Method for preparing polylactic acid super-hydrophobic membranes by aid of phase separation process

A phase separation method, polylactic acid technology, applied in the field of preparation of polylactic acid superhydrophobic film, can solve the problems of low surface microstructure strength, high cost, environmental pressure, etc., achieve good environmental friendliness, low production cost, and reduce reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

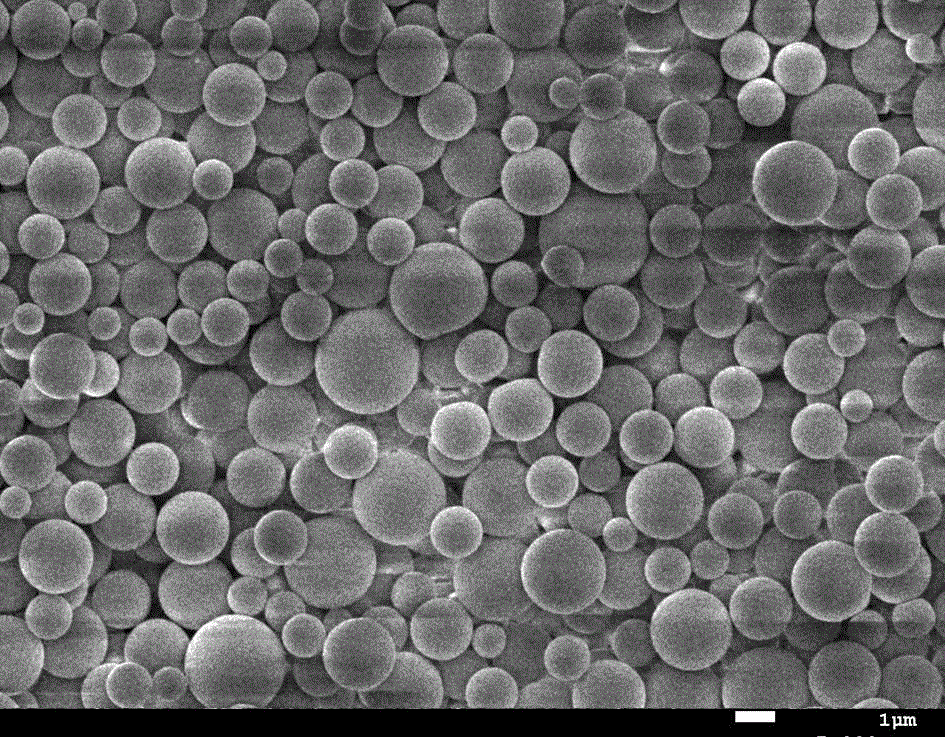

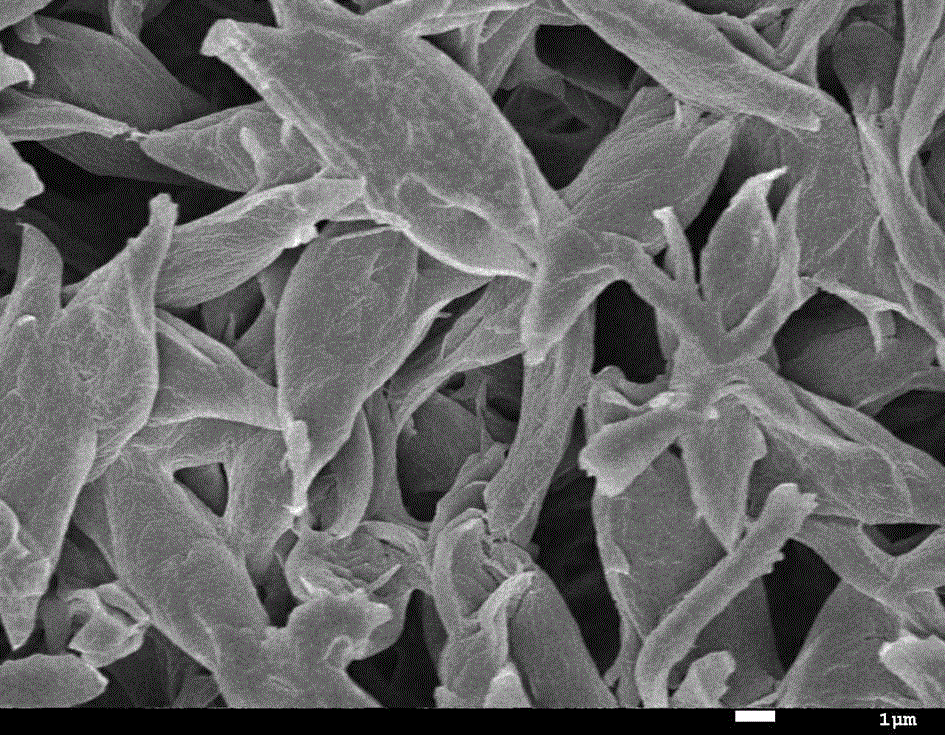

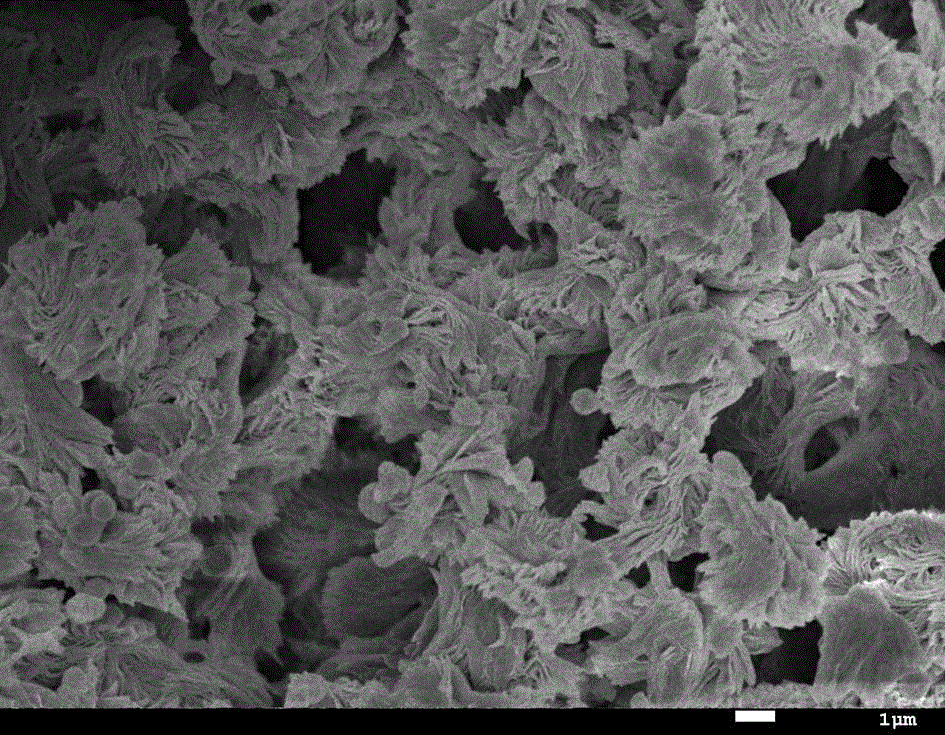

Image

Examples

Embodiment 1~14

[0036] The polylactic acid superhydrophobic films of Examples 1-14 were prepared by the phase separation method. The types and amounts of each substance added in the preparation process are shown in Table 1. The specific steps are:

[0037] (1) Set the volume to V 1 A poor solvent absolute ethanol is added to a volume of V 2 In the good solvent dichloromethane, stir, add 2.34g polylactic acid into the above mixed solvent, stir, so that polylactic acid is fully dissolved to obtain a pre-coating solution;

[0038] (2) Set the volume to V 3 The poor solvent absolute ethanol was added to 50mL of the above pre-coating solution, and stirred to obtain a coating solution;

[0039] (3) Apply 2.5mL of coating solution evenly on the carrier, pre-dry it under the cover with a certain gap for 12h~18h, and then put the carrier in an oven at 45±5℃ to dry for 48h~72h, that is A layer of polylactic acid superhydrophobic film is formed on the carrier.

[0040] The carrier used requires a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com