High-speed pad sewing machine

A sewing pad machine, high-speed technology, applied in sewing machine components, sewing machines for sewing quilts, sewing machines for program control, etc., can solve the problems of low production efficiency, low degree of automation, deformation, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

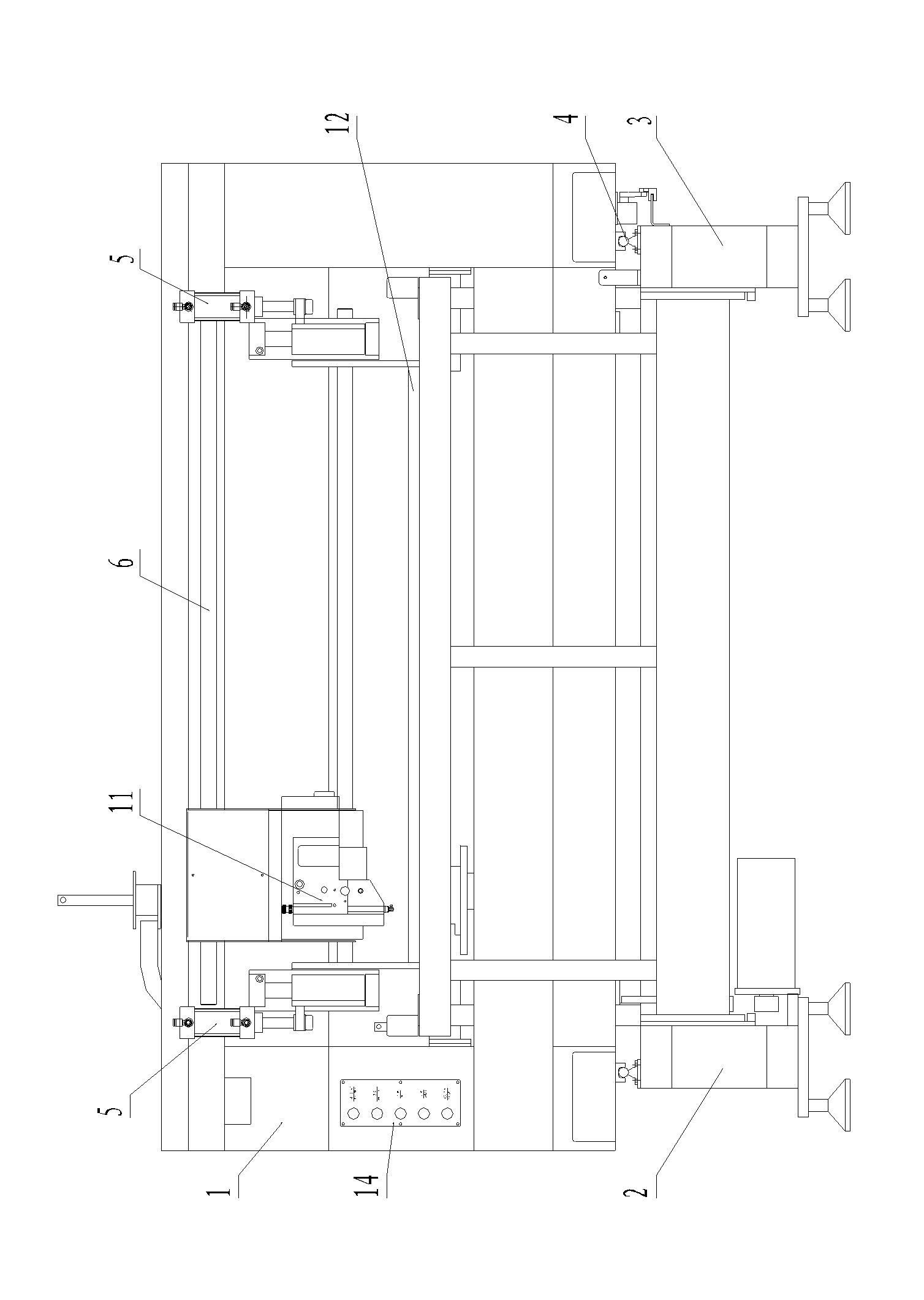

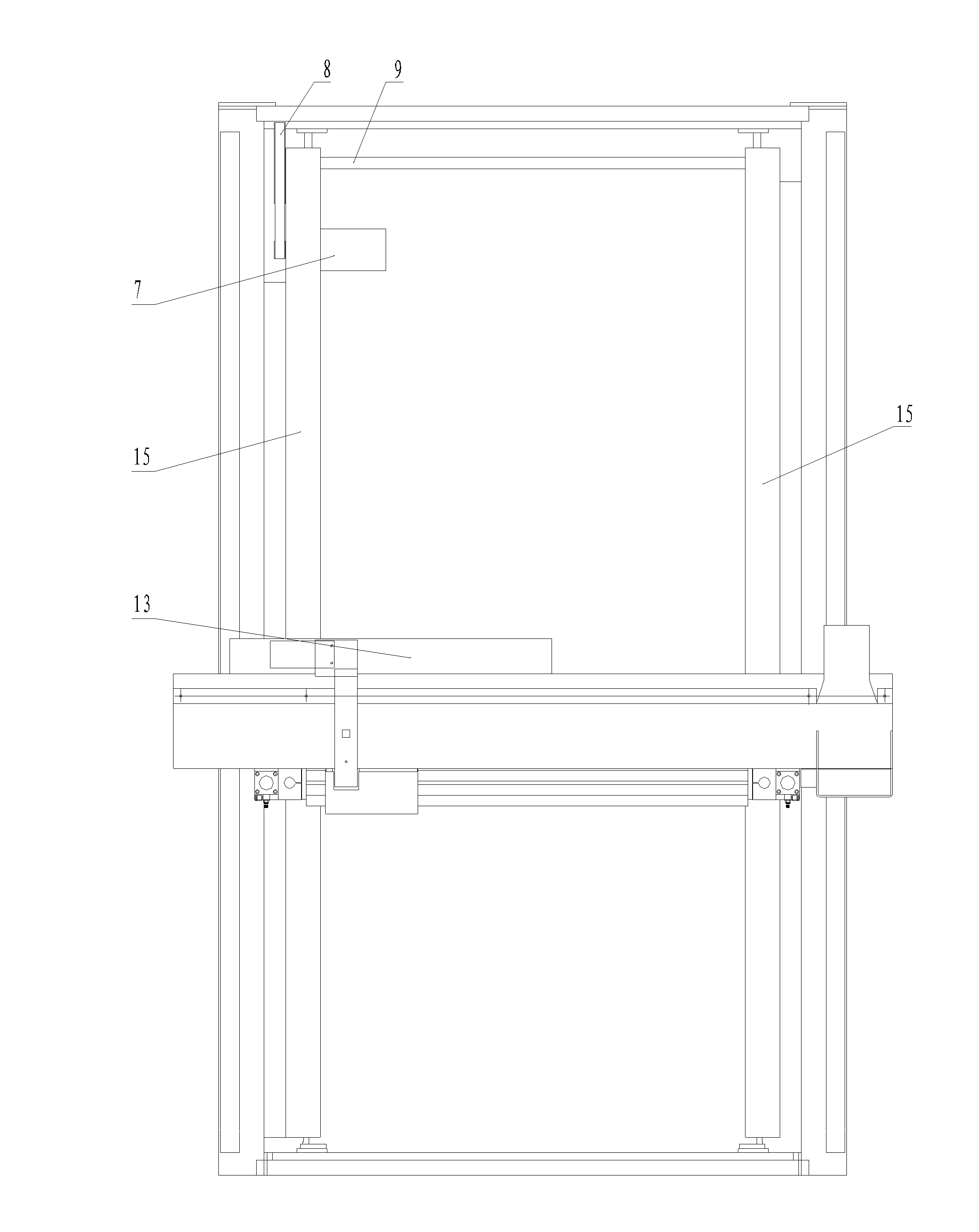

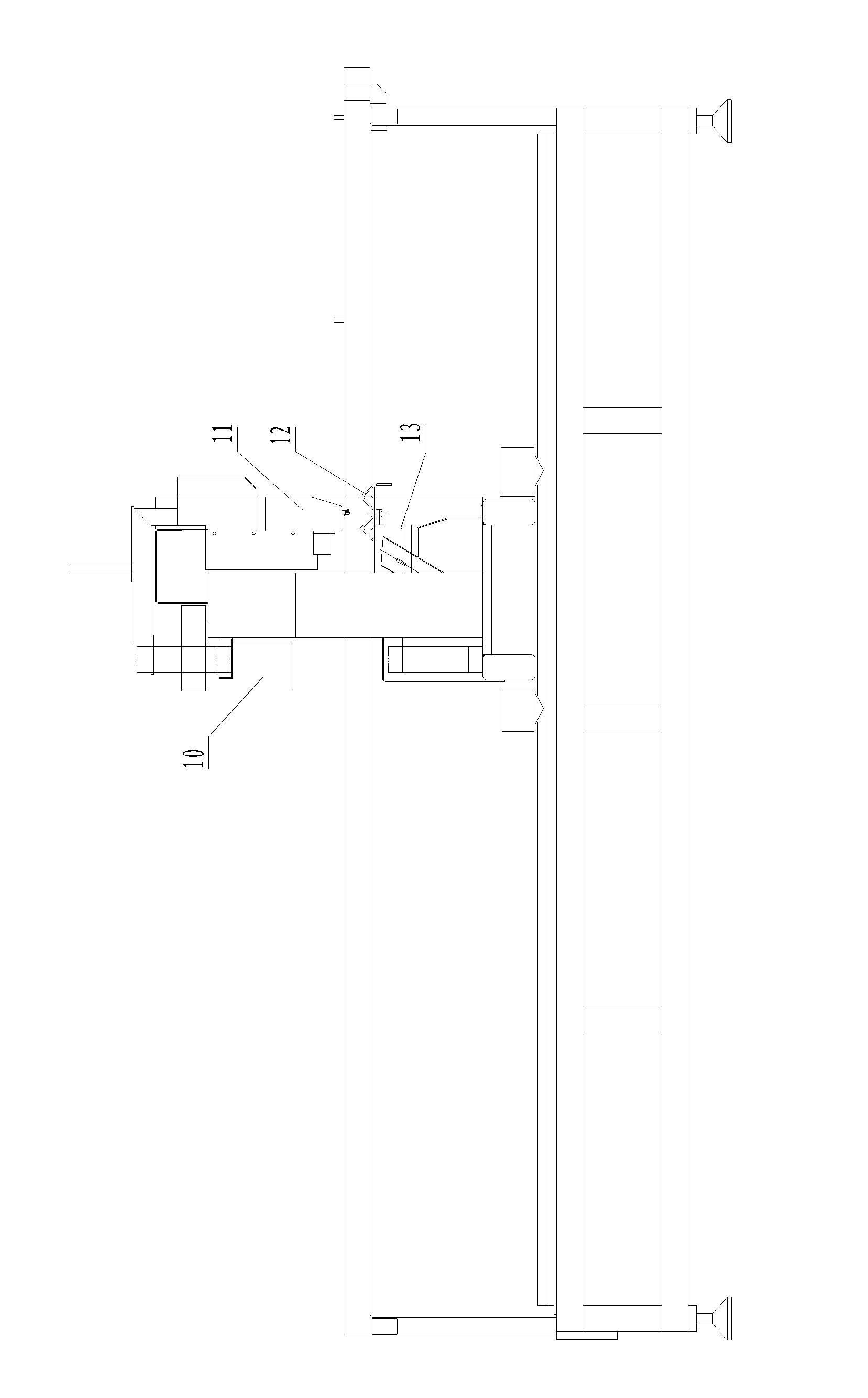

[0012] as attached Figure 1-3 The shown high-speed pad sewing machine of the present invention includes a gantry frame 1, a left frame 2, a right frame 3, a cylinder 5, an X-direction rail 6, an X-direction stepping motor 10, a head part 11, and a pressure groove 12. Machine base component 13, computer 14, L-shaped synchronous belt 8, Y-direction transmission shaft 9, Y-direction H-shaped synchronous belt 15; the left frame 2 and the right frame 3 are arranged in parallel and alternately; the left frame 2. The upper surface of the right frame 3 is respectively provided with Y guide rails 4; the two ends of the gantry frame 1 are respectively arranged on the Y guide rails 4 of the left frame 2 and the right frame 3; the gantry frame 1 can slide along the Y guide rail 4; the X guide rail 6 is horizontally arranged on the gantry frame 1; the head part 1 is sleeved on the X guide rail 6 and can slide along the X guide rail 6; The base part 13 is arranged on the bottom of the gan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com