A kind of encapsulating material, related adhesive film and its preparation method and photovoltaic module

An encapsulation material and encapsulation film technology, which can be applied to films/sheets without carriers, adhesives, film/sheet adhesives, etc. It can solve problems such as increasing difficulty, and achieve the effect of high reliability and reduced value of bond strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

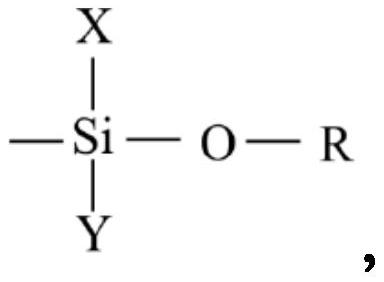

Method used

Image

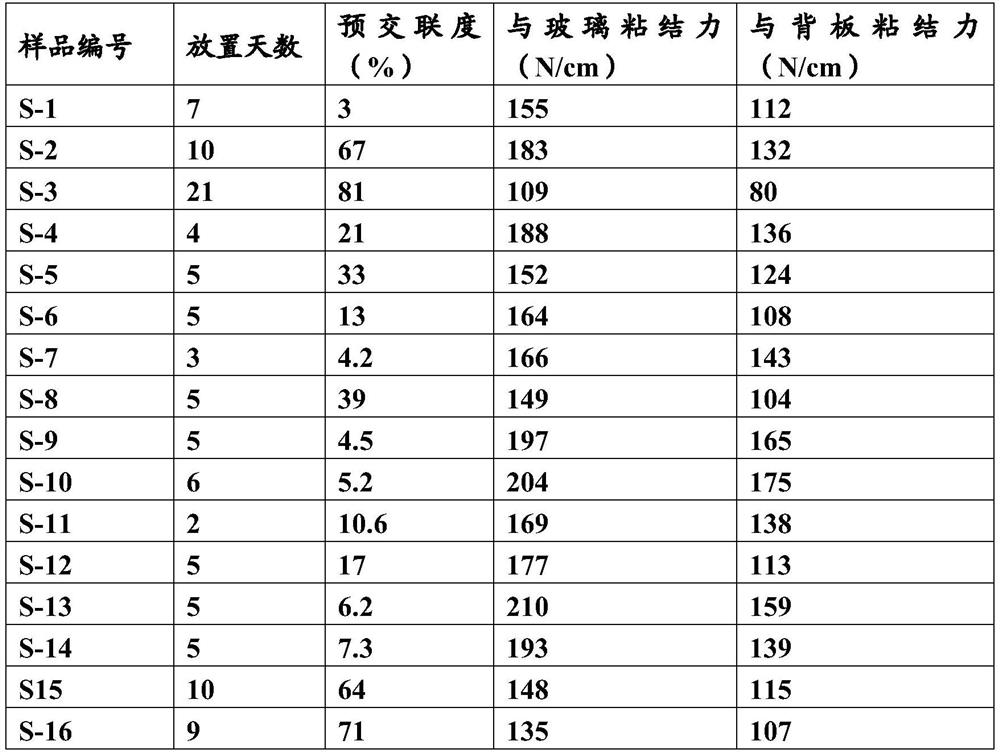

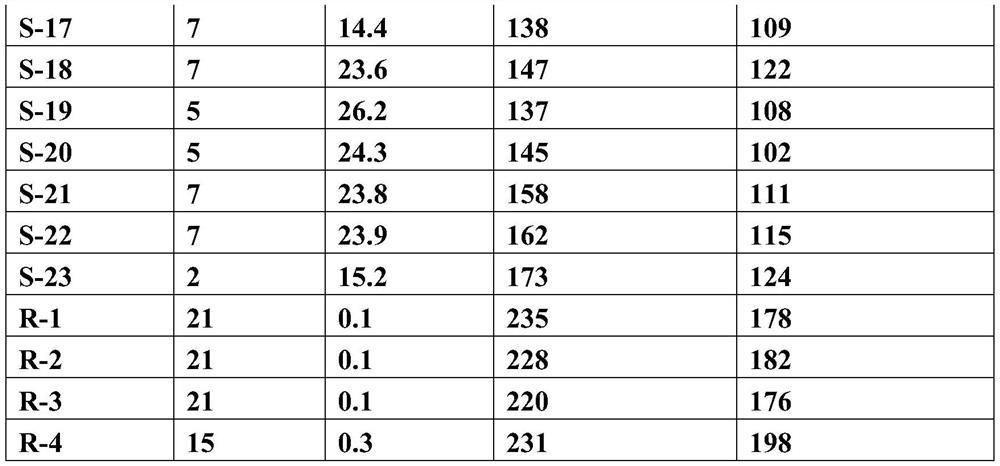

Examples

Embodiment 1

[0087] 93.069% by weight of ethylene-vinyl acetate copolymer with a melt index of 30g / 10min, 5% by weight of ethylene-vinyl acetate copolymer containing 1.0% by weight of carboxylic acid anhydride groups, 0.01% by weight of ethylene glycol, 0.001% by weight of di Methyl benzylamine, 0.5% by weight of tert-butyl peroxyisopropyl carbonate, 0.9% by weight of triallyl isocyanurate, 0.5% by weight of vinyltriethoxysilane, 0.02% by weight of bis (2,2,6,6-Tetramethyl-4-piperidinyl) sebacate is fully mixed and then added to the extruder to melt and extrude, cast through a T-shaped die to form a film, leave it for 7 days, and record it as S-1.

Embodiment 2

[0089] A mixture of 29.355% by weight of ethylene-butene copolymer and ethylene-propylene copolymer with a melt index of 20g / 10min, 30% by weight of ethylene-butene copolymer containing 10.0% by weight of trimethoxysilane coupling groups, 40% by weight of ethylene-butene copolymer containing 1% by weight of hydroxyl groups, 0.5% by weight of dioctyltin dithiolate, 0.1% by weight of 2,5-dimethyl-2,5-(bis-tert-butylperoxy) Hexane, 0.02% by weight of triallyl cyanurate, 0.02% by weight of vinyltrimethoxysilane, 0.005% by weight of bis(1-octyloxy-2,2,6,6-tetramethyl -4-piperidinyl) sebacate was fully mixed and added to an extruder to melt and extrude, cast through a T-shaped die to form a film, and leave it for 10 days, which was recorded as S-2.

Embodiment 3

[0091] 3.355% by weight of ethylene-pentene copolymer with a melt index of 15g / 10min, 95% by weight of ethylene-pentene copolymer containing 3.0% by weight of isocyanate groups, 0.01% by weight of 1,3-propylene glycol, 0.005% by weight of Stannous octoate, 0.01% by weight of 1,1-bis(tert-amylperoxy)cyclohexane, 0.02% by weight of propoxylated trimethylolpropane triacrylate, 0.8% by weight of tert-butyl vinyl triperoxide Base silane, 0.8% by weight of bis-2,2,6,6-tetramethylpiperidinol of sebacic acid are fully mixed and then added to the extruder to melt and extrude, cast through a T-shaped die to form a film, and place it for 5 days , denoted as S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com