Preparation method of self-heating laser-induced graphene flexible NO2 gas sensor

A gas sensor and laser-induced technology, applied in the field of sensors, can solve the problems of small response and slow response/recovery process, and achieve the effects of short manufacturing cycle, reduced process complexity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Above-mentioned self-heating laser-induced graphene flexible NO gas sensor preparation method, the method steps are as follows:

[0037] (1) Cut the polyimide (Polyimide, PI) tape into a rectangular shape of appropriate size (it is better to completely cover the surface of the glass slide in step (2));

[0038] (2) Through hydrosol (such as common water-soluble gel containing PVA (polyvinyl alcohol), PVP (polyvinyl pyrrolidone), CMC (sodium carboxymethylcellulose), low modulus sodium silicate and cationic gum arabic, etc. Any glue can be dissolved in water again and quickly lose its adhesive properties) stick the PI tape obtained through step (1) to the surface of the glass slide;

[0039] (3) Use the high-energy laser to induce three-dimensional graphene patterns on the PI tape obtained in step (2), in which the square graphene patterns at both ends are the electrode connection areas, and the single-line graphene area is used as a bridge for the electrode connection ar...

Embodiment 1

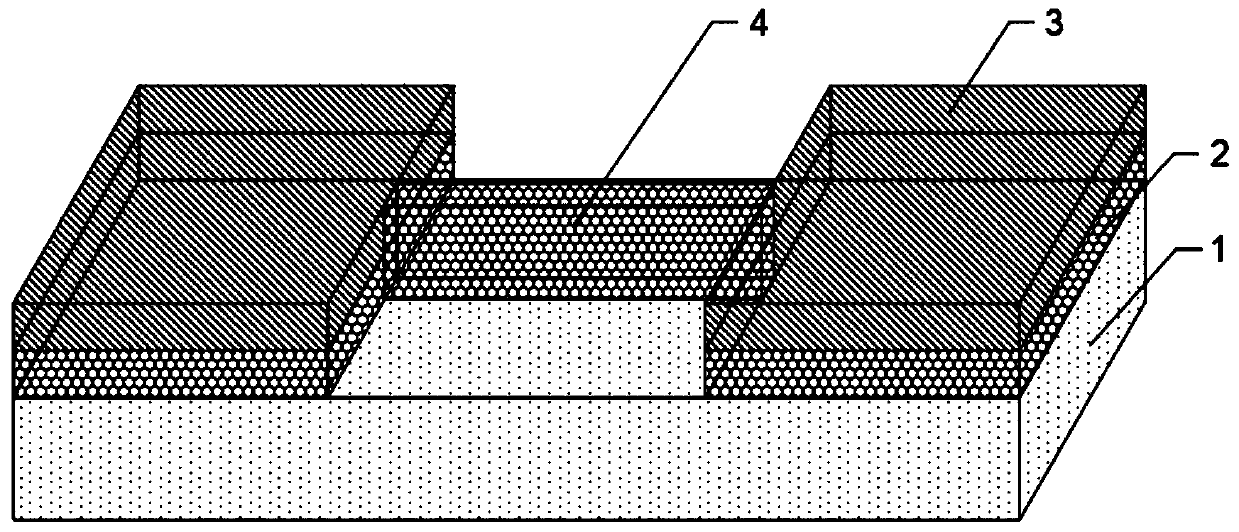

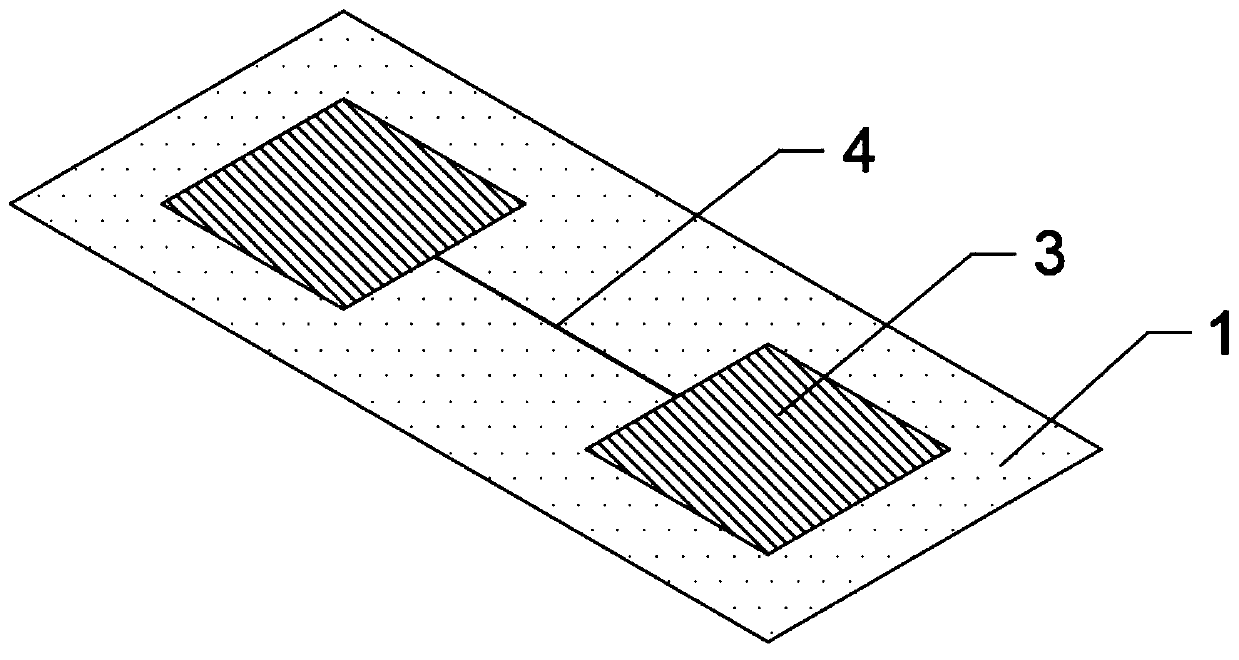

[0043] In this embodiment, the self-heating laser-induced graphene flexible NO2 gas sensor includes an insulating region, an electrode region, a silver coating region and a gas-sensitive region, the insulating region is arranged at the bottom, and the electrode region is arranged at the insulating region On the upper surface, the left and right ends of the electrode area are provided with two electrode connection areas formed by laser-induced graphene, and the upper surface of the electrode connection area is coated with a silver coating to form a silver coating area.

[0044] The two electrode connection areas are connected together by the single-line graphene formed by laser-induced graphene; the area where the single-line graphene is located is directly the gas-sensitive area; the width of the single-line graphene is 60 μm; the two electrode connection areas and the single-line graphene form a barbell shape structure. The electrode connection area is a square structure with...

Embodiment 2

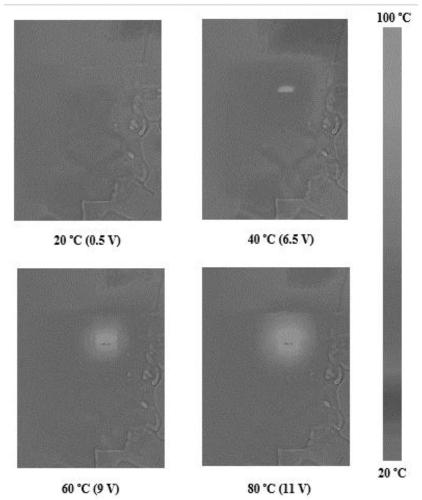

[0048] The difference between the technical solution of this embodiment and Embodiment 1 is that the concentration of the test gas is different. This embodiment only describes the different parts, and the same parts will not be repeated. The test gas in this embodiment is NO2, the test temperature in the gas sensitive area is 40°C, the test concentration is 0.2ppm, 0.4ppm, 0.6ppm, 0.8ppm, 1ppm, 2ppm, 5ppm, and it is found that the detection range of NO2 is relatively wide, and the resolution It has high rate and obvious response, which can meet the requirements of air quality monitoring and breath detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com