A kind of encapsulation material, related adhesive film and photovoltaic module and preparation method

A technology of packaging materials and packaging film, which is applied in the direction of photovoltaic power generation, film/sheet without carrier, adhesive, etc., can solve the problem of the bonding performance of packaging materials, the attenuation of bonding performance between packaging materials and glass, packaging materials and glass, and backplanes. Problems such as delamination and high reliability risk, to achieve the effect of reducing the bond strength reduction value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

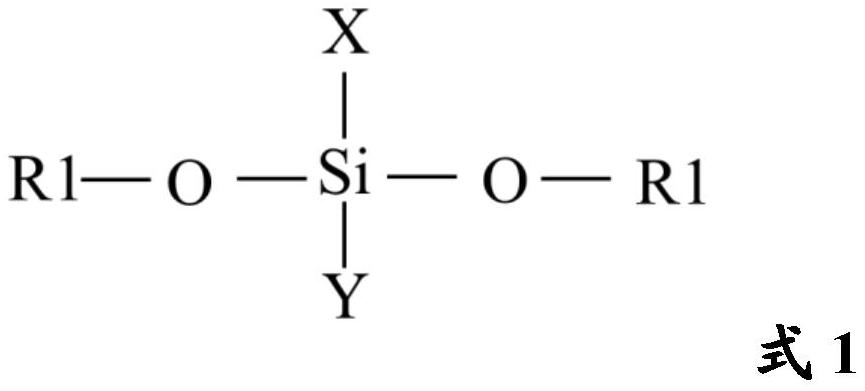

Method used

Image

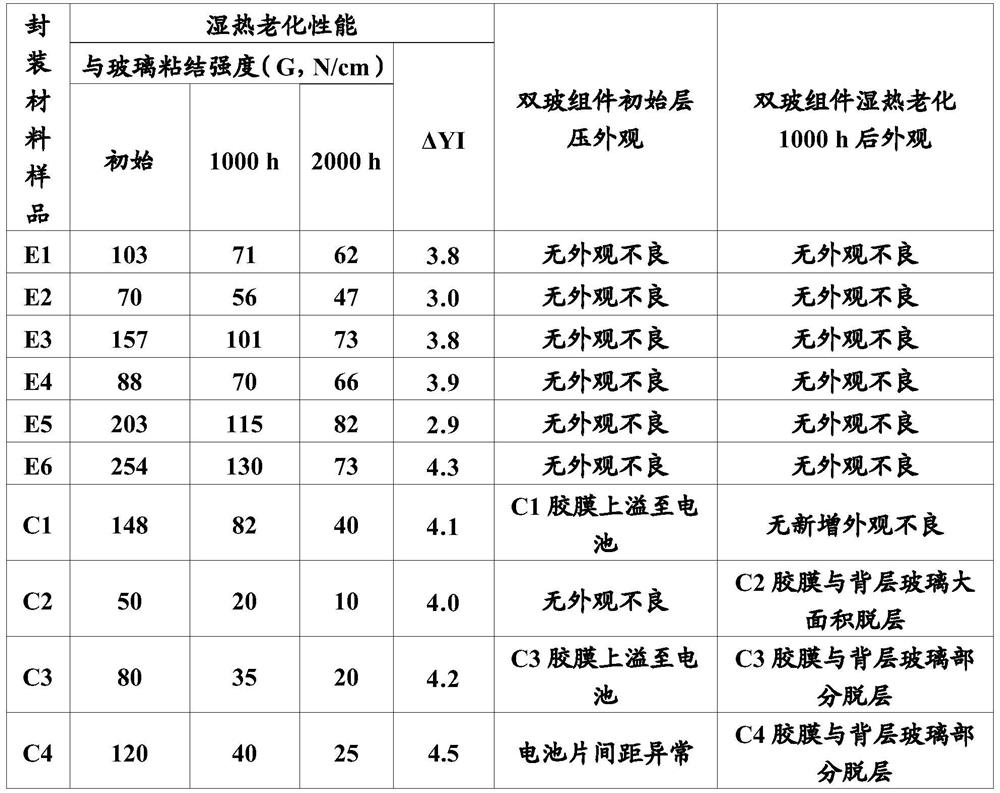

Examples

Embodiment 1

[0096] Put 1 mole of vinyltriethoxysilane monomer in a 1L reaction kettle, slowly add 0.75 moles of water with a pH value of 2, and stir evenly. After adding the water, raise the temperature to 50°C. The reaction was continued for a total of 5 hours. After the reaction, the ethanol produced was removed by a rotary evaporator, and the remaining product was the desired vinyltriethoxysilane oligomer. Wherein, the mass proportion of the vinyltriethoxysilane oligomer whose polymerization degree Xn is 2-7 is 50% by weight, and the number average molecular weight is 688g / mol.

[0097] Prepare a kind of packaging adhesive film, it is prepared by following components: 100 parts by weight ethylene-vinyl acetate copolymers (the mass fraction of vinyl acetate is 33%), 0.2 parts by weight crosslinking agent tert-butyl peroxyisopropyl carbonate ester, 15 parts by weight of magnesium oxide and 5 parts by weight of titanium dioxide, 1 part by weight of sensitizer trimethylolpropane triacrylat...

Embodiment 2

[0100] Put 0.5 mole of γ-methacryloxypropyl trimethoxysilane monomer and 0.5 mole of vinyl tris (2-methoxyethoxy) silane monomer in a 1L reaction kettle, drop slowly Add 0.75 moles of water with a pH value of 2, and stir evenly. After the water is added, raise the temperature to 50°C and continue the reaction. Total reaction time is 5 hours. After the reaction, the methanol produced is removed by a rotary evaporator, and the remaining products are the required γ-methacryloxypropyl trimethoxysilane and vinyl tris(2-methoxyethoxy) Silane monomer copolymer mixture. The copolymerization mixture comprises γ-methacryloxypropyltrimethoxysilane homopolymer, vinyl tris(2-methoxyethoxy)silane homopolymer and γ-methacryloxypropyl Base trimethoxysilane and vinyl tri (2-methoxyethoxy) silane monomer copolymer; Wherein the degree of polymerization Xn is 2-7 The sum mass proportion of components is 75% by weight, and the number average molecular weight is 855g / mol.

[0101]Prepare a kind...

Embodiment 3

[0104] Put 0.5 mole of vinyltrimethoxysilane monomer and 0.5 mole of methylvinyldiethoxysilane monomer in a 1L reaction kettle, slowly drop 0.6 mole of water with a pH value of 2, and stir evenly. After the water was added, the temperature was raised to 50°C to continue the reaction. Total reaction time is 5 hours. After the reaction, the produced methanol is removed by a rotary evaporator, and the remaining product is the required copolymerization mixture of vinyltrimethoxysilane and methylvinyldiethoxysilane monomers. Wherein said copolymerization mixture comprises vinyltrimethoxysilane oligomer, methylvinyldiethoxysilane oligomer and vinyltrimethoxysilane and methylvinyldiethoxysilane copolymer, wherein polymerized The mass ratio of the component whose degree Xn is 2-7 is 75% by weight, and the number average molecular weight is 458g / mol.

[0105] Prepare an encapsulation film, which is prepared from the following components: 100 parts of metallocene catalyzed ethylene bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com