Aramid fiber composite material, composite material for preparing solid tyre and manufacturing methods of two

A composite material, aramid fiber technology, used in special tires, tire parts, transportation and packaging, etc., can solve the problems of not well-utilized leftover materials, rising prices of synthetic rubber, and short service life, reducing material Cost, extended service life, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

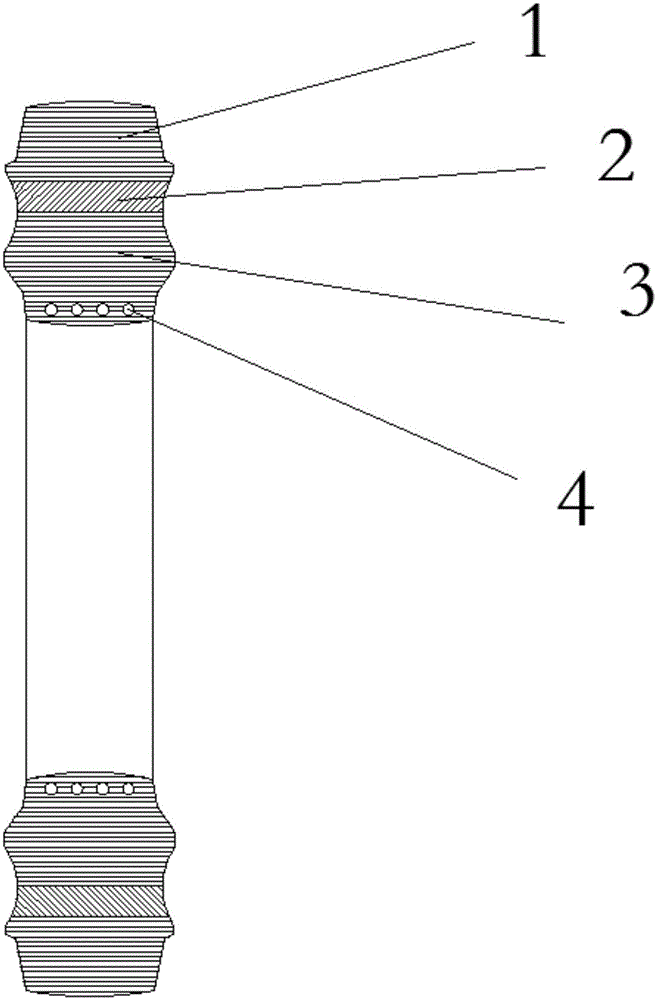

Image

Examples

Embodiment 1

[0065] The composite material components and parts by weight of the tread rubber layer are:

[0066] Styrene butadiene rubber 1500: 20 parts; natural rubber: 40 parts; butadiene rubber: 10 parts; cage polyvinyl silsesquioxane: 1 part; aramid fiber: 3 parts; Combustion agent: 3 parts; vulcanizing agent: 2 parts; accelerator: 1 part; zinc oxide: 3 parts; stearic acid: 1 part; carbon black N220: 50 parts; aromatic oil: 3 parts; oxidized paraffin wax: 2 parts; Comaron: 2 parts; Adhesive X-100: 3 parts; Antiaging agent 4010NA: 1 part; Antiaging agent RD: 1 part; White carbon black: 3 parts; Paraffin wax: 0.5 parts; Sulfur: 2 parts.

[0067] The raw material components and parts by weight of the tire base rubber composite material are:

[0068] Natural rubber: 10 parts; styrene-butadiene rubber: 10 parts; aramid fiber: 2 parts; basalt fiber: 3 parts; cotton fiber: 3 parts; rubber scraps: 30 parts; anti-scorch agent: 0.5 parts; carbon black N330: 20 parts; flame retardant: 3 parts;...

Embodiment 2

[0070] The composite material components and parts by weight of the tread rubber layer are:

[0071]Styrene butadiene rubber 1500: 30 parts; natural rubber: 50 parts; butadiene rubber: 20 parts; cage polyvinyl silsesquioxane: 2 parts; aramid fiber: 5 parts; Combustion agent: 5 parts; Vulcanizing agent: 3 parts; Accelerator: 2 parts; Zinc oxide: 5 parts; Stearic acid: 2 parts;

[0072] Carbon black N220: 55 parts; aromatic oil: 6 parts; oxidized paraffin: 3 parts; solid Marlon: 4 parts;

[0073] Adhesive X-100: 5 parts; anti-aging agent 4010NA: 3 parts; anti-aging agent RD: 2 parts; white carbon black: 5 parts; paraffin: 1 part; sulfur: 3 parts.

[0074] The raw material components and parts by weight of the tire base rubber composite material are:

[0075] Natural rubber: 20 parts; styrene-butadiene rubber: 20 parts; aramid fiber: 3 parts; basalt fiber: 5 parts; cotton fiber: 6 parts; rubber scraps: 40 parts; anti-scorch agent: 0.8 parts; carbon black N330: 30 Flame retarda...

Embodiment 3

[0077] The composite material components and parts by weight of the tread rubber layer are:

[0078] Styrene butadiene rubber 1500: 25 parts; natural rubber: 45 parts; butadiene rubber: 15 parts; cage polyvinyl silsesquioxane: 1.5 parts; aramid fiber: 4 parts; Combustion agent: 4 parts; Vulcanizing agent: 2.5 parts; Accelerator: 1.5 parts; Zinc oxide: 4 parts; Stearic acid: 1.5 parts; Carbon black N220: 52.5 parts; Aromatic oil: 4.5 parts; Comaron: 3 parts; Adhesive X-100: 4 parts; Antiaging agent 4010NA: 2 parts; Antiaging agent RD: 1.5 parts; White carbon black: 4 parts; Paraffin wax: 0.75 parts; Sulfur: 2.5 parts.

[0079] The raw material components and parts by weight of the tire base rubber composite material are:

[0080] Natural rubber: 15 parts; styrene-butadiene rubber: 15 parts; aramid fiber: 2.5 parts; basalt fiber: 4 parts; cotton fiber: 4.5 parts; rubber scraps: 35 parts; anti-scorch agent: 0.65 parts; carbon black N330: 25 parts flame retardant: 4.5 parts; rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com