In-mold decorating apparatus and method for manufacturing in-mold decorated molded product

A technology for forming and decorating sheets, which is applied in the field of forming and decorating devices and the manufacturing fields of forming and decorating formed products, and can solve the problems of the decorative sheet 121 being broken, difficult to continuously form, and broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 》

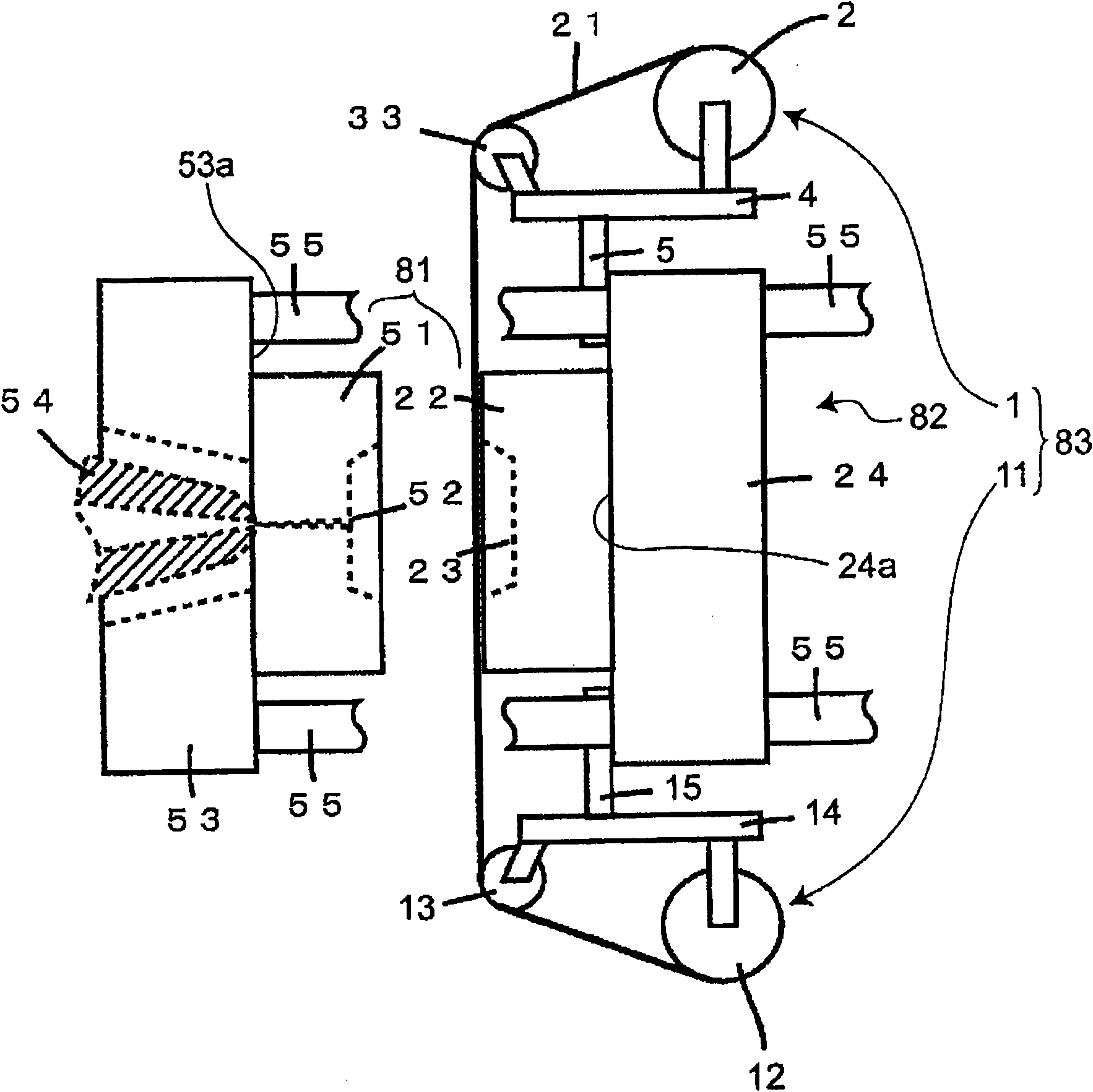

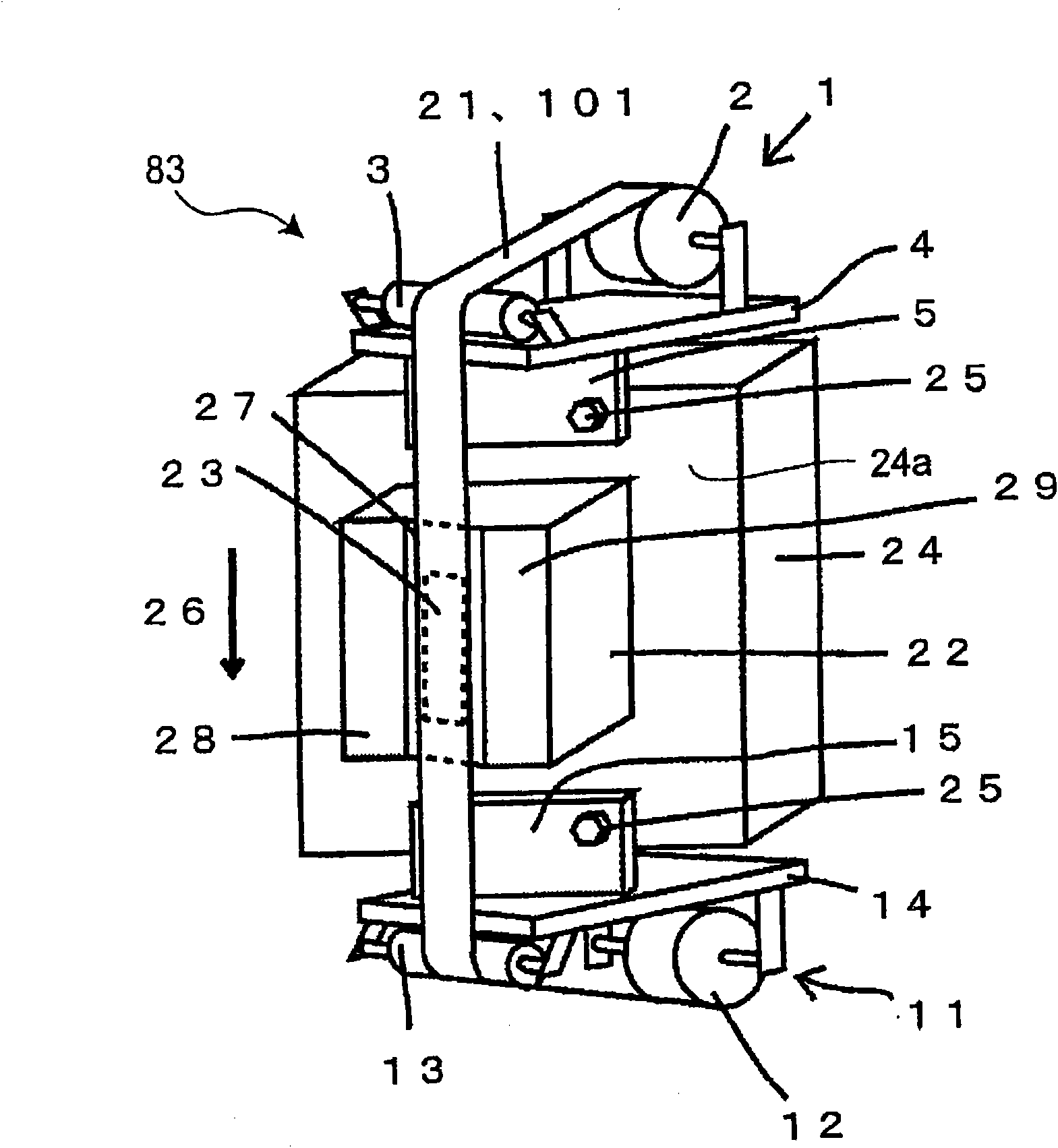

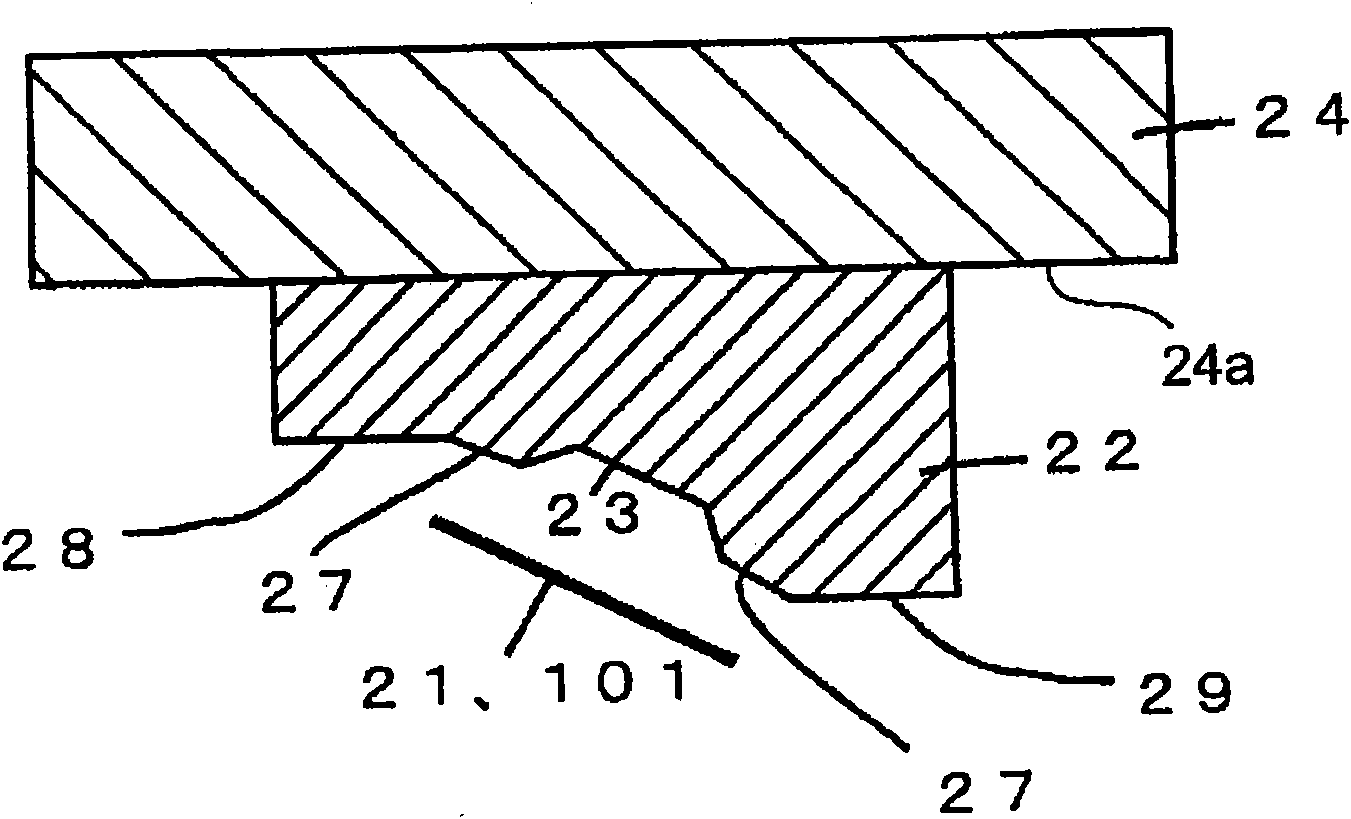

[0069] use Figure 1 ~ Figure 4 A simultaneous molding and decorating device according to the first embodiment of the present invention will be described. figure 1 It is a side view schematically showing the structure of the simultaneous molding and decorating apparatus of this 1st Embodiment. figure 2 It is a perspective view which shows the state which attached the decorative sheet supply apparatus to the movable platen in this 1st Embodiment. image 3 It is cut on a plane perpendicular to the moving direction of the decorative sheet figure 2 cutaway view of the composition. Figure 4 is shown in figure 1 A cross-sectional view of the structure of a transfer sheet, which is an example of a decorative sheet used in the forming and decorating device of .

[0070] figure 1 The molding and decorating device of the first embodiment shown includes a mold 81 , an injection molding machine 82 , and a decorative sheet supply device 83 .

[0071] The mold 81 has a movable m...

no. 2 Embodiment approach 》

[0093] use Figure 5 A simultaneous molding and decorating device according to a second embodiment of the present invention will be described. Figure 5 It is a perspective view which shows the state which attached the decorative sheet supply apparatus to the movable platen in 2nd Embodiment of this invention. The molding and decorating device of the second embodiment is different from the molding and decorating device of the above-mentioned first embodiment in that instead of fixing the fixing parts 5 and 15 to the frames 4 and 14, the fixing parts 5 and 15 and the frames Turntables 6, 16 are arranged between 4, 14, and frames 4, 14 and turntables 6, 16 are fixed by fixing screws 7, 17, which are an example of a fixing unit. The other aspects are the same, so repeated explanations will be omitted below, and differences will be mainly described.

[0094] In this second embodiment, if Figure 5 As shown, the fixed parts 5, 15 are fixed on the turntables 6, 16. The turntable...

no. 3 Embodiment approach 》

[0097] A simultaneous molding and decorating device according to a third embodiment of the present invention will be described with reference to FIG. 6 . 6 is a perspective view illustrating a state in which a decorative sheet supply device according to a third embodiment of the present invention is attached to a movable platen. The molding and decorating device of the third embodiment is different from the molding and decorating device of the above-mentioned first embodiment in that an insert sheet is used as the decorative sheet 21, and a clamping device 301 is provided instead of the decorative sheet winding device 11. and drive device 302. The other aspects are the same, so repeated explanations will be omitted below, and differences will be mainly described.

[0098] The difference between the insert sheet and the transfer sheet 101 is that it does not have the release layer 103 . That is, the insert sheet is a sheet that can be used without peeling off the base sheet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com