Star-shaped hydrogenated styrene diene copolymer and preparation method thereof

A hydrogenated styrene and copolymer technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of poor shear stability, poor dissolution, poor low temperature performance, etc., and achieve improved processing performance and thickening effect Good, the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The star-shaped hydrogenated styrene diene copolymer prepared in this embodiment has a structural formula of (EP-SEB)n-C, and the preparation method is as follows:

[0036] 1) Add 180.0 g of refined cyclohexane and 15.0 g of refined isoprene to a 500 ml glass reaction bottle with magnetic stirring after three times of vacuuming and argon gas circulation, and add 180.0 g of refined cyclohexane and 15.0 g of refined isoprene. 0.4ml of n-butyl lithium with a concentration of 1.0M in n-hexane was reacted for 60 minutes, then 0.145g of tetrahydrofuran (THF), 2.0g of refined styrene and 3.0g of refined butadiene were added, and the reaction was continued for 60 minutes to obtain an active amphibolite segment (PI-SPB-Li).

[0037] 2) Add metered divinylbenzene ([DVB] / [Li]=3.0) to the reaction flask to couple the active block polymer chains, add metered isopropanol after 60 minutes of coupling reaction, isopropanol The molar ratio of alcohol to active lithium is 1:1, and then ...

Embodiment 2

[0045] Repeat Example 1, the mass of added monomers is respectively: 18g of isoprene, 0.4g of styrene, and 1.6g of butadiene; the polymerization temperature is 70°C, the reaction time is 90 minutes, and the initiator is sec-butyl Lithium base, the addition is 1mmol; the polar regulator is diethylene glycol dimethyl ether (2G), the addition is 0.2mmol; the coupling agent is silicon hexachloride, the addition is 1 / 6mmol, and the reaction temperature is 20°C, the reaction time is 180 minutes; the hydrogenation reaction catalyst is nickel naphthenate and triisobutylaluminum, the nickel addition is 2.0mg / g polymer, the Al / Ni molar ratio is 2:1, and the hydrogenation reaction temperature is 90 °C, the hydrogen pressure is 6.0MPa.

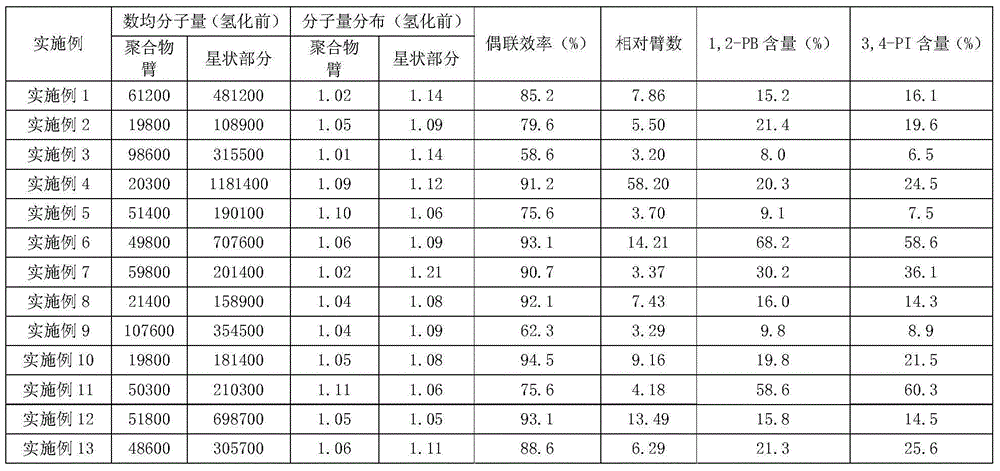

[0046] The structure and performance test results of the copolymer are shown in Table 1, and the performance test results of the copolymer as a viscosity index improver are shown in Table 2.

Embodiment 3

[0048] Repeat Example 1, the quality of added monomers is respectively: isoprene is 6.0g, styrene is 3.0g, butadiene is 11.0g; initiator addition is 0.2mmol, no polar additives are added, and the polymerization temperature is 50°C, the reaction time is 120 minutes, the amount of coupling agent added is 0.1mmol, the reaction temperature is 90°C, the reaction time is 30 minutes; the hydrogenation reaction temperature is 40°C, the catalyst is nickel naphthenate and triisobutylaluminum, The amount of nickel added is 20.0mg / g polymer, the molar ratio of Al / Ni is 3:1, the hydrogen pressure is 0.5MPa, and the reaction is carried out for 8 hours.

[0049] The structure and performance test results of the copolymer are shown in Table 1, and the performance test results of the copolymer as a viscosity index improver are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com