Manufacturing method of laminated glass

A manufacturing method, technology of laminated glass, applied in the direction of adhesive heating bonding method, chemical instrument and method, glass/slag layered product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

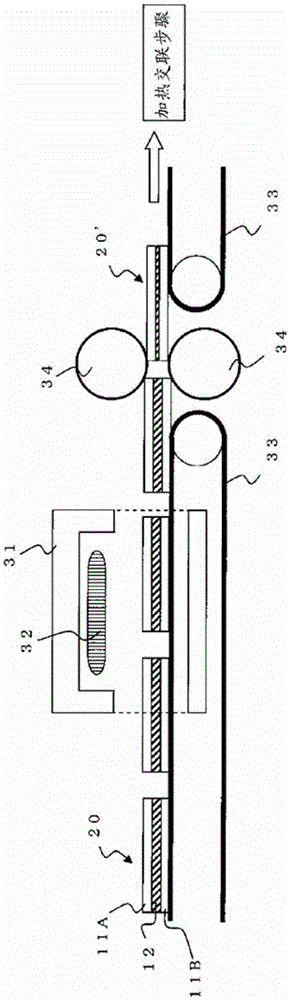

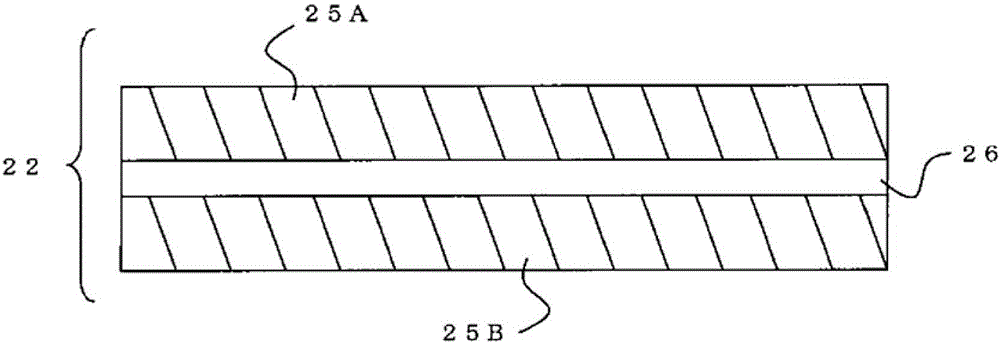

[0039] Now, the method for producing laminated glass of the present invention will be described with reference to the accompanying drawings. figure 1 is a schematic cross-sectional view of an exemplary embodiment for explaining the method for producing laminated glass of the present invention. exist figure 1 In the laminated glass, the laminated body 20 including the interlayer film 12 sandwiched between two glass plates 11A and 11B is prepared, the laminated body is pre-compressed under heat and pressure, and then heated to make it prepared by crosslinking.

[0040]As the glass plates 11A and 11B in the manufacturing method of the laminated glass of the present invention, any transparent glass plate, for example, a green glass plate, a silicate glass plate, an inorganic glass plate, and an uncolored transparent glass plate can be used. Alternatively, plastics such as polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polyethylenebutyrate (polyethylenebutyra...

Embodiment 1-14, comparative example 1-10

[0092] 1. Preparation of interlayer

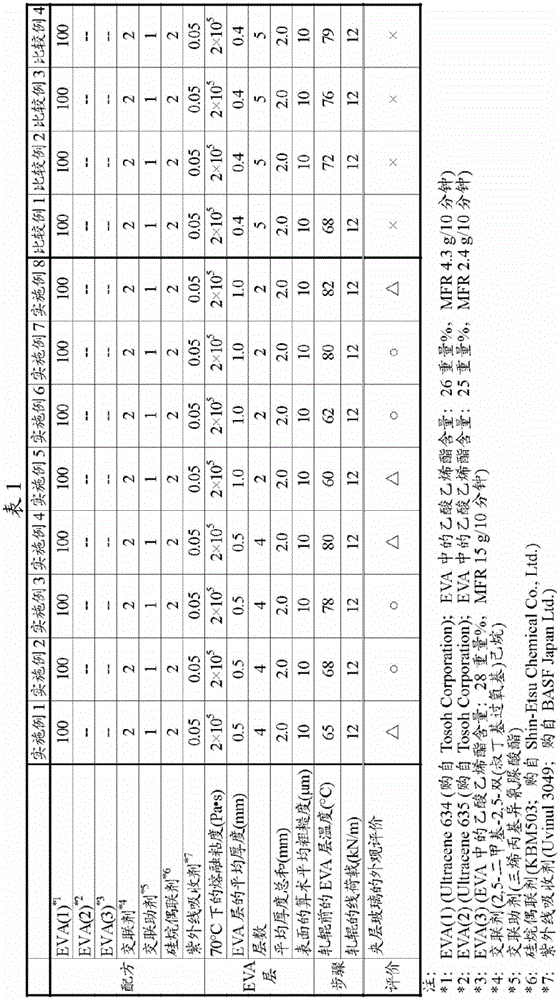

[0093] Compositions having formulations as described in Table 1 and Table 2 were used as raw materials and calendered. Thus, a molded article was prepared. The composition was kneaded for 15 minutes at 80°C, the calender roll temperature was set to 80°C, and the processing speed was set to 5 m / min. After that, one surface of the molded product is embossed with a small embossing roller. Thus, the EVA layers (size: 1000 mm×1000 mm) of Examples 1-14 and Comparative Examples 1-10 having the surface thicknesses and surface properties (arithmetic mean roughness Ra) shown in Tables 1 and 2 were obtained. Subsequently, EVA layers having the number of layers shown in Table 1 and Table 2 were laminated one by one to prepare an intermediate film.

[0094] The viscosity of the EVA layer was measured using a capillary rheometer by applying thereto a predetermined shear rate of 0.1 mm / min. The surface property (arithmetic mean roughness Ra) of the E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com