Method for manufacturing molded article, molded article, and device for manufacturing molded article

A manufacturing method and technology of molded products, applied in the field of molded products, can solve the problems of prepreg distortion, time required for molded products, difficulty in forming a uniform resin layer, etc., and achieve the effect of improving productivity and suppressing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

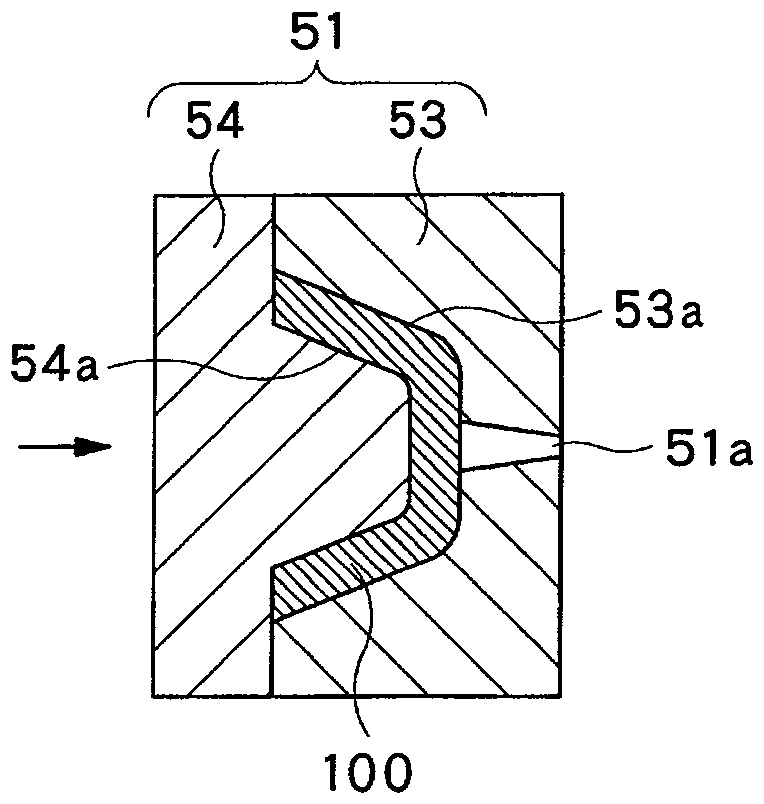

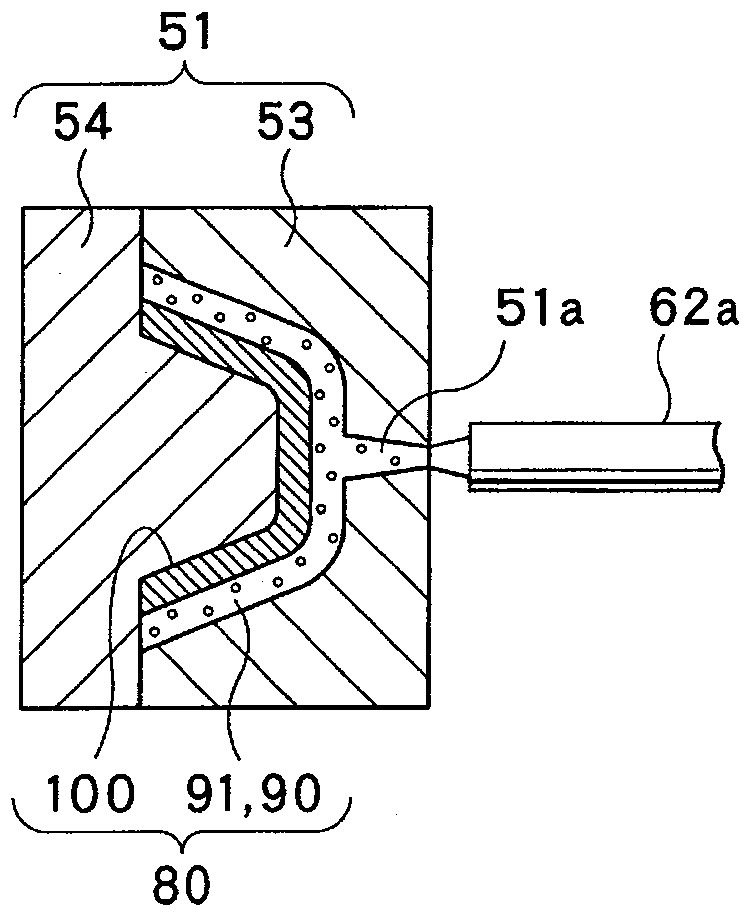

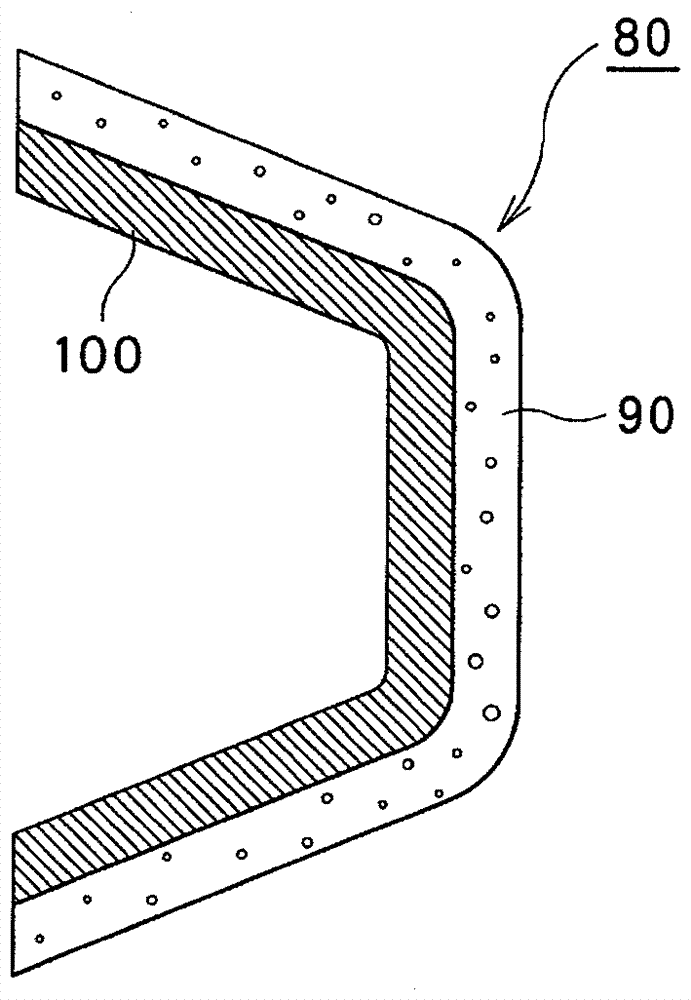

[0019] Below, refer to figure 1 Moving to FIG. 3 , an embodiment of the present invention will be described. figure 1 3 to 3 are diagrams showing an embodiment of the present invention. In addition, in each of the following figures, the same reference numerals are attached to the same parts, and some detailed descriptions may be omitted.

[0020] (Configuration of Molded Product Manufacturing Equipment)

[0021] First, according to figure 1 , the configuration of a molded article manufacturing apparatus that executes the molded article manufacturing method of this embodiment will be described. figure 1 It is a perspective view showing a molded product manufacturing apparatus.

[0022] Such as figure 1 As shown, the molded product manufacturing apparatus 10 includes, for example, a storage unit 11 , a transport device 12 , a heating device 13 , a mold device 14 , an injection device 15 , and a control device 19 . The molded article manufacturing apparatus 10 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com