Cartridge for viscous fluid object

A viscous flow and material technology, applied in the field of moisture-curing compositions, can solve the problems of damaged appearance, low productivity, easy to form wrinkles, etc., and achieve good moisture resistance, high productivity, and high storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

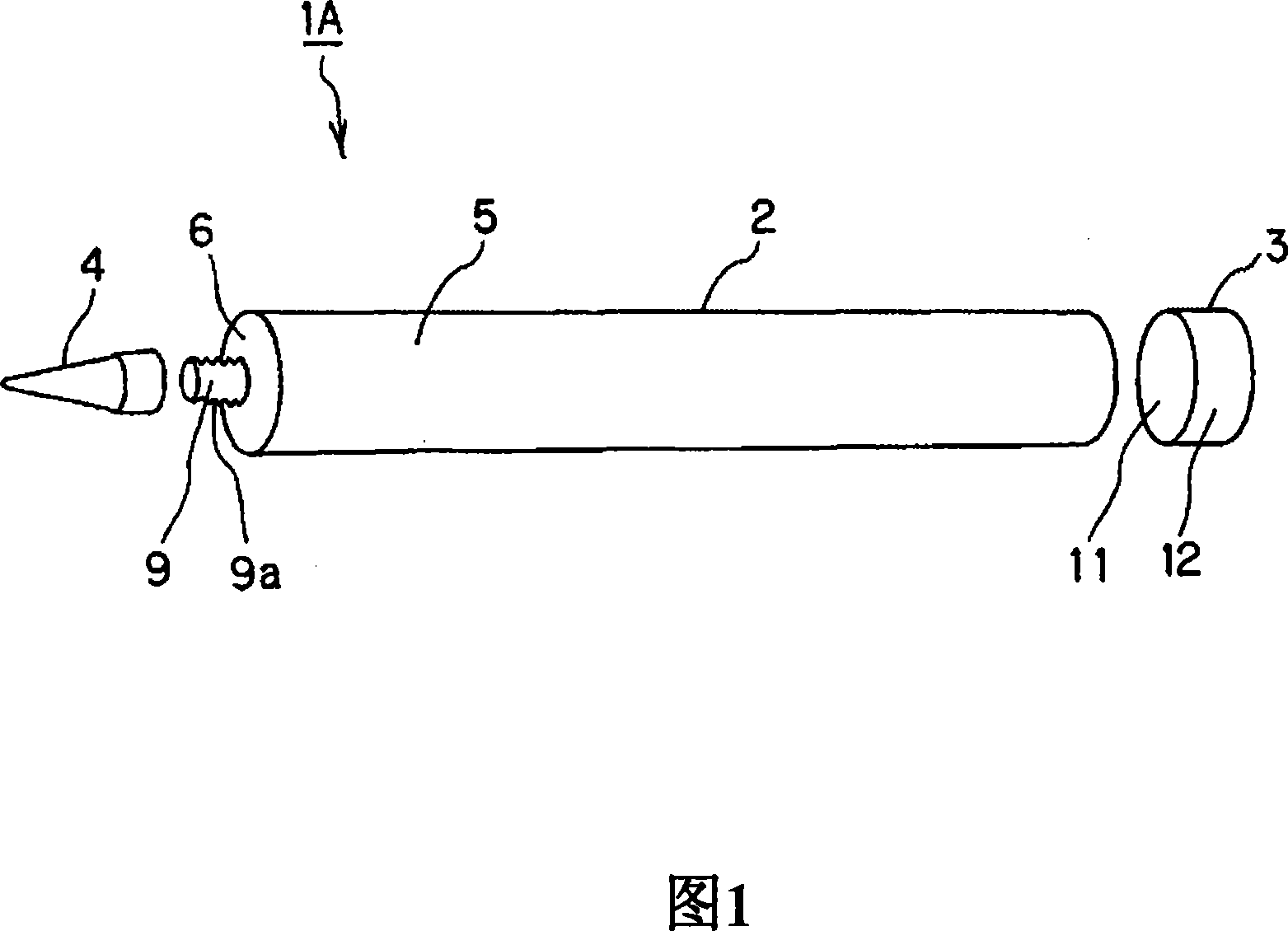

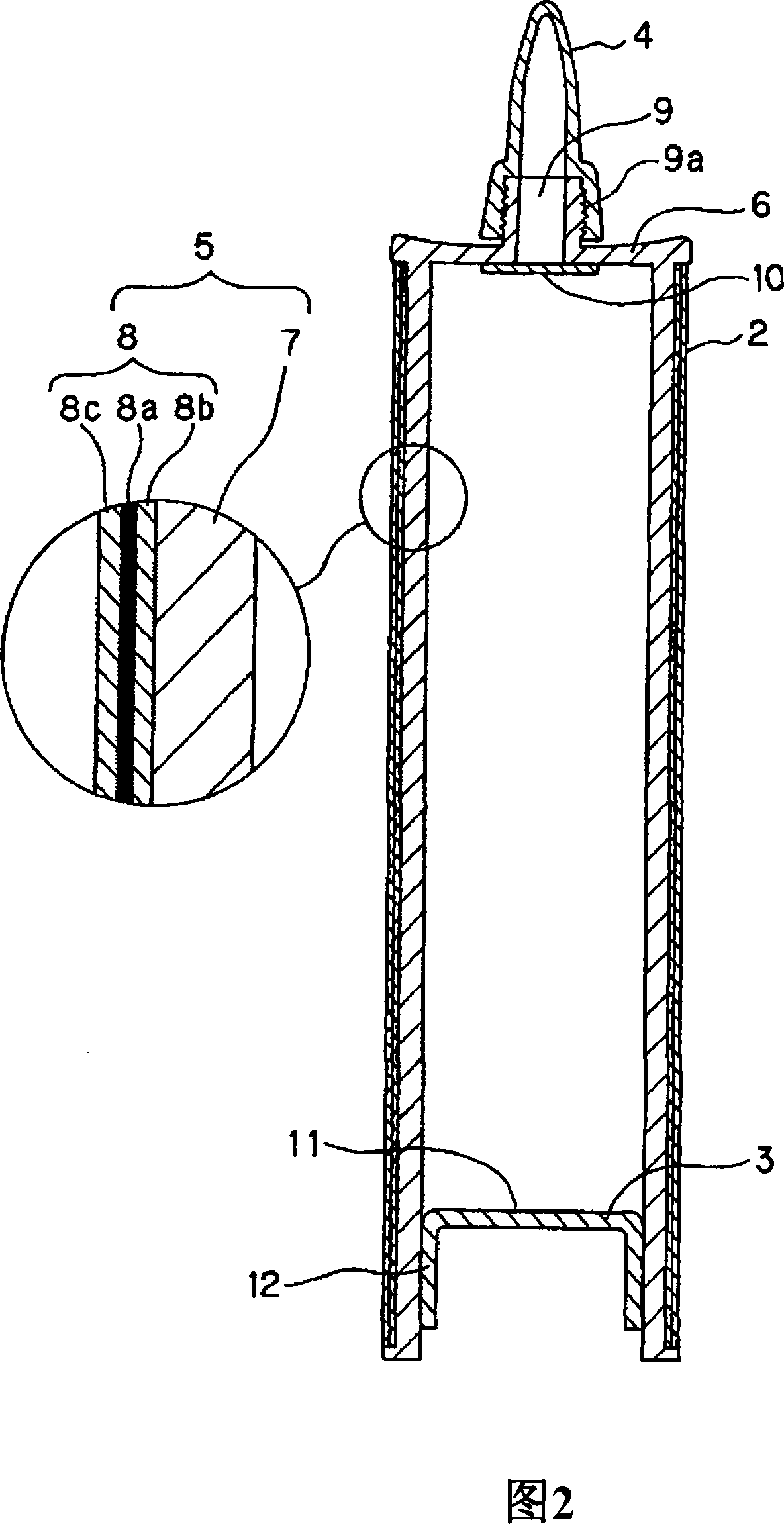

[0083] Polyethylene resin is used as the injection resin, and a composite film having a layer structure in which a PE layer, Al foil, PET layer, and OPP layer are laminated in sequence is used as an insert film for a gas barrier layer, and is produced by injection molding as shown in Fig. 1 and Fig. 2 shows a cartridge body A having a cylindrical body portion provided with a gas barrier layer on the outer peripheral portion.

[0084] The obtained cartridge main body 1A has a shape in which one end of the cylindrical body part is closed with a top cover part 6 provided with a cylindrical mouth part (discharge part) 9 at the center, and has an inner diameter of 48 mm and a total internal length of 213 mm. The inner volume is about 381mm 3 . Its cross-sectional structure has the following layer structure: the whole has a plastic layer 7 of high-density polyethylene resin, the wall thickness of the cylindrical barrel part is 1.15 mm, and the outer peripheral part is provided with...

Embodiment 2

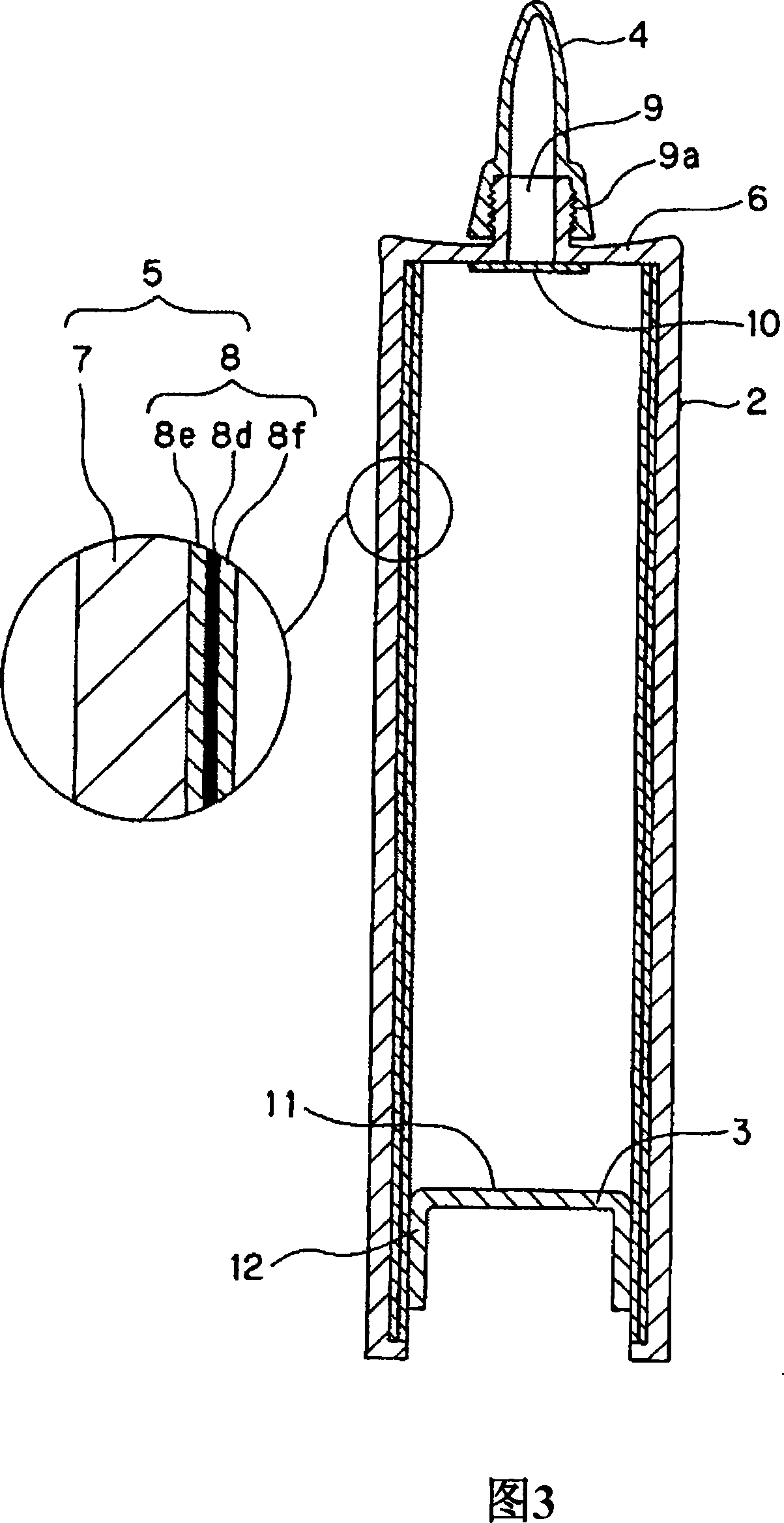

[0088] Using the same injection resin and composite film as in Example 1, a cartridge body B having a cylindrical body portion with a gas barrier layer provided on the inner peripheral portion shown in FIGS. 1 and 3 was manufactured by injection molding.

[0089] The shape and size of the obtained cartridge body B were the same as in Example 1. Its cross-sectional structure has a layer structure in which a gas barrier layer composed of a PE bonding layer, an Al foil layer, a PET layer, and the innermost layer of OPP is provided on the inner peripheral portion of the cylindrical body.

[0090] The cartridge main body B is the same as in Example 1. The sealing film 10 is welded on one side of the top cover part 6, the nozzle 4 is screwed and fixed, and the inner peripheral surface of the opening at the other end is coated with polybutene and micron. A mixture of crystal waxes (mixing ratio 6:4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com