Orderly arranged In2O3 nanofibers and application of same in preparation of ultra-fast response alcohol sensor

A technology of orderly arrangement of nanofibers, applied in the application field of preparing ultra-fast response alcohol semiconductor sensors, can solve the problems of long response recovery time, etc., and achieve the effects of low production cost, simple preparation steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

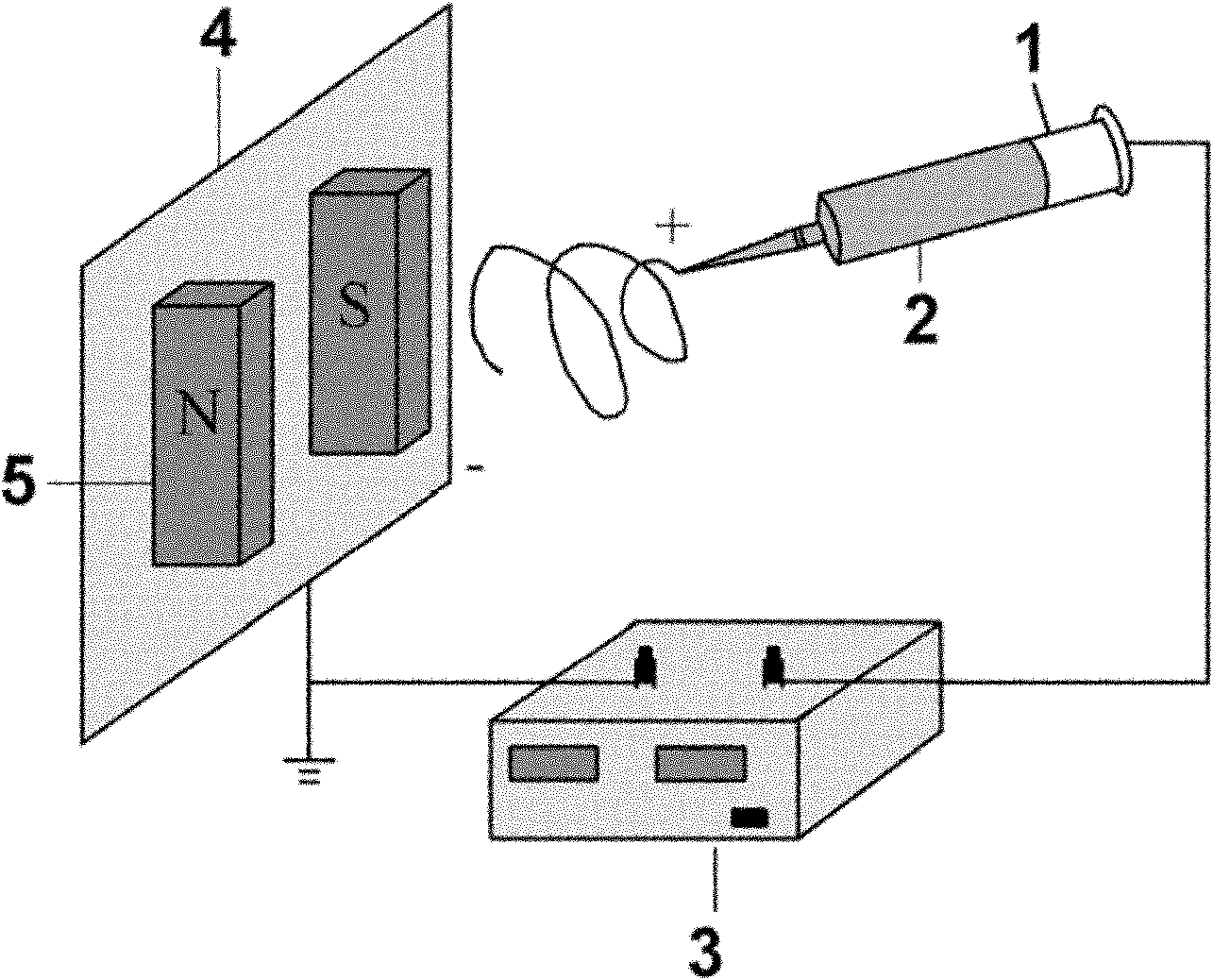

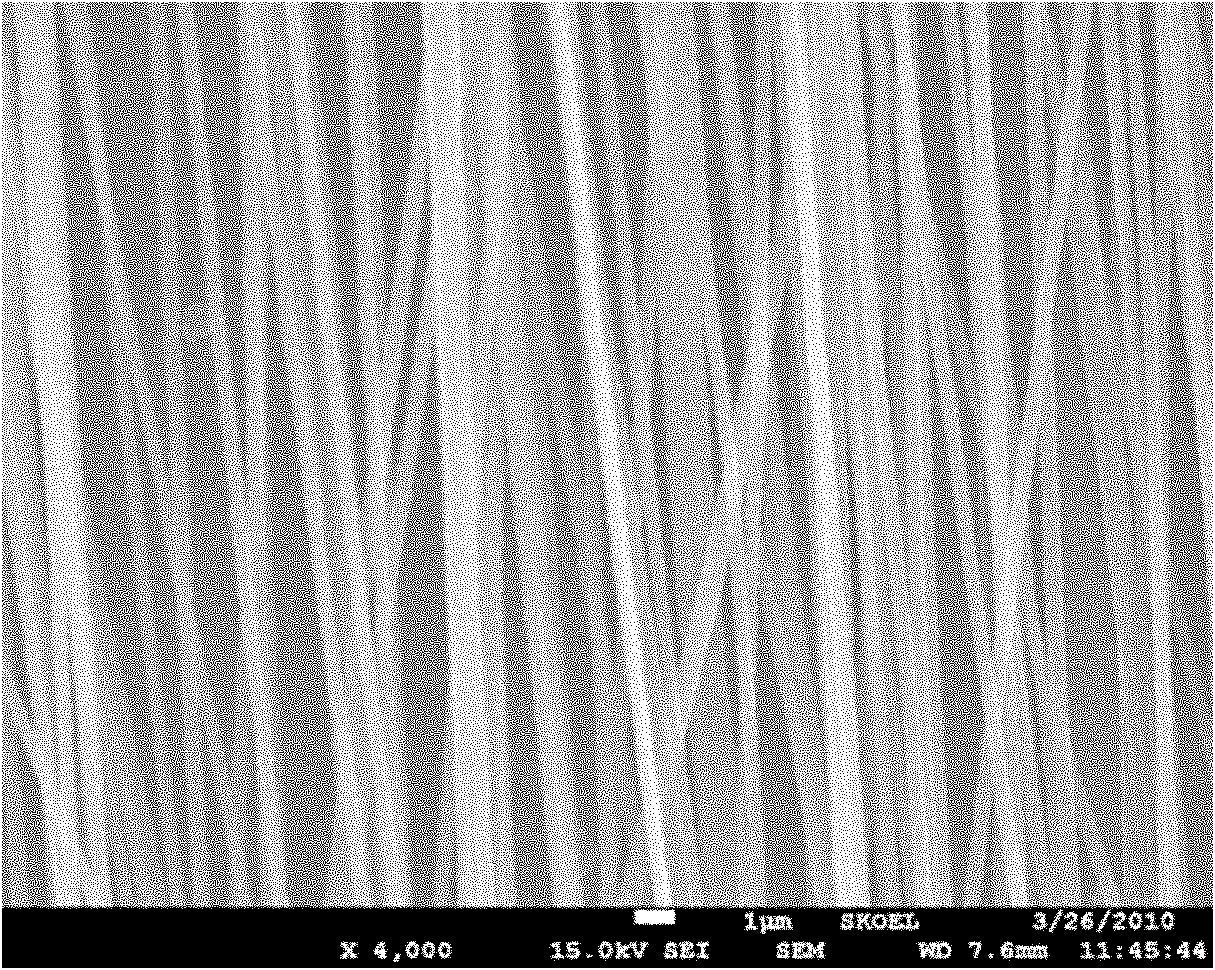

[0029] 1. In a 50ml Erlenmeyer flask, dissolve 1g of indium nitrate in 10ml of dimethylformamide solvent, seal the bottle with a parafilm and stir at room temperature for 20min to dissolve completely. Add 2 g of polyvinylpyrrolidone to the above solution, continue to seal and stir at room temperature for 10 h to obtain a spinning precursor. Put the precursor solution into the spinneret of the electrospinning equipment, pass the copper wire connected to the high-voltage end into the precursor solution, use parallel permanent magnets as cathodes, and the distance between the permanent magnets is 2.5cm, and the spinneret and The distance between the permanent magnets was 15 cm, and the applied voltage was 18 kV for spinning. After 36 h of electrospinning, the In(NO 3 ) 3 / PVP composite nanofibers were loaded into a crucible and calcined in a muffle furnace at 600°C for 3h at a temperature gradient of 2°C / min. 2 o 3 Nanofibers.

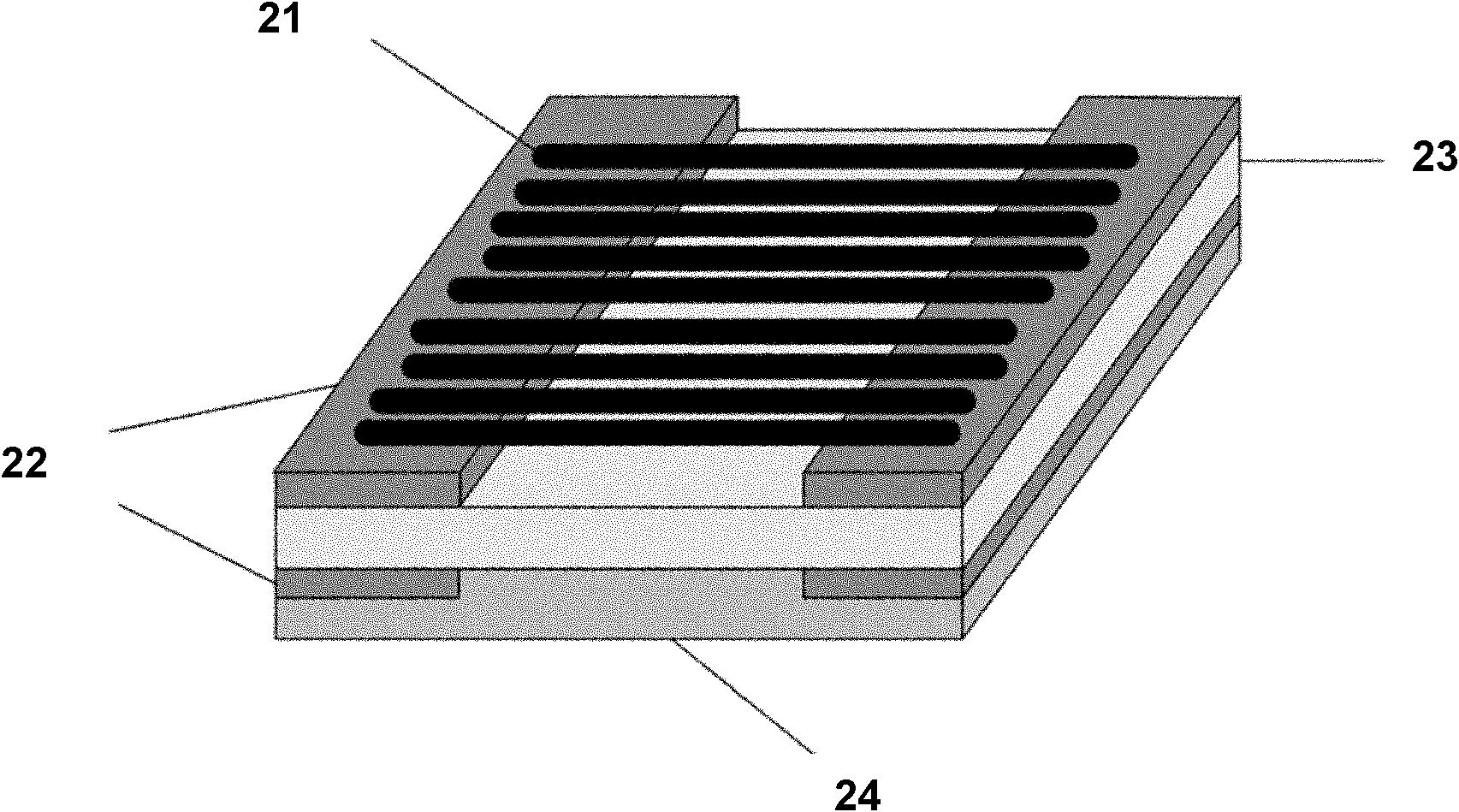

[0030] 2. Arrange the In orderly 2 o 3 The n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com