Preparation method of molybdenum disulfide/cerium oxide composite gas-sensing structure and its application in gas-sensing coatings, components and sensors

A molybdenum disulfide, gas sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high working temperature, high resistance of pure cerium oxide, etc., and achieve good selectivity, good reversibility, response// Fast recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

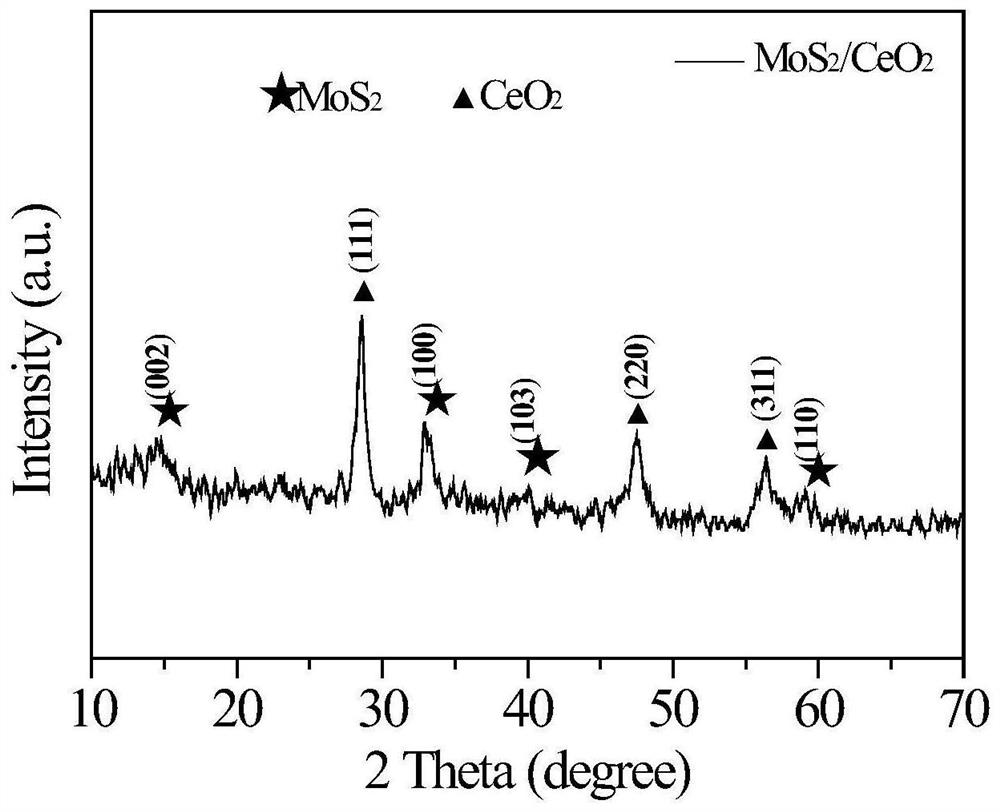

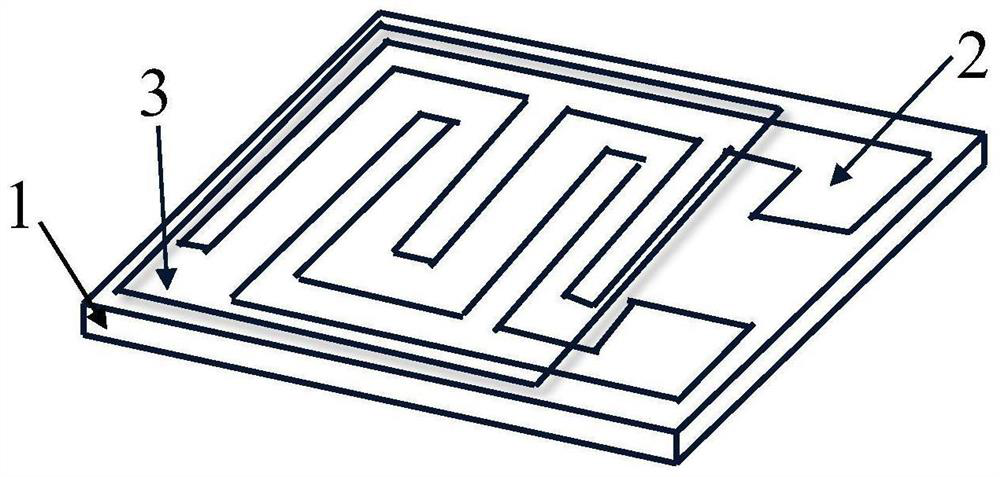

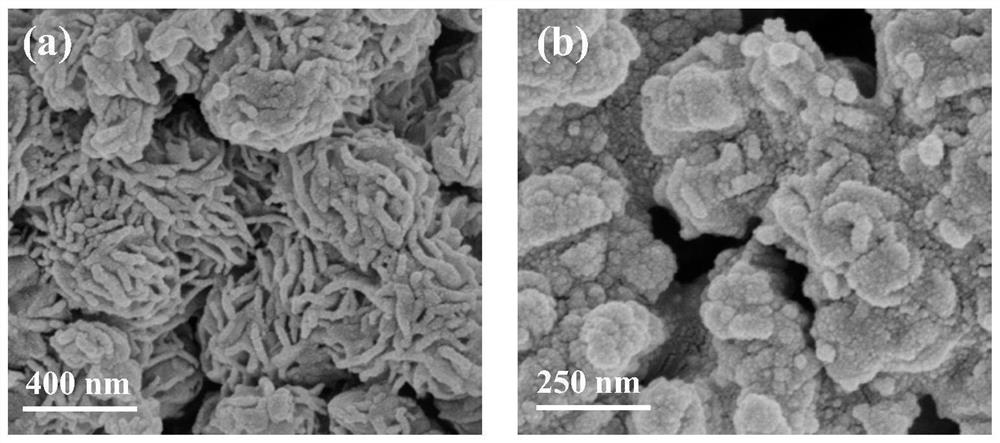

[0049] like Figure 1-11 shown, a molybdenum disulfide / cerium oxide composite gas-sensing structure by incorporating CeO 2 Nanoparticles are tightly attached to MoS 2 surface of nanoflowers to obtain molybdenum disulfide / cerium oxide composite gas sensing structure, the MoS 2 Flower-like structure with many worm-like micelles.

[0050] The MoS 2 The diameter of the nanoflowers is 600-720 nm and the thickness is 200-240 nm. The CeO 2 The diameter of the nanoparticles is 10–30 nm.

[0051] The present invention also includes a method for preparing the molybdenum disulfide / cerium oxide composite gas-sensing structure,

[0052] ①Preparation of MoS 2 Hydrothermal solution: under strong magnetic stirring, the Na 2 MoO 4 ·2H 2 O and thioacetamide were added to deionized water to obtain a mixed solution, and 2 mol / L HCl was added to the mixed solution until the pH value of the solution reached 5;

[0053] ②Preparation of MoS 2 Powder: transfer the mixed solution obtained in...

Embodiment 2

[0079] The present invention also includes a method for preparing the molybdenum disulfide / cerium oxide composite gas-sensing structure,

[0080] ①Preparation of MoS 2 Hydrothermal solution: put 1.0 g of Na 2 MoO 4 ·2H 2 O and 1.2 g of thioacetamide were added to 80 mL of deionized water, and the stirring temperature was controlled to 40-50 o C. The stirring speed is 600~800 rpm, and the stirring time is 10~15 min, and 2 mol / L HCl is added to adjust the pH of the solution to 5 to obtain MoS 2 hydrothermal solution;

[0081] ②Preparation of MoS 2 Powder: transfer the mixed solution obtained in step ① to the reaction kettle, and put it at 220 o MoS was obtained after heating at C for 14 h and washing with deionized water for several times. 2 Powder, and dry, drying temperature is 60~80 o C, the drying time is 12~24 h;

[0082] ③ Combine the MoS obtained in step ② 2 was added to a mixed solution of 50 mL of deionized water and 30 mL of ethanol, and then the Ce(NO 3 ) ...

Embodiment 3

[0087] A preparation method of an ethanol gas sensor whose gas sensitive coating is a molybdenum disulfide / cerium oxide composite structure, is carried out according to the following steps:

[0088] ① First, put 1.0 g of Na 2 MoO 4 ·2H 2 O and 1.2 g of thioacetamide were added to 80 mL of deionized water to obtain a mixed solution, which was magnetically stirred at 600 rpm for 10 min. Next, 2 mol / L HCl was added to the mixture solution until the pH value of the solution reached 5;

[0089] ② Transfer the mixture obtained in step ① to a 100 mL reaction kettle, and put it at 220 o Heated at C for 14 h. MoS was obtained after several washes with deionized water 2 powder, at 60 o Dry at C for 12 h;

[0090] ③ Put the 0.5 g MoS obtained in step ② 2 Add to 50 mL of deionized water and 30 mL of ethanol. Then, 0.06 g of Ce(NO 3 ) 3 ·6H 2 O is dissolved in the above dispersion, and the molar ratio of the Ce and Mo is 1:20;

[0091] ④ Move the dispersion liquid obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com