Automotive radiator grille body structure

A radiator and body technology, which is applied in the field of the body structure of the radiator grille for automobiles, can solve the problems of uneven product boundaries, easy shrinkage and deformation, product difficulties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

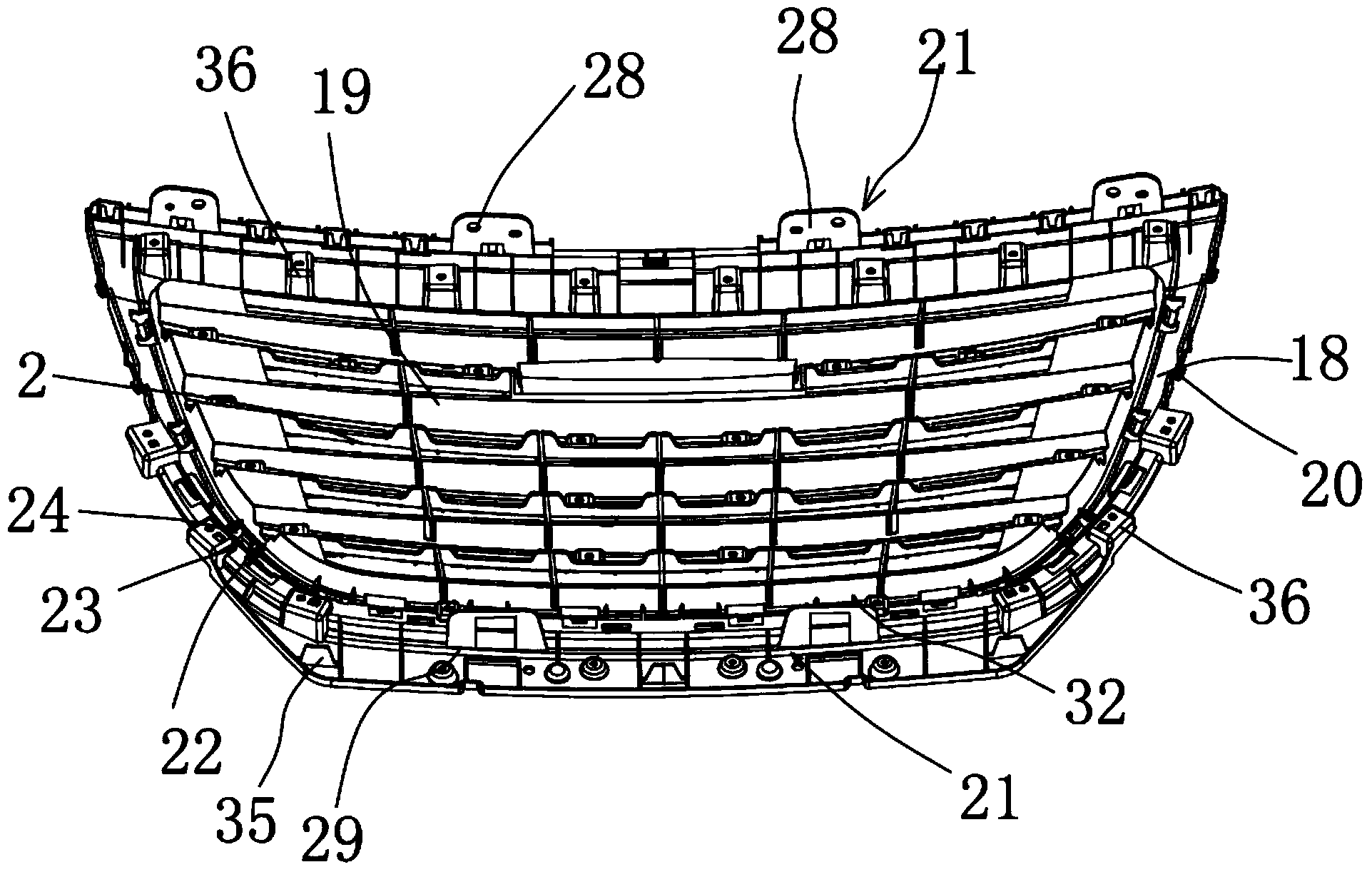

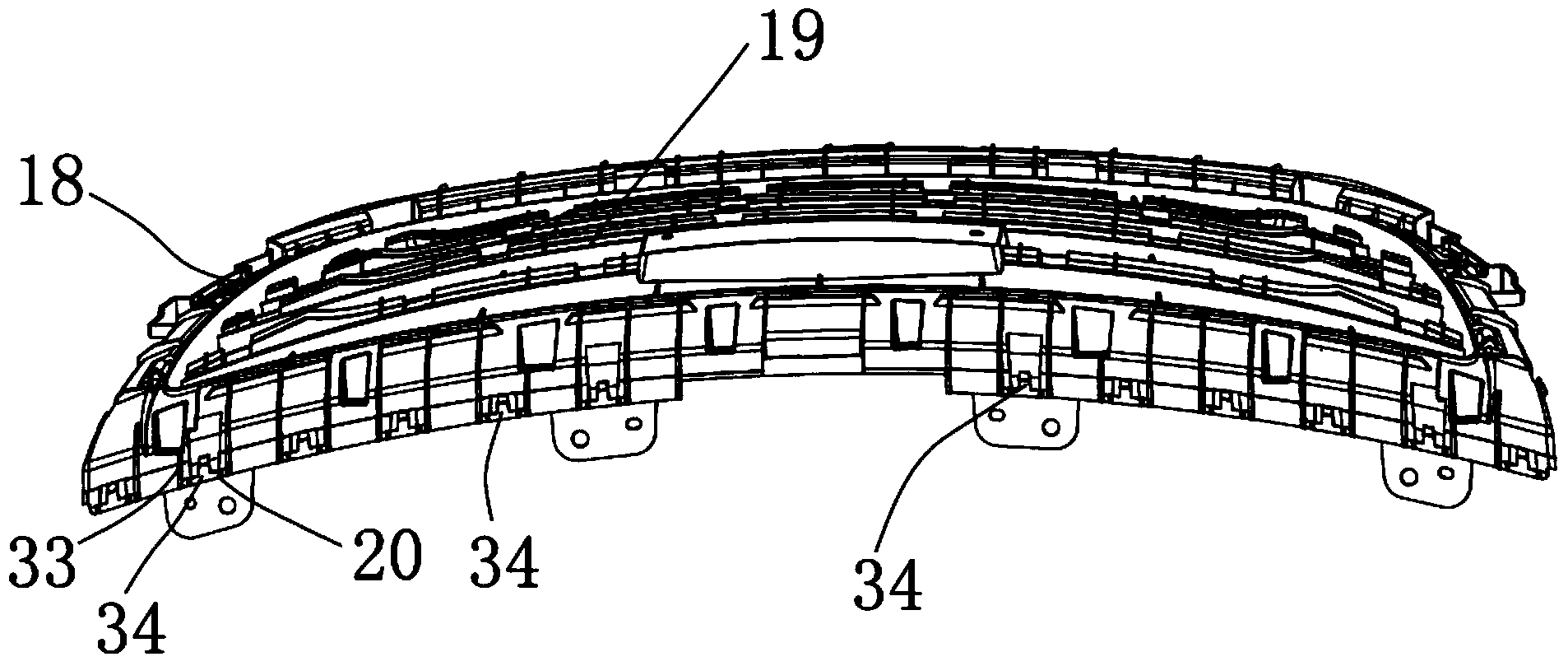

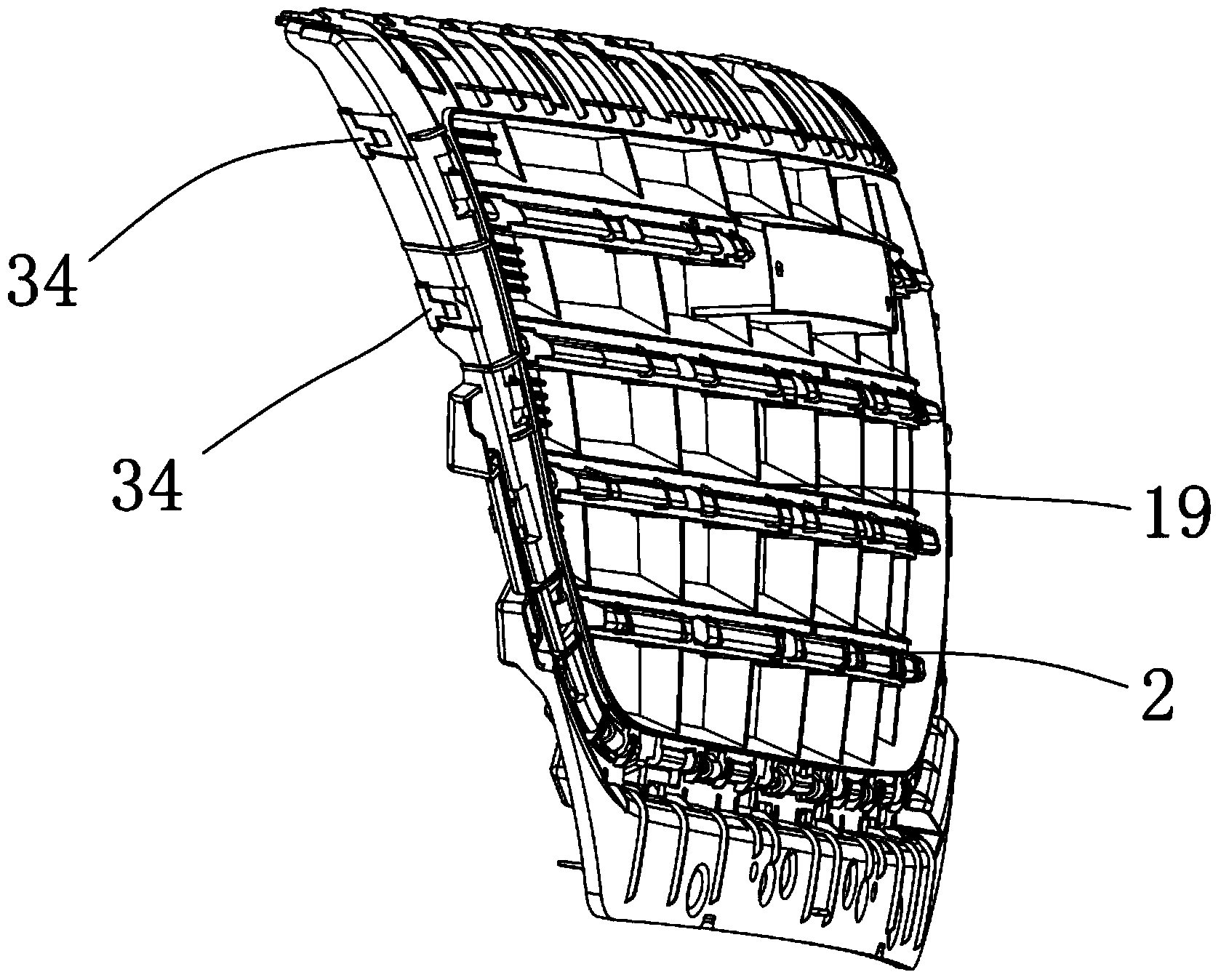

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0043] In the figure, the horizontal bright bar body 1; the horizontal body 2; the self-tapping screw mounting column 3; the insertion claw 4; the locking piece 5; the insertion groove 6; the insertion part 6a; the extension connection part 6b; the thickening part 7; ; Slant body 9; Anti-shrinkage tank 10; Rib body 11; Flange portion 12; Reinforcing rib 13; Bevel structure 14; Break structure 15; Fixing area 18; horizontal bright strip fixing area 19; peripheral side fixing part 20; upper and lower fixing parts 21; outer frame claw part 22; U-shaped claw 23; Protruding angle 27; upper locking piece 28; lower fixed claw 29; card part 30; flared part 31; supporting piece 32; side base 33; side claw 34; 36.

[0044] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com