Production process of loop tweed

A production process and tweed technology, applied in the direction of liquid-repellent fibers, textiles, yarns, etc., can solve problems such as difficult care, achieve the effects of easy care, reduce fiber felt shrinkage, and increase surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

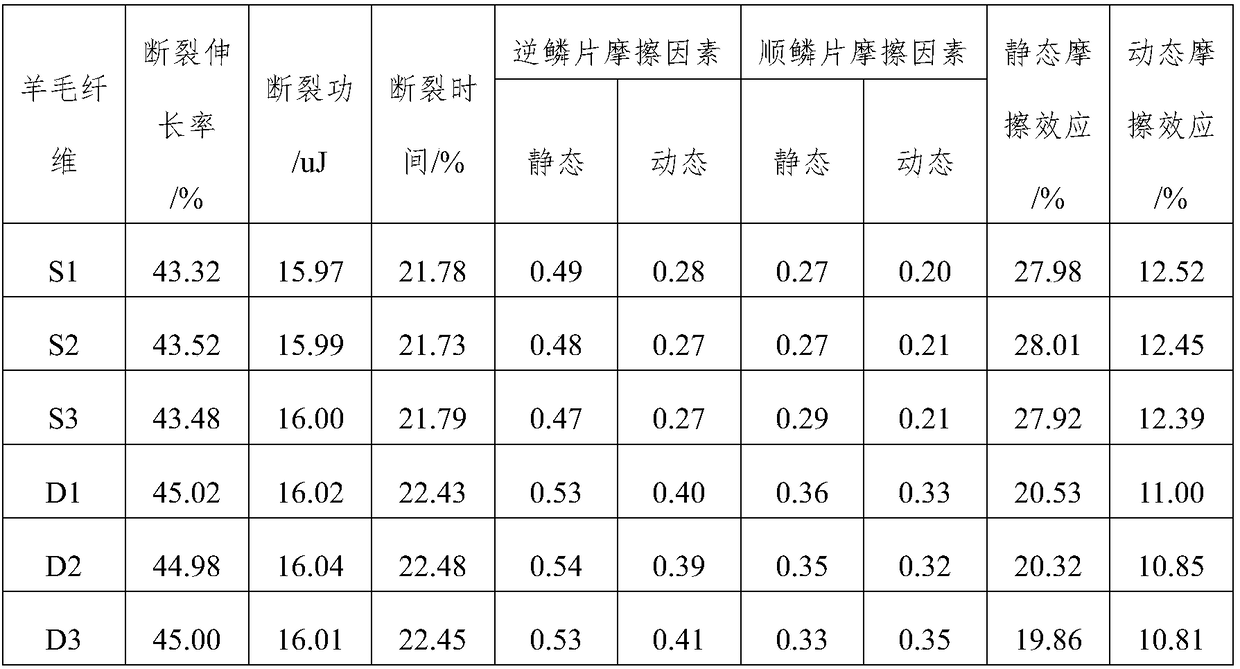

Embodiment 1

[0016] The present invention is a kind of production technique of bobbin tweed, comprising the following sequential process steps:

[0017] S1: Prepare raw materials for boucle tweed, including 25% polyester fiber by weight, 25% Australian short slivers with a quality count of 64S, 30% Australian wool tops with a quality count of 64S and 20% viscose fiber ;

[0018] S2: Spin dyed or undyed polyester fiber, Australian short sliver with a quality count of 64S, Australian wool top with a quality count of 64S and viscose fiber into worsted yarn of 38 / 2 public count and Worsted yarn of 4 / 1 public count; in the spinning process, the relative humidity is controlled at 50% to 65%, and the temperature is 25°C to 30°C;

[0019] S3: Warp the yarn obtained in S2, wherein the worsted yarn of 38 / 2 public count and 4 / 1 public count is interwoven as weft yarn, and the worsted yarn of 38 / 2 public count is used as warp yarn; the spun yarn is The rapier loom adopts single warp and single weft ...

Embodiment 2

[0026] The only difference from Example 1 is that in the pretreatment process for Australian short slivers with a quality count of 64S and Australian wool tops with a quality count of 64S between steps S2 and S3, the pretreated raw fiber Immerse in the treatment solution for 10 minutes; in the pretreatment process of polyester fibers and / or viscose fibers between steps S2 and S3, dry the raw fibers at 85°C for 3 hours after cleaning.

Embodiment 3

[0028] The only difference from Example 1 is that in the pretreatment process for Australian short slivers with a quality count of 64S and Australian wool tops with a quality count of 64S between steps S2 and S3, the pretreated raw fiber Immerse in the treatment solution for 7 minutes; in the pretreatment process of polyester fibers and / or viscose fibers between steps S2 and S3, dry the raw fibers at 85°C for 2.5 hours after cleaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com