Washing machine

A technology of washing machine and washing tub, applied in the field of washing machine, can solve the problems such as easy to produce wrinkles, and achieve the effect of not easy to wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

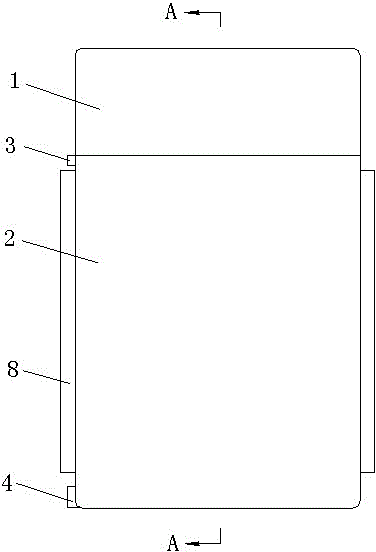

Image

Examples

Embodiment 1

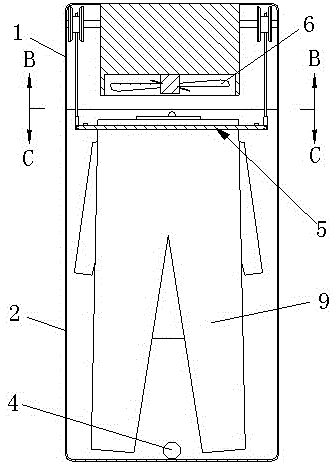

[0019] Such as Figure 4 As shown, the fixture 5 includes a rectangular fixture frame, and the fixture frame includes first and second frame bars 51, 52 arranged in parallel, and the two ends of the first and second frame bars 51, 52 are respectively connected by first and second guide rails 53 , 54 are connected, in other words, the fixture frame is a rectangular frame surrounded by the first and second frame strips 51, 52 and the first and second guide rails 53, 54, and the fixture frame is provided with several The second guide rail 53, 54 constitutes a clamp group of sliding fit, and the clamp group includes two clip bars 55, and an elastic hasp 56 for fixing the two clip bars 55, the clamp frame is connected with the first power unit, and the clothes 9 are used during use. Clamped by two clip bars 55, and fasten with elastic hasp 56, clothing 9 is not come off.

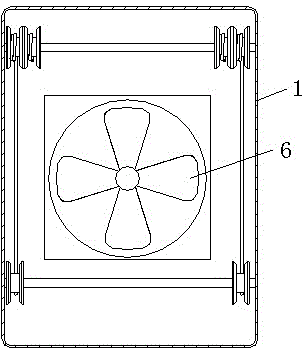

[0020] Such as Figure 5 As shown, the first power device includes a driving shaft 71 and a driven shaft 72 ...

Embodiment 2

[0023] Such as Figure 6 As shown, the fixture 5 includes a rectangular fixture frame, and the fixture frame includes first and second frame bars 51, 52 arranged in parallel, and the two ends of the first and second frame bars 51, 52 are respectively connected by first and second guide rails 53 . , the outer periphery of the fixture frame is provided with a fixing part 58, the fixing part 58 is connected with the upper cover 1, and a grid-like flat plate 57 is arranged parallel to the bottom of the fixture frame, and the flat plate 57 is connected with the first power device.

[0024] The first power unit includes a driving shaft 71 and a driven shaft 72 arranged in parallel, and the driving shaft 71 and the driven shaft 72 are located in the same horizontal plane. The two ends of the driving shaft 71 are respectively provided with first and second driving shafts from inside to outside. Wheels 73, 74, the two ends of the driven shaft 72 are respectively provided with driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com