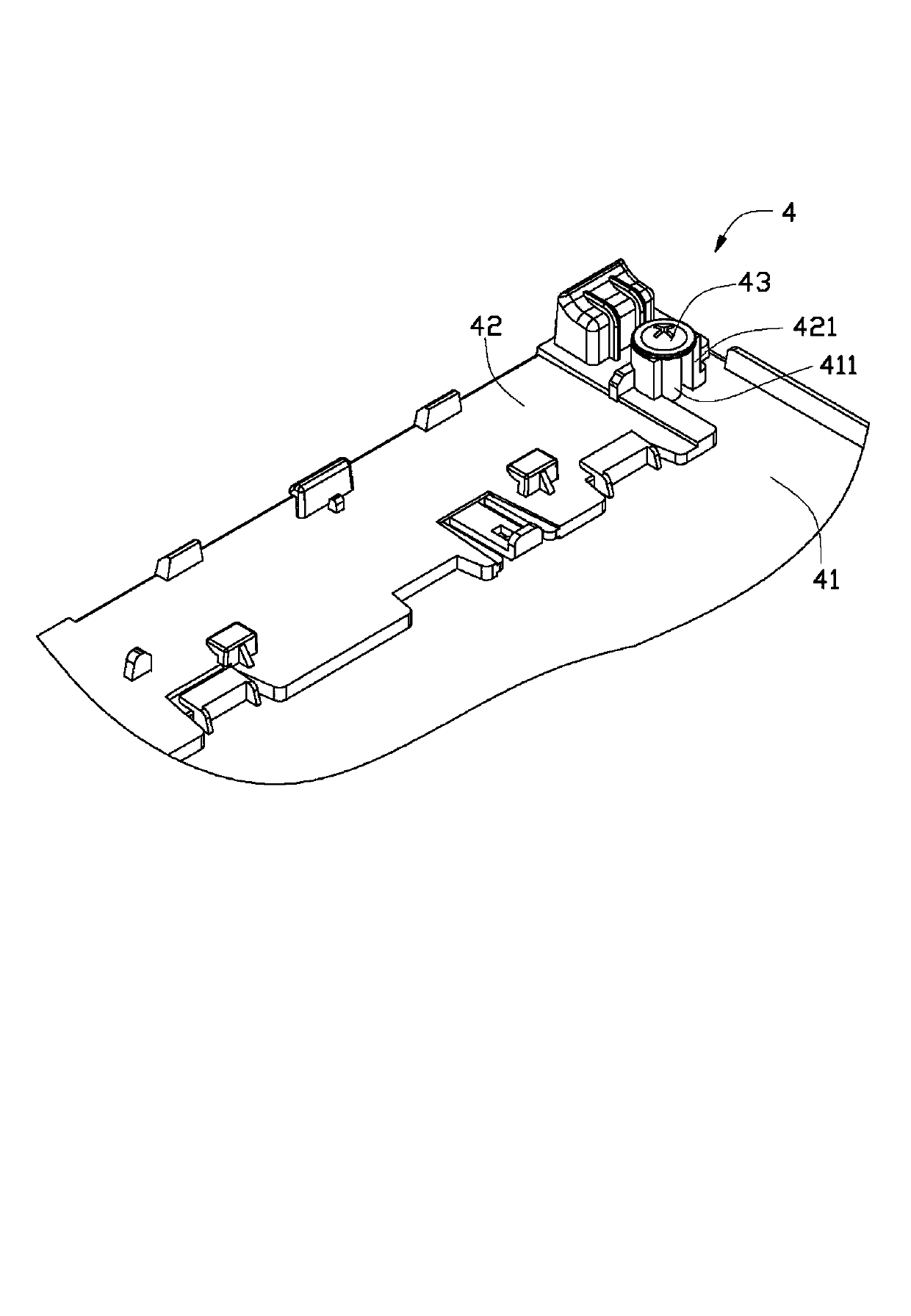

[0012] Such as Figure 3-4 As shown, a fixing structure 4 includes a housing 41, a fixed part 42, and at least one locking part 43. The housing 41 is fixed with at least one fixing post 411, and the fixed part 42 includes at least one support 421, The supporting member 421 is slightly higher than the fixing post 411. The locking member 3 includes a stop portion 31 and a locking portion 32. The locking portion 32 is inserted into the fixing column 411. The supporting member 421 is a flat plate. A flat plate is bent around the fixing post 411, the locking portion 32 is inserted into the fixing post 411, and cooperates with the fixing post 411 to prevent the locking portion from falling off, and the stop portion 32 abuts the support 421 , So that the fixed member 42 is fixed to the housing 41.

[0013] In this embodiment, the housing 41 is a transparent mirror housing, the fixed part 42 is a decorative part, and the locking part 43 and the fixing post 411 are screws and studs, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com