a kind of wo 3 Preparation of Nanoflower Materials and Its Application in Gas Sensors

A technology of nanomaterials and nanoflowers, applied in the fields of analysis of materials, material resistance, nanotechnology, etc., can solve problems such as high prices, and achieve the effects of good reversibility, good selectivity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

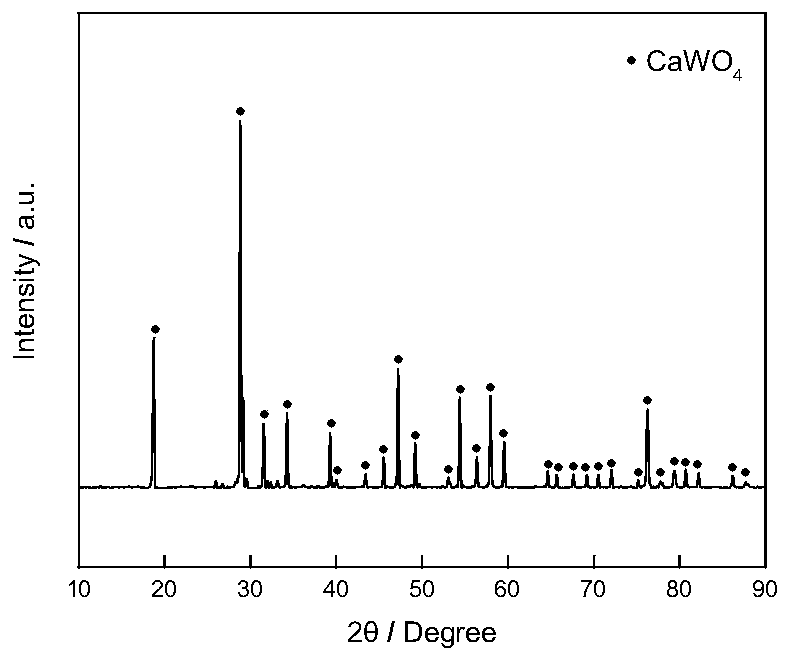

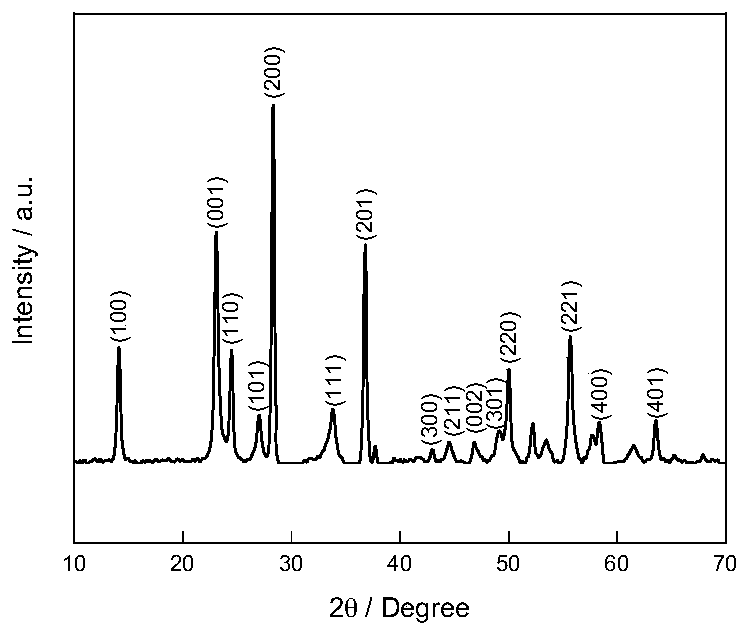

[0037] The invention is a kind of WO which is self-assembled by nanosheets synthesized by using scheelite concentrate. 3 The method of nanoflower and its function in NO 2 Application of gas sensor. The X-ray diffraction pattern of the scheelite concentrate that the present invention adopts is as figure 1 As shown, the results show that the main useful mineral in the scheelite concentrate is CaWO 4 .

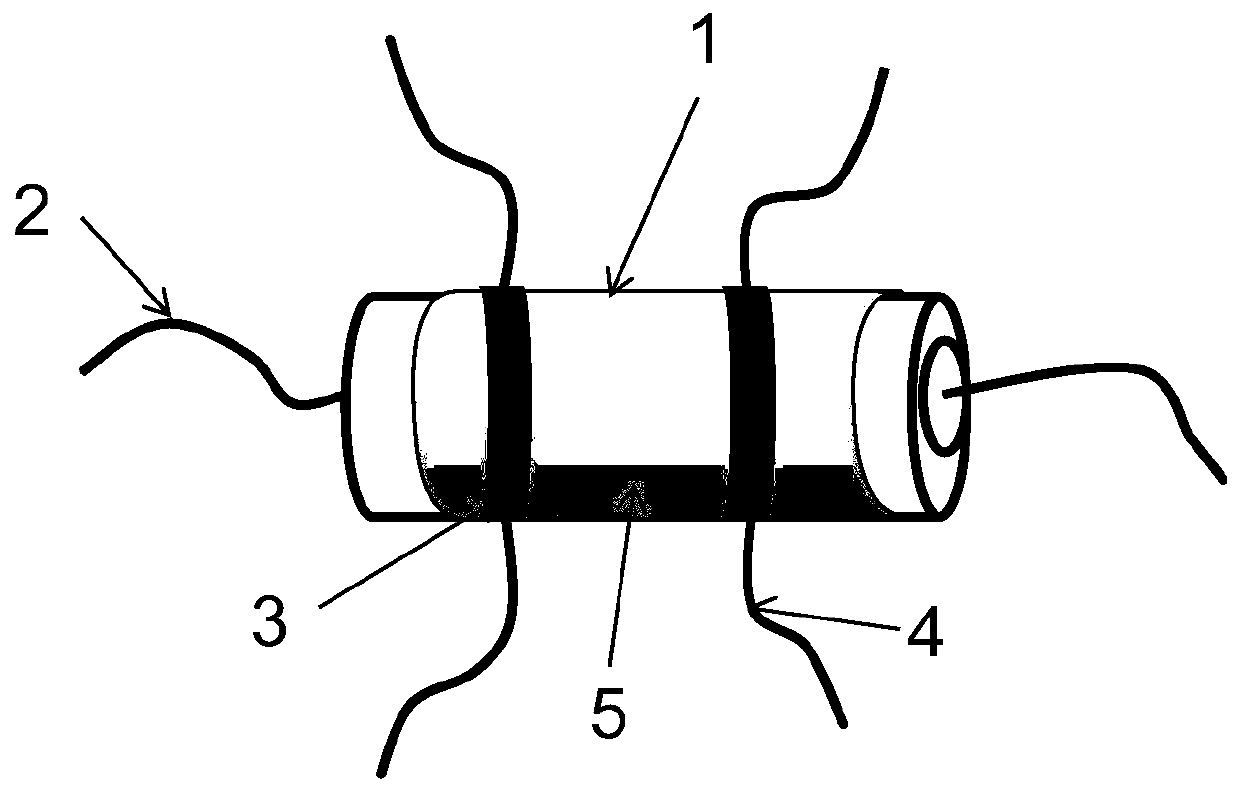

[0038] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 As shown, the Ni-Cr heating wire 2 traverses the Al 2 o 3 The ceramic tube 1 is welded on the heating electrode of the hexagonal base, and the gold electrode 3 is coated on Al 2 o 3 The outer surface of the ceramic tube 1 is welded to the measuring electrode of the hexagonal base through four platinum wires 4 , and the gas-sensitive coating 5 is coated on the gold electrode 3 and the outer surface of the cerami...

Embodiment 2

[0055] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 shown.

[0056] A kind of WO synthesized by self-assembly of nanosheets from scheelite concentrate 3 Preparation method of nanoflowers and NO 2 Gas sensor, follow the steps below:

[0057] ①Use the sodium hydroxide leaching process to extract tungsten from scheelite concentrate: place scheelite concentrate in a NaOH solution with a concentration of 15mol / L, at a liquid-solid ratio of 2:1, a reaction temperature of 170°C, and a stirring speed of 600rpm , holding time of 180min under the experimental conditions, filter the obtained leaching product to obtain filtrate and leaching residue, wash the leaching residue with deionized water 3 times to obtain washing liquid, and mix the obtained filtrate and the obtained washing liquid to obtain tungsten-containing The leachate of acid radical ions, the concentration of W ...

Embodiment 3

[0065] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 shown.

[0066] A kind of WO synthesized by self-assembly of nanosheets from scheelite concentrate 3 Preparation method of nanoflowers and NO 2 Gas sensor, follow the steps below:

[0067] ①Extract tungsten from scheelite concentrate by using sodium hydroxide leaching process: place scheelite concentrate in NaOH solution with a concentration of 18mol / L, at a liquid-solid ratio of 3:1, a reaction temperature of 190°C, and a stirring speed of 700rpm , holding time of 30min under the experimental conditions, the obtained leaching product was filtered to obtain the filtrate and leaching residue, the leaching residue was washed 3 times with deionized water to obtain the washing liquid, and the obtained filtrate and the obtained washing liquid were mixed to obtain a tungsten-containing The leachate of acid radical ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com