Patents

Literature

143results about How to "Less prone to wrinkles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

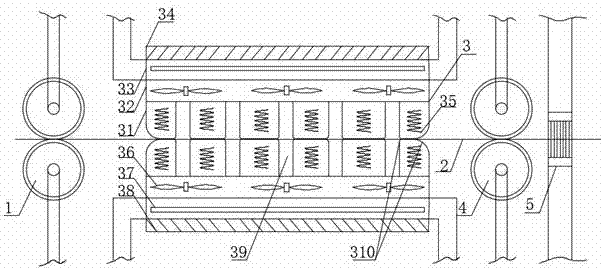

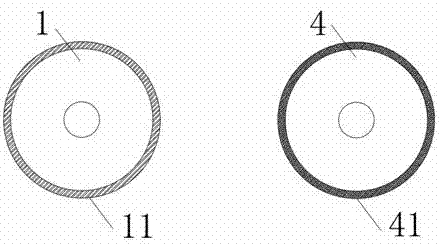

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

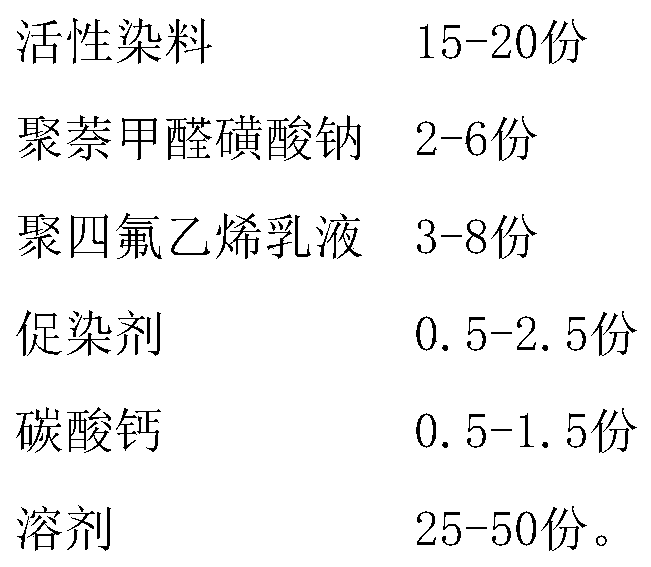

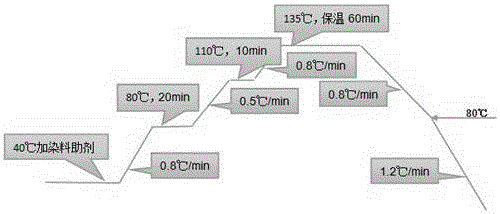

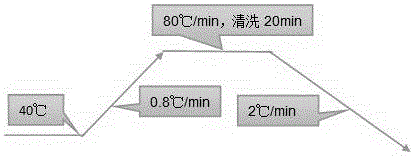

Dyeing and fishing method for brocade/viscose fiber/spandex knitting fabric

InactiveCN102444033AEmission reductionLow process temperatureFibre treatmentDyeing processEngineeringFishing

The present invention discloses a dyeing and fishing method for brocade / viscose fiber / spandex knitting fabric. The method comprises processes of open-width pre-shrinking, scouring and dyeing in one bath, low temperature neutralizing and soaping, acid dyeing, soaping, drying and softening finishing. The open-width pre-shrinking process is performed by adopting a steaming shrinking machine. The scouring and dyeing in one bath process comprises: adding 1-2 g / l of a refined degreasing agent, and 2-3 g / l of an aqueous solution of soda to a dye vat, treating for 15-20 minutes at a temperature of 60-80 DEG C, then adding an active dye, 25-70 g / l of sodium sulfate, and 20g-25 g / l of soda, dyeing for 50-70 minutes at the temperature of 60-65 DEG C. The dyeing and fishing method for the brocade / viscose fiber / spandex knitting fabric has characteristics of simple operation, treatment time saving and low energy consumption. With the method of the present invention, the amount of the sewage discharge can be effectively reduced, and the prepared finished product has good hand feeling and full color.

Owner:杭州天宇印染有限公司

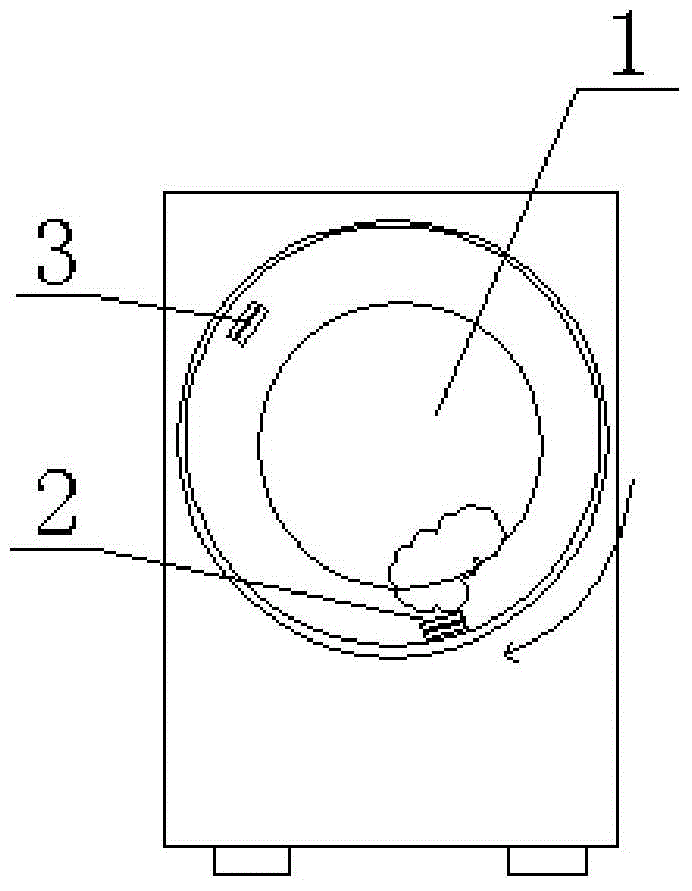

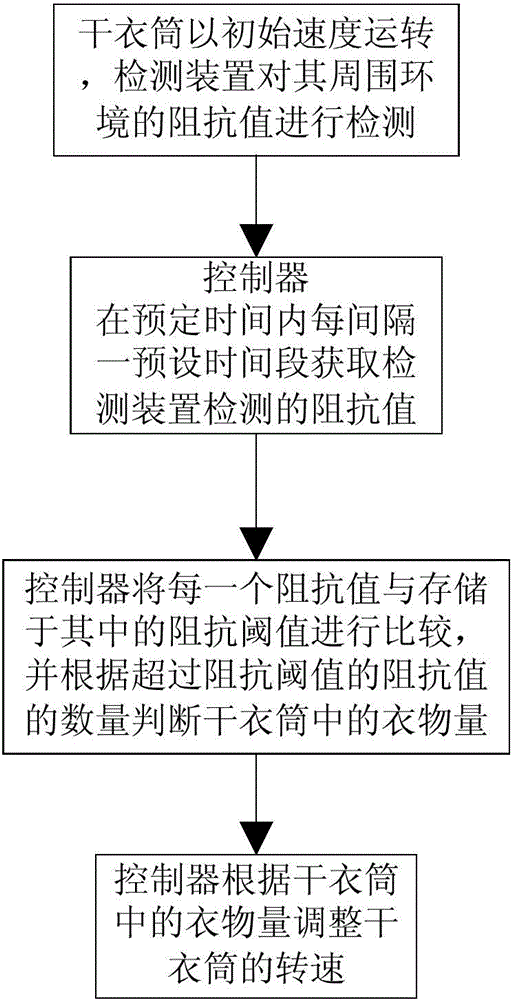

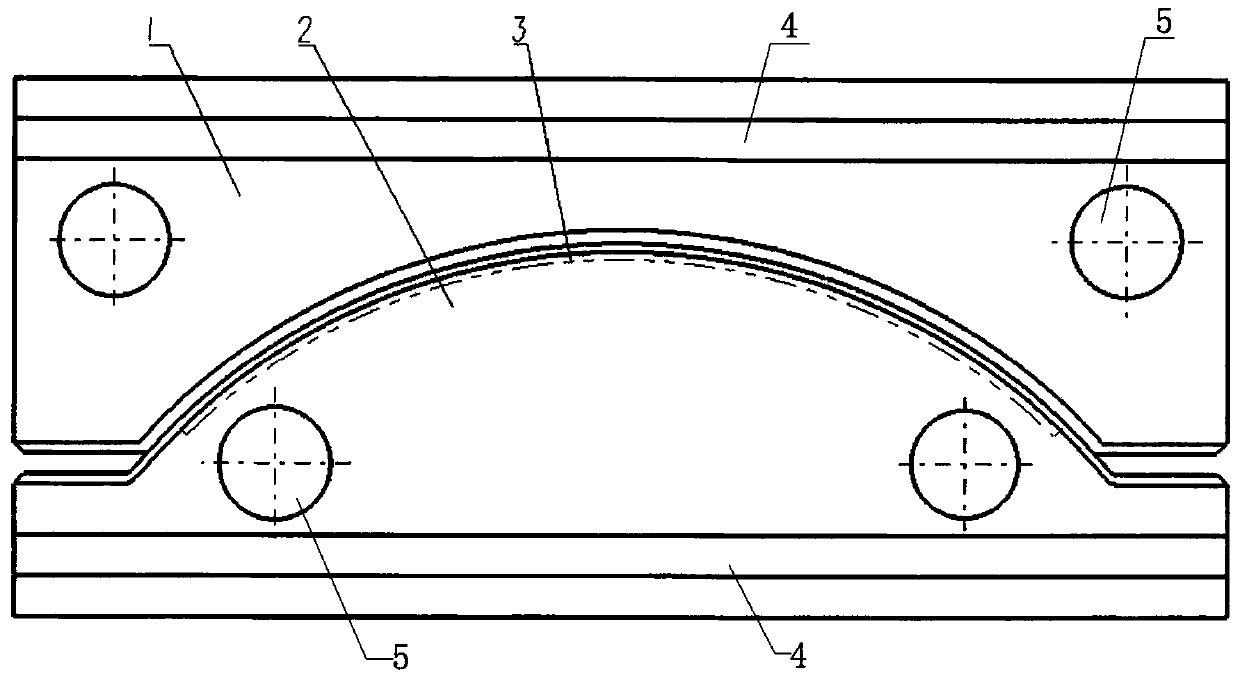

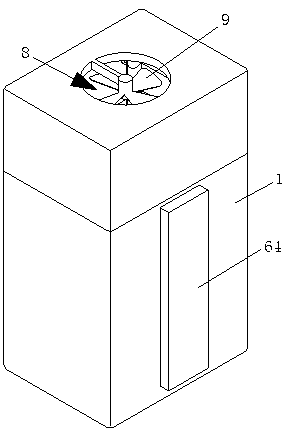

Clothes dryer and control method thereof

ActiveCN106149330ASolve prone to wrinklesSolve for uniformityTextiles and paperLaundry driersControl theoryMoisture sensor

The invention discloses a clothes dryer and a control method thereof. The clothes dryer comprises a clothes drying cylinder, a humidity sensor used for detecting a clothes humidity value and a detection device are arranged at a clothes putting opening of the clothes drying cylinder, and the detection device is arranged on the inner side of the edge of the clothes putting opening; the detection device is connected with a controller and used for detecting resistance values of an ambient environment of the detection device every other a preset time period in preset time and transmitting the resistance values to the controller. According to the clothes dryer, the detection device is arranged and used for detecting the resistance values of the ambient environment of the detection device every other the preset time period in the preset time, the controller compares all the resistance values with a resistance threshold value stored in the controller, judges the clothes number in the clothes drying cylinder according to the number of the resistance values exceeding the resistance threshold value and then adjusts the rotation speed of the clothes drying cylinder according to the clothes number, and therefore the problems that in the prior art, in the clothes drying process of a clothes dryer, clothes creasing is prone to occur, and the clothes drying effect is not uniform are solved.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Method for forming titanium alloy sheet metal part

The invention provides a method for forming a titanium alloy sheet metal part. The method is simple, and effectively achieves heated equipment, devices and high temperature resistant moulds in the titanium alloy sheet metal part heating forming method in the prior art and lubrication and pollution prevention under high temperature, heat preservation and pressure maintaining are mainly carried out on titanium alloy materials for a certain time for forming at the temperature of stress relaxation and the creeping state, and high-quality and high-stability forming can be carried out on the titanium alloy sheet metal part successfully.

Owner:SHENYANG AIRCRAFT CORP

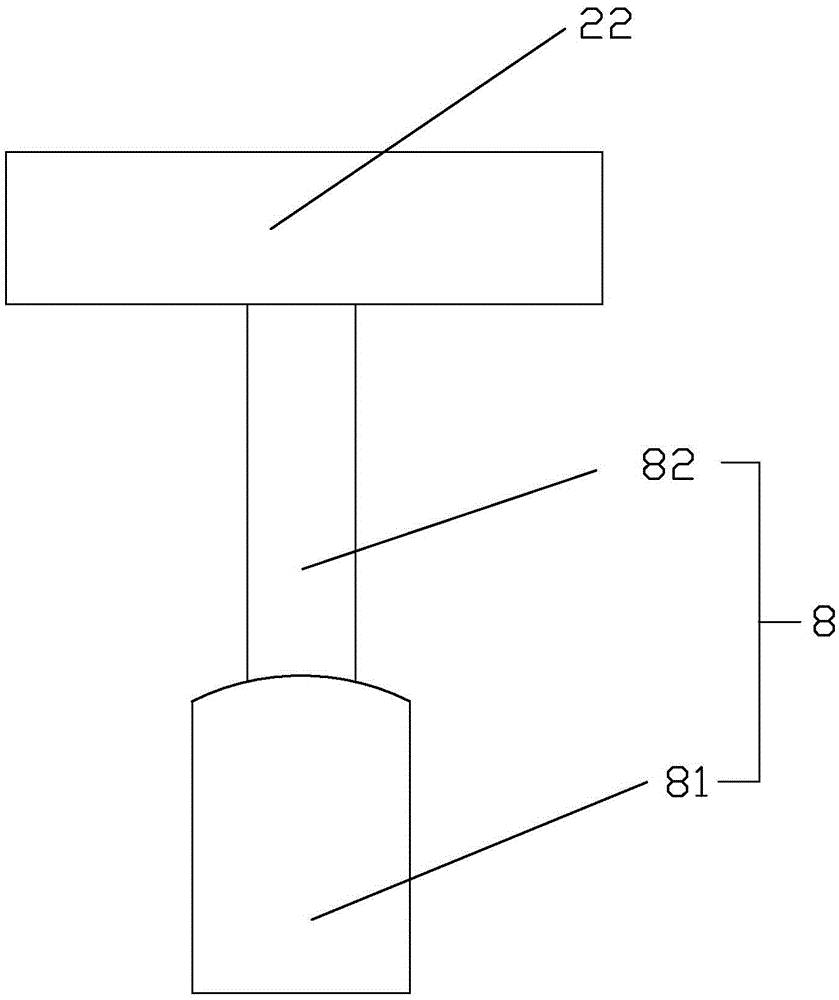

Washing machine

InactiveCN103266447ATo achieve the washing effectLess prone to wrinklesOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention relates to a washing machine which comprises a washing groove and a clamping movement device. The clamping movement device conducts clamping or suspending on clothes, and the clamping movement device can further drive water in the washing groove to move in the process of washing and generate a water current contacted with the clothes, and driving frequency of the clamping movement device on the water is smaller than 20000 hertz. According to the technical scheme, in the process of washing of the washing machine, the clothes are clamped or suspended by the clamping movement device, meanwhile the clamping movement device drives the water in the washing groove to generate movement and forms the water current contacted with the clothes, therefore, the washing effect is achieved, after washing, the clothes can not be stacked in a chaos mode or wound together, and folds are not easily generated.

Owner:WHIRLPOOL CHINA

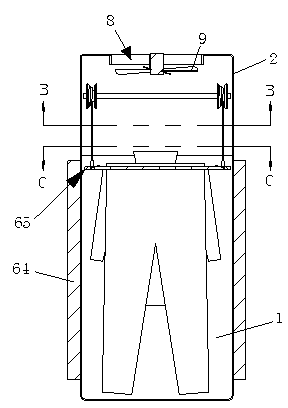

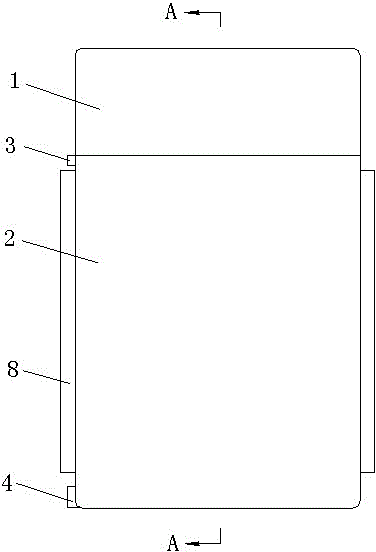

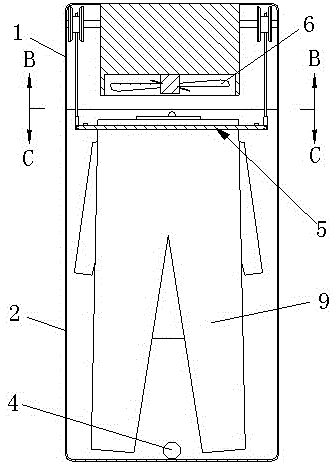

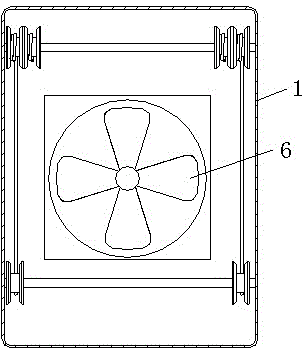

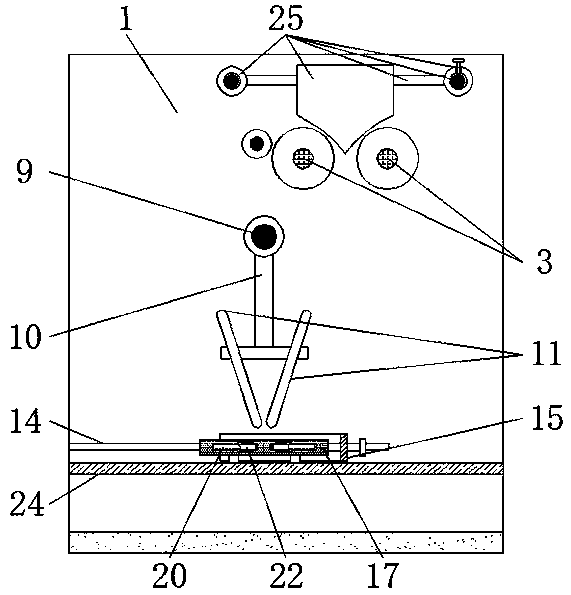

Washing machine

InactiveCN102720036AAchieve the effect of rinsing clothesLess prone to wrinklesOther washing machinesOther drying apparatusEngineeringMechanical engineering

The invention relates to a washing machine. The washing machine comprises an upper cover, a washing bucket and a clamp for clamping clothes, wherein a water inlet and a water outlet are formed on the washing bucket; the clamp moves up and down along the axial direction of the washing bucket and moves horizontally along the radial direction of the washing bucket under the action of a first power device and a second power device; a fan is arranged on the upper cover and is connected with a third power device; and the first power device, the second power device and the third power device are connected with a controller. According to the technical scheme of the invention, clothes are clamped on the clamp and washed when the clamp moves along the radial direction and the axial direction of the washing bucket under the action of the first power device and the second power device in the washing process of the washing machine, and can be dried by the fan directly during dewatering, so that the clothes are not piled up disorderly or intertwined together and not crumpled easily in the whole washing process.

Owner:WHIRLPOOL CHINA

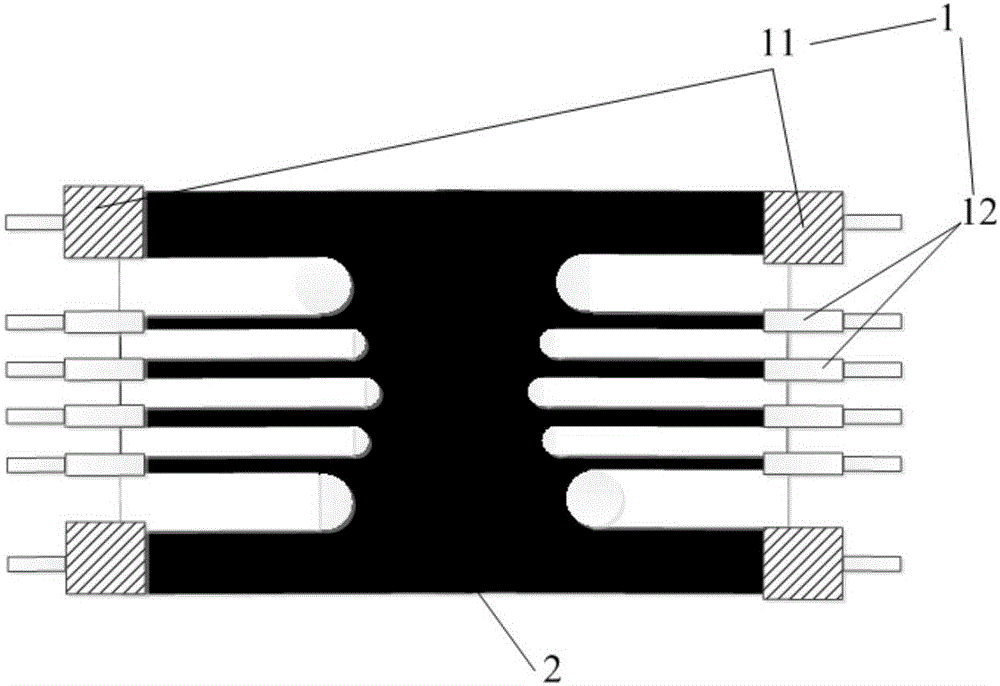

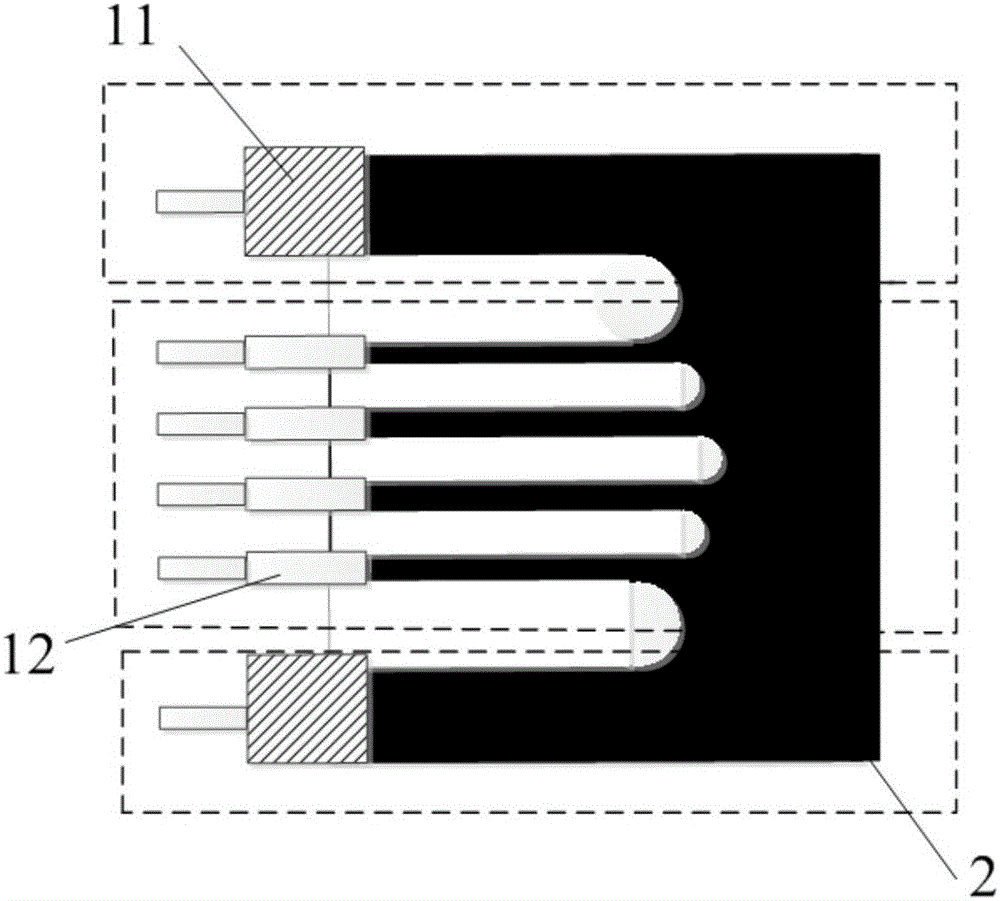

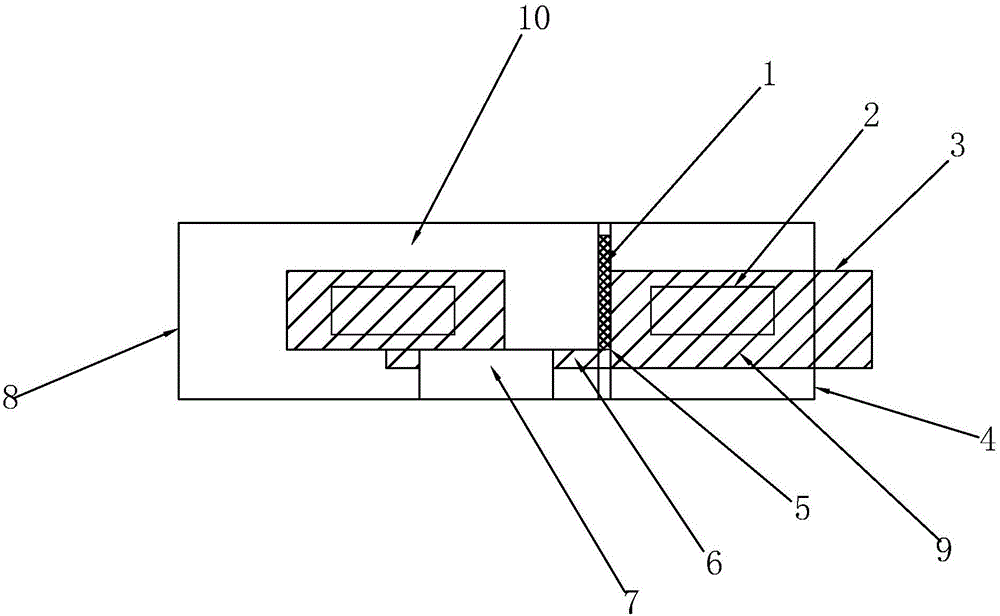

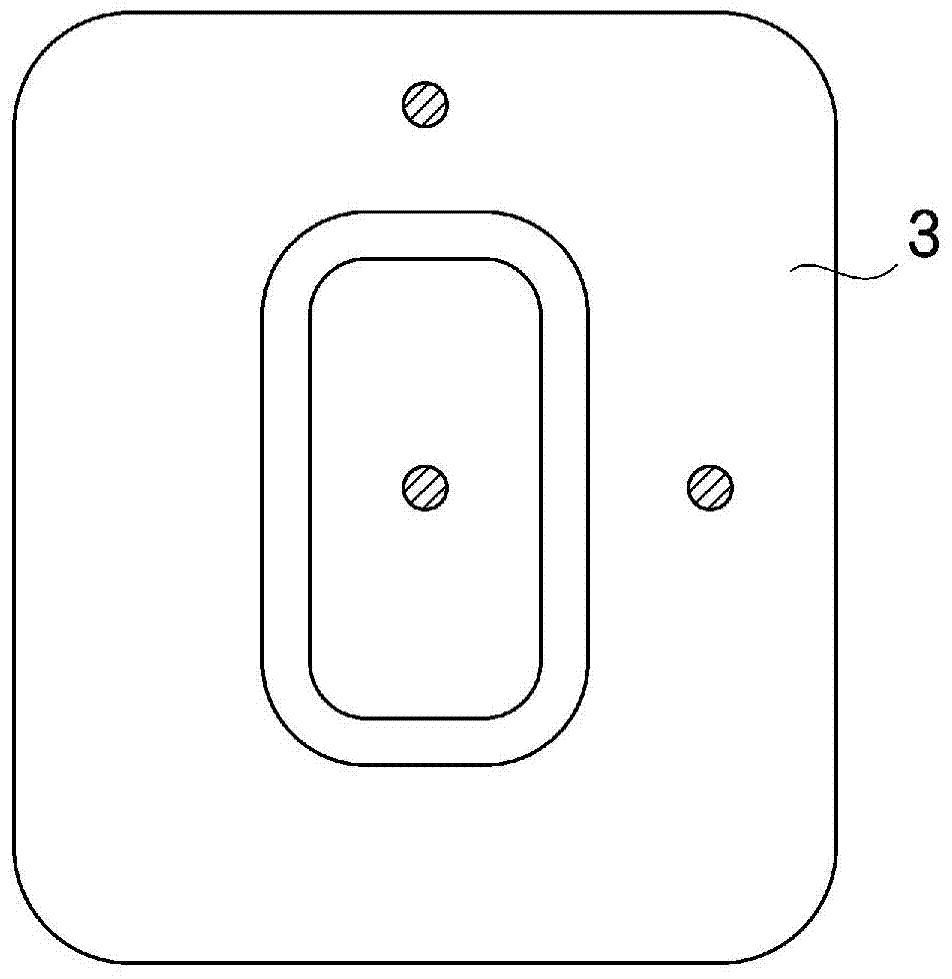

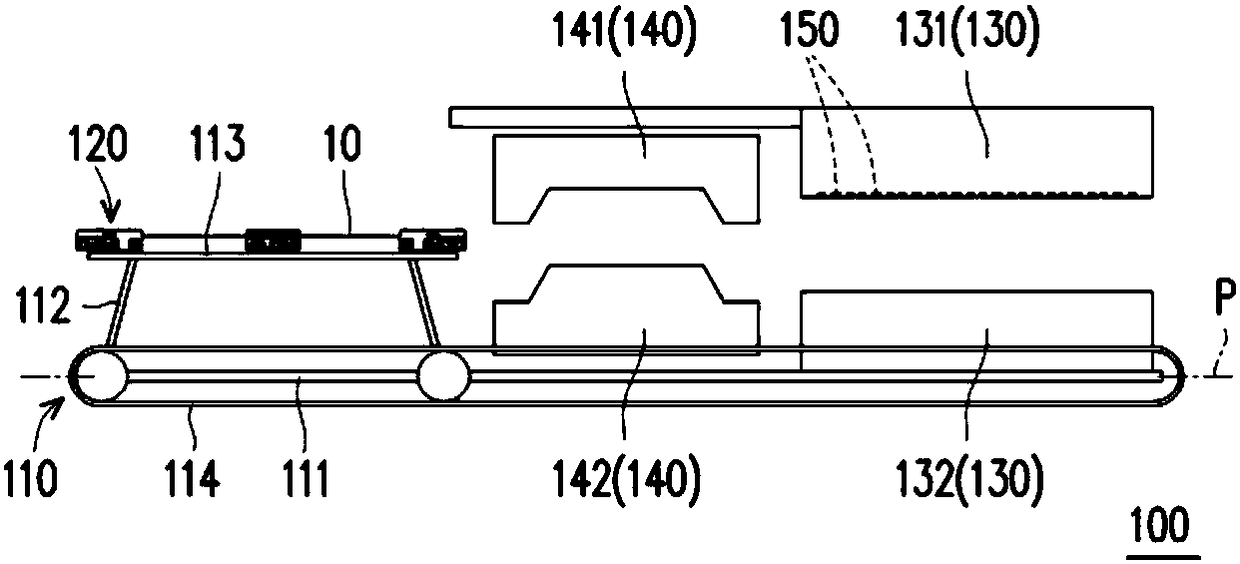

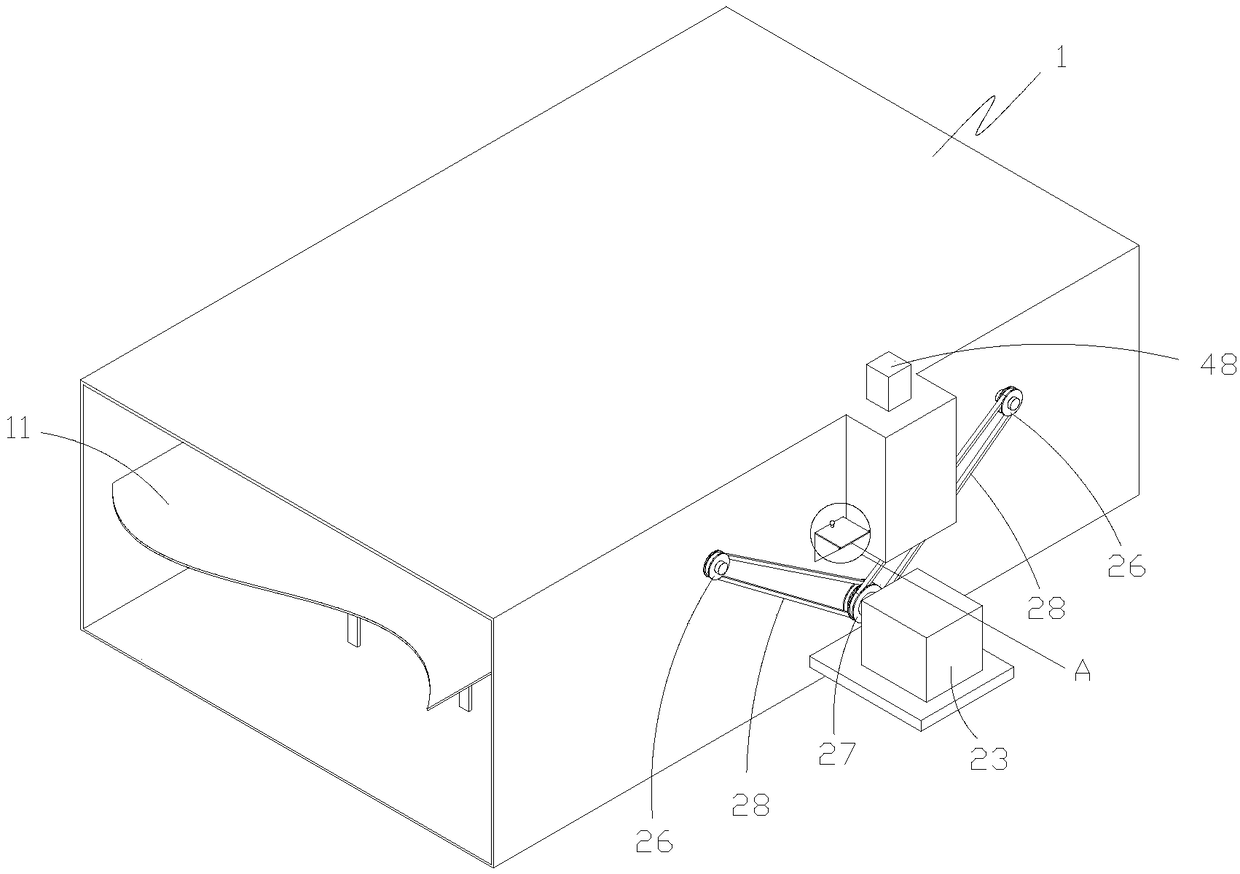

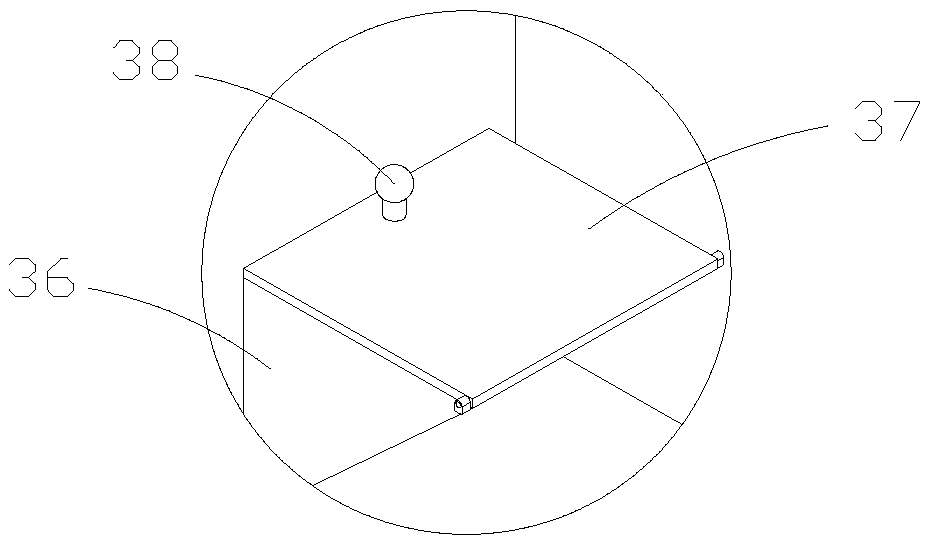

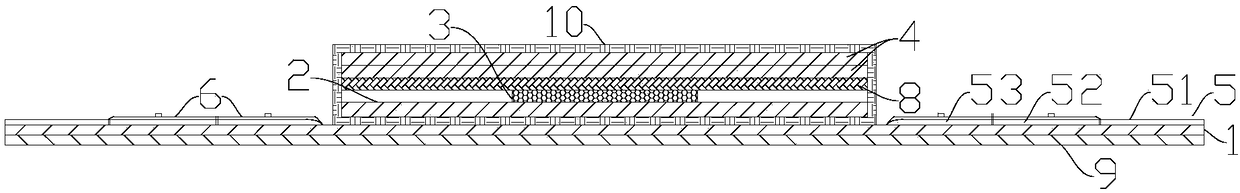

Netting device and netting method for mask template

ActiveCN106086784AStretch smoothlyAccurate adjustment effectVacuum evaporation coatingSputtering coatingEngineeringColor mixing

The invention provides a netting device and a netting method for a mask template, and belongs to the technical field of display, and the problem that red, green and blue devices are mixed in color due to the fact a current mask plate generates folding as a result of uneven tension can be solved. The netting device for the mask template adopts two pairs of first clamps to separately clamp and stretch four corners of the mask template; the edge of the mask template is clamped and stretched by a plurality of second clamps which are arranged between adjacent first clamps, so that the plurality of the second clamps realize precise regulating and control, and uniform stretching of the mask template, and therefore, netting capacity is improved, the mask template is not liable to generate folding, color mixing is reduced and a display yield is increased. The netting device for the mask template provided by the invention is suitable for stretching various mask templates, and is especially suitable for manufacturing the mask template of a small-dimension display panel.

Owner:BOE TECH GRP CO LTD +1

Pressure-sensitive adhesive covering material for application to skin

Provided is a pressure-sensitive adhesive covering material for application to the skin which is less apt to peel off from a part where the covering material has been applied, and which is less apt to crease and is suitable for use especially in the prevention and / or treatment of bedsore. The pressure-sensitive adhesive covering material for application to the skin is characterized in that it comprises a layered substrate obtained by superposing a knitted fabric on one side of a film and a pressure-sensitive adhesive layer formed on the film on its side opposite to the knitted fabric, and that the film has an elongation of 150-1,500% and the knitted fabric is formed from filaments having an elongation of 1-200%.

Owner:ALCARE CO LTD

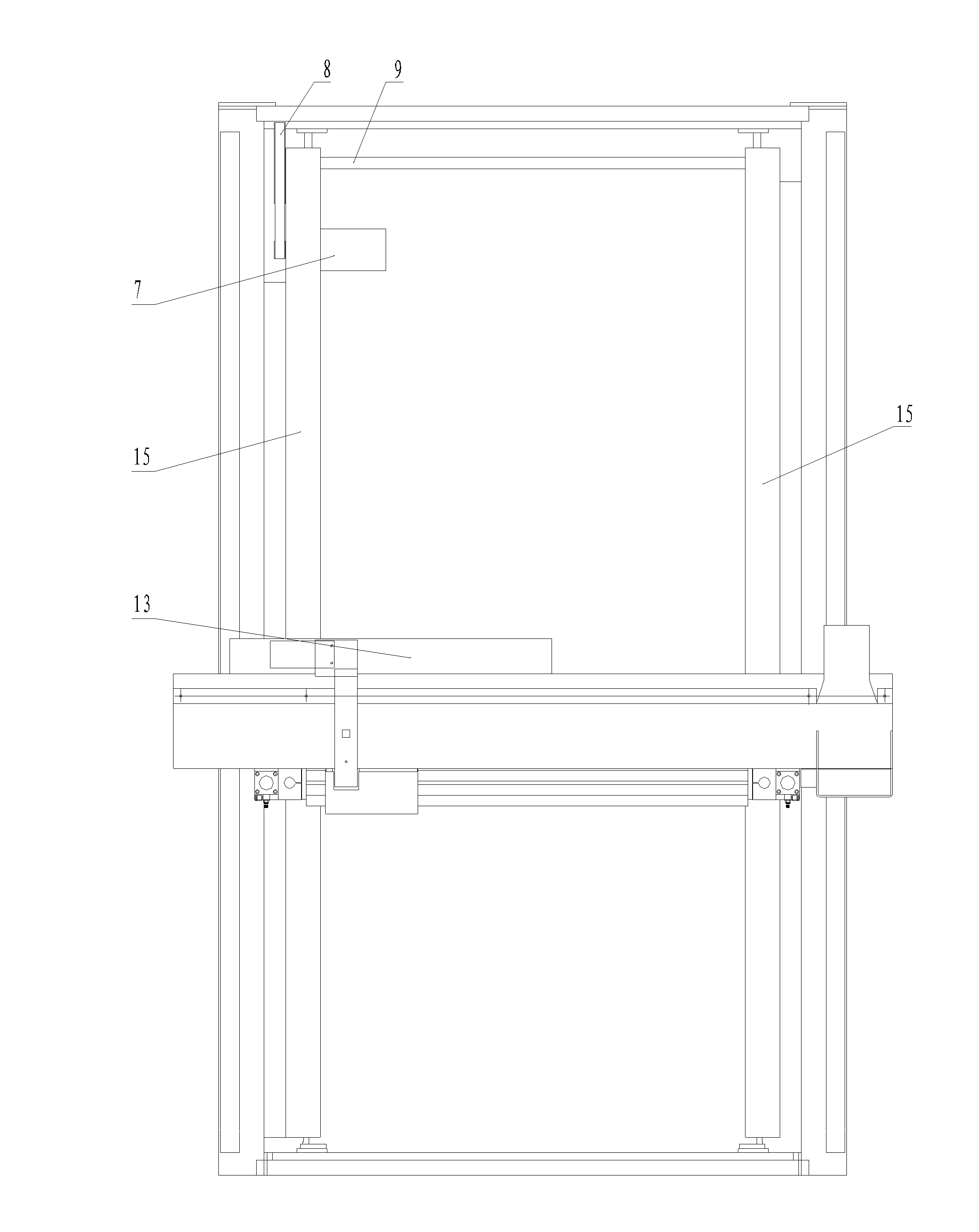

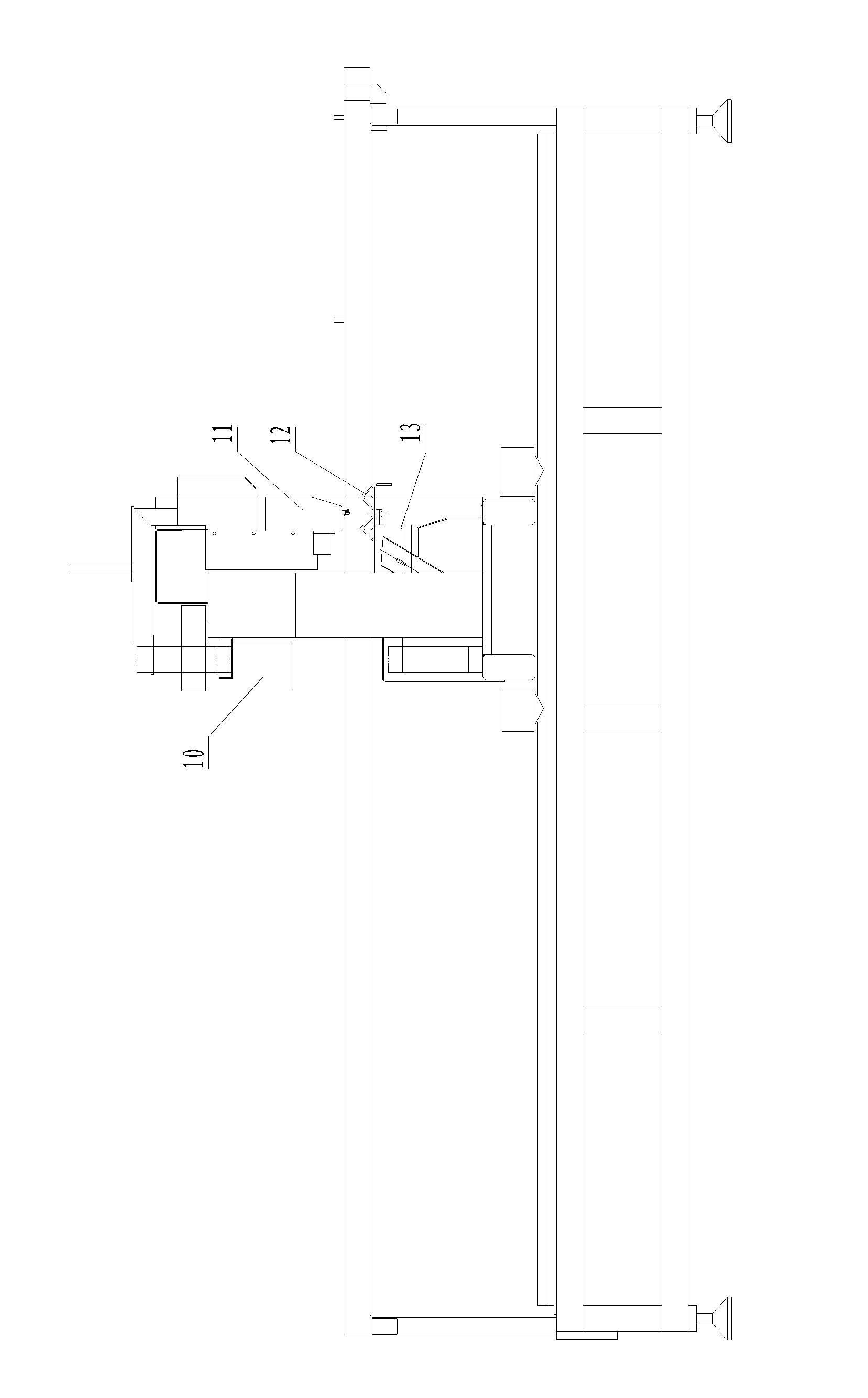

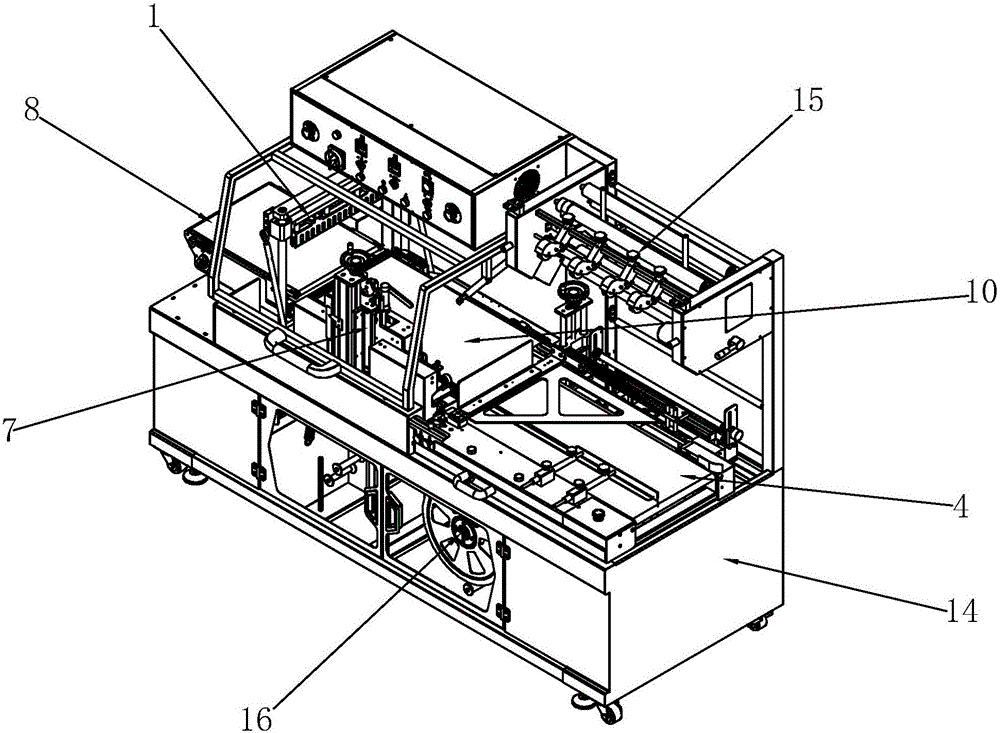

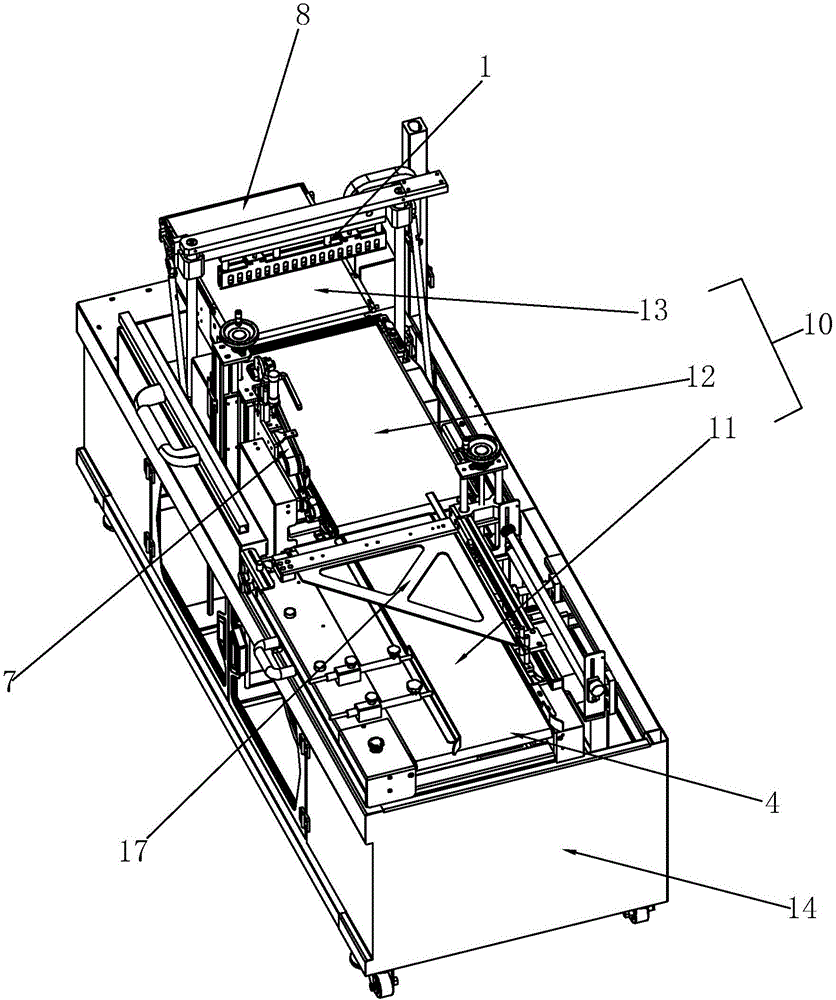

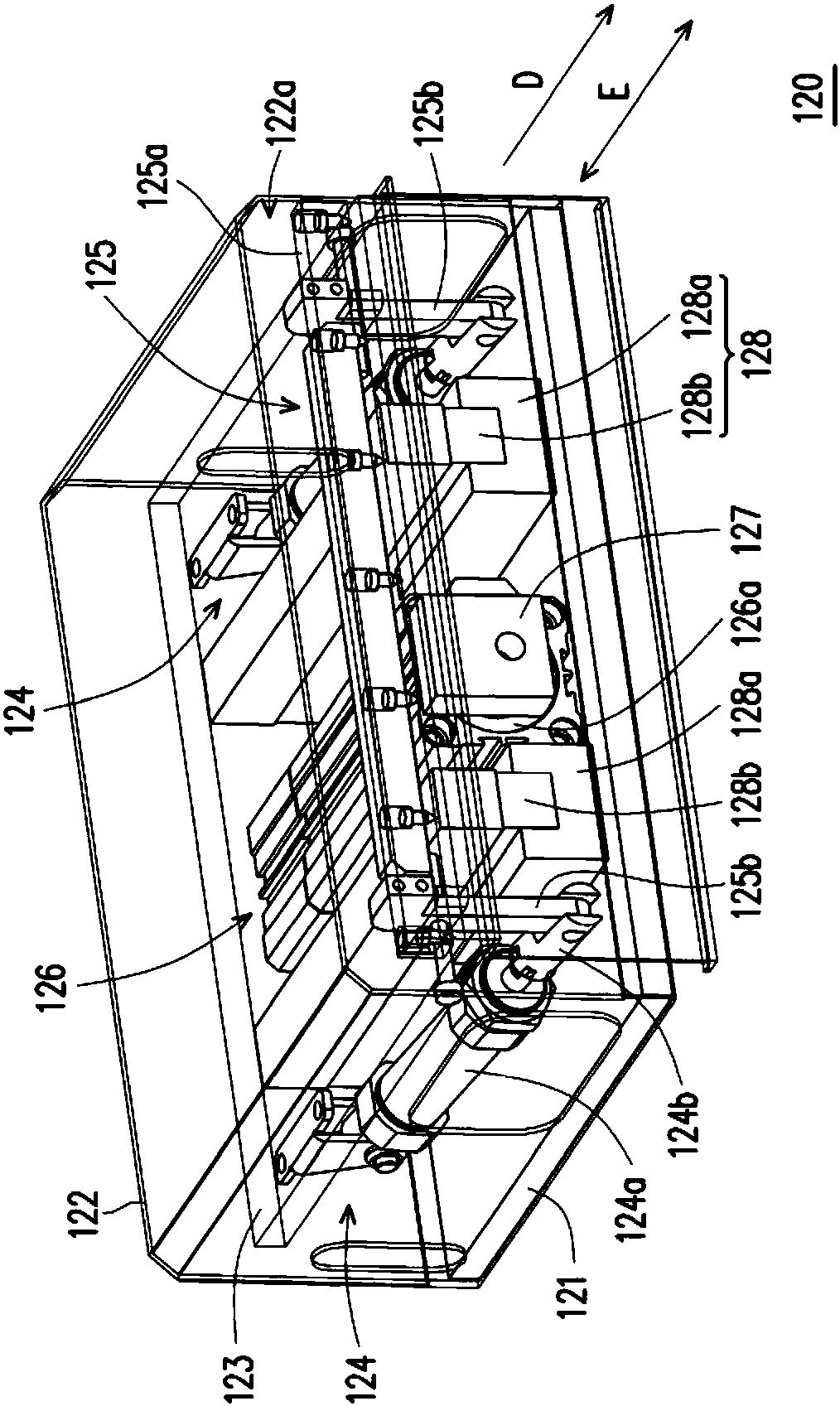

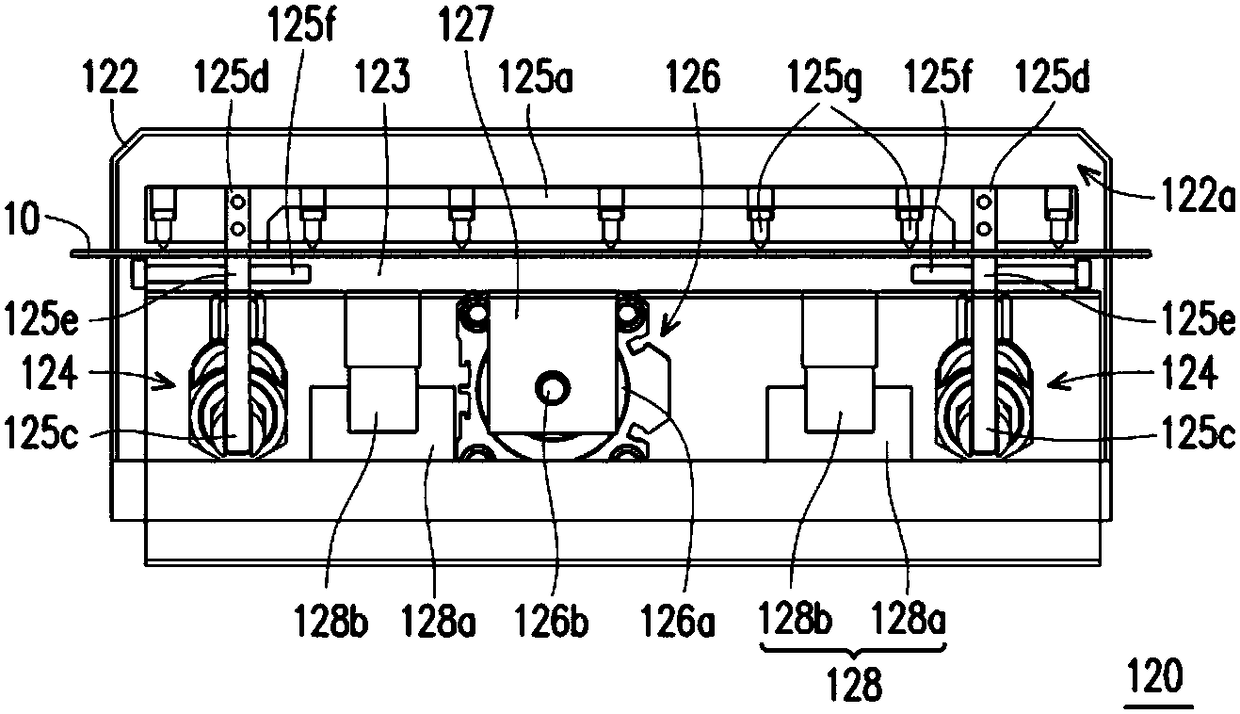

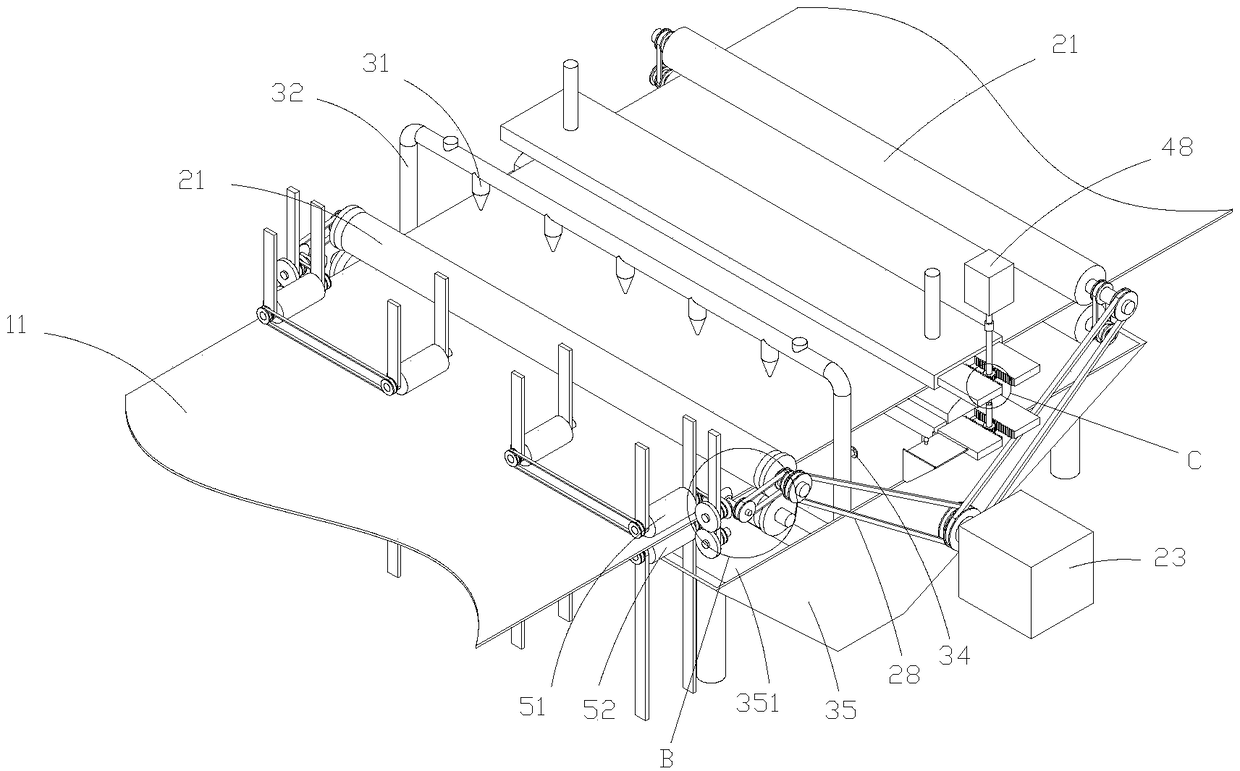

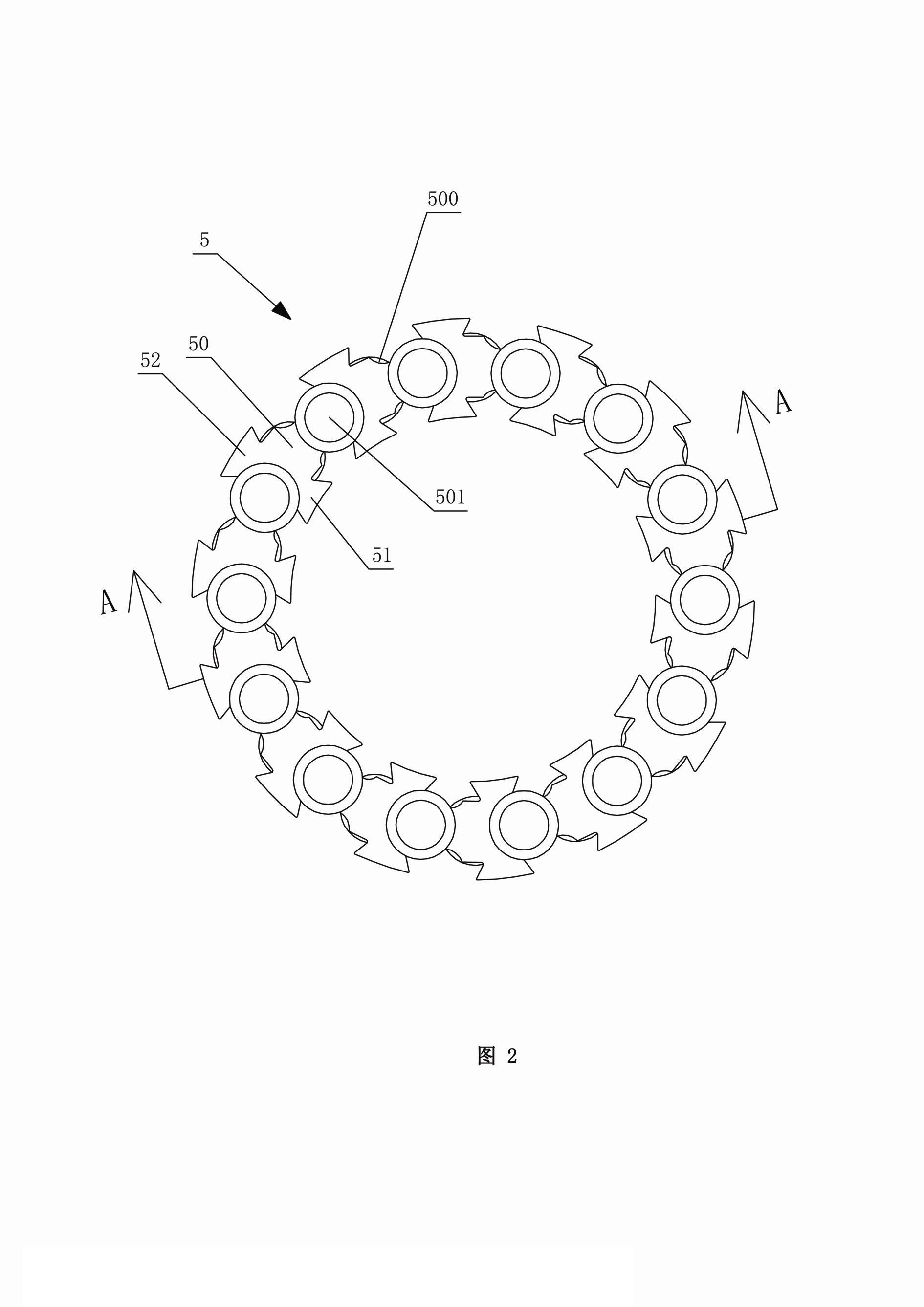

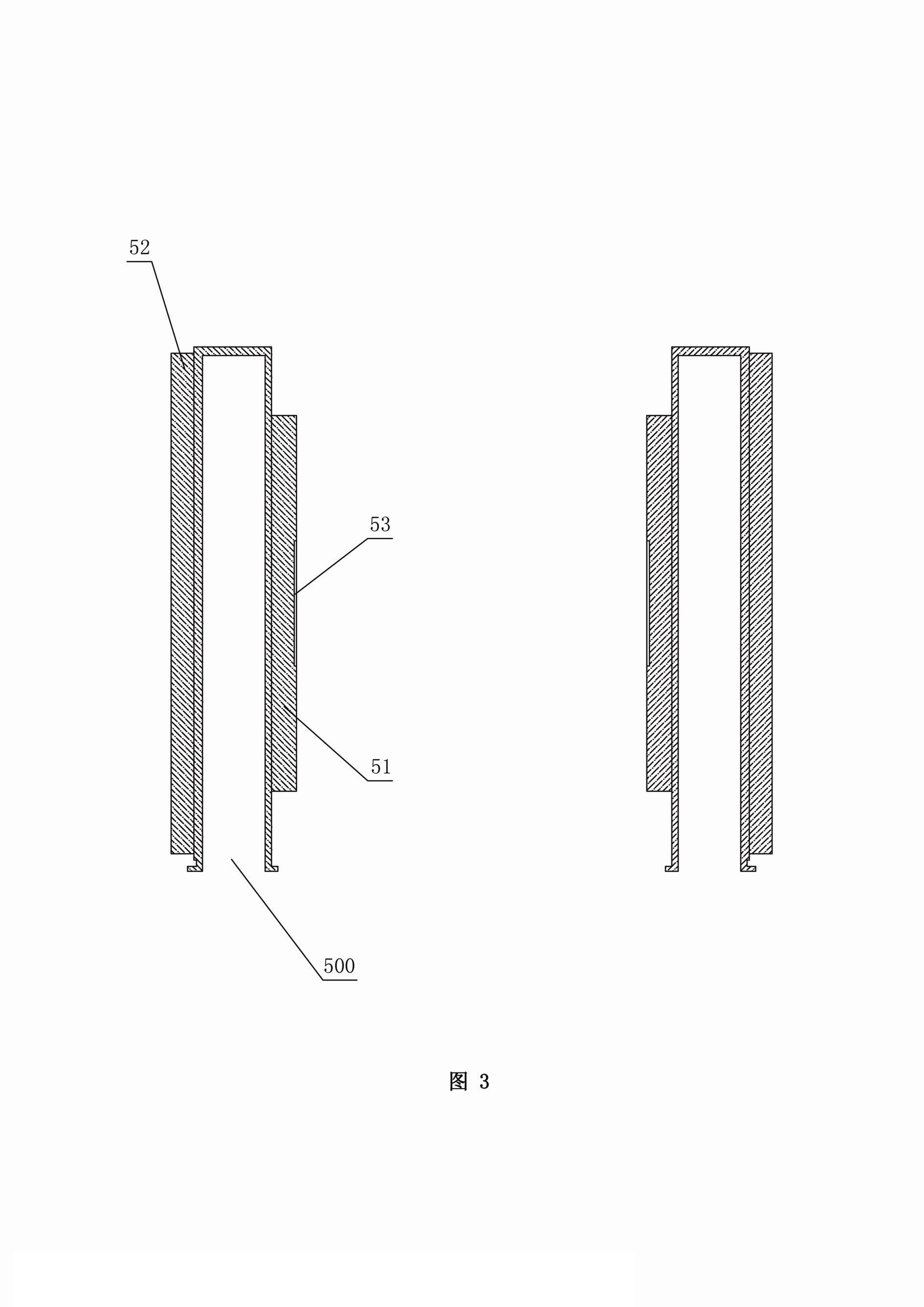

High-speed pad sewing machine

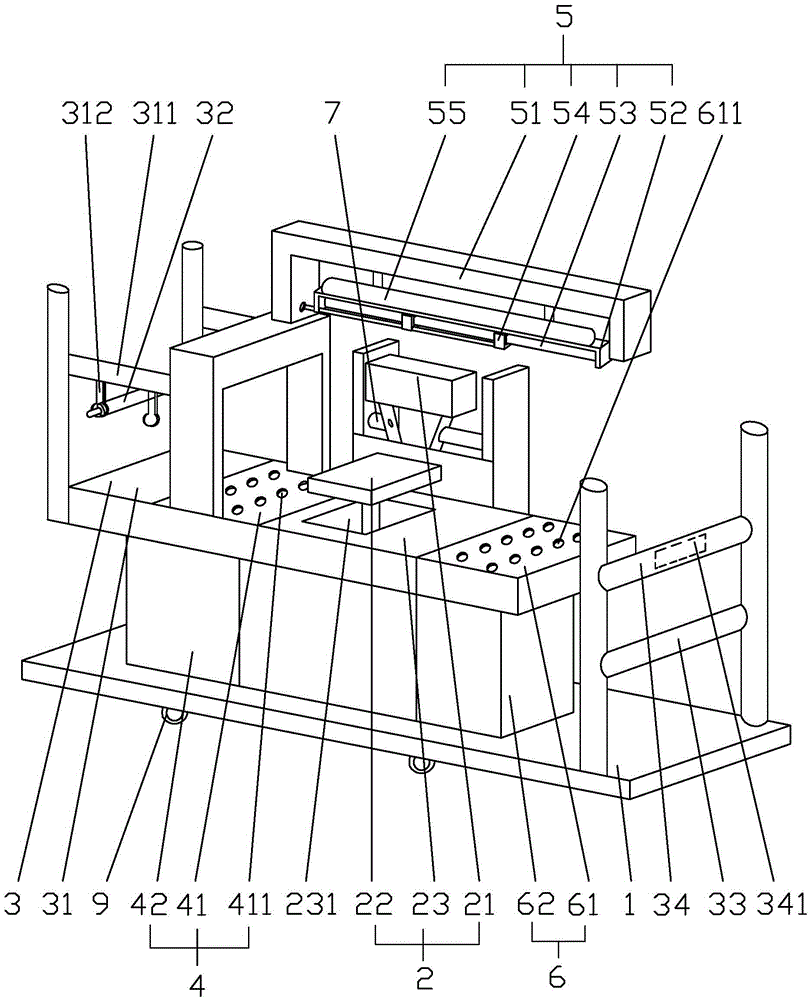

InactiveCN102535025ALess prone to wrinklesAvoid deformationProgramme-controlled sewing machinesWork-feeding meansEngineeringSewing machine

The invention discloses a high-speed pad sewing machine which comprises a gantry frame, a left lateral frame, a right lateral frame, a cylinder, an X directional guide rail, a machine head part, a pressing slot, a machine base part and a computer, wherein the left lateral frame and the right lateral frame are parallel and spaced from each other; a Y direction guide rail is arranged on the upper surface of each of the left lateral frame and the right lateral frame; two ends of the gantry frame are respectively arranged on the Y direction guide rails of the left lateral frame and the right lateral frame; the gantry frame is capable of sliding along the Y direction guide rails; the X directional guide rail is horizontally arranged on the gantry frame; the machine head part is sleeved on the X directional guide rail and is capable of sliding along the X directional guide rail; the machine base part is arranged at the lower part of the gantry frame and moves together with the gantry frame; the pressing slot is arranged above the machine base part; and the computer is used for controlling the movement of the gantry frame and the machine head part. According to the scheme of the invention, a Y directional stepping motor, an X directional stepping motor, a machine head motor and a machine base motor are controlled to move by the computer, so that the sewing processing is completely automated and the production efficiency is greatly increased.

Owner:苏州市正步机器制造有限公司

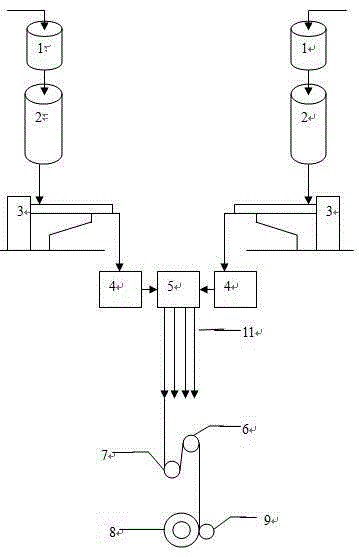

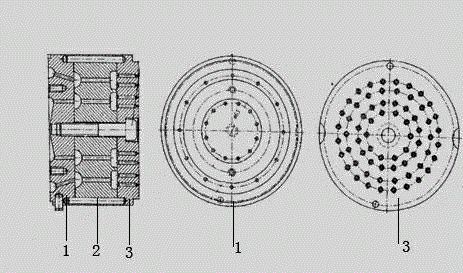

Single-spinneret-plate binary skin-core-type composite-spinning multiple-different-yarn production process

ActiveCN103060979AFeel novelIncrease elasticityNew-spun product collectionFilament forming substance formingYarnPolymer science

The invention relates to a single-spinneret-plate binary skin-core-type composite-spinning multiple-different-yarn production process. According to the production process, a composite spinning device including two secondary box bodies and one primary box body is used. Two different components, namely semi-dull (SD) slices and cationic slices (CD), undergo drying treatment, melting and metering treatment by means of respective drying equipment, screw rod extruders and the secondary box bodies, and then enter the primary box body to undergo spinning finish by means of a composite spinneret assembly to obtain combined medium oriented yarns (MOY), and then the combined MOY undergoes winding finish and elasticity finish to obtain finished products. Due to adoption of the technical scheme, fabrics which are novel in feel (wool feeling as an most obvious feeling, fluffy, full, flexible, crease resistant, good in elasticity, strong in three-dimensional performance, firm and the like), good in thermal-wet comfort, easy to maintain and good in performance can be manufactured.

Owner:SHAOXING UNIVERSITY +1

Fully automatic film sealing and cutting packing machine

ActiveCN105857667ALess prone to wrinklesConveyor levelingSuccessive articlesFully automaticEngineering

The invention discloses a fully automatic film sealing and cutting packing machine. The packing machine adopts the technical scheme that the packing machine comprises a main frame, a film feeding mechanism fixed on the main frame, and a conveying platform, with a feed end and a discharge end, arranged on the main frame, wherein a traction side sealing mechanism and a vertical sealing mechanism are arranged on the conveying platform; the vertical sealing mechanism is positioned on one side, facing the discharge end, of the traction side sealing mechanism. The invention aims at providing the fully automatic film sealing and cutting packing machine with the characteristics that a film is not easy to tear, and the sealing and cutting quality is good.

Owner:ZHEJIANG DINGYE MACHINERY

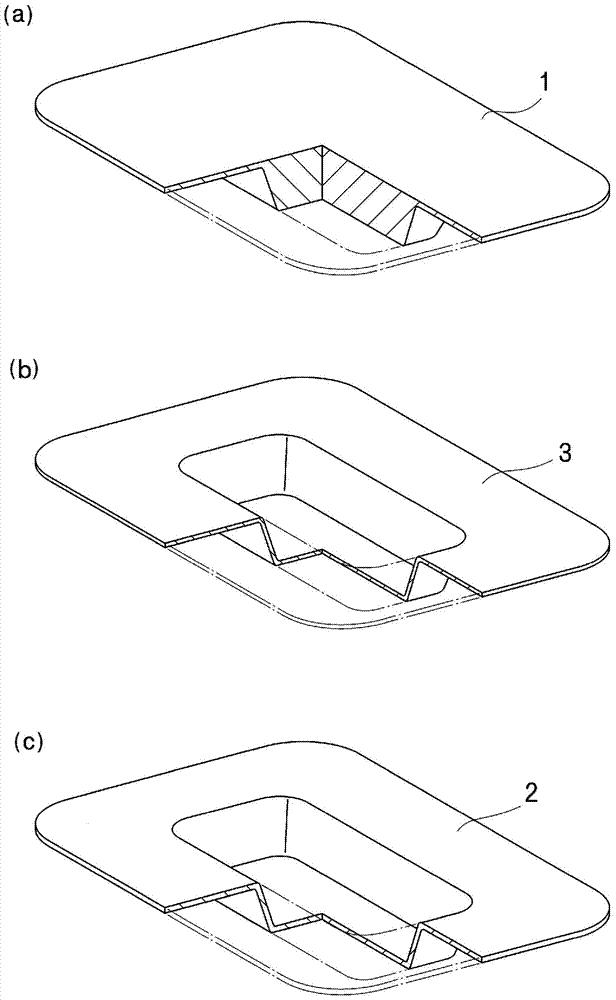

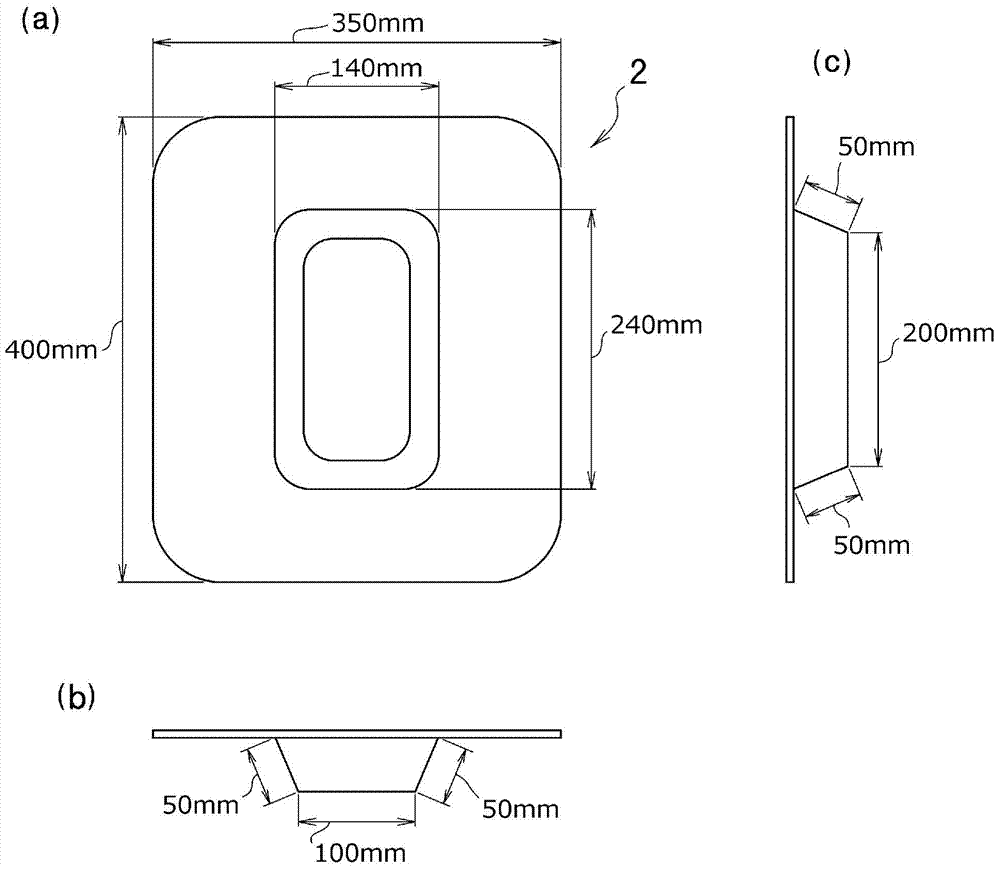

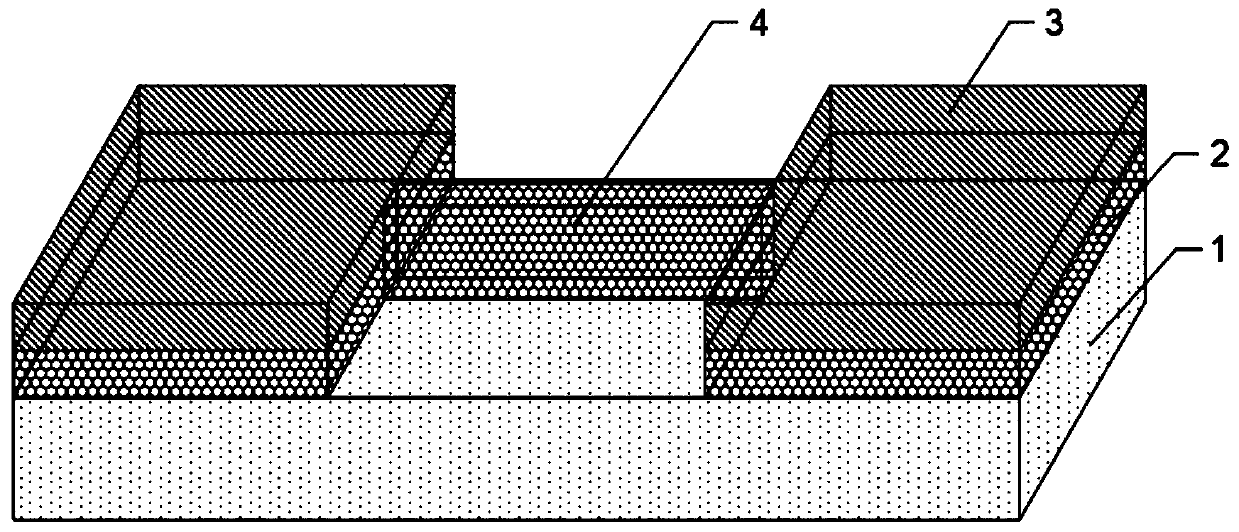

Nonwoven fabric for press molding, method for producing same, and method for producing molded article

InactiveCN103946433ALess prone to wrinklesWoven fabricsNon-woven fabricsPolymer scienceCrystallization temperature

Provided is a nonwoven fabric for press molding, and with the nonwoven fabric fiberboard-molding time is shorter and molded article quality is excellent, even in press three-dimensional molding, also provided is a molded article. The nonwoven fabric for press molding is a nonwoven fabric formed from polylactic acid fibers and natural fibers, and is characterized in that the melt crystallization temperature of polylactic acid fibers is 120 C or higher, the tensile strength of the nonwoven fabric is 20 N / cm2 or higher, and the nonwoven fabric tensile stress at 30% elongation in a 200 C atmosphere is 80 N / cm2 or less. The molded article uses the nonwoven fabric for press molding.

Owner:TORAY IND INC

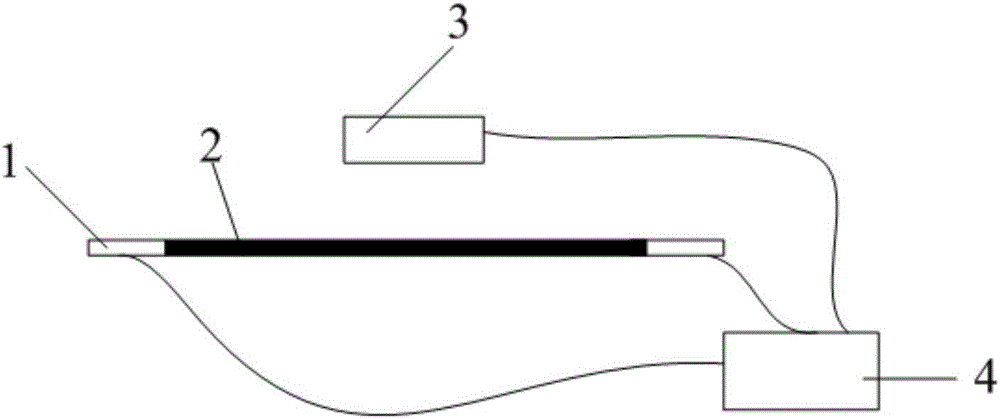

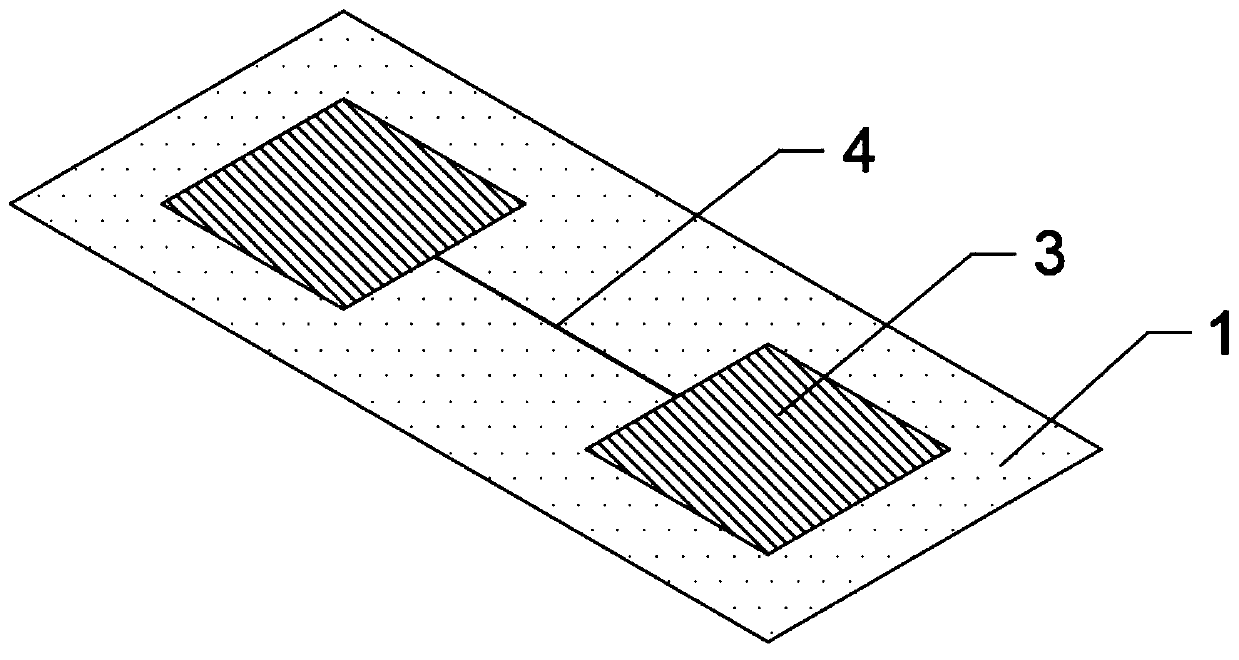

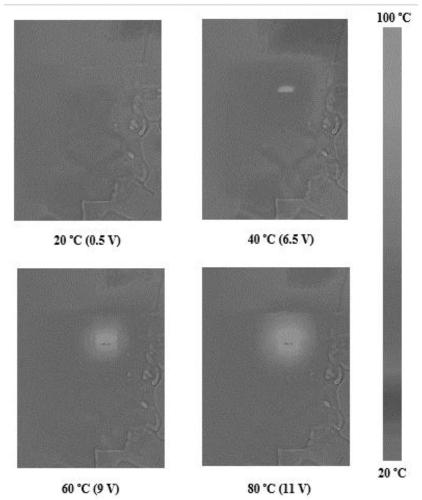

Preparation method of self-heating laser-induced graphene flexible NO2 gas sensor

InactiveCN111537575AFast response/recoveryGood repeatabilityGrapheneNanotechnologyPorous grapheneHigh energy

The invention relates to a preparation method of a self-heating laser-induced graphene flexible NO2 gas sensor. The gas sensor comprises an insulating region, an electrode region, a silver coating region and a gas sensitive region; the insulating region is arranged at the bottom end; the electrode region and the gas sensitive region are arranged on the upper surface of the insulating region; the silver coating region is arranged on the electrode connecting regions at the two ends of the electrode region; and the electrode region and the gas sensitive region are three-dimensional porous graphene patterns which are prepared through high-energy one-step induction of laser and have larger porosity structures. Due to the unique graphene three-dimensional structure size of the gas sensitive region, the step of additionally adding a gas sensitive material can be omitted, and gas adsorption with the same or even better effect is achieved. The method is beneficial to rapid desorption of NO2 gasmolecules, improves the use repeatability of the sensor, reduces the manufacturing cost, is short in manufacturing period and high in sensitivity, has the detection limit reaching 10ppb, and has a wide application prospect in the aspects of environmental monitoring and medical diagnosis.

Owner:HEBEI UNIV OF TECH

Fabric with low washing shrinkage rate and preparation process thereof

ActiveCN110774683AImprove wearing comfortGood skin affinitySynthetic resin layered productsGrip property fibresYarnPolymer science

The invention relates to the technical field of clothing fabrics, in particular to a fabric with low washing shrinkage rate and a preparation process thereof. The fabric is formed by weaving of a composite yarn, the composite yarn is formed by laminating a surface yarn, an elastic fiber yarn and a bottom yarn, after lamination shaping, the surface yarn forms a surface layer, the elastic fiber yarnforms an elastic middle layer, and the bottom yarn forms a base layer; the surface yarn is unshrinkable wool fiber with a metric number of 1 / 80Nm-1 / 60Nm and a count of 90S; the elastic fiber yarn islow-temperature spandex with Denier of 30-60D; and the base yarn is polypropylene fiber with Denier of 45-75D and a hole count of 45-75F. By adopting the three yarn fibers for blending weaving, the prepared fabric includes three sequentially formed yarn layers, and the middle layer has elasticity, thus improving the wearing comfort and skin friendliness of the fabric, and the fabric has the functions of environmental protection, warmth retention, machine washability, no ironing and the like, does not generate stuffiness and skin-sticky feel, is comfortable to wear, and low in washing shrinkagerate.

Owner:DONGGUAN SENLIN TEXTILE LTD

Dyeing and finishing process of double-layer down-proof fabric

InactiveCN105755869ALess damageFeel goodHeating/cooling textile fabricsDry-cleaning apparatus for textilesFiberEngineering

The invention relates to a dyeing and finishing process of double-layer down-proof fabric. The dyeing and finishing process comprises the following steps: desizing, dyeing, setting and drying and waterproof setting, wherein the loose type continuous desizing is adopted. On one hand, through the used loose type continuous desizing, the crease generation probability is reduced; on the other hand, through temperature rise control and active driving performed by a variable frequency motor, the fabric crease generation probability is ensured to be reduced while the fabric shrinks in a relaxed state, so that the damage caused to fibers is minimized in the reduction process. According to the double-layer down-proof fabric prepared by the process, the user demands on air permeability, hand feeling and other aspects are met while the down-proof performance of the double-layer down-proof fabric can also be ensured.

Owner:WUJIANG FUHUA WEAVING

Dyeing process of T/R cloth

The invention discloses a dyeing process of T / R cloth. The process comprises the steps of grey cloth preparation, pre-shaping, singeing, enzyme processing, washing, dispersion priming, dyeing, color fixing, post-treating, product inspecting, and packaging. According to the invention, with the added pre-shaping step, crinkle marks can hardly form during a cloth dyeing process, and unit-area mass, washing shrinkage, and the like of a fabric can be stabilized. Therefore, product stability is promoted. The process provided by the invention is simple, such that the process is suitable for industrialized productions.

Owner:TAICANG MINGLIU GARMENT

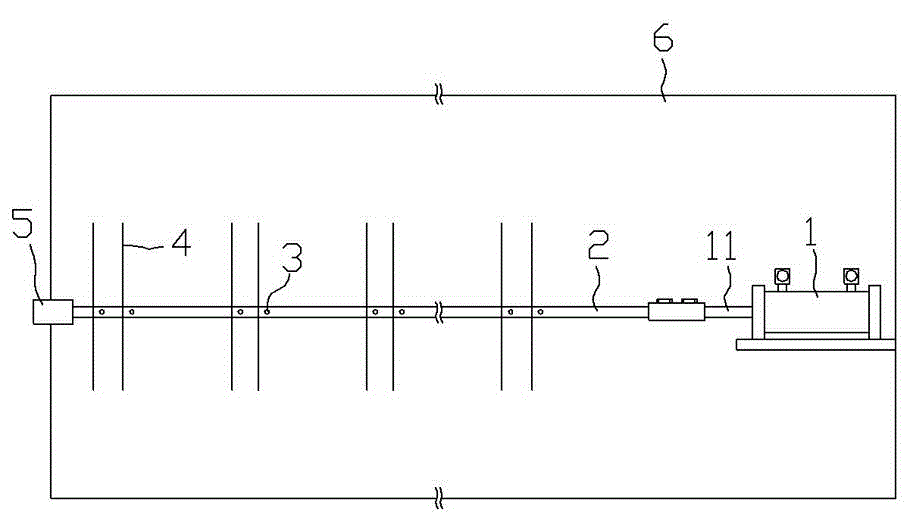

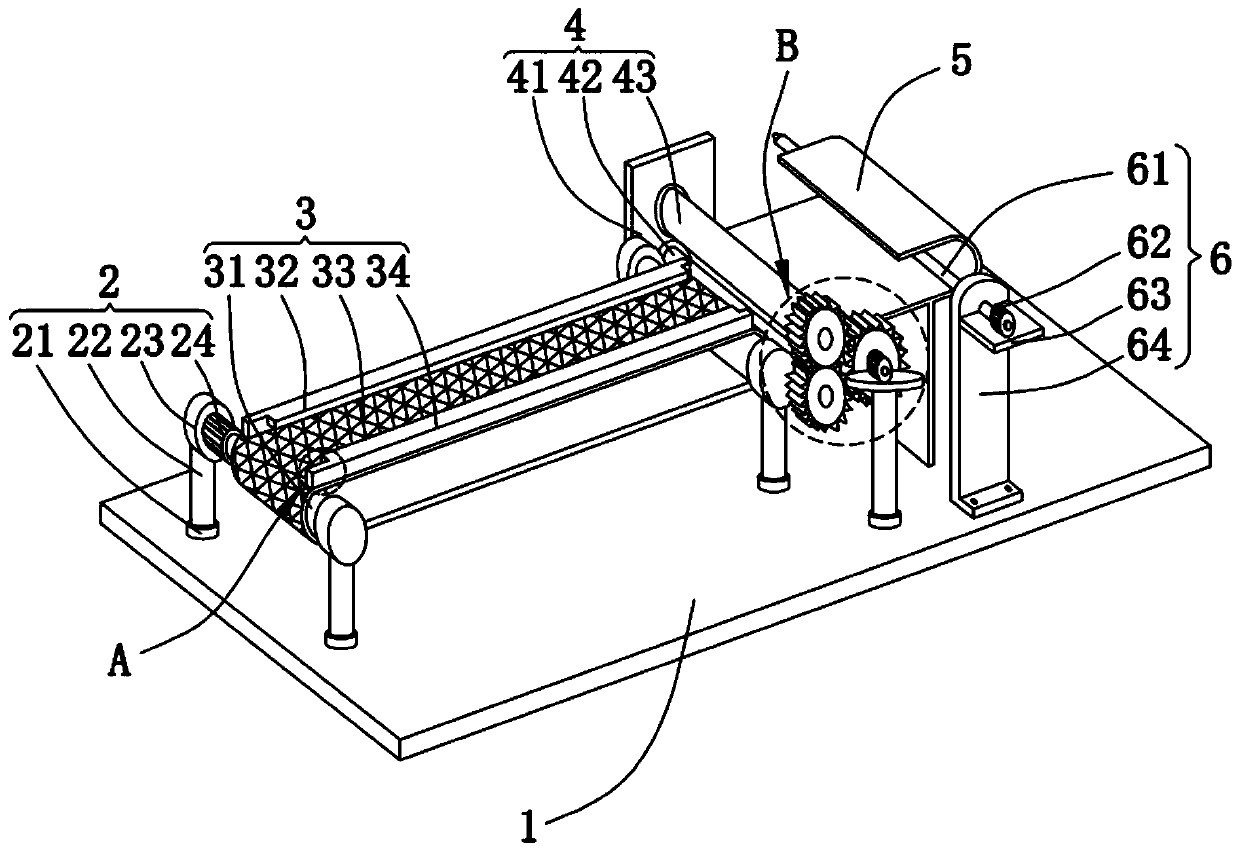

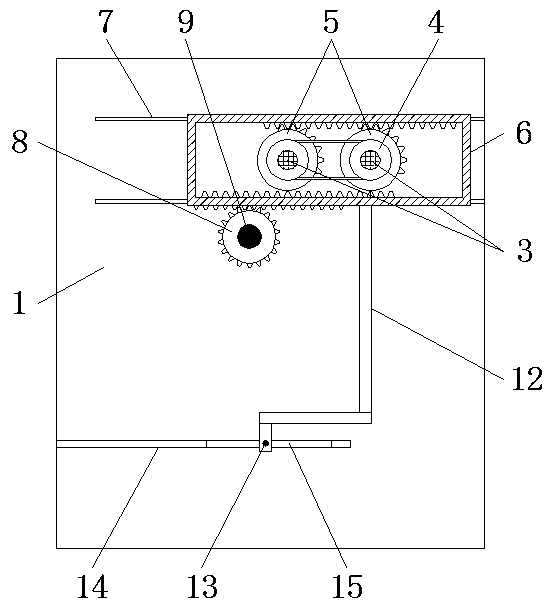

Fabric inspecting and rolling machine

ActiveCN109879098AConvenient inspectionLess prone to wrinklesInspecting textilesWebs handlingEngineeringMechanical engineering

The invention relates to the technical field of needle textile machines, in particular to a fabric inspecting and rolling machine. An installing bottom plate, a supporting mechanism, a conveying mechanism, a flattening mechanism, a guiding plate and a winding mechanism are included; the conveying mechanism is installed on the top of the supporting mechanism; the flattening mechanism is fixedly installed on one side, on the top face of the installing bottom plate, of the conveying mechanism; and the winding mechanism is fixedly installed on the side, deviating from the conveying mechanism on the top face of the installing bottom plate, of the flattening mechanism. According to the fabric inspecting and rolling machine, due to the fact that a conveying belt is wound and connected to two conveying belt shafts in a sliding manner, fabric is can be completely unfolded on the conveying belt, so that a user can conveniently inspect the fabric; and meanwhile, one end of one of the conveying belt shafts is rotationally connected with a conveying driving motor so that the fabric can freely rotate along with the conveying belt, and inspection on the fabric is further facilitated.

Owner:叶建华

Paper drying equipment

InactiveCN107270684AGuaranteed smoothAvoid recondensationDrying gas arrangementsDrying machines with progressive movementsPaper tapePulp and paper industry

The invention discloses paper drying equipment. The equipment comprises a paper tape and a drying device, wherein drying devices are both arranged on an upper side and a lower side of the paper tape; a group of extrusion roller shafts are arranged on a left side of

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

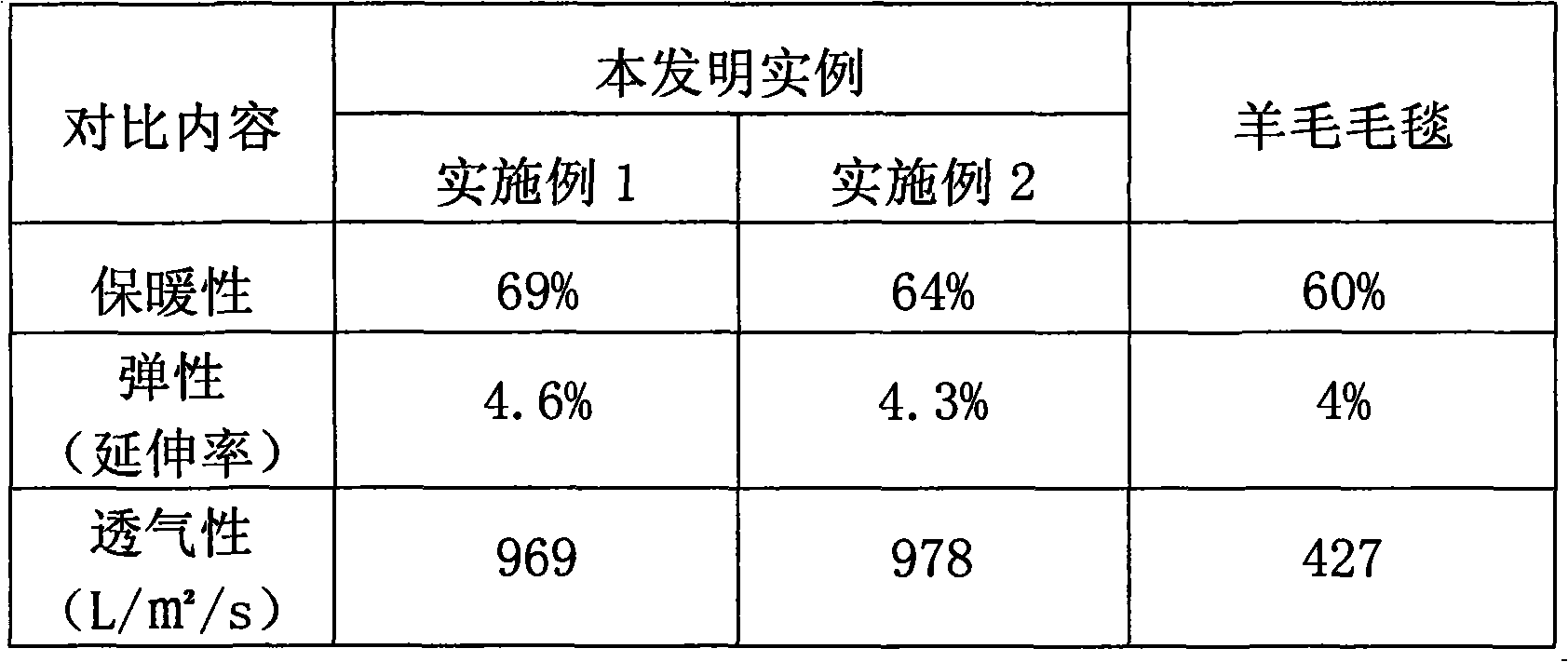

Terylene wool-like blanket and preparation method thereof

The invention relates to a terylene blanket and the technical field of the preparation method thereof. For the terylene wool-like blanket of the invention, the surface filament is HFY filament compounded with POY and FDY, and the bottom filament is FDY terylene filament of 50-150dtex. The terylene wool-like blanket of the invention changes the traditional process procedure both in raw materials and in preparation method and synthesizes suitable fiber raw materials, brand new preparation procedure and equipment, and the woven blanket has smooth suede and does not need neatening; the finished product has stable gram weight, strong stereoscopic impression of suede, expected effect of hair height, soft and flurry hand feeling, good hygroscopicity, no unhairing phenomenon and bright color, can directly contact with skin and is sure to get the favour of people.

Owner:徐建平

Multi-layer tube

InactiveCN1650126AHigh melt adhesionWon't peel offSynthetic resin layered productsFlexible pipesPolymer scienceHexafluoropropylene

Owner:SAMSUNG GROUP

Treatment method for inner surface of steel high pressure gas cylinder for high purity gas

InactiveCN106002644AImprove the finishNot easy to wrinkleGrinding/polishing apparatusGrindingHigh pressure gas

The invention discloses a treatment method for an inner surface of a steel high pressure gas cylinder for a high purity gas. The treatment method comprises the steps of cleaning drying treatment, shot blasting treatment, secondary cleaning drying treatment, grinding treatment and tertiary cleaning drying treatment. According to the treatment method, in the grinding treatment step, when the steel high pressure gas cylinder and a polishing tube relatively rotate, the polishing tube sprays a mixed liquid of polishing powder and a grinding liquid to the inner surface of the steel high pressure gas cylinder to sequentially carry out coarse grinding, fine grinding and polishing on the inner surface of the steel high pressure gas cylinder, so that the degree of finish and purity of the inner surface of the steel high pressure gas cylinder are effectively guaranteed, and the purity and long-term stability of the accommodated high purity gas can be effectively guaranteed.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

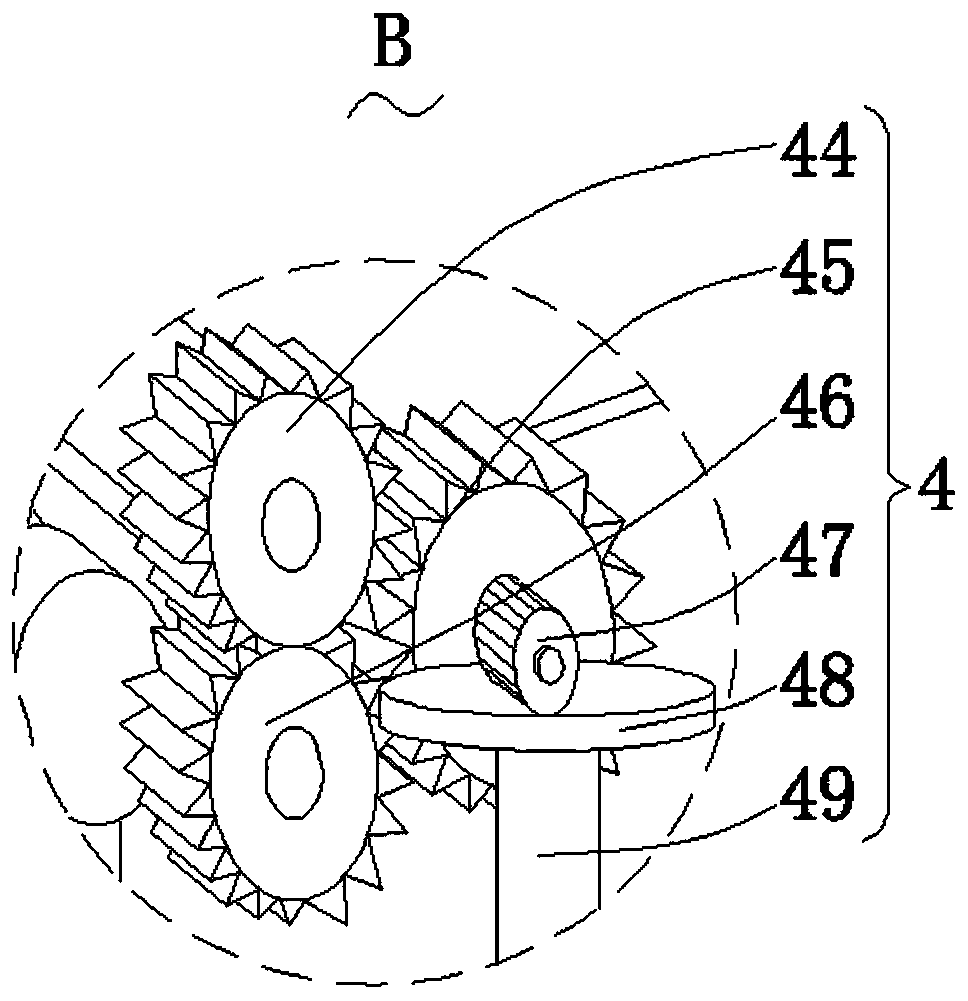

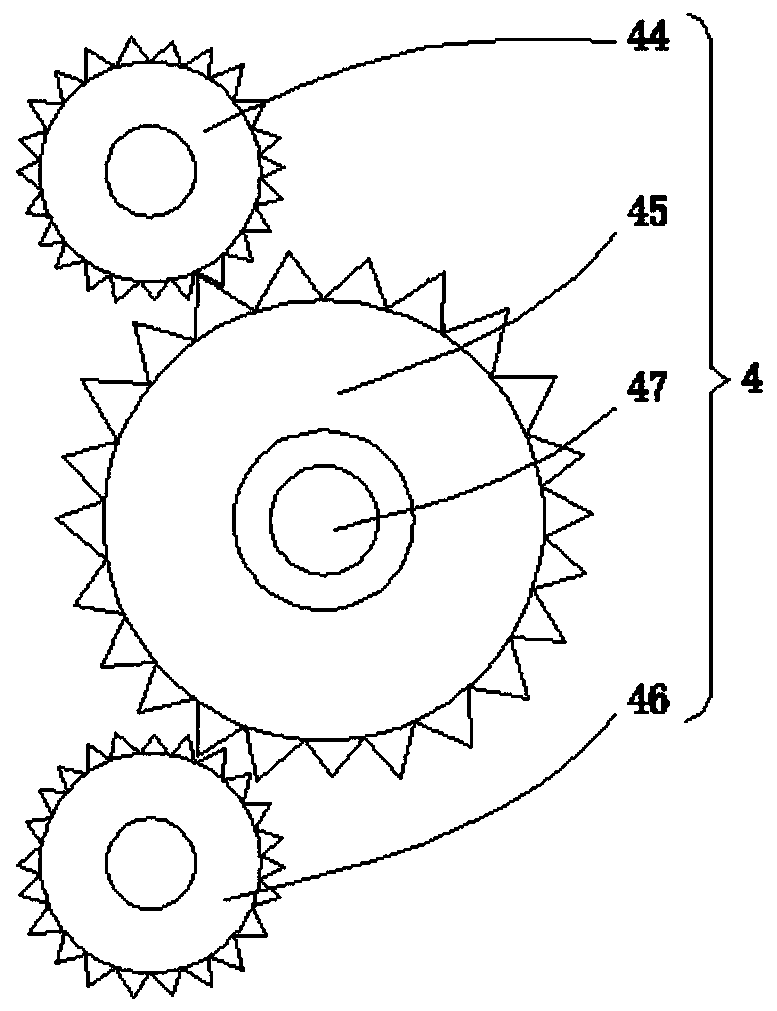

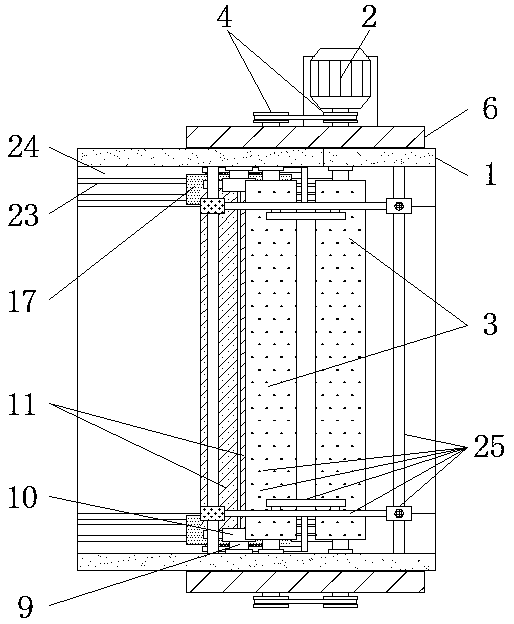

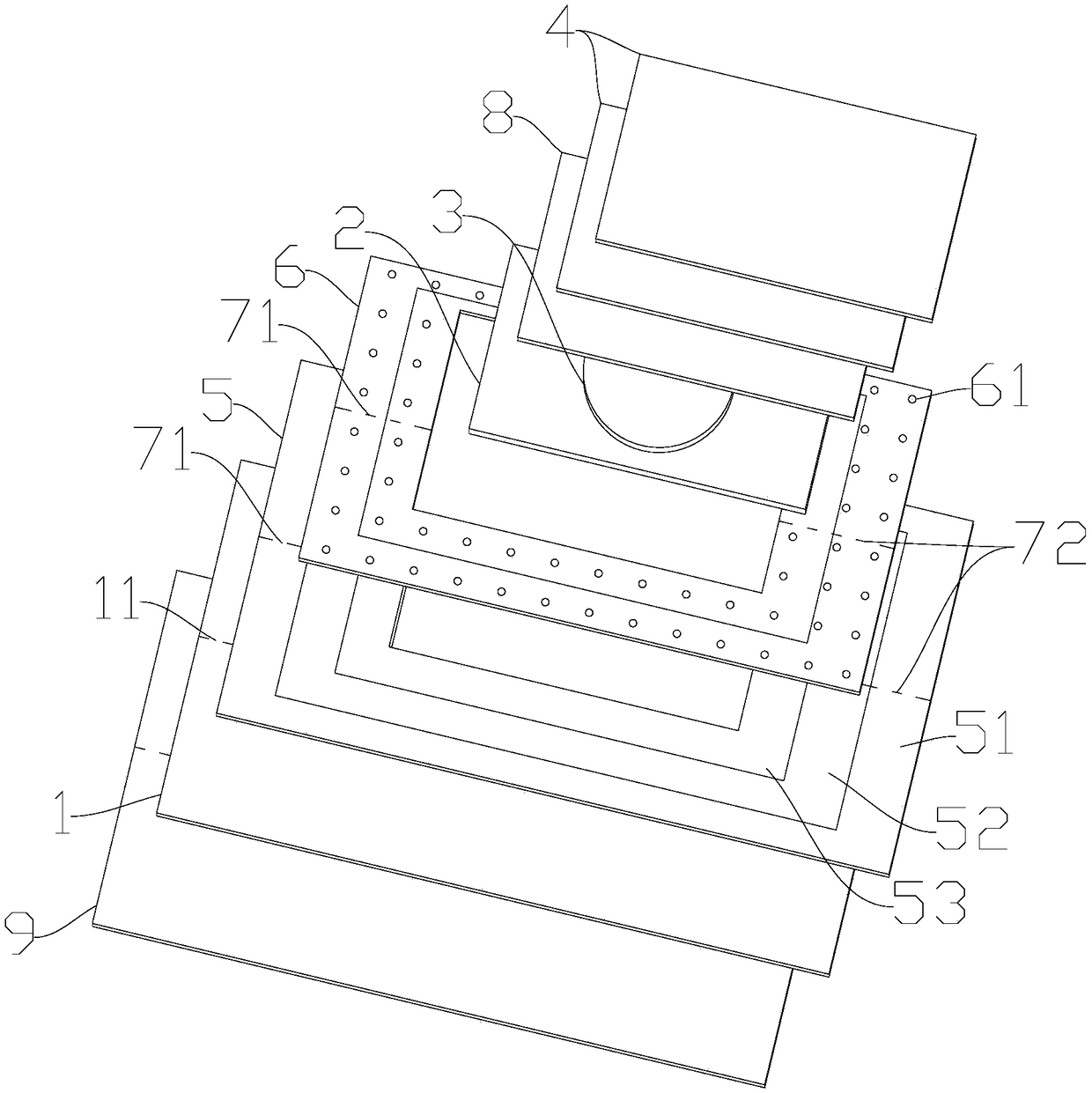

Integrated linking cloth arrangement device used for bag fabric processing

ActiveCN110733914ANeatly stackedLess prone to wrinklesGearingFolding thin materialsElectric machineryElectrical and Electronics engineering

The invention discloses an integrated linking cloth arrangement device used for bag fabric processing. The integrated linking cloth arrangement device comprises a frame plate, a control motor, cloth loosening roller bodies, a belt transmission mechanism and a limiting mechanism body. The control motor is fixed to the outer side of the frame plate. A working nail is fixed to the outer side of a functional block and penetrates through a trigger plate. A first inner gear is connected with a second inner gear, and the second inner gear is installed in the functional block. Shifting columns are fixed to the second inner gear and a fourth inner gear. The functional block is connected with a bottom groove which is formed in the upper end face of a base plate, and the base plate is fixed to the inner wall of the frame plate. According to the integrated linking cloth arrangement device used for bag fabric processing, the novel structural design is adopted so that auxiliary shifting of fabric can be achieved when the fabric swings leftwards and rightwards, it is guaranteed that the leftward movement amplitude and the right movement amplitude of the fabric are the same, and the fabric can bestacked in order; and because auxiliary shifting and limiting of the fabric are carried out when the fabric moves leftwards and rightwards, wrinkles of the fabric are unlikely to be generated.

Owner:浙江三强塑胶有限公司

Manufacturing apparatus and manufacturing method of plastic component

InactiveCN108215133ANot easy to wrinkleImprove quality and yieldMechanical conveyorsMoulding deviceEngineering

Owner:SWANCOR INDSWANCOR IND CO LTD +1

Spray dyeing machine for fabric dyeing

ActiveCN109295630AAffect the dyeing effectAvoid wastingTextile treatment by spraying/projectingTextile treatment carriersMechanical engineeringDyeing

The invention discloses a spray dyeing machine for fabric dyeing. The spray dyeing machine comprises a rack, a material roller capable of moving back and forth, a collecting roller capable of moving back and forth, a driving device for driving fabric to move and a spraying device for spraying dyeing liquid; the spraying device comprises a sprayer, a spraying pipe communicated with the sprayer anda conveying piece communicated with the spraying pipe; the rack is provided with a smearing device for evenly smearing the dyeing liquid on the fabric and a flattening device for flattening the fabric. According to the spray dyeing machine for fabric dyeing, through the arrangement of the smearing device, the dyeing liquid sprayed onto the surface of the fabric is evenly smeared so that the fabriccan be evenly dyed, and the effect of dyeing the fabric is greatly improved.

Owner:SHAOXING UNIVERSITY

Woundplast

PendingCN108056856AUse diversificationPaste effect is goodElectrotherapyAdhesive dressingsChinese charactersEngineering

The invention relates to a woundplast. The woundplast includes viscose cloth, blood sucking cotton, a magnetic sheet and an anti-adherent film. The blood sucking cotton, the magnetic sheet and the anti-adherent film are sequentially arranged on the middle of the viscose cloth from bottom to top; the periphery of the viscose cloth is provided with release paper, the release paper includes a first release-paper segmented piece, a second release-paper segmented piece and a third release-paper segmented piece; the first release-paper segmented piece, the second release-paper segmented piece and the third release-paper segmented piece are in a shape like the Chinese character 'hui'. The release paper is composed of several release-paper segmented pieces, a user can selectively uncover the outermost first release-paper segmented piece according to the skin characteristics when the user uses the woundplast, the first release-paper segmented piece and the second release-paper segmented piece are uncovered or the first release-paper segmented piece, the second release-paper segmented piece and the third release-paper segmented piece are uncovered, and the woundplast is more diverse in use.Meanwhile, the release-paper segmented pieces are in a shape like the Chinese character 'hui', the sticky area on the viscose cloth torn down from the release-paper segmented pieces is distributed onthe periphery of the woundplast, and the sticky effect is good.

Owner:武汉明康医疗器械有限公司

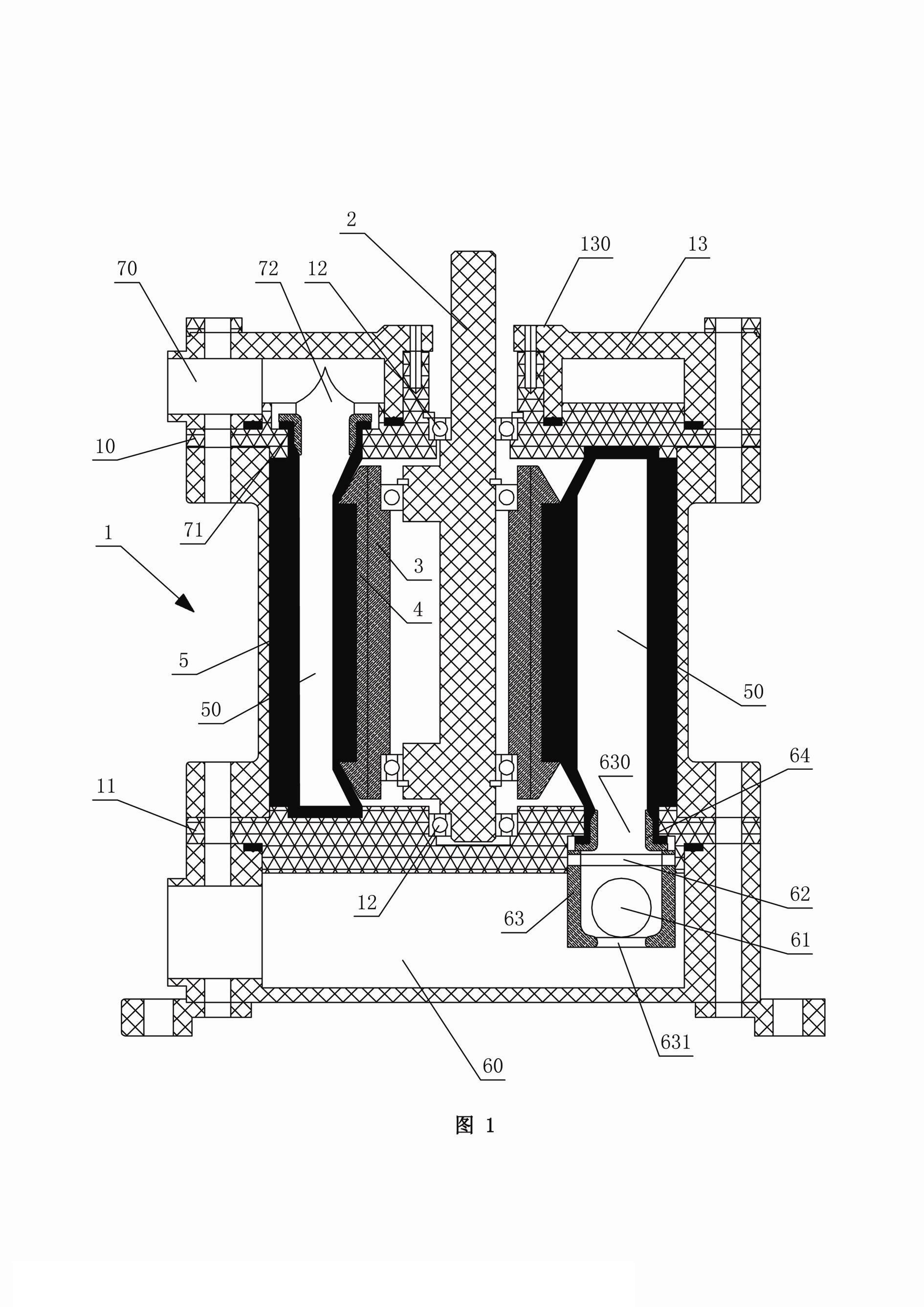

Leakage-free special pump

ActiveCN102606456AIdeal structural designLess prone to wrinklesPositive displacement pump componentsFlexible member pumpsInlet valveEngineering

A leakage-free special pump comprises a pump body, an eccentric shaft, an inner movable sleeve, an outer movable sleeve, an upper cover inner plate, a lower cover inner plate and a cylindrical capsule, wherein the eccentric shaft, the inner movable sleeve, the outer movable sleeve, the upper cover inner plate, the lower cover inner plate and the cylindrical capsule are disposed in the pump body. The capsule is provided with a plurality of capsule cavities in radial arrangement, the eccentric shaft is bridged between the upper cover inner plate and the lower cover inner plate through a bearing, and the inner movable sleeve and the outer movable sleeve are both sleeved inside and outside the eccentric shaft respectively. The capsule is mounted between the inner wall of the pump body and the outer movable sleeve, and a water inlet pipe opening and a water outlet pipe opening of each capsule cavity are correspondingly communicated with a water inlet valve assembly and a water outlet valve assembly on the pump body. The inner wall of the pump body is provided with an outer dovetail groove, the outer lateral wall of the outer movable sleeve is provided with an inner dovetail groove, and the inner lateral wall and the outer lateral wall of the capsule are provided with an inner dovetail protrusion and an outer dovetail protrusion which are in inserting fit with the inner dovetail groove and the outer dovetail groove respectively. The leakage-free special pump is satisfactory in structural design, water sucked in the capsule is high in quantity by forcedly stretching and extruding the capsule, and integral performance of the pump body is improved.

Owner:FUJIAN GENEROUS SLEEP TECH CO LTD

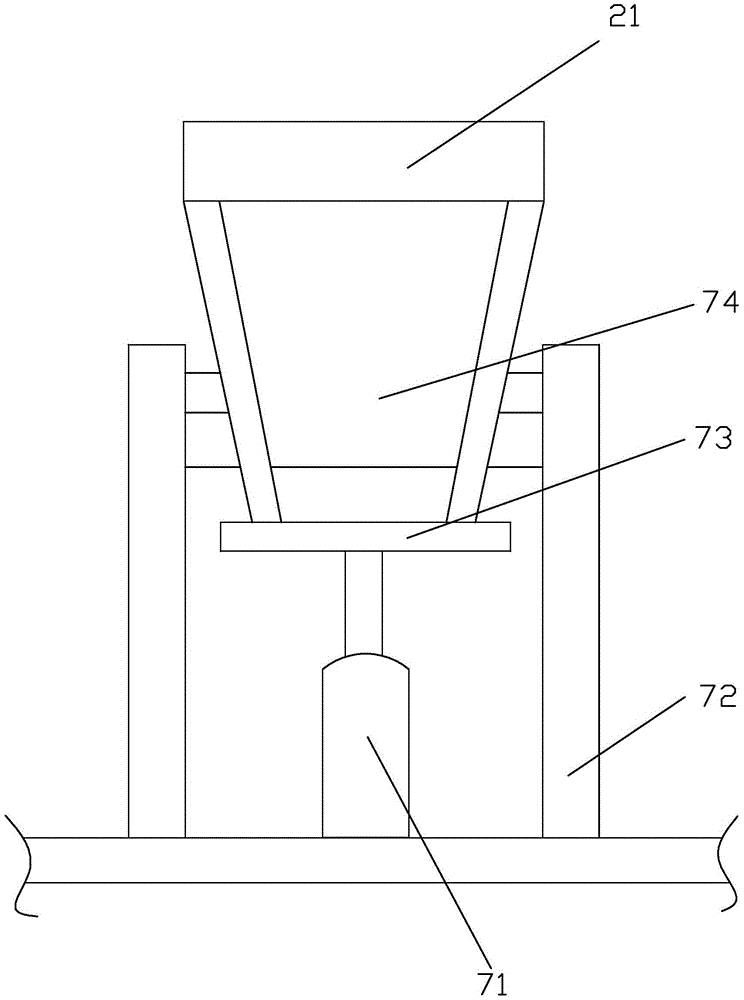

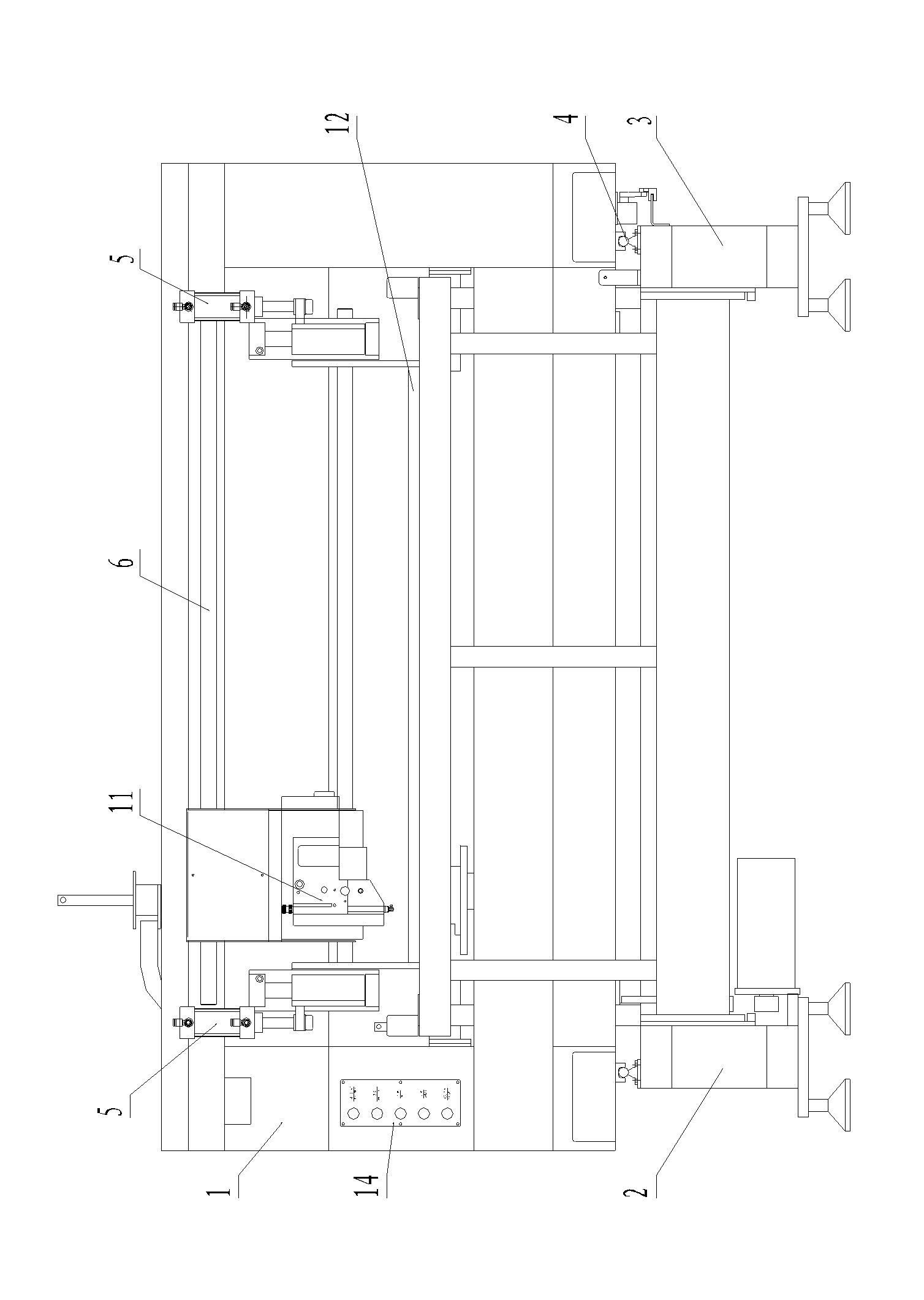

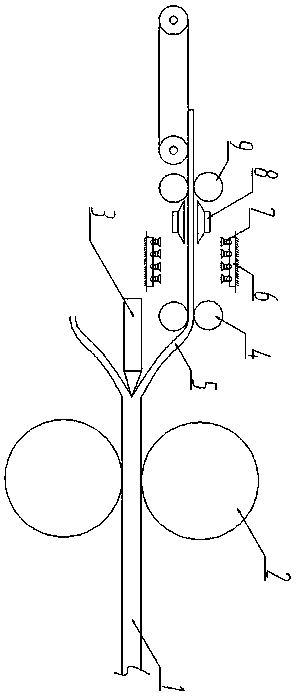

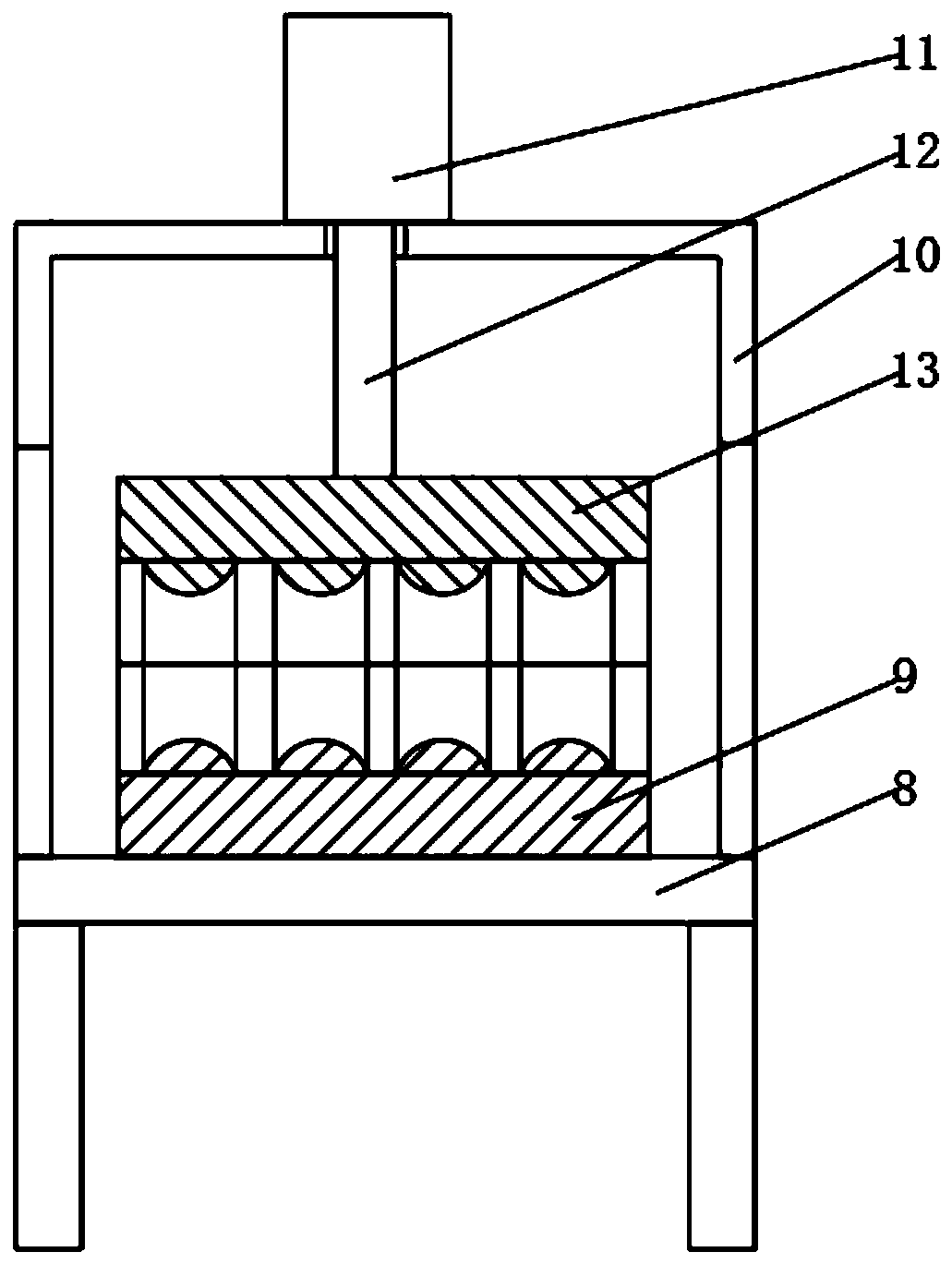

Spraying-drying-ironing integrated leather splitting machine

InactiveCN108950093AQuality improvementLess prone to wrinklesSkins/hides/leather/fur manufacturing apparatusLeather surface mechanical treatmentSpray driedMechanical engineering

The invention discloses a spraying-drying-ironing integrated leather splitting machine. The spraying-drying-ironing integrated leather splitting machine comprises a leather splitting device, a spraying device, drying devices and an ironing device; the leather splitting machine comprises leather, a conveying clamp roller and a splitting cutter, the upper side and the lower side of the splitting cutter are provided with a pair of guiding rollers, a leather sheet is arranged between the guiding rollers, and the guiding rollers are driven by a servo motor; the spraying device is arranged behind the guiding rollers and comprises spraying plates and spray heads; the drying devices are arranged behind the spraying device and located on the upper side and the lower side of the leather sheet; the ironing device is arranged behind the drying devices and composed of two pressing rollers; and a conveying mechanism is arranged behind the ironing device. According to the spraying-drying-ironing integrated leather splitting machine, the two sides of the leather sheet are provided with the guiding rollers, the spraying device, the drying devices and the ironing device, accordingly, the split leather can automatically flatly enters onto the conveying mechanism after entering the guiding rollers, and the leather is stable in quality and not prone to wrinkling.

Owner:NANJING AIFENG TECH CO LTD

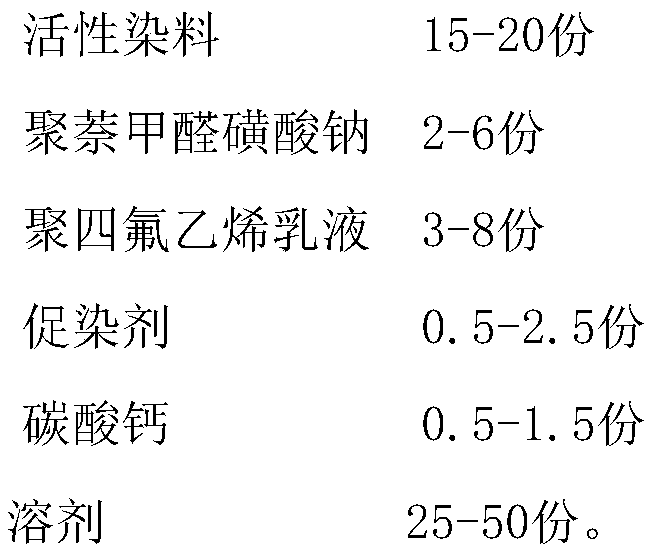

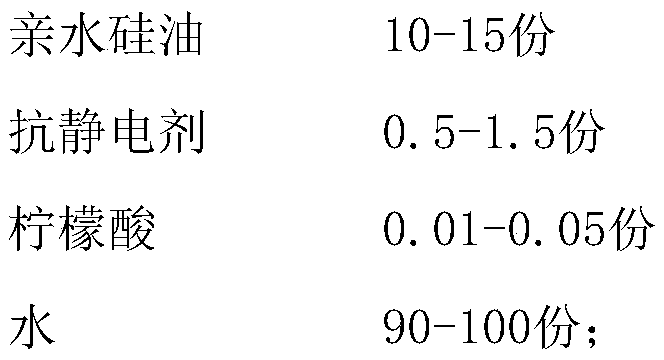

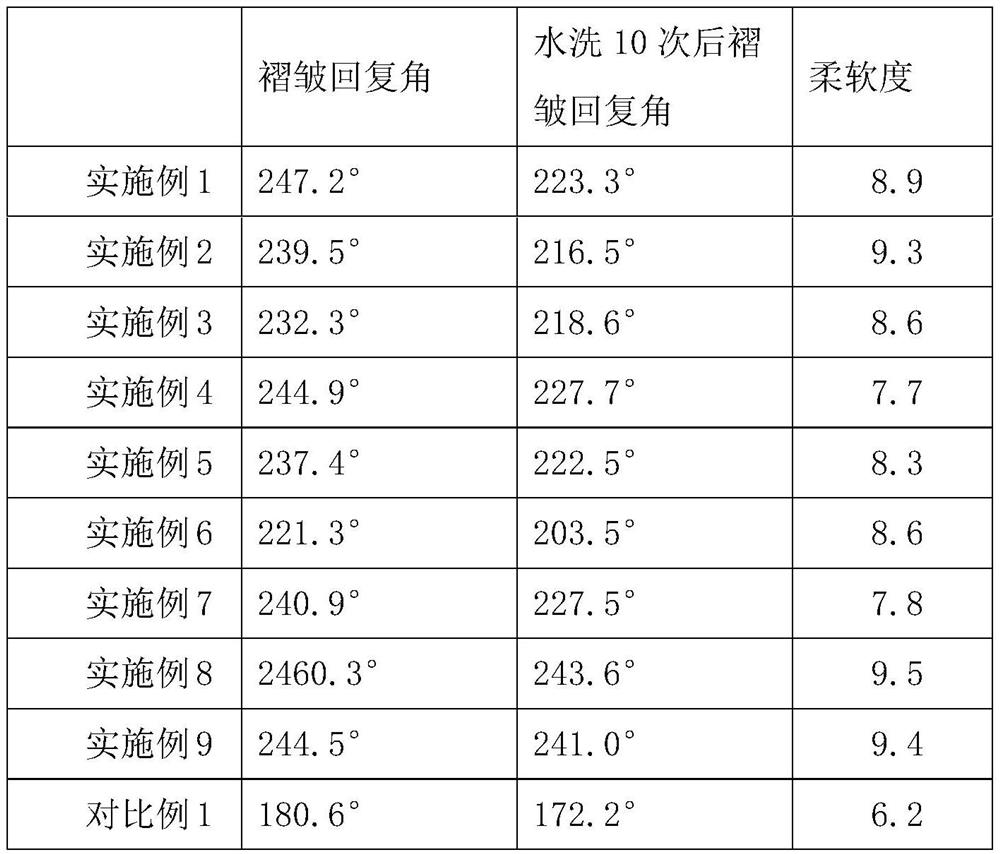

Antibacterial and anti-wrinkle cotton and linen fabric and preparation method thereof

PendingCN113914104APlay a protective effectLess prone to wrinklesBiochemical fibre treatmentWrinkle resistant fibresCelluloseFiber

The invention provides an antibacterial and anti-wrinkle cotton and linen fabric and a preparation method thereof. Antibacterial and anti-wrinkle finishing liquid prepared through reaction of modified vinyl silicone oil, silver ions and organic amine is used for performing an antibacterial and anti-wrinkle finishing process, and rich amino groups and carboxyl groups on the modified vinyl silicone oil and cellulose macromolecules form a covalent cross-linked structure, so that the fabric has the advantage that wrinkles are not prone to being generated; and on the other hand, the high viscosity, the adhesivity and the dispersity of the vinyl silicone oil structure are utilized, so that sulfydryl groups and silver ions can be fully and uniformly contacted with the cotton and linen fibers. The fabric can be subjected to antibacterial and crease-resistant finishing at the same time, and the technological process is simplified. The preparation process does not generate formaldehyde and has good environmental protection property.

Owner:ZHEJIANG KINGSAFE INTERLINING

Stretch fabric with two-way extension

The invention discloses the bounce covering cloth with the both directional stretchy, the yarn arranging with the latitude and longitude direction is interlaced to form according to the certain sinking and emerging rule, the said yarn is produced by the spinning fiber which is 88-98% in weight percent enlacing and covering the ammonia silk which is 2-12% in weight percent, the weight of the double directional elongating elastic cloth interlaced by the yarn is 200-400g / m2. The cloth produced by the invention has well flexibility in latitude and the warp direction and it makes the cloth produced form the surface material comfort during the wearing.

Owner:山东耶莉娅服装集团有限公司

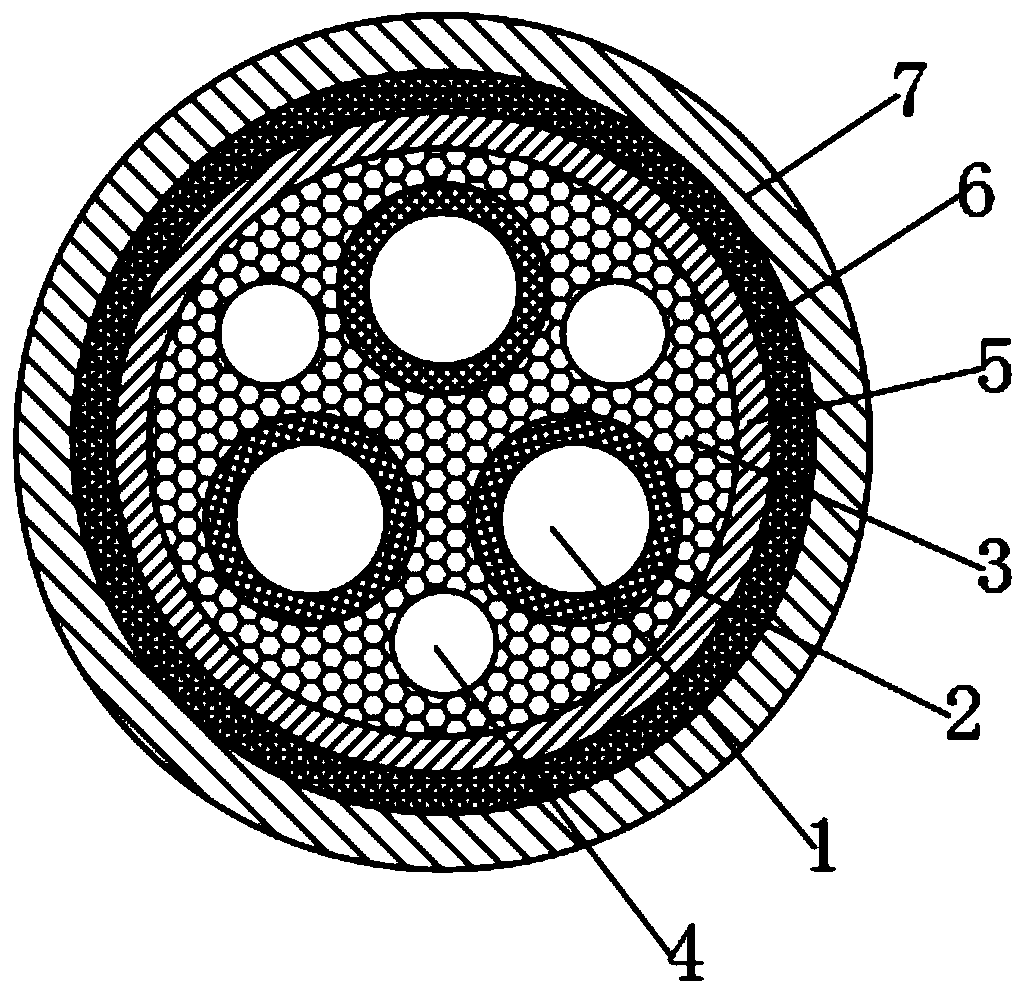

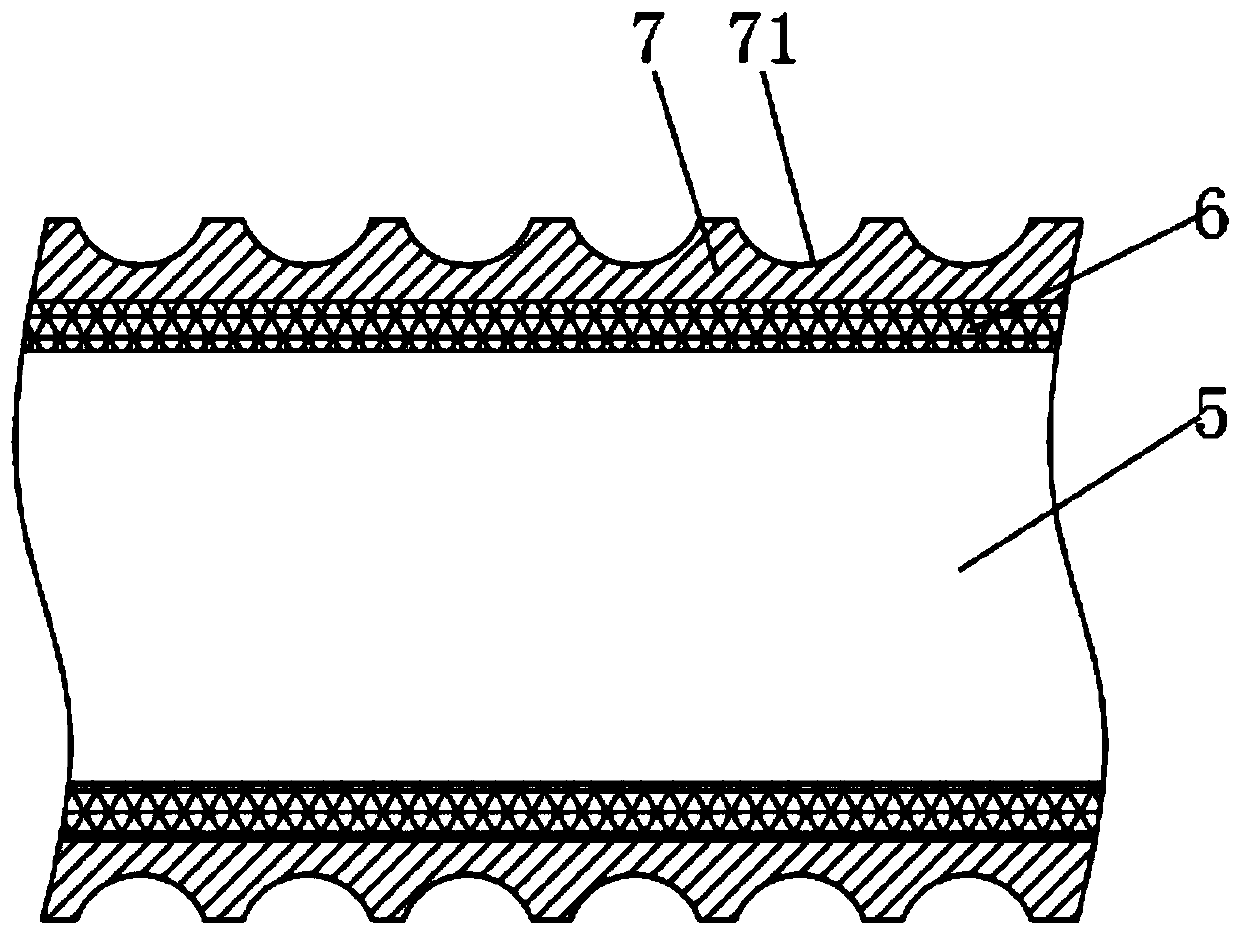

Bending-resistant high-flexibility drag chain cable and production method thereof

InactiveCN111564244AImprove bending resistanceImprove structural strengthClimate change adaptationApparatus for heat treatmentNylon threadAramid

The invention belongs to the field of cables, particularly relates to a bending-resistant high-flexibility drag chain cable and a production method thereof, and solves the problems that the existing drag chain cable is poor in bending resistance, poor in wear resistance and not high enough in strength, wrinkles are extruded during production, and cracks exist on the surface of a protective outer layer after the drag chain cable is cooled. The bending-resistant high-flexibility drag chain cable comprises a wire core, wherein the outer side of the wire core is coated with a core-spun layer, theouter side of the core-spun layer is provided with a water-blocking layer, a nylon wire is arranged in the water-blocking layer, the outer side of the water-blocking layer is provided with a protective inner layer, the outer side of the protective inner layer is provided with a reinforcing layer, and the outer side of the reinforcing layer is provided with a protective outer layer. According to the invention, the annular groove is designed in the surface of the protective outer layer, and the protective outer layer is extruded by the wear-resistant rubber, so that the bending resistance and the wear resistance of the cable can be good; and the structural strength and the pulling resistance of the cable can be high by designing the reinforcing layer woven by the aramid fiber wires and adding the nylon wire into the water-blocking paste.

Owner:ZHEJIANG TIANJIE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com