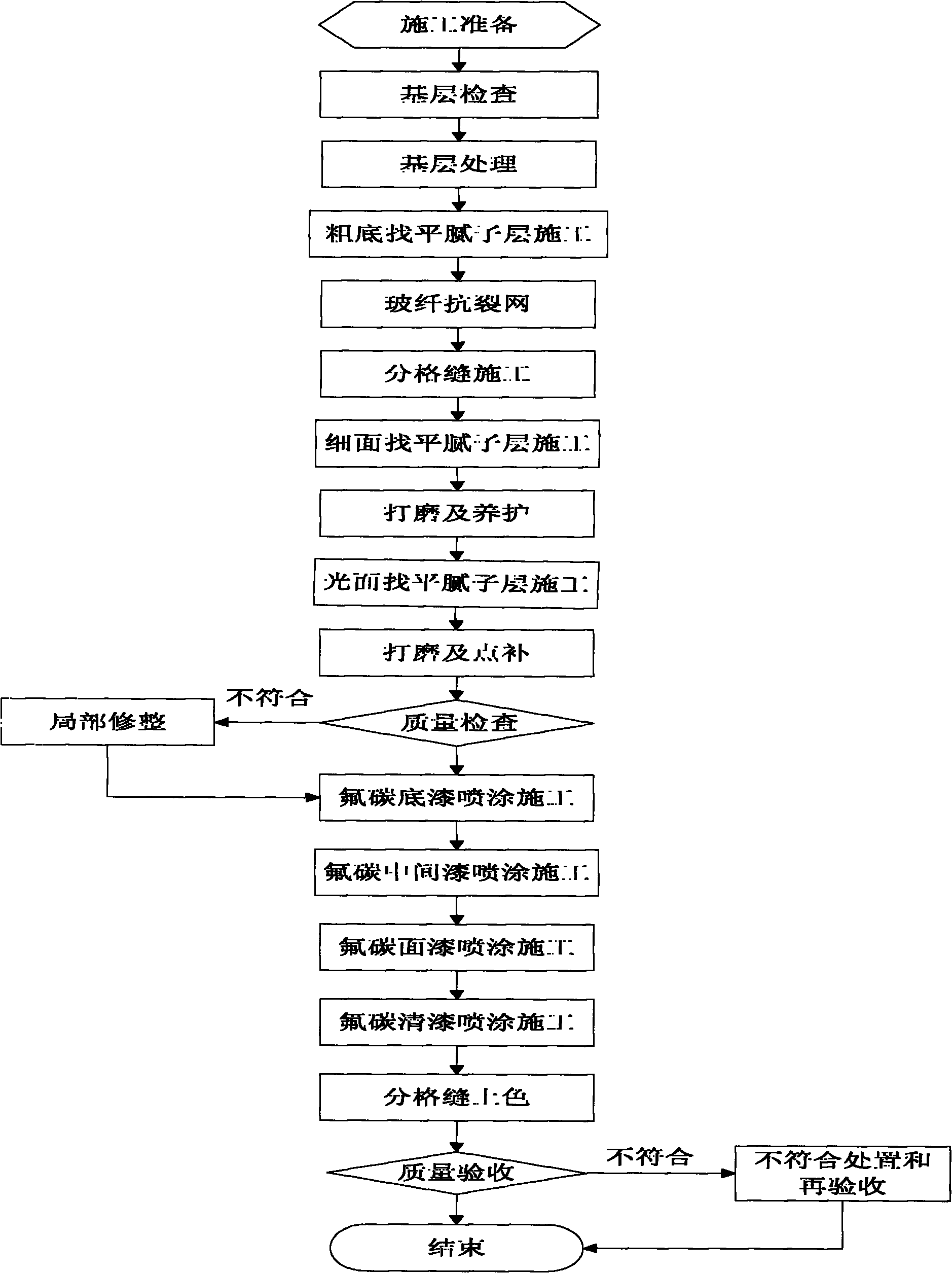

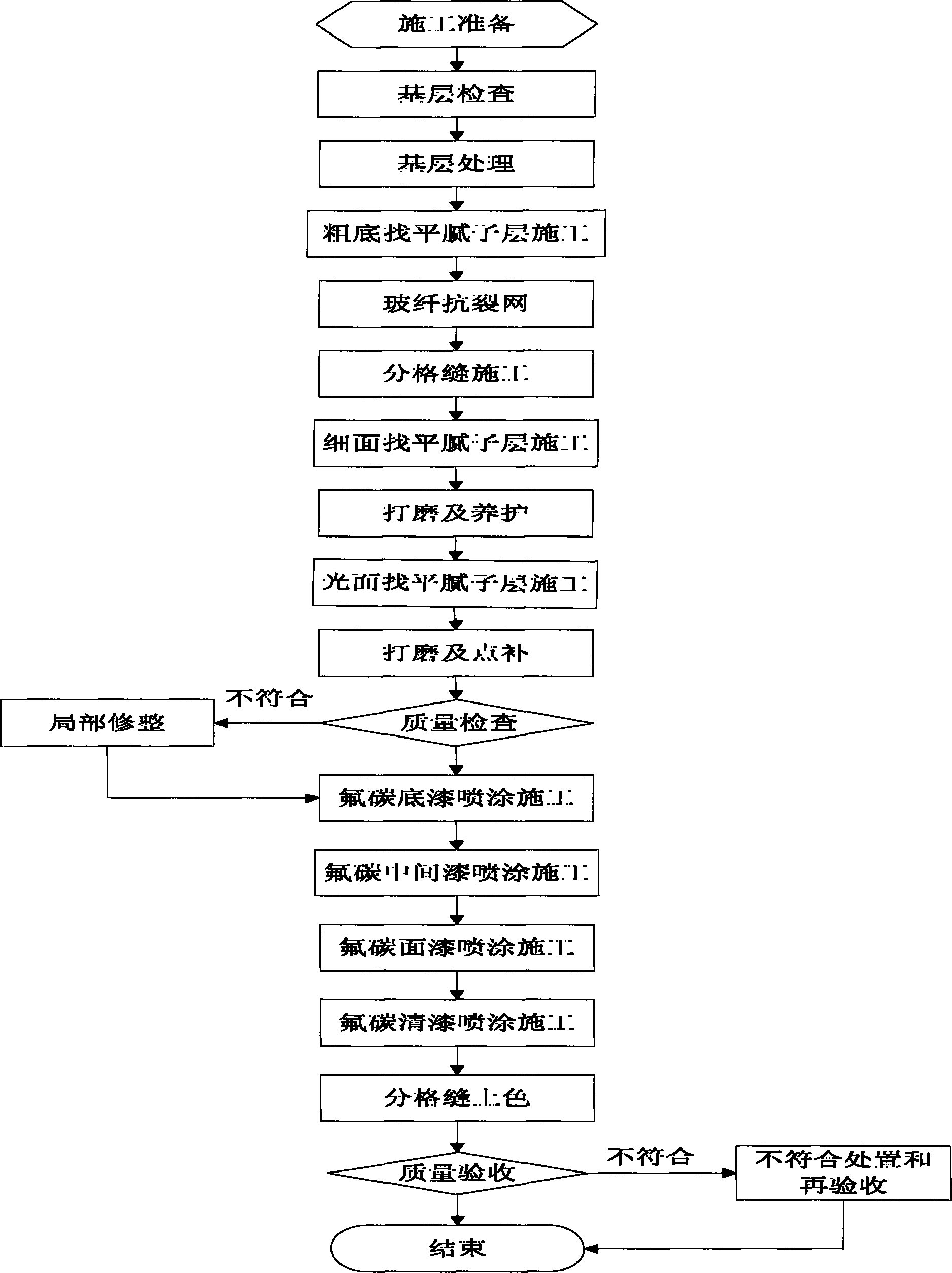

Construction process for outer wall metal fluorocarbon coating

A construction technology, fluorocarbon paint technology, applied in the direction of architecture, building structure, etc., can solve the problems of affecting the appearance of building facades, affecting the appearance of buildings, affecting the quality of projects, etc., to achieve rich and delicate surface self-cleaning functions, construction technology Reasonable design to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this embodiment, when the leveling putty is prepared before the construction of the rough bottom leveling putty layer, the volume ratio between the binder contained in the finished putty and the added quartz sand is 1:0.5. And when the rough bottom leveling putty layer is constructed, use the scraper back and forth scraping method to apply 3 to 4 times, and then level it with a scraper. The surface of the rough bottom leveling putty layer after the final construction should be flat and firm, and there are no cracks, hollows, peeling and bursting points on the surface, and its surface flatness should meet the high-level plastering quality requirements (allowable deviation ≤ 2mm). After the rough bottom leveling putty layer is completely dry, sandpaper grinding can be carried out. Specifically, sandpaper above 200 is used for even sanding, and care should be taken not to wear through the film layer; at the same time, the rough bottom leveling putty layer should be well ...

Embodiment 2

[0064] In this embodiment, when the leveling putty is prepared before construction of the rough bottom leveling putty layer, the volume ratio between the binder contained in the finished putty and the added quartz sand is 1:1.5. When spraying the primer, the air pressure of the high-pressure spraying equipment is between 0.8MPa and the spray distance is 400mm; while the fluorocarbon varnish is sprayed, the consumption of the fluorocarbon varnish is 150g / m 2 , the rest of the steps are the same as in Example 1.

Embodiment 3

[0066] In this embodiment, when the leveling putty is prepared before the construction of the rough bottom leveling putty layer, the volume ratio between the binder contained in the finished putty and the added quartz sand is 1:0.8. When spraying the primer, the air pressure of the high-pressure spraying equipment is between 0.5MPa and the spray distance is 480mm; while the fluorocarbon varnish is sprayed, the consumption of the fluorocarbon varnish is 130g / m 2 , the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com