Shell polishing and shaping method, shell and electronic product

A technology for electronic products and shells, which is applied in the field of electronic product manufacturing, can solve problems such as manufacturing waste and appearance failure to pass inspection standards, and achieve the goals of saving production costs, improving the appearance yield of shells, and increasing the utilization rate of shells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

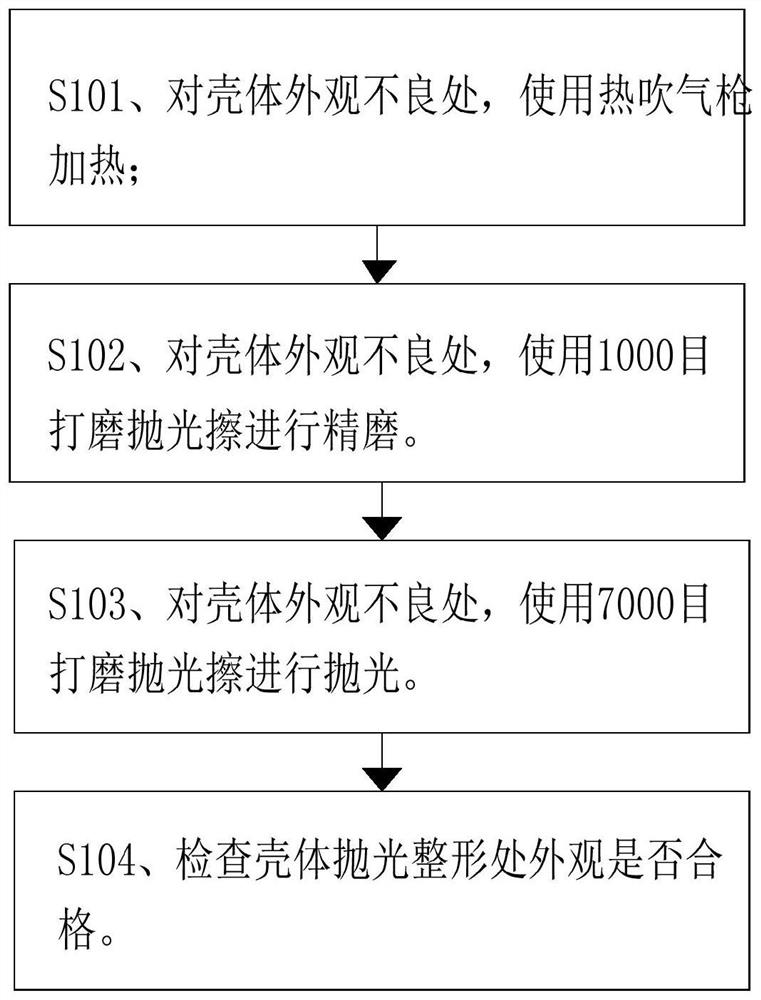

[0020] Such as figure 1 As shown, the shell polishing and shaping method of the present invention includes the following steps:

[0021] S101. Use a hot air gun to heat the bad appearance of the shell; the bad appearance of the shell includes bumps, dents and gaps on the shell. Preferably, use the nozzle of a hot air gun to blow hot air for 3 to 5 seconds on the poor appearance of the shell. The temperature of the hot gas is 230±10°C. The housing is reinforced polycarbonate plastic containing 10% glass fibers.

[0022] S102. Use 1000-mesh grinding and polishing to finely grind the parts with poor appearance of the shell.

[0023] S103. Use a 7000-mesh grinding and polishing wipe to polish the parts with poor appearance of the shell.

[0024] The mesh refers to the number of points that can be accommodated in a size of 1 square centimeter. Such as sandpaper (abrasive cloth), gauze, etc., the density is calculated in "mesh".

[0025] S104. Check whether the appearance of t...

Embodiment 2

[0034] The present invention also provides a shell, which is a matte material shell, which is repaired by the aforementioned shell polishing and shaping method.

Embodiment 3

[0036] The present invention also provides an electronic product, which is repaired by the aforementioned casing polishing and shaping method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com