Interlayer for laminated glass and laminated glass

A technology of laminated glass and interlayer film, applied in the direction of glass/slag layered products, windshields, applications, etc., which can solve the problems of poor appearance of laminated glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] Preparation of the composition for forming the first layer:

[0220] 100 parts by weight of polyvinyl acetal resin shown in Table 1 below, 60 parts by weight of plasticizer shown in Table 1 below, 0.2 part by weight of ultraviolet shielding agent (Tinuvin326), and antioxidant ( H-BHT) 0.2 parts by weight were thoroughly mixed to obtain a composition for forming the first layer.

[0221] Preparation of compositions for forming the second and third layers:

[0222] 100 parts by weight of polyvinyl acetal resin shown in Table 1 below, 38 parts by weight of plasticizer shown in Table 1 below, 0.2 parts by weight of ultraviolet shielding agent (Tinuvin326), and antioxidant (H-BHT) 0.2 weight part, the composition for forming the 2nd layer and the 3rd layer was obtained.

[0223] Production of interlayer film:

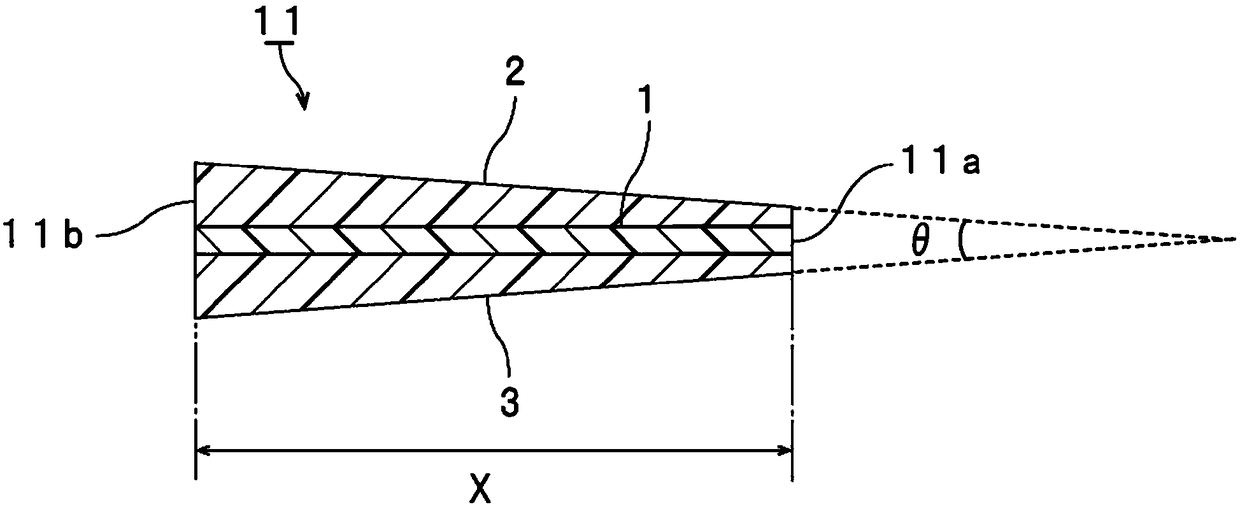

[0224] Using an extruder, the composition for forming the first layer and the compositions for forming the second and third layers are coextruded, and the intermed...

Embodiment 2

[0226] Preparation of the composition for forming the interlayer:

[0227] 100 parts by weight of polyvinyl acetal resin shown in Table 1 below, 38 parts by weight of plasticizer shown in Table 1 below, 0.2 parts by weight of ultraviolet shielding agent (Tinuvin326), and antioxidant (H-BHT) 0.2 weight part, the composition for forming an intermediate film was obtained.

[0228] Production of interlayer film:

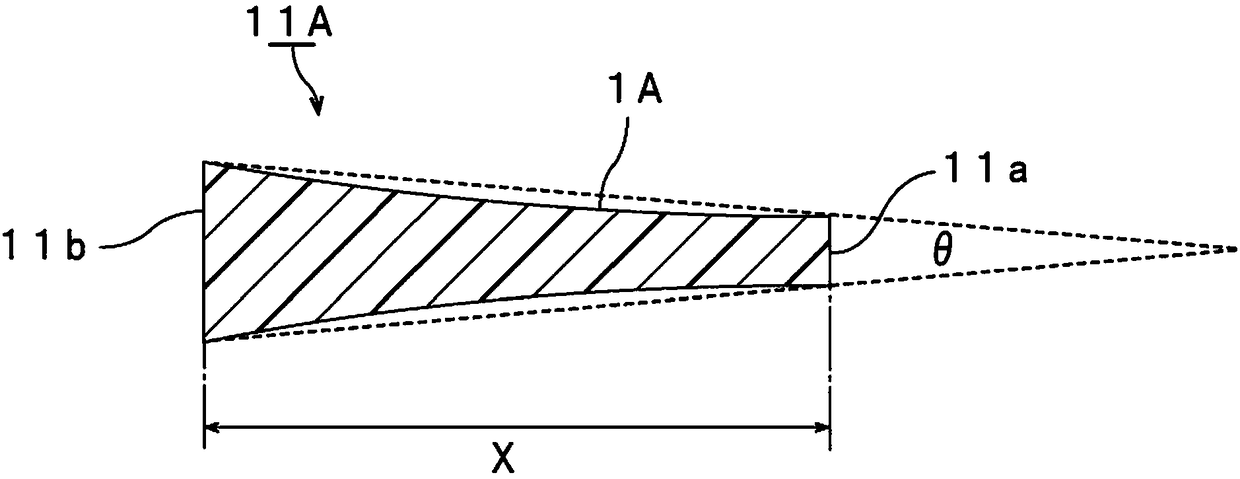

[0229] Use an extruder to extrude the composition for forming the intermediate film, heat the intermediate film to 100°C to 150°C, hold it for a holding time of 1 minute, then lower the temperature to 25°C, and wind the intermediate film to obtain a coil body. A single-layer interlayer film having a wedge-shaped cross-sectional shape in the thickness direction was fabricated. The thicknesses at the first position of 0.05X from one end to the other end, the second position of 0.5X from one end to the other end, and the third position of 0.95X from one end to the other ...

Embodiment 3

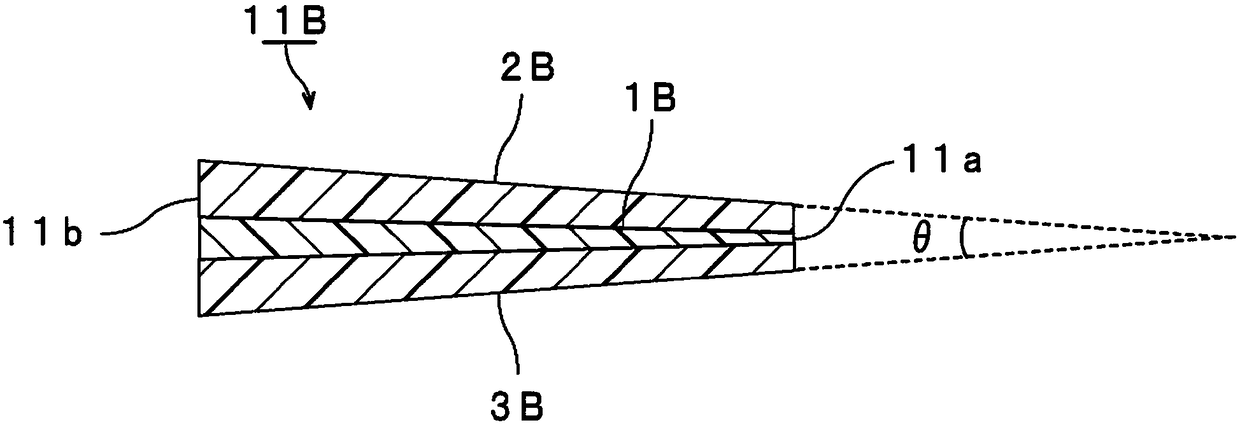

[0235] A three-layer interlayer film was obtained in the same manner as in Example 1 except that the mold temperature was changed and the thickness of the interlayer film was changed according to Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com