Manufacturing apparatus and manufacturing method of plastic component

A manufacturing method and technology of plastic parts, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of softening and sagging of plastic sheets, affecting product yield and quality, and easy wrinkling of plastic parts, etc., to achieve improvement Yield and quality, wrinkle-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

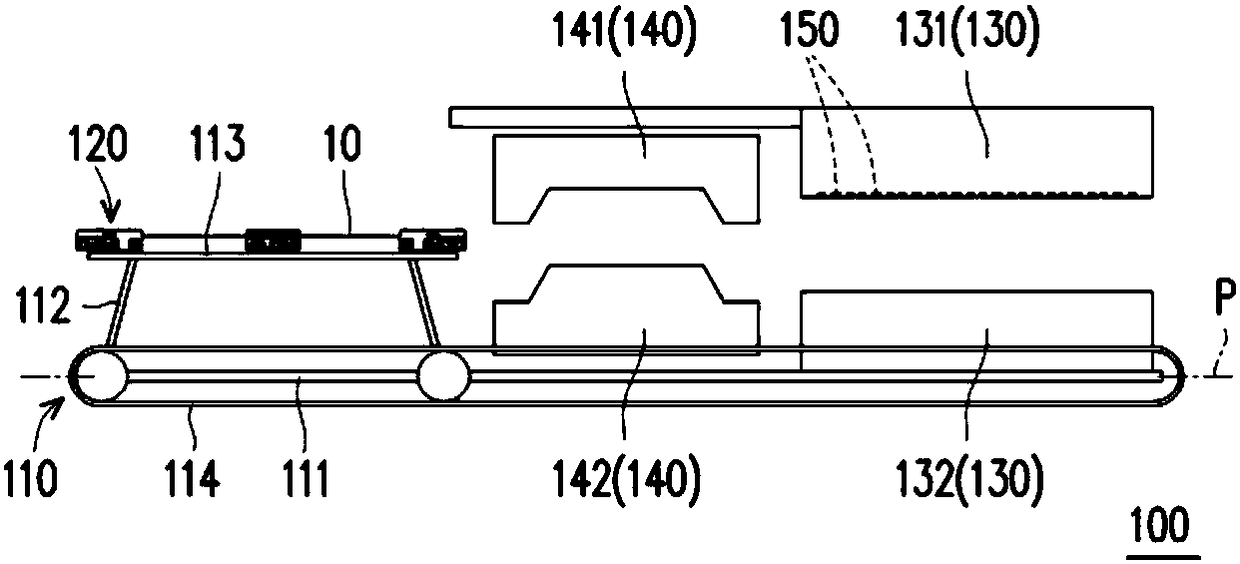

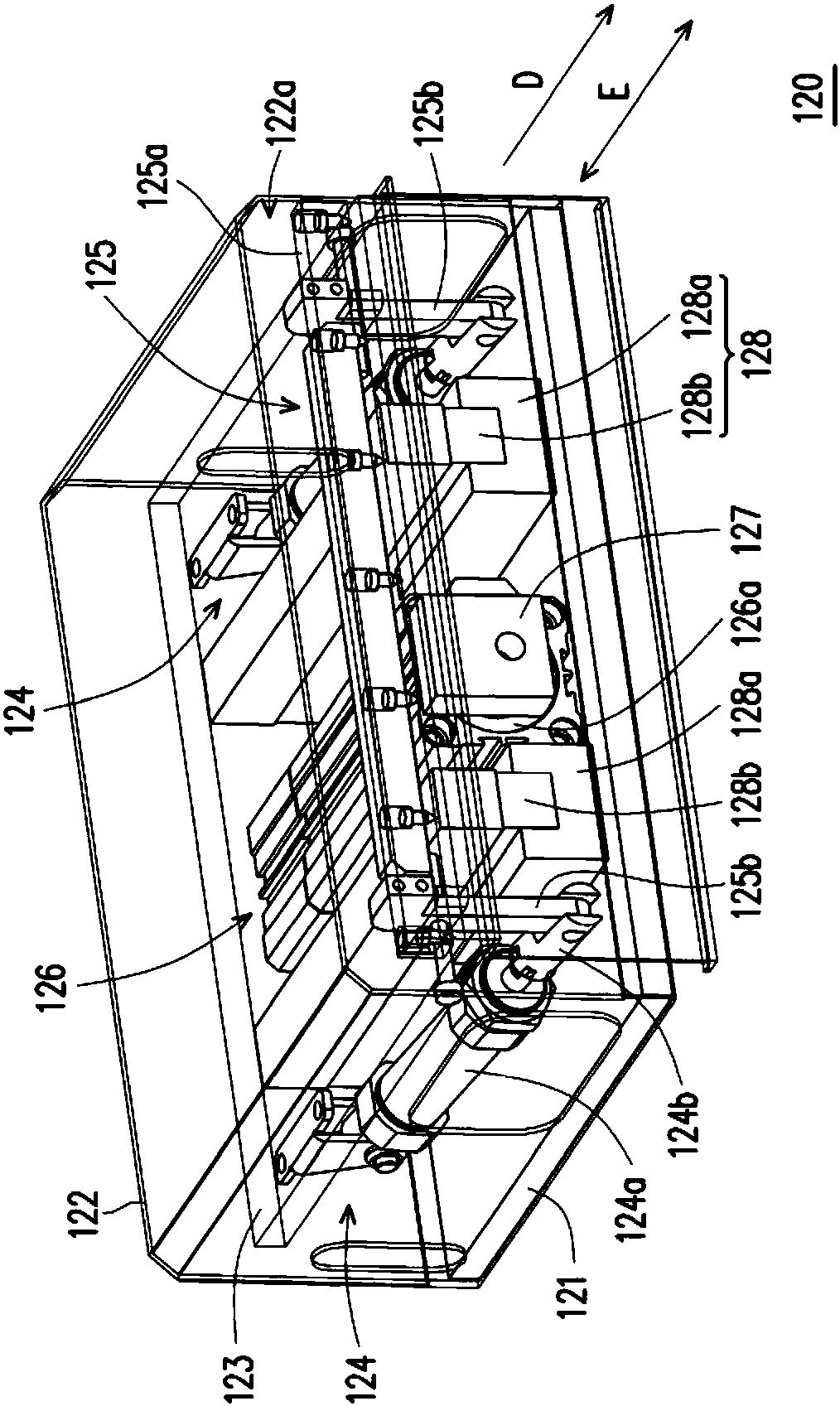

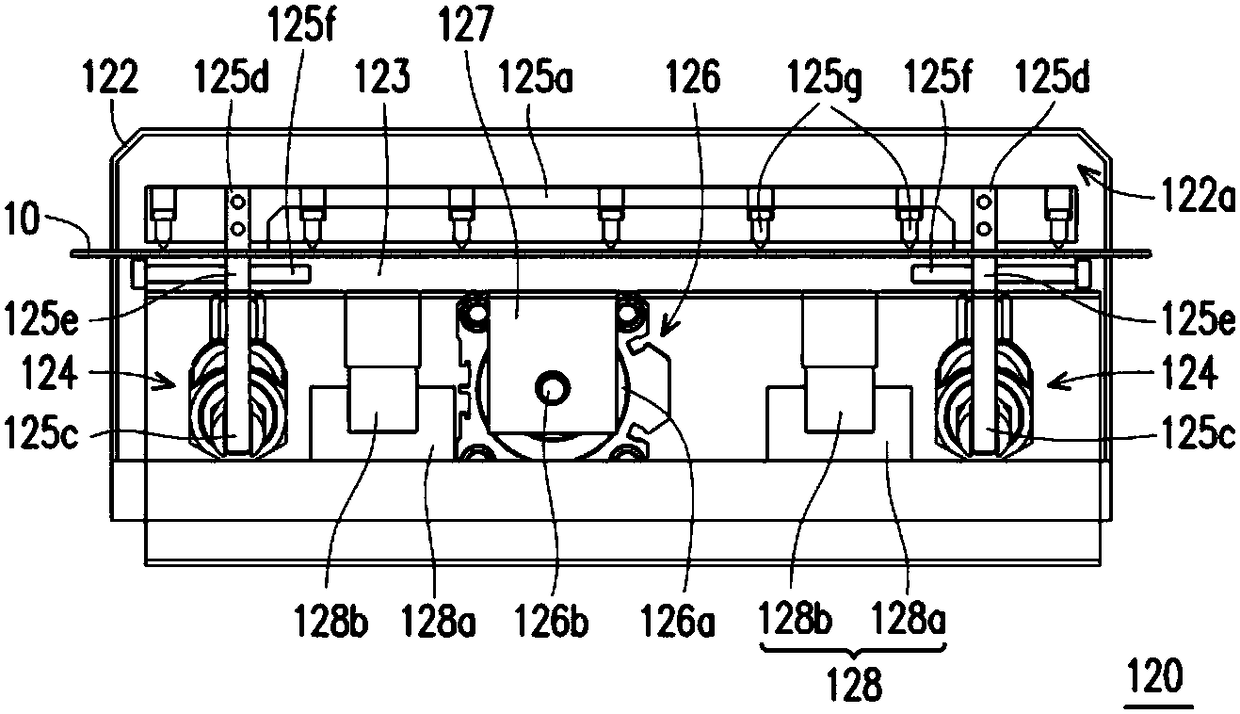

[0083] Figure 1A It is a schematic diagram of a manufacturing equipment of a plastic part according to an embodiment of the present invention. Figure 1B yes Figure 1A Schematic diagram of the clamping device. Figure 1C yes Figure 1A Schematic front view of the clamping device. Figure 1D yes Figure 1A The schematic top view of the plastic sheet being clamped above the frame by the clamping device. For clarity and ease of explanation, Figure 1B and Figure 1C Some components of the are shown in perspective, and Figure 1C A state in which a part of the plastic sheet 10 is fixed between the clamping portion 125 a and the carrier plate 123 is shown. Please refer to Figure 1A to Figure 1D , in this embodiment, the production equipment 100 can be used to produce plastic parts, wherein the plastic parts can be the shell of the trunk, the vehicle shell, the vehicle lamp housing, the vehicle fender or other common plastic parts, the present invention is for the plastic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com