Refrigerator

A refrigerator and an outer box technology, applied in the field of refrigerators, can solve the problems of poor appearance of the outer box 11 and peeling off of the vacuum insulation material 21, and achieve the outstanding effects of preventing poor appearance and preventing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

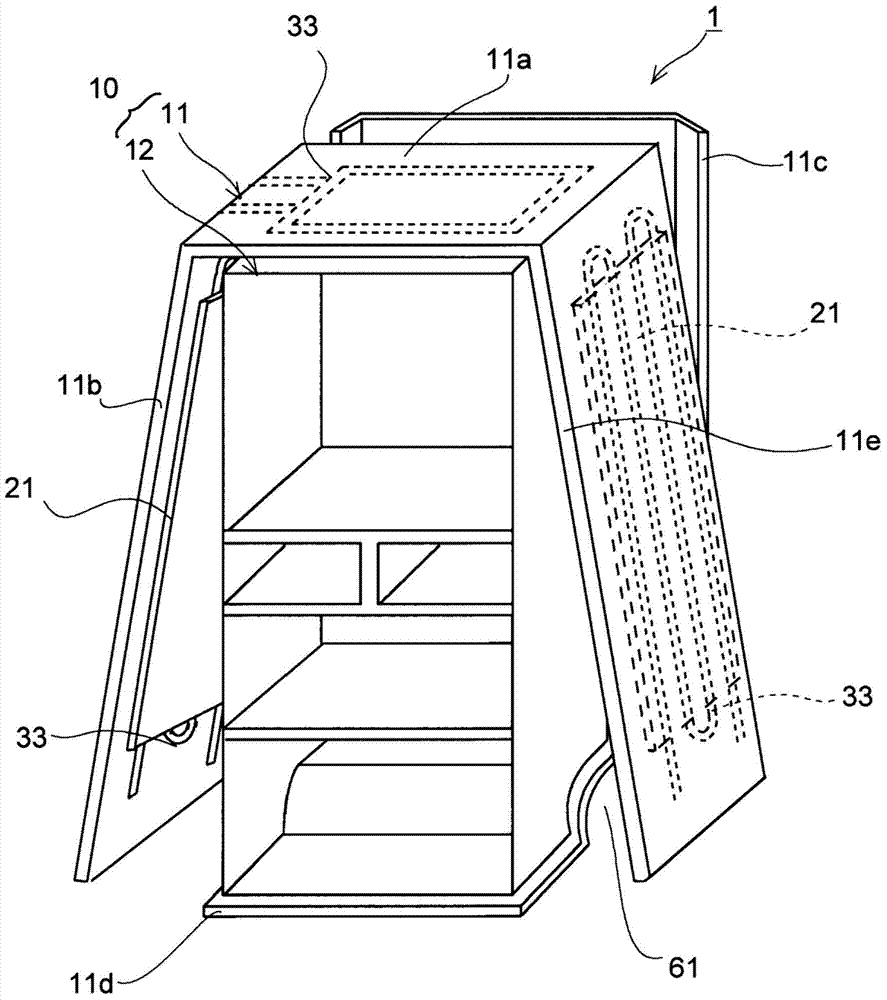

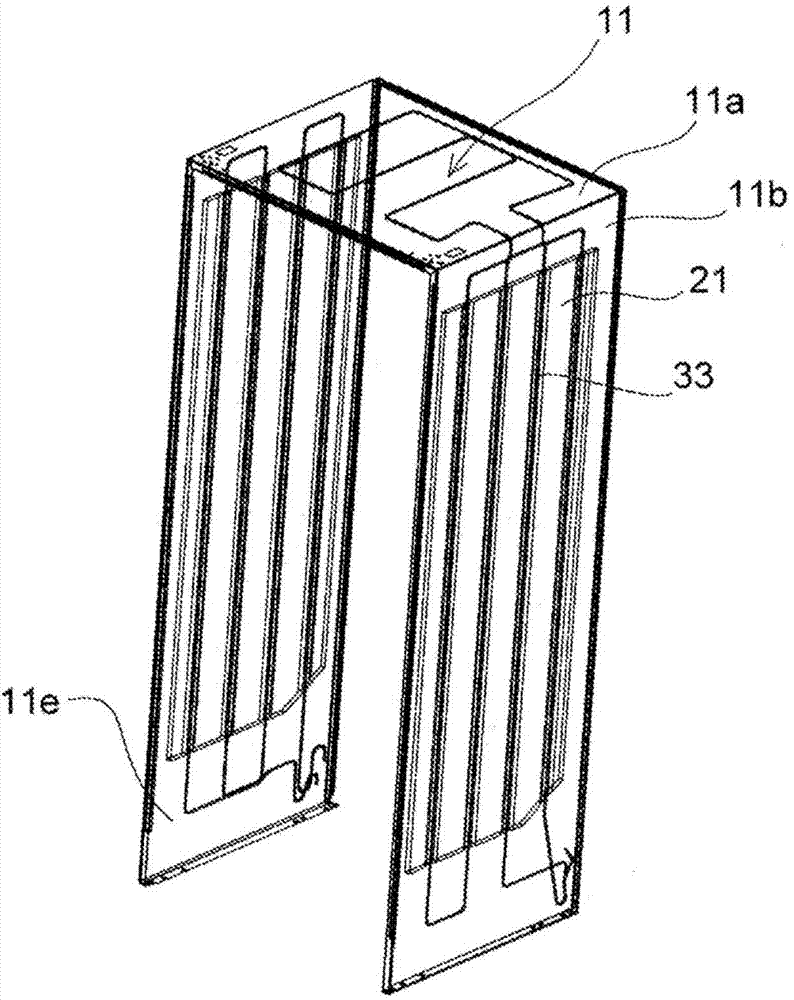

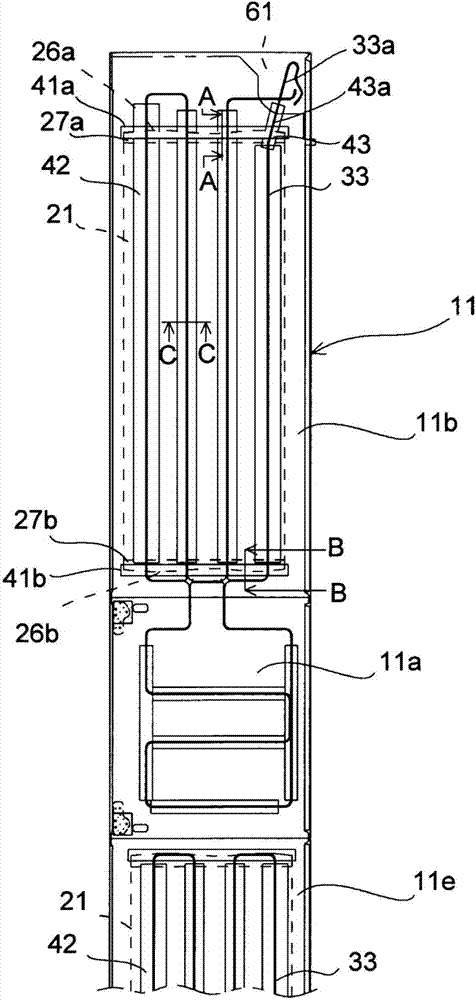

[0102] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an exploded perspective view showing the refrigerator of this embodiment, figure 2 It is a perspective view showing part of the outer box 11, image 3 It is a plan view showing a part of the outer case 11 in development.

[0103] The heat insulation box body 10 of the refrigerator 1 is a box shape with an open front. The outer surface of the heat insulation box 10 is formed by an outer case 11 , and the inner surface is formed by an inner case 12 . The outer case 11 is formed into a box shape with an open front by a top plate 11a, side plates 11b, 11e, back plate 11c, and bottom plate 11d made of metal plates such as iron plates. The inner box 12 is a resin molded product, and is divided into a plurality of cooling chambers opened at the front. The space between the outer box 11 and the inner box 12 is filled with foaming heat insulating material (not shown) s...

no. 2 approach )

[0121] Figure 7 It is a plan view showing a part of the outer case 11 of the refrigerator according to the second embodiment in development. In addition, the same code|symbol is attached|subjected to the same part as 1st Embodiment, and description is abbreviate|omitted. Compared with the first embodiment, the second embodiment omits the first adhesive tape 41b and only has the first adhesive tape 41a.

[0122] The end parts 26a, 26b of the vacuum heat insulating material 21 straddle the heat radiation pipe 33 arrange|positioned in multiple rows. Moreover, the end part 26a is being fixed to the outer case 11 by the 1st adhesive tape 41a. On the other hand, the end portion 26b is not covered by the first adhesive tape 41b (refer to image 3 ) is fixed on the outer box 11. Therefore, a space portion 29a is formed at the end portion 26a of the cover material 26, and no space portion is formed at the end portion 26b. On the other hand, a plurality of through holes 42a are fo...

no. 3 approach )

[0129] Figure 8 It is a plan view showing a part of the outer case 11 of the refrigerator according to the third embodiment in development. In addition, the same code|symbol is attached|subjected to the same part as 1st Embodiment and 2nd Embodiment, and description is abbreviate|omitted. Compared with 1st Embodiment and 2nd Embodiment, 3rd Embodiment does not affix 1st adhesive tape 41a, 41b to the vacuum heat insulating material 21. As shown in FIG.

[0130] Both ends of the heat radiation pipe 33 in the extending direction are fixed to the outer case 11 by the first adhesive tapes 41a and 41b straddling the parallel arrangement direction. Moreover, the heat radiation pipe 33 is fixed to the outer case 11 by the 2nd adhesive tape 42 overlapped with the 1st adhesive tape 41, and arrange|positioned along the extending direction. The second adhesive tape 42 extends to the outside of the heat insulation box 10 and forms a communication channel. The inside of the groove porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com