Method for protecting conductive lead-out bar in insulated paint immersing process

An insulating varnish and baking varnish technology, which is used in the manufacture of circuits, electrical components, inductors/transformers/magnets, etc., can solve problems such as scratches, poor appearance, and difficulty in cleaning insulating varnishes, reducing man-hours and making it easy to remove and clean. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

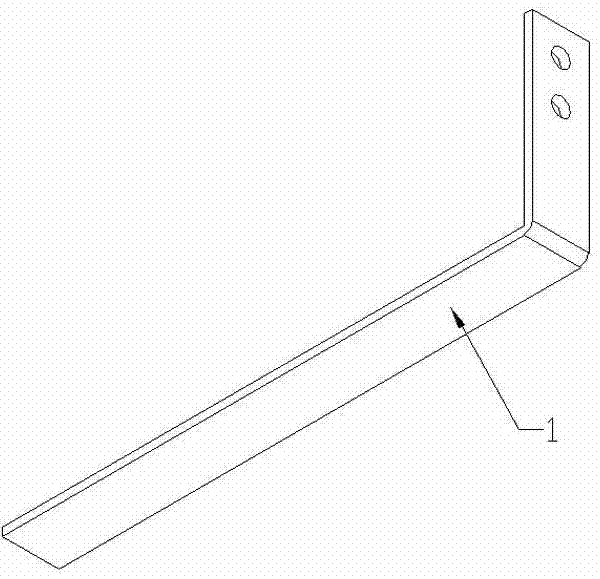

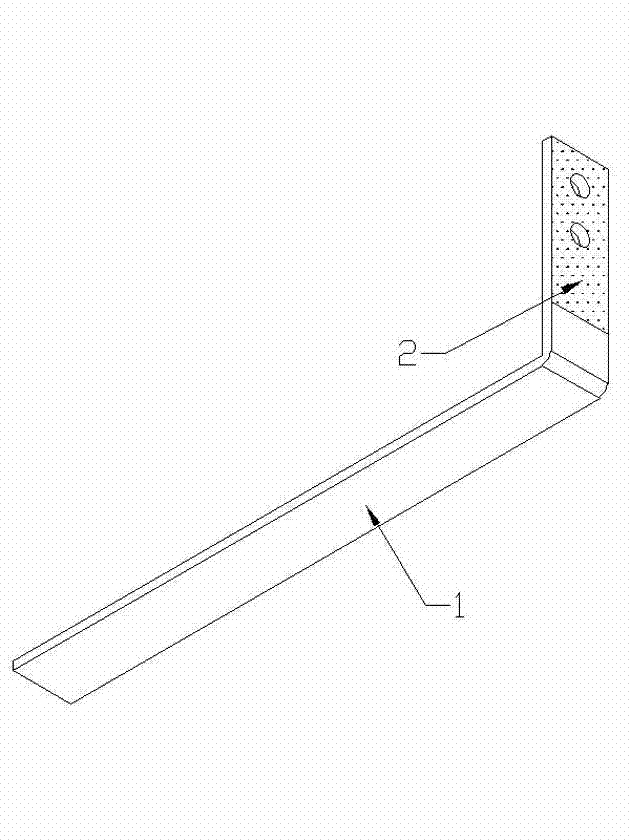

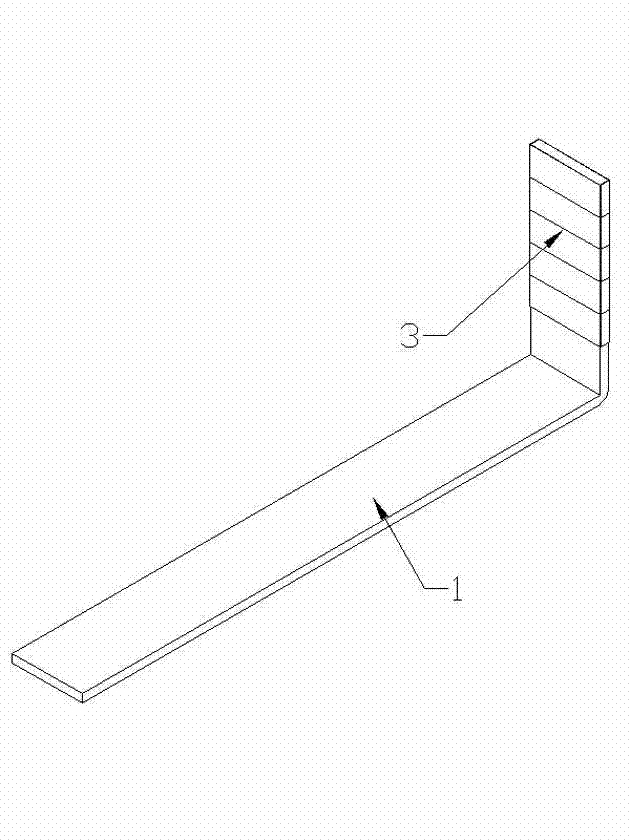

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in this embodiment, the method for protecting conductive lead-out bars of the present invention by immersing insulating varnish is mainly used to protect conductive lead-out bars on reactors or transformer products. The conductive lead-out row is arranged on a reactor or a transformer product. The present invention comprises the following steps:

[0021] (1) Evenly coat a layer of thermal conductive silicone grease on the conductive lead-out row;

[0022] (2) Wrap a layer of tape on the surface of the conductive lead-out row coated with thermal conductive silicone grease, and the tape is transparent tape;

[0023] (3) The reactor or transformer product equipped with the conductive lead-out bar treated in the above step (2) is dipped in insulating varnish;

[0024] (4) The reactor or transformer product processed in step (3) is subjected to baking paint treatment;

[0025] (5) Remove the tape on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com