Based on mxene/sno 2 Heterojunction passive wireless ammonia gas sensor and preparation method

A gas sensor, passive wireless technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, instruments, etc., can solve the problems of enhanced gas sensing performance, higher than 100 ℃, unsatisfactory characteristics, etc. Achieve the effects of enhanced gas sensing performance, simple process flow, and improved response/recovery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

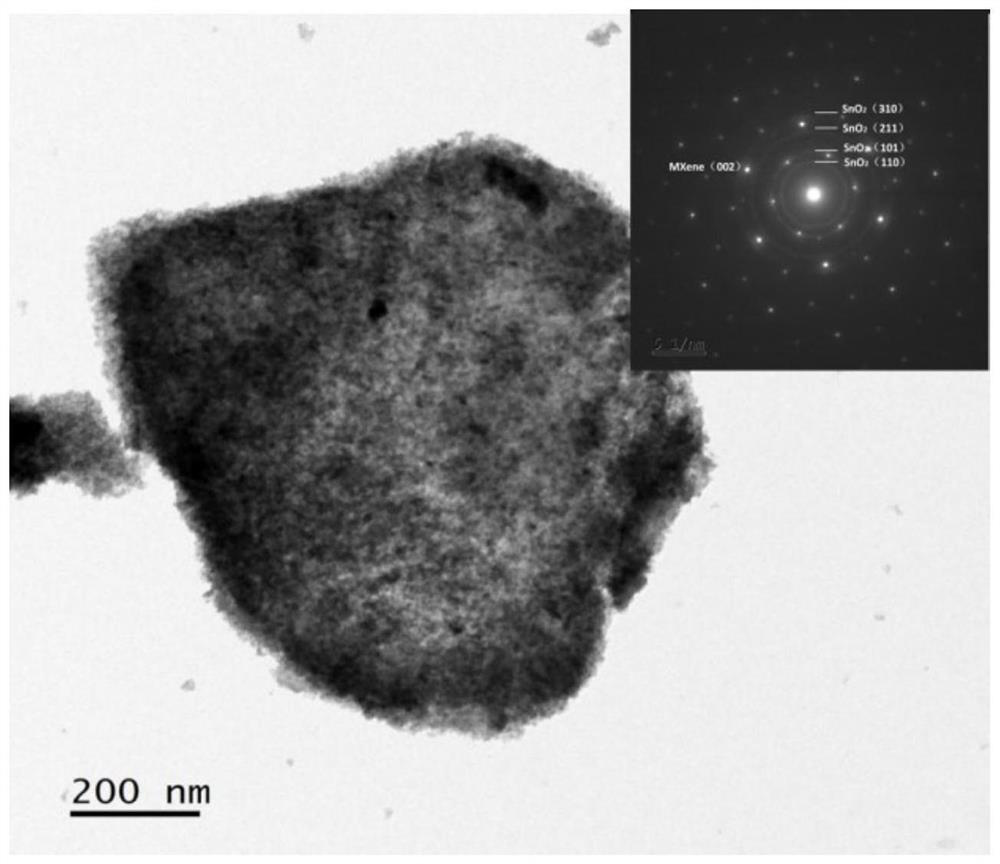

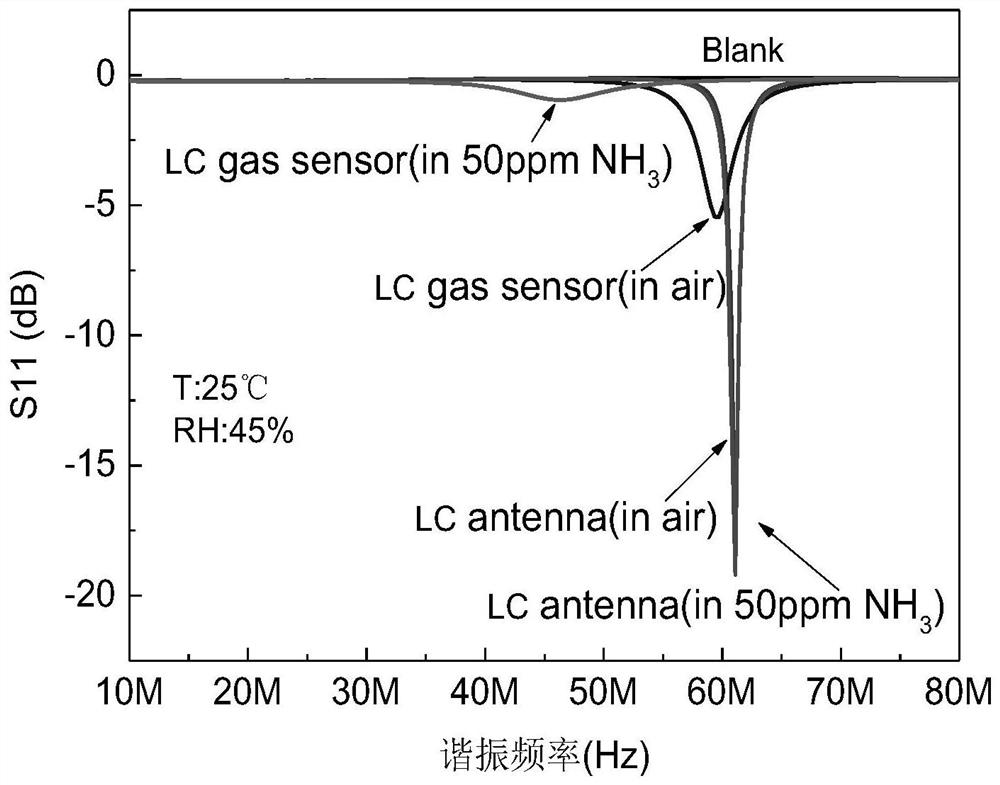

[0032] A MXene / SnO-based 2 A heterojunction passive wireless ammonia sensor consists of a gas-sensing material and an LC resonant antenna, the gas-sensing material is coated on the surface of the interdigitated electrode of the LC resonant antenna, and the coating thickness is 100 μm. The gas sensitive material composition is MXene and SnCl 4 ·5H 2 O is mixed according to the mass fraction ratio of 2:1, and the MXene / SnO generated under the hydrothermal condition of 180°C for 12h 2 Heterojunction Composite Nanomaterials.

[0033] The preparation method comprises the following steps:

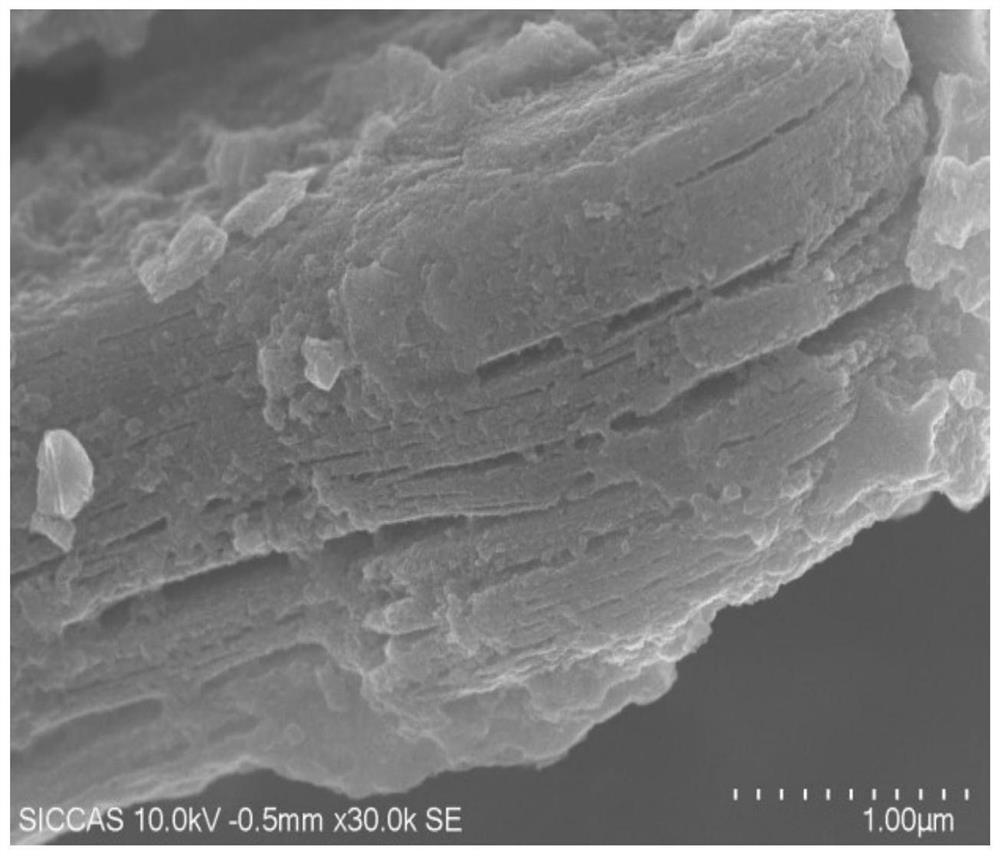

[0034] Step 1, preparation of layered MXene materials: LiF and Ti 3 AlC 2Mix according to the mass fraction ratio of 2:1, slowly add into 9mol / L hydrochloric acid while stirring, stir at 60°C for 48 hours, and the etched powder is repeatedly washed with deionized water (DI) and centrifuged until The pH value of the supernatant was 6. The collected powder obtained by centrifugation was sonic...

Embodiment 2

[0040] A MXene / SnO-based 2 The passive wireless ammonia gas sensor is composed of a gas-sensitive material and an LC resonant antenna, the gas-sensitive material is coated on the surface of the interdigitated electrode of the LC resonant antenna, and the coating thickness is 1 μm. The gas sensitive material composition is MXene and SnCl 4 ·5H 2 O is mixed according to the mass fraction ratio of 1:1, and the MXene / SnO generated under the hydrothermal condition of 160°C for 18h 2 Heterojunction Composite Nanomaterials. The preparation method comprises the following steps:

[0041] Step 1, preparation of layered MXene materials: LiF and Ti 3 AlC 2 Mix according to the mass fraction ratio of 1:1, slowly add into 9mol / L hydrochloric acid while stirring, stir at 35°C for 72 hours, and the etched powder is repeatedly washed with deionized water (DI) and centrifuged until The pH value of the supernatant was 5, and the collected powder obtained by centrifugation was sonicated for...

Embodiment 3

[0045] A MXene / SnO-based 2 A heterojunction passive wireless ammonia sensor consists of a gas-sensing material and an LC resonant antenna, the gas-sensing material is coated on the surface of the interdigitated electrode of the LC resonant antenna, and the coating thickness is 50 μm. The gas sensitive material composition is MXene and SnCl 4 ·5H 2 O is mixed according to the mass fraction ratio of 1:2, and the MXene / SnO generated under the hydrothermal condition of 200 ° C for 6 h 2 Heterojunction Composite Nanomaterials. The preparation method comprises the following steps:

[0046] Step 1, preparation of layered MXene materials: LiF and Ti 3 AlC 2 Mix according to the mass fraction ratio of 6:1, slowly add into 9mol / L hydrochloric acid while stirring, stir at 80°C for 24 hours, and the etched powder is repeatedly washed with deionized water (DI) and centrifuged until The pH value of the supernatant was 7, and the collected powder obtained by centrifugation was sonicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com