Method for forming titanium alloy sheet metal part

A sheet metal part, forming processing technology, applied in the field of aviation titanium alloy sheet metal parts, can solve the problems of poor manufacturability, low bending ability, low plasticity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

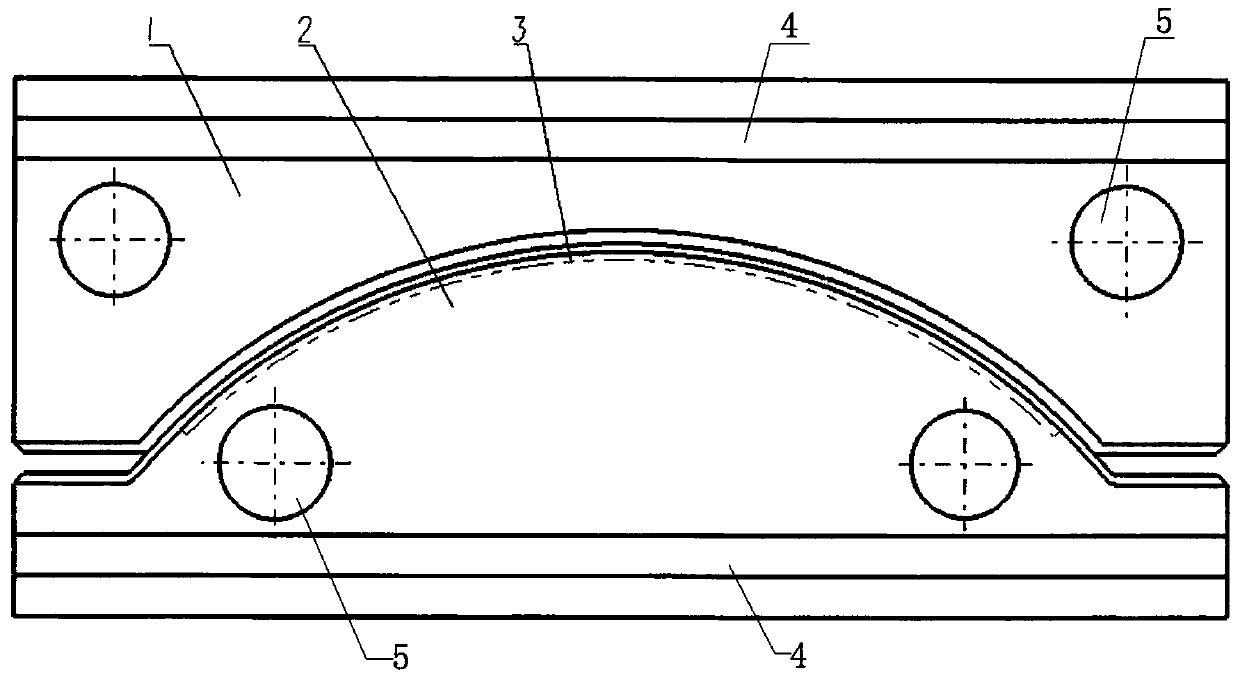

Image

Examples

Embodiment Construction

[0020] A method for forming and processing titanium alloy sheet metal parts, comprising the steps of:

[0021] 1) Clean the upper mold, the lower mold and the titanium alloy sheet metal parts of the forming mold with acetone, and coat the upper mold, the lower mold and the titanium alloy sheet metal parts with graphite;

[0022] 2) Turn on the thermoforming machine, heat the upper and lower molds to 630-650 degrees, place the titanium alloy sheet metal parts on the lower mold, and preheat at 630-650 degrees for 5-10 minutes;

[0023] 4) After the temperature of the titanium alloy sheet metal parts and the lower mold is balanced, the upper and lower molds are closed, and the temperature is kept at 630-650 degrees. The clamping pressure is controlled at 80 tons, and the pressure is kept for 15 minutes; The gap distance between the mold and the lower mold is adapted to the thickness of the titanium alloy sheet metal part;

[0024] 4) Control the thermoforming machine to open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com