Cloth ironing machine

A technology for ironing machine and cloth, applied in spray/jet textile material treatment, heating/cooling fabric, textile and papermaking, etc., can solve the problems of reduced profit, low work efficiency, large power consumption, etc., to improve ironing work Efficiency, improved ironing effect, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

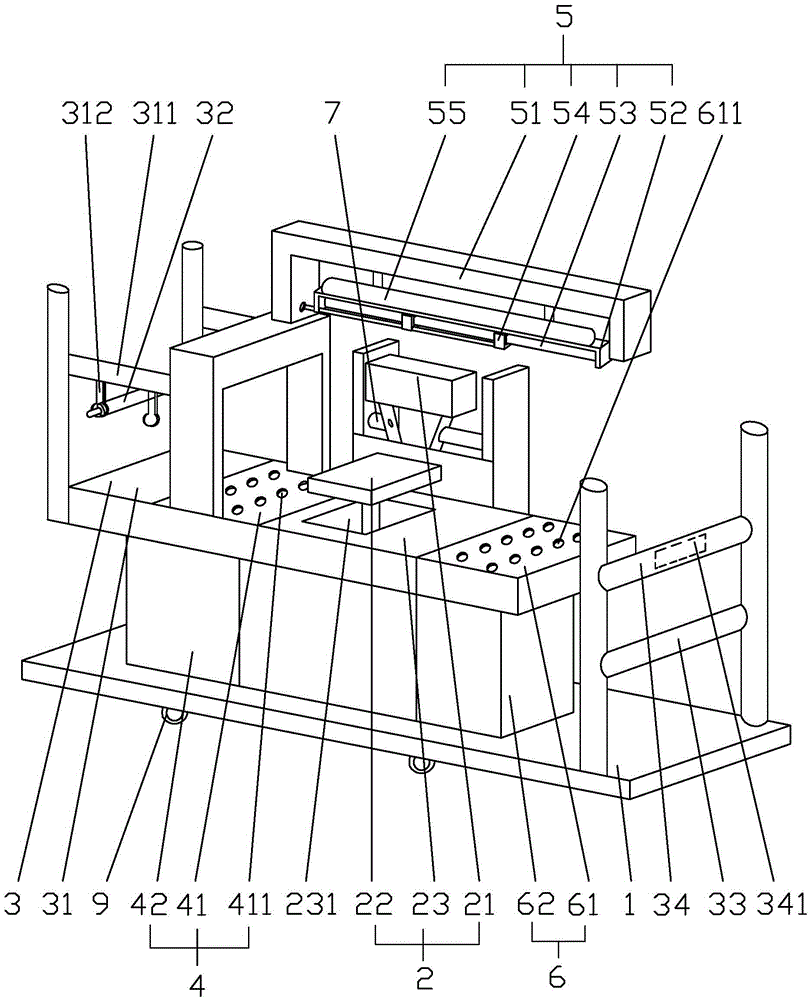

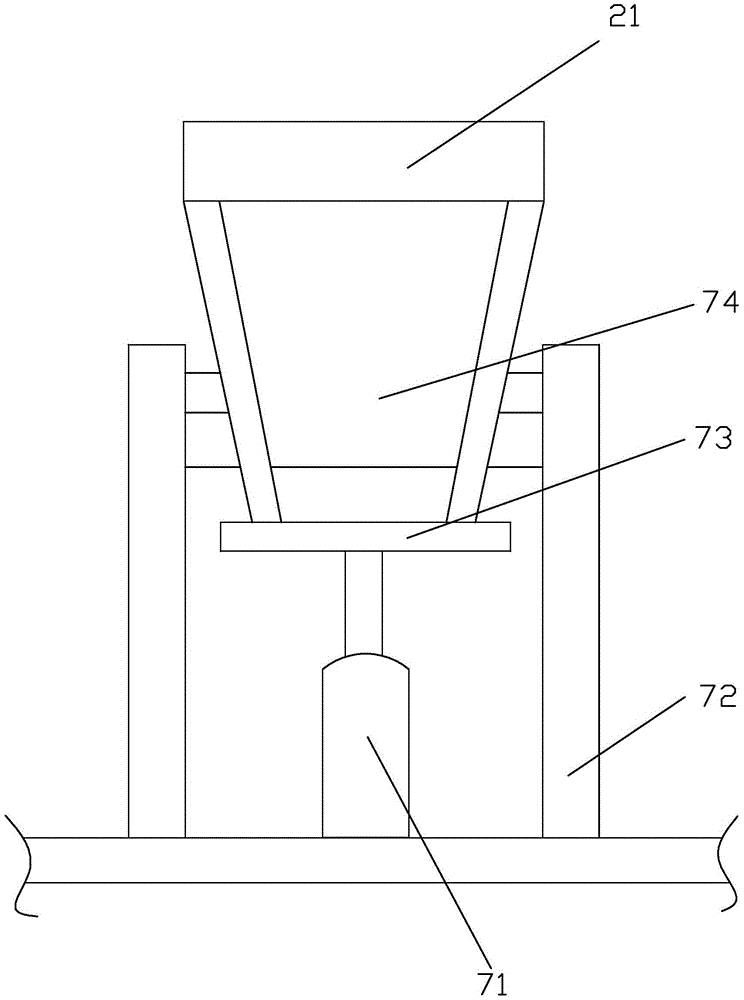

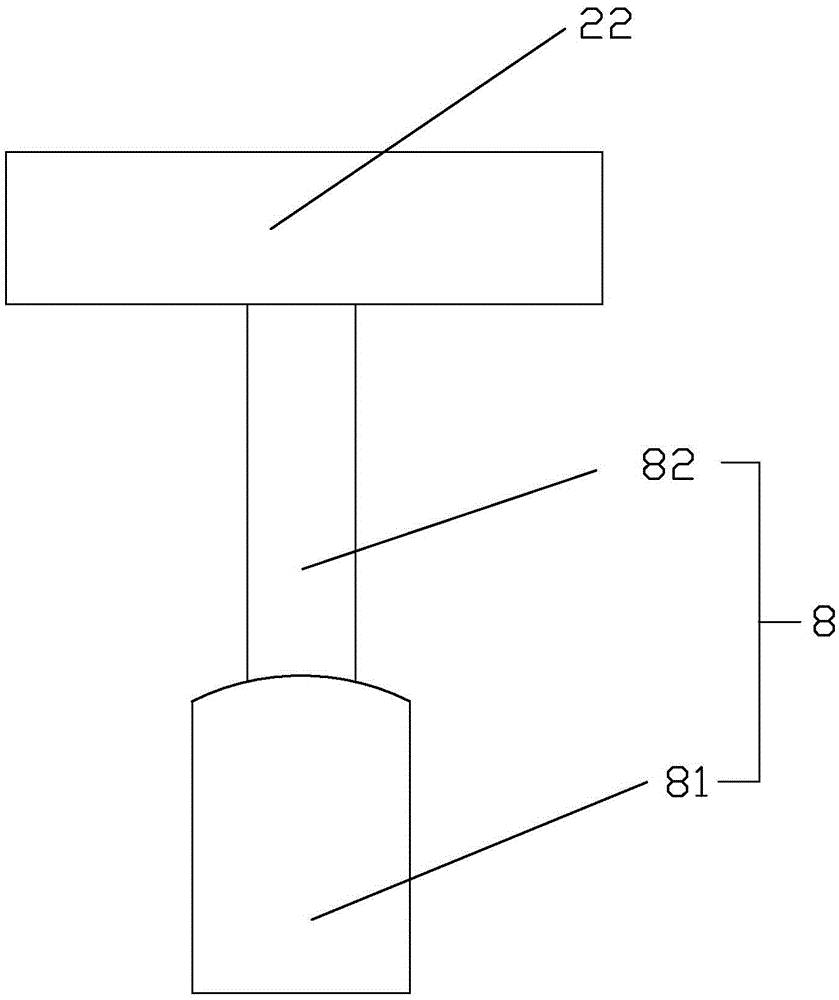

[0021] Such as Figure 1-6 As shown, a cloth ironing machine includes a frame 1, an ironing mechanism 2 and a transmission mechanism 3, and also includes a preheating mechanism 4, a sterilizing mechanism 5 and a drying mechanism 6, and the preheating mechanism 4 is located in the ironing mechanism 2 on the feed side, the sterilizing mechanism 5 is located on the discharge side of the ironing mechanism 2. The conveying mechanism 3 includes a feeding platform 31, a cloth releasing roller 32 and a cloth rolling roller 33, the cloth releasing roller 32 is located above the discharging platform 31, and hanging rods 311 are provided on both sides of the discharging platform 31, and the The hanging rods 311 are respectively provided with at least two pairs of hanging rings 312 . The hanging rings 312 are slidingly connected with the hanging r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com