Single-spinneret-plate binary skin-core-type composite-spinning multiple-different-yarn production process

A production process and a skin-core technology, which is applied to the production process of the same-board binary skin-core composite spinning multi-differential yarn, can solve the problems such as the lack of hand feeling of wool-like fabrics, and achieve a novel hand feeling, good elasticity, and not easy to wrinkle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

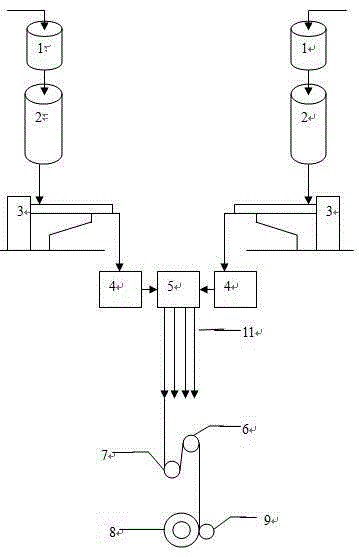

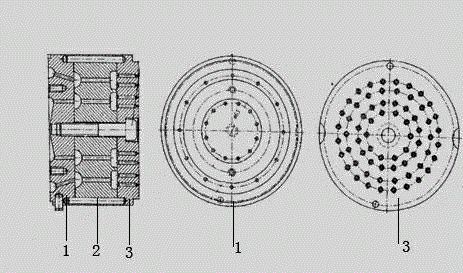

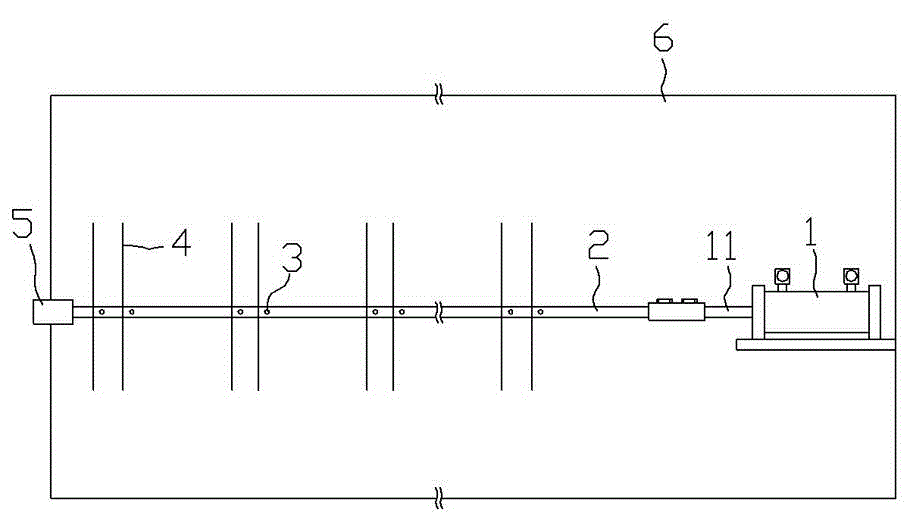

[0027] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings. As shown in Figures 1 to 5, it is a preferred embodiment of the production process of the present invention.

[0028] (1) Main test equipment and main raw materials

[0029]Drying equipment: The production capacity of Beijing Dehoupu is 60kg / hr and 30kg / hr pilot drying equipment respectively.

[0030] Screw machine press: Shanghai JWELL Chemical Fiber Machinery Manufacturing Co., Ltd. manufactures two JWM-45 screw machine presses, horizontal L / D=25.

[0031] Spinning equipment: one set of 1-bit x 6-head composite spinning pilot equipment manufactured by Shanghai JWELL Chemical Fiber Machinery Manufacturing Co., Ltd.

[0032] Winding equipment: one set of 835 automatic winding machine manufactured by Shanghai JWELL Chemical Fiber Machinery Manufacturing Co., Ltd.

[0033] Texturing equipment: a 33H texturing machine from Murata Corporati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com