Terylene wool-like blanket and preparation method thereof

A blanket and polyester technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of rough suede, high consumption of raw materials, and hard acrylic blankets, achieve good printing or dyeing effect, and improve machine quality. Good performance and thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

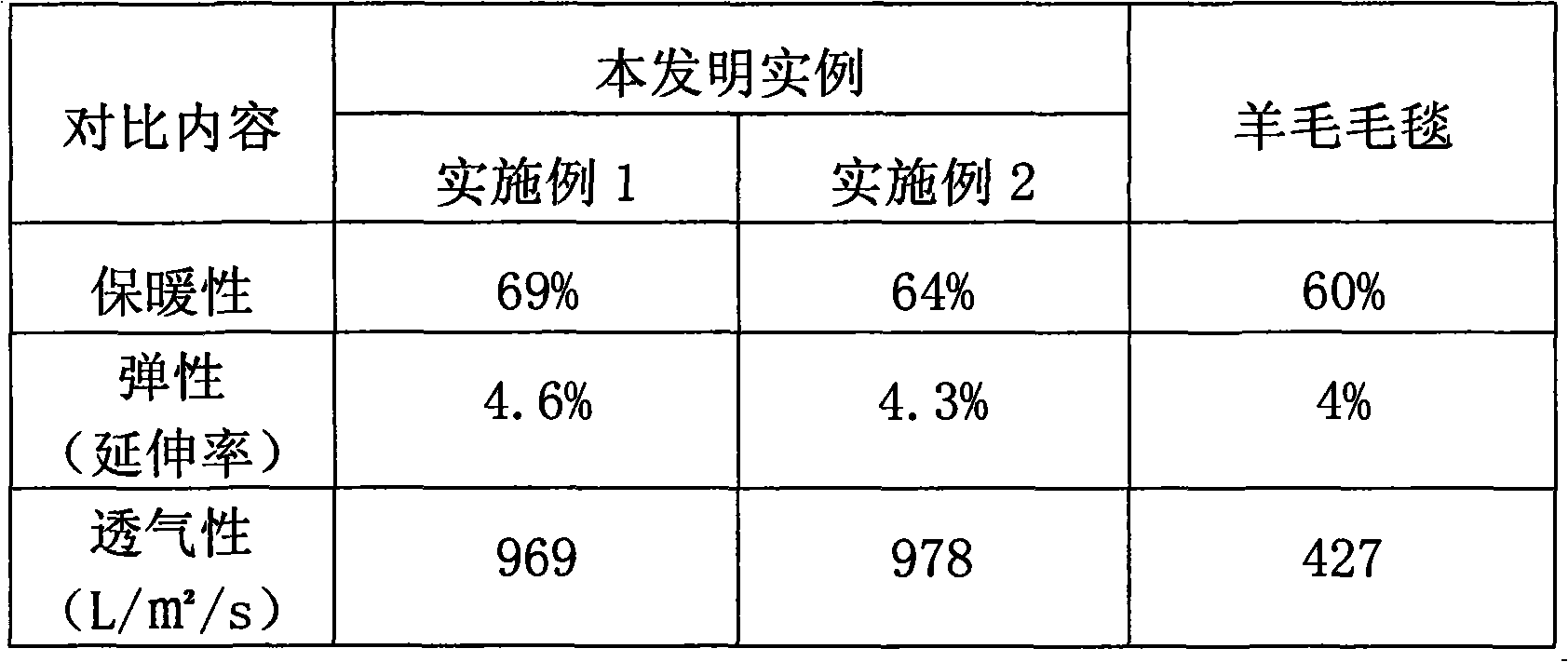

Examples

example 1

[0026] Polyester wool-like blanket production:

[0027] (1) Selection of raw materials: HFY composite yarn of 135D / 72F POY and FDY is used as the top yarn, 68D polyester FDY is used as the bottom yarn; HFY composite yarn accounts for 65%, and 68D polyester FDY accounts for 35%.

[0028] (2) Adopt the E22-2064W type plush cutting machine, use the British steel wire runway, cut the pile by double-needle clamping knife method, the wool yarn height is 35mm, and the gray cloth surface is smooth without horizontal stripes;

[0029] (3) After the gray cloth is obtained, use the prior art to carry out heat setting, printing or dyeing, rear fluffing, and napping for the gray cloth;

[0030] (4) Cutting and sewing into blankets and household items.

example 2

[0032] Polyester wool-like blanket production:

[0033] (1) Raw material selection The applicant recommends 80D / 48F HFY composite yarn as the top yarn, and 100D polyester FDY as the bottom yarn; HFY composite yarn accounts for 75%, and 68D polyester FDY accounts for 25%.

[0034] (2) E22-2064W type plush circular knitting machine is adopted, and the steel wire runway made in the UK is used. The double-needle clamping knife method is used for cutting pile. The surface of the woven gray cloth is flat without horizontal stripes, the yarn height is 8mm, and the weight is about 250 grams. ;

[0035] (3) After the gray cloth is obtained, the gray cloth is heat-set, printed or dyed in the same steps as in the prior art, and the back is raised and finished, and the shape is napped;

[0036] (4) Cutting and sewing into blankets and household items.

example 3

[0038] Polyester wool-like blanket production:

[0039] (1) Selection of raw materials: 80D / 48F POY and FDY HFY composite yarn is selected as the top yarn, 100D polyester FDY is used as the bottom yarn; HFY composite yarn accounts for 75%, and 68D polyester FDY accounts for 25%.

[0040] (2) E22-2064W-shaped plush circular knitting machine is used, and the steel wire runway made in the UK is used. The double-needle clamping knife method is used for cutting pile, and the gray cloth surface is flat without horizontal stripes, and the yarn height is 4mm; the weight is about 170 grams. ;

[0041] (3) After obtaining the gray cloth, utilize existing technology to carry out heat setting, printing or dyeing to the gray cloth, fluffing and finishing on the back, napping and setting;

[0042] (4) Cutting and sewing into blankets and household items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com