ABS resin composition capable of maintaining high glossiness in thermoforming and ABS sheet using same

A technology of ABS resin and composition, applied in the field of ABS sheet preparation, can solve the problems of physical properties decline, emulsifier and coagulant cannot be completely removed, residual and other problems, and achieve the effect of excellent surface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

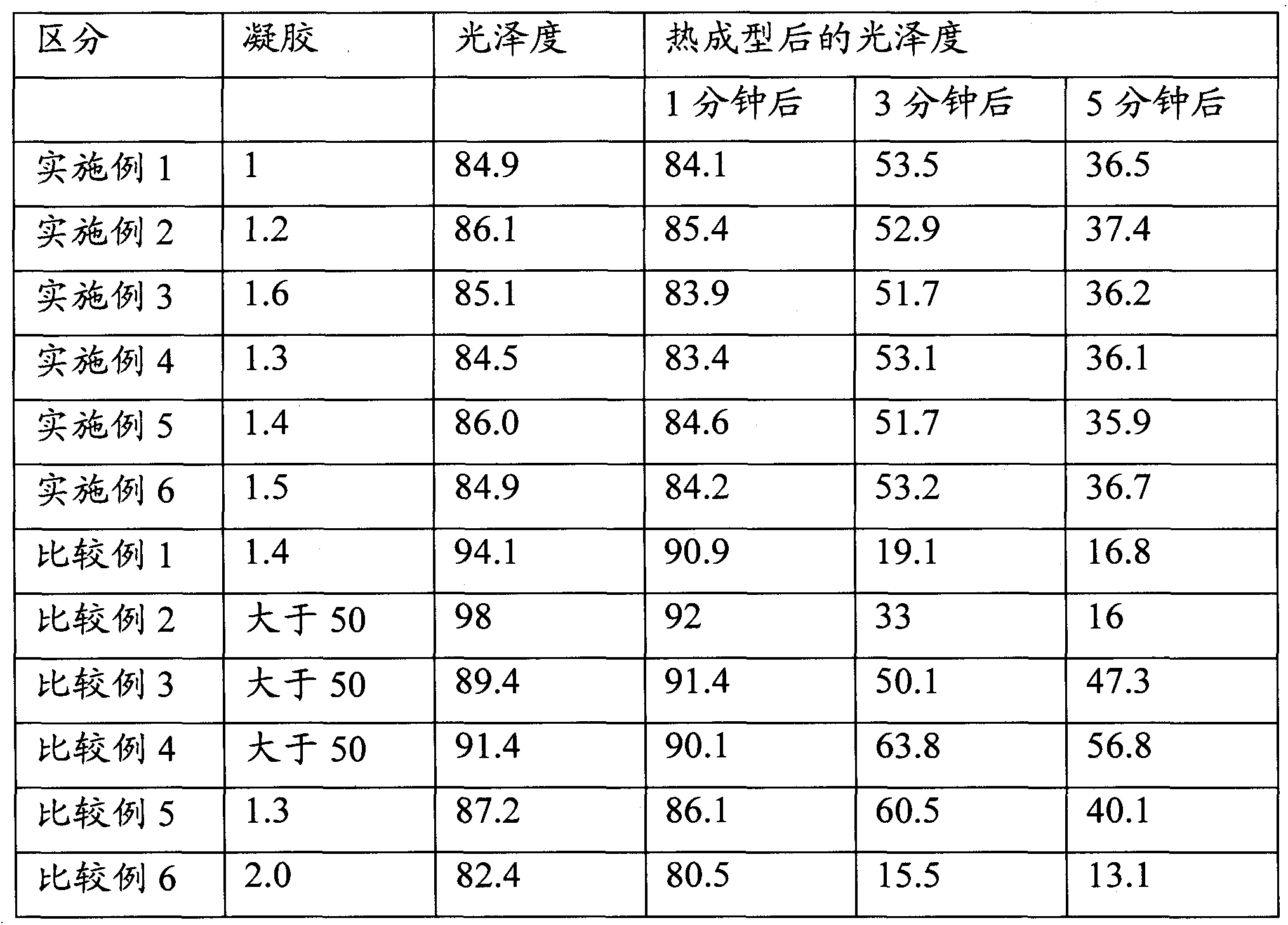

Examples

Embodiment 1

[0051] Using a twin-screw extruder, at 240°C, 600g of ABS resin with a melt index of 6g / 10 minutes (230°C) and an acrylonitrile content of 17% by weight and an acrylonitrile content of 16% by weight produced by bulk polymerization 240g of the SAN copolymer and 160g of the MBS copolymer with a rubber particle size of 0.08-0.1μm were melt-extruded, dried at 80°C for 4 hours, and then a glossy film with a thickness of 100μm was prepared by an extruder.

Embodiment 2

[0053] A glossy film was produced in the same procedure as in Example 1 except that 400 g of ABS resin having an acrylonitrile content of 17% by weight was used.

Embodiment 3

[0055] A glossy film was produced in the same procedure as in Example 1 except that 80 g of a SAN copolymer having an acrylonitrile content of 16% by weight was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com