Fully automatic film sealing and cutting packing machine

A fully automatic, packaging machine technology, applied in packaging, multiple packages, transportation and packaging, etc., can solve the problems of easy offset, 5 tearing of corners, weakness, etc. The effect of the vulnerability gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

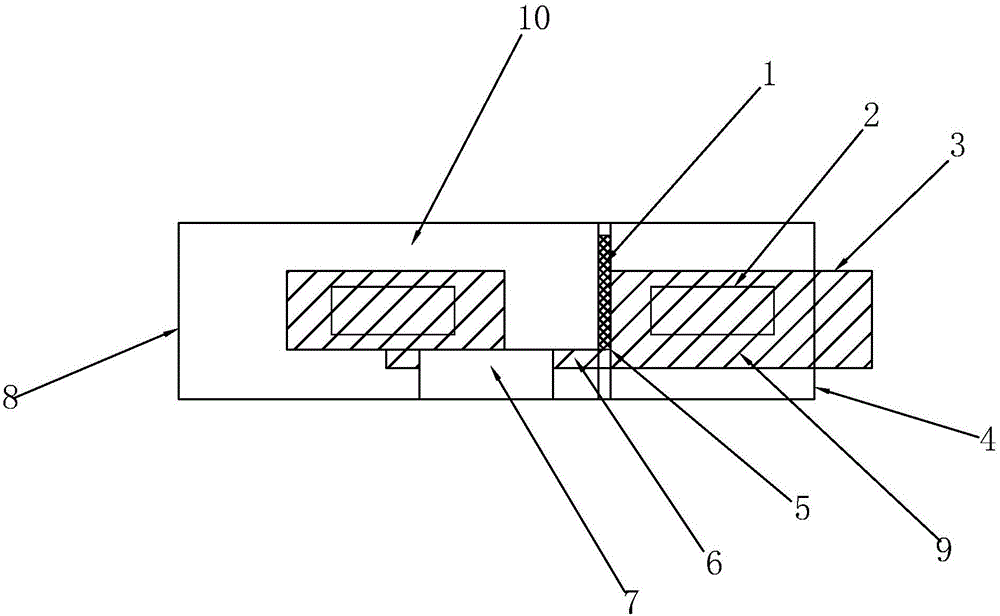

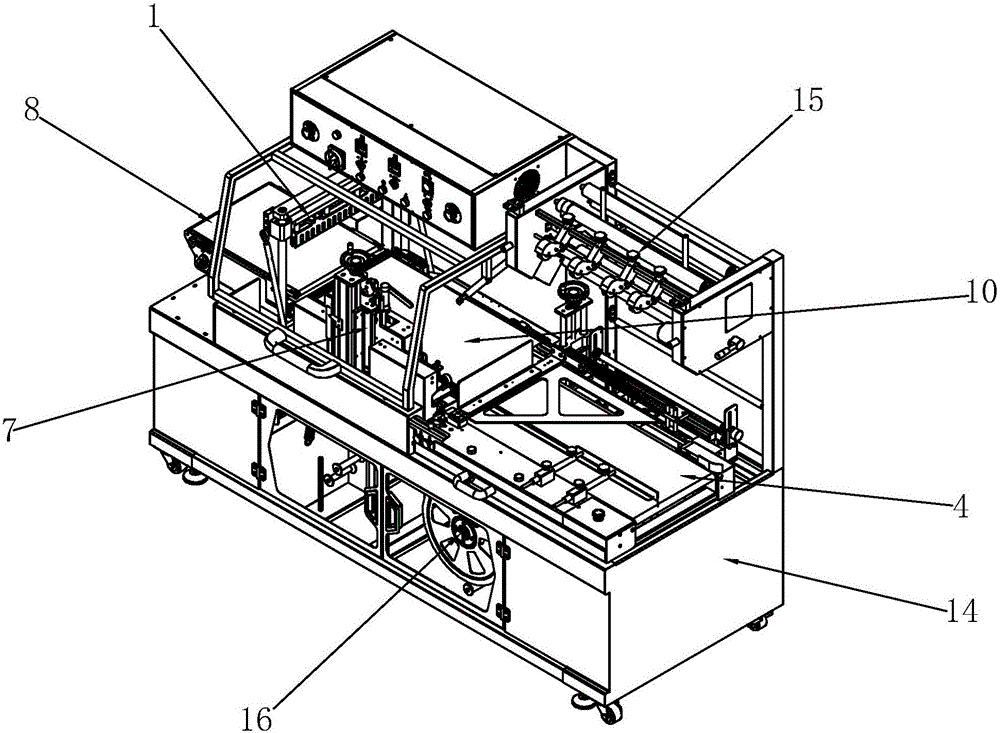

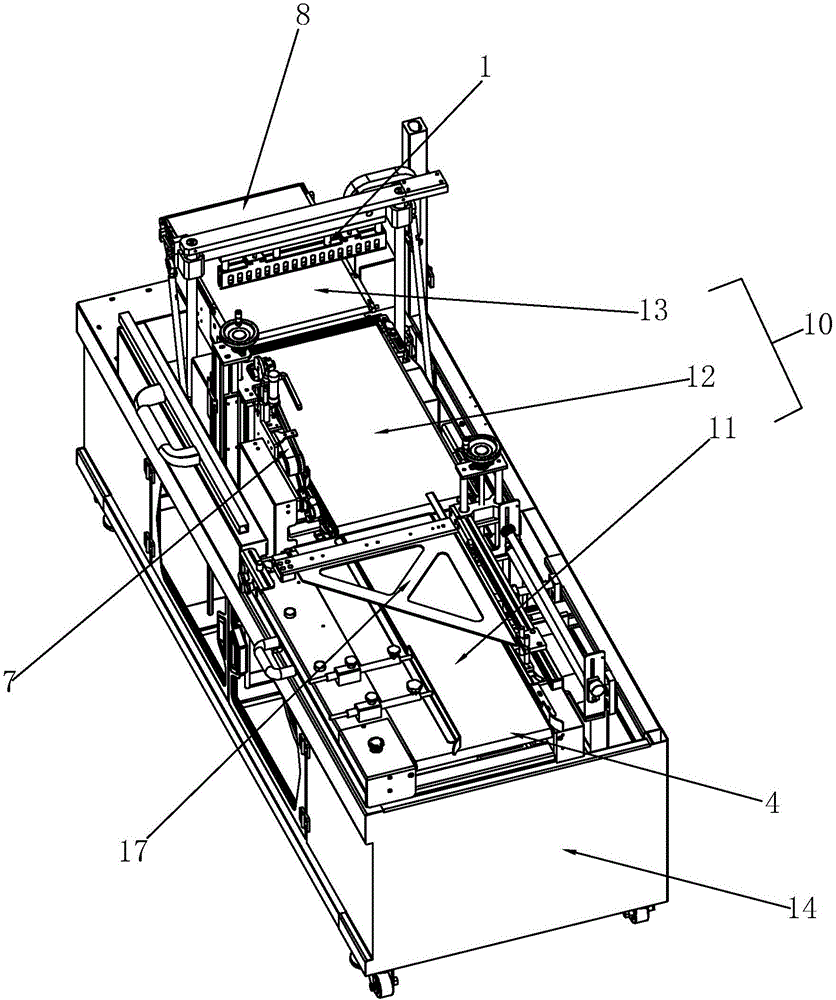

[0048] Embodiment one, a kind of automatic film sealing and packaging machine, such as figure 2 As shown, it includes the main frame 14, the conveying platform 10 arranged on the main frame 14, and the traction side sealing mechanism 7 arranged at the side of the conveying platform 10 and the longitudinal seal between the traction side sealing mechanism 7 and the output end 8 In the mechanism 1, a film feeding mechanism 15 is provided above the side of the conveying platform 10 close to the input end 4, and a scrap recovery mechanism 16 is provided in the main frame 14.

[0049] Such as image 3 As shown, the delivery platform 10 includes a first delivery platform 11, a second delivery platform 12, and a third delivery platform 13 distributed from the input end 4 to the output end 8; the traction side sealing mechanism 7 is located at the second delivery platform 12, and the vertical sealing Mechanism 1 is arranged between the second conveying platform 12 and the 3rd conveyi...

Embodiment 2

[0065] Embodiment two, a kind of fully automatic sealing and packaging machine, such as Figure 20 As shown, the difference from Embodiment 1 is that the side of the second delivery platform 12 away from the traction side sealing mechanism 7 is provided with a traction mechanism 101 opposite to the traction side sealing mechanism 7, and the traction mechanism 101 is connected to the traction side sealing mechanism 7. The only difference is that the sealing and cutting part is not included. By setting the traction mechanism 101, the traction force on both sides of the film 3 can be made more uniform, so that the film 3 is conveyed more smoothly, thereby achieving better sealing and cutting quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com