A screw barrel cooling device

A cooling device and screw barrel technology, applied in the field of extruders, can solve the problems of seeping out of the barrel and liquid easily infiltrating between two flanges, etc., and achieve the effect of uniform temperature and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

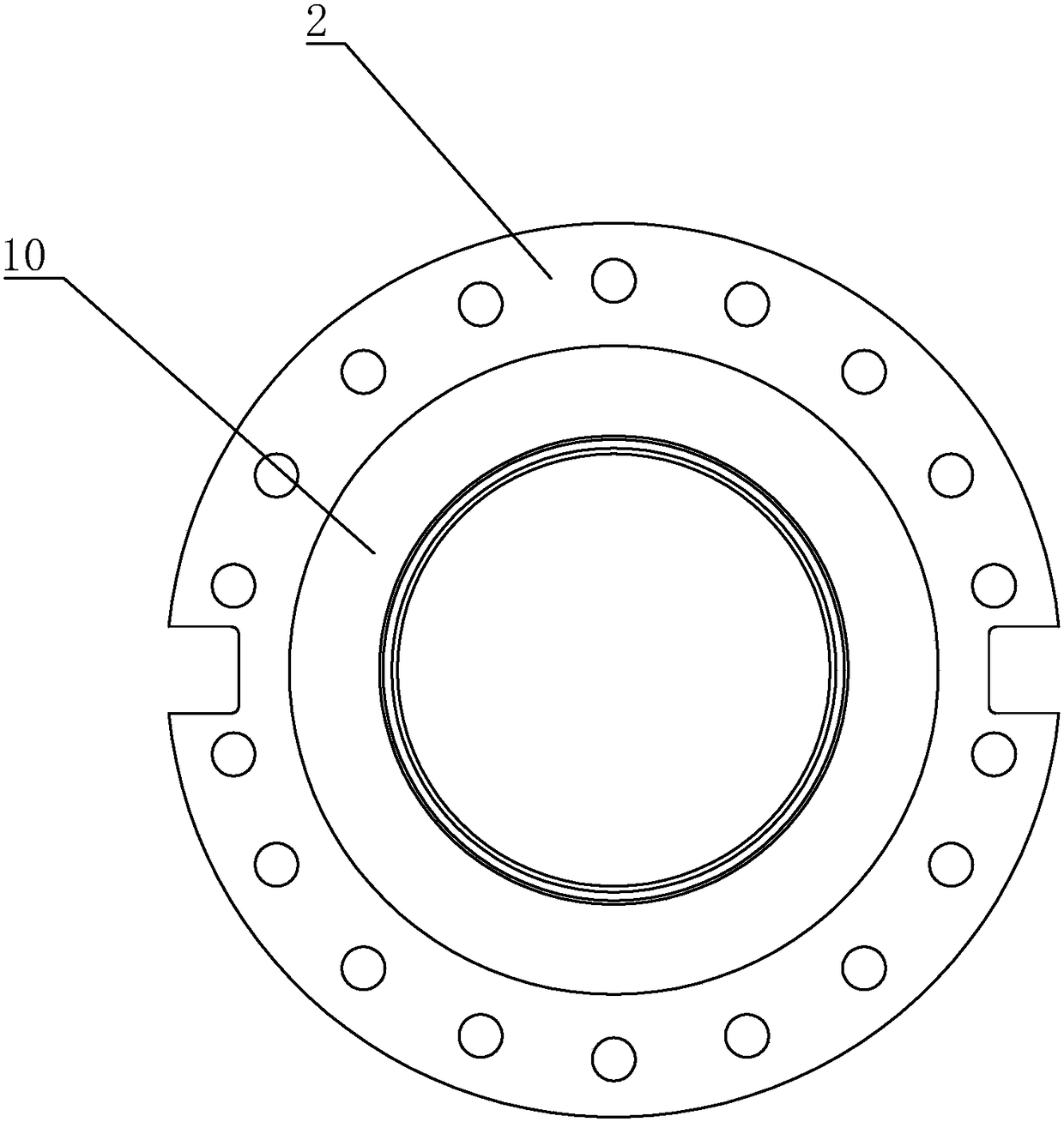

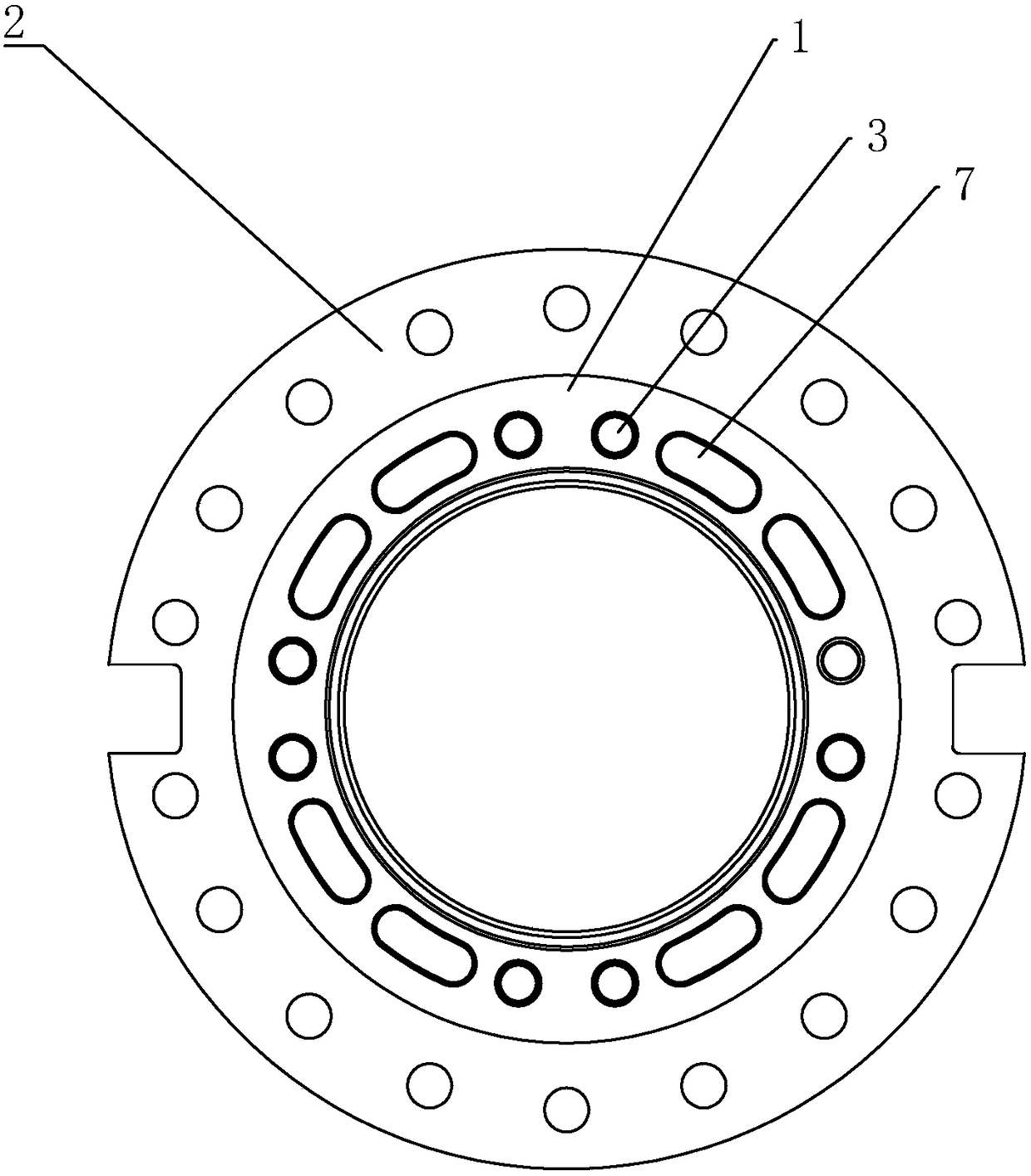

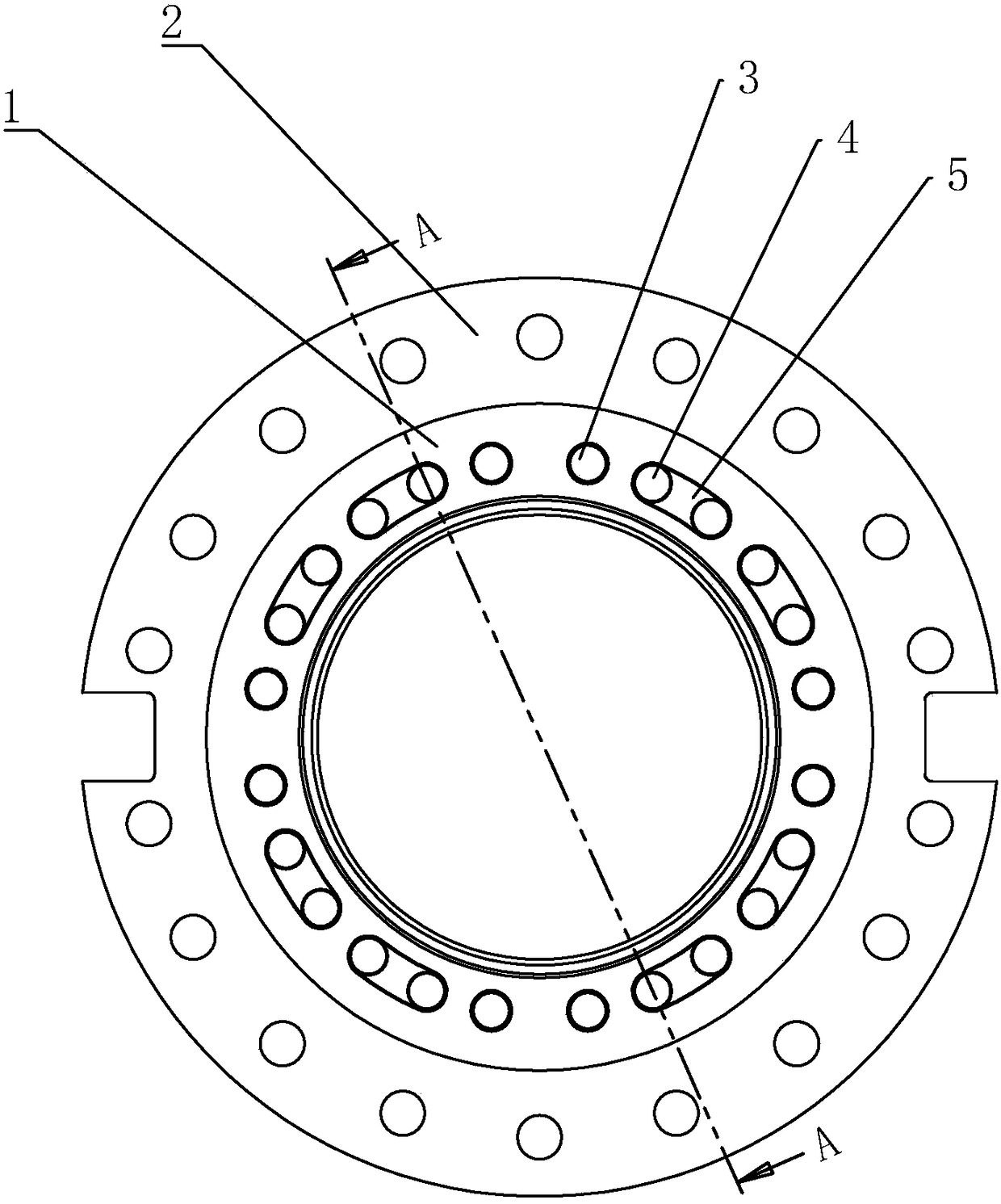

[0037] Embodiment 1: a kind of screw barrel cooling device, such as image 3 , 5As shown, it includes a screw barrel 1 and connecting flanges 2 at both ends of the screw barrel 1. The wall of the screw barrel 1 is provided with a number of first holes that run through both ends of the screw barrel 1 and are parallel to the axis of the screw barrel 1. The cooling channels 3 and the second cooling channels 4, the first cooling channels 3 and the second cooling channels 4 are evenly distributed on the screw barrel 1 in the circumferential direction, the first cooling channels 3 and the second The cooling channels 4 are arranged at intervals, and one end of the screw barrel 1 is provided with a first circulation groove 5 for the media in the adjacent first cooling channel 3 and the second cooling channel 4 to circulate, and the other end is provided with a communication groove 5. The second cooling channel 4 and the second circulation groove 6 of the other adjacent first cooling ...

Embodiment 2

[0044] Embodiment 2: The difference from Embodiment 1 is that first heat exchange blades 14 are helically arranged on the inner wall of the first cooling channel 3 along the axial direction of the first cooling channel 3 . Through the first heat exchange vanes 14 arranged on the inner wall of the first cooling channel 3, the medium flows in a spiral manner during the circulation process, which increases the circulation path of the medium and enables the medium to more fully communicate with the first cooling channel. The inner wall of a cooling channel 3 is in contact with the first heat exchanging blade 14, so that the medium can take away more heat in the process of circulation, thereby achieving the purpose of rapid cooling. Second heat exchange blades 15 are helically arranged on the inner wall of the second cooling channel 4 along the axial direction of the second cooling channel 4 . By adopting the above-mentioned technical solution, the second heat exchange blade 15 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com