Battery case nickel-plating fault treatment process

A treatment process and battery case technology, which is applied in the field of battery case barrel nickel plating fault treatment process, and can solve the problems of product scrap, plating loss, and plating peeling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

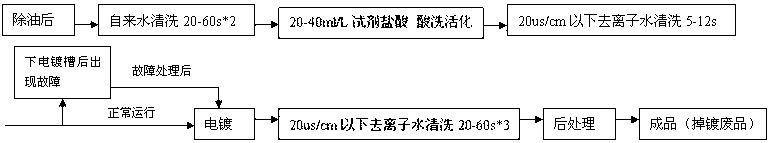

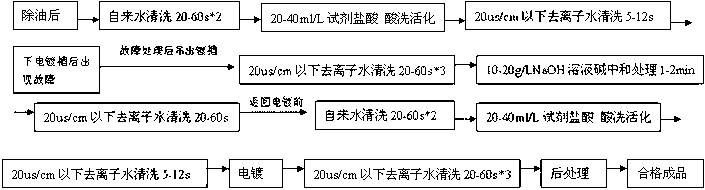

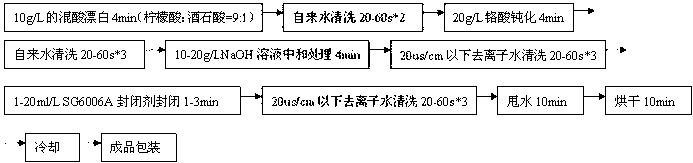

[0014] Barrel-plated nickel battery case figure 1 During normal process operation, after degreasing the battery shell, it is first washed with tap water twice for 20s each, and then pickled and activated in 30ml / l reagent hydrochloric acid (HCL content, mass % 36-38) solution for a certain period of time (2A, 3A and 3A The following battery case 6min, SC type, C type, D type, F type battery case 10min), and then washed with deionized water for 10s, and electroplated in the lower tank (electroplating solution: 210g / L nickel sulfate, 55g / L nickel chloride, 48g / L boric acid, pH value 4.5, temperature 50 degrees acidic solution, add 0.1ml / l barrel plating bright nickel 998-A brightener and 4ml / l barrel plating bright nickel softener) for 3 hours, and deliver the parts through three deionization Rinse with water for 20 seconds each, and finally post-process to obtain the finished product. Post-processing steps such as image 3 Shown: first bleach in 10g / L mixed acid (citric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com