Dyeing and finishing process of double-layer down-proof fabric

A fleece-proof fabric, dyeing and finishing technology, applied in the treatment of textile materials, dyeing method, fabric surface trimming, etc., to achieve the effect of avoiding wrinkles, avoiding sublimation and overflow, and improving the effect of fleece-proof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

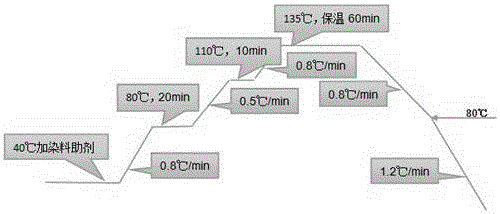

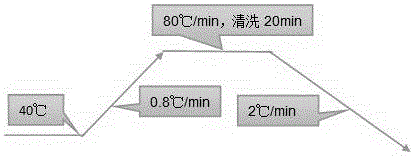

Embodiment 1

[0021] The dyeing and finishing process of a double-layer fleece-proof fabric is carried out as follows: desizing→dyeing→sizing and drying→waterproofing and setting, wherein: the desizing adopts loose-type continuous desizing, and the loose-type continuous desizing The desizing working solution is prepared by mixing NaOH, chelating dispersant, desizing agent TF-127, and deoiling spirit 101 in a weight ratio of 1.5:1:0.8:1, and adding 31 times the total weight of the three deionized water. The resulting aqueous solution, wherein the desizing agent is desizing agent TF-127; deoiling spirit is deoiling spirit 101.

[0022] The dyeing prescription includes 1.3g / l polyester special high temperature leveling agent, 2g / l defoamer, 0.8g / l glacial acetic acid, 0.4g / l softener, 0.08% (o.w.f) disperse dyes, wherein the polyester special high temperature The leveling agent is polyester special high-temperature leveling agent TF-212F, and the amount of dye refers to the weight percentage o...

Embodiment 2

[0028] A kind of dyeing and finishing process of double-layer anti-velvet fabric is carried out as follows

[0029] Line: desizing→dyeing→sizing and drying→waterproofing and setting, wherein: the desizing adopts loose continuous desizing.

[0030] The desizing working solution of the pine continuous desizing is mixed by NaOH, chelating dispersant, desizing agent TF-127, and deoiling spirit 101 in a weight ratio of 2:1:1:1, adding the total weight of the three and 32 times deionized water, wherein the desizing agent is desizing agent TF-127; the deoiling agent is deoiling agent 101.

[0031] The dyeing prescription includes 1.5g / l polyester special high temperature leveling agent, 2g / l defoamer, 0.8g / l glacial acetic acid, 0.5g / l softener, 0.08% (o.w.f) disperse dyes, wherein the polyester special high temperature The leveling agent is polyester special high-temperature leveling agent TF-212F, and the amount of dye refers to the weight percentage of the fabric, that is, % (o.w...

Embodiment 3

[0037] The dyeing and finishing process of a double-layer fleece-proof fabric is carried out as follows: desizing → dyeing → setting and drying → waterproofing and setting, wherein: the desizing adopts loose continuous desizing.

[0038] The desizing working solution of the pine continuous desizing is mixed by NaOH, chelating dispersant, desizing agent TF-127, and deoiling spirit 101 in a weight ratio of 2.5:1:1.2:1, adding the total weight of the three and 33 times deionized water, wherein the desizing agent is desizing agent TF-127; deoiling agent is deoiling agent 101.

[0039]The dyeing prescription includes 1.8g / l polyester special high temperature leveling agent, 2g / l defoamer, 0.8g / l glacial acetic acid, 0.6g / l softener, 0.08% (o.w.f) disperse dyes, wherein the polyester special high temperature The leveling agent is special high-temperature leveling agent TF-212F for polyester, and the amount of dye refers to the weight percentage of the fabric, that is, % (o.w.f).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com